Unlocking the Potential of Electric Motors: Emerging Trends and Challenges

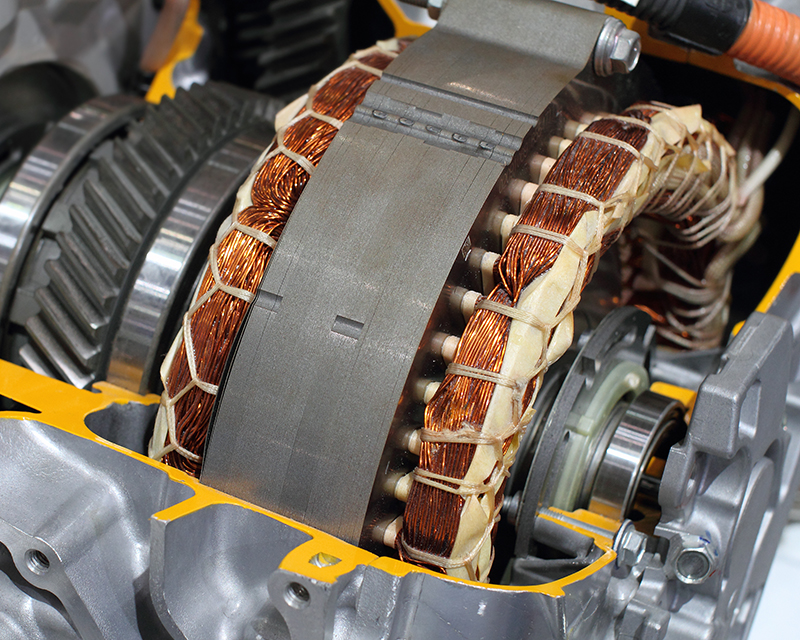

The automotive industry is undergoing a significant transformation with the rise of electric vehicles (EVs). As the world shifts towards more sustainable and environmentally friendly transportation options, the demand for efficient and reliable electric motors is increasing. Electric motor testing and validation are critical components of the EV development process, ensuring that these vehicles meet the required performance, efficiency, and safety standards. The growing importance of electric vehicles and electric motors in the automotive industry has created a need for advanced testing and validation methods.

Recent trends in the industry indicate a shift towards more sophisticated testing and validation techniques, including the use of advanced simulation tools, testing protocols, and data analysis. These methods enable manufacturers to optimize electric motor performance, reduce development time, and improve overall efficiency. However, the increasing complexity of electric motor systems also presents new challenges, such as the need for more advanced testing and validation methodologies.

Electric vehicle and electric motor testing and validation trends are evolving rapidly, driven by advances in technology and changing regulatory requirements. The development of more efficient and reliable electric motors is critical to the widespread adoption of EVs, and manufacturers must stay ahead of the curve in terms of testing and validation techniques. By leveraging advanced testing and validation methods, manufacturers can ensure that their electric motors meet the required standards, while also reducing development time and costs.

The use of advanced simulation tools, such as finite element analysis and computational fluid dynamics, is becoming increasingly prevalent in electric motor testing and validation. These tools enable manufacturers to simulate various operating conditions, reducing the need for physical prototyping and testing. Additionally, the use of testing protocols and data analysis enables manufacturers to optimize electric motor performance and identify potential issues early in the development process.

As the industry continues to evolve, it is essential for manufacturers to stay up-to-date with the latest electric vehicle and electric motor testing and validation trends. By doing so, they can ensure that their products meet the required standards, while also staying competitive in a rapidly changing market. The development of more efficient and reliable electric motors is critical to the widespread adoption of EVs, and advanced testing and validation methods are essential to achieving this goal.

How to Ensure Electric Motor Reliability and Efficiency through Rigorous Testing

Ensuring the reliability and efficiency of electric motors is crucial for the widespread adoption of electric vehicles. Testing and validation play a critical role in achieving this goal, as they enable manufacturers to identify and address potential issues early in the development process. The use of simulation tools, testing protocols, and data analysis are essential components of a rigorous testing and validation process.

Simulation tools, such as finite element analysis and computational fluid dynamics, allow manufacturers to simulate various operating conditions and predict electric motor performance. This enables them to optimize motor design and reduce the need for physical prototyping and testing. Testing protocols, on the other hand, provide a standardized framework for evaluating electric motor performance and identifying potential issues. Data analysis is also critical, as it enables manufacturers to interpret test results and make data-driven decisions.

The use of advanced testing and validation methods is essential for ensuring the reliability and efficiency of electric motors. By leveraging these methods, manufacturers can reduce development time and costs, while also improving overall efficiency. Electric vehicle and electric motor testing and validation trends are evolving rapidly, and manufacturers must stay ahead of the curve to remain competitive.

One of the key benefits of rigorous testing and validation is the ability to identify potential issues early in the development process. This enables manufacturers to address these issues before they become major problems, reducing the risk of costly rework and improving overall efficiency. Additionally, rigorous testing and validation enable manufacturers to optimize electric motor performance, reducing energy consumption and improving overall efficiency.

The use of testing and validation methods is not limited to the development process. These methods can also be used to evaluate electric motor performance in real-world operating conditions. This enables manufacturers to identify potential issues and optimize motor performance in real-time, improving overall efficiency and reducing energy consumption.

In conclusion, ensuring the reliability and efficiency of electric motors is critical for the widespread adoption of electric vehicles. The use of simulation tools, testing protocols, and data analysis are essential components of a rigorous testing and validation process. By leveraging these methods, manufacturers can reduce development time and costs, while also improving overall efficiency.

The Role of Advanced Simulation Tools in Electric Vehicle Testing and Validation

Advanced simulation tools play a crucial role in electric vehicle testing and validation, enabling manufacturers to optimize electric motor performance, reduce physical prototyping and testing time, and improve overall efficiency. Finite element analysis (FEA) and computational fluid dynamics (CFD) are two of the most commonly used simulation tools in electric vehicle testing and validation.

FEA is used to simulate the behavior of electric motors under various operating conditions, including temperature, vibration, and electromagnetic interference. This enables manufacturers to optimize motor design, reduce material costs, and improve overall efficiency. CFD, on the other hand, is used to simulate the flow of fluids and gases within the electric motor, enabling manufacturers to optimize cooling systems, reduce energy consumption, and improve overall performance.

The use of advanced simulation tools in electric vehicle testing and validation offers several benefits, including reduced physical prototyping and testing time, improved accuracy, and increased efficiency. By leveraging these tools, manufacturers can optimize electric motor performance, reduce development time and costs, and improve overall efficiency. Electric vehicle and electric motor testing and validation trends are evolving rapidly, and the use of advanced simulation tools is becoming increasingly important for manufacturers to remain competitive.

One of the key advantages of using advanced simulation tools is the ability to simulate various operating conditions, including extreme temperatures, vibrations, and electromagnetic interference. This enables manufacturers to optimize electric motor performance, reduce material costs, and improve overall efficiency. Additionally, advanced simulation tools enable manufacturers to optimize cooling systems, reduce energy consumption, and improve overall performance.

The use of advanced simulation tools is not limited to the development process. These tools can also be used to evaluate electric motor performance in real-world operating conditions, enabling manufacturers to identify potential issues and optimize motor performance in real-time. This improves overall efficiency, reduces energy consumption, and enhances the overall driving experience.

In the context of electric vehicle and electric motor testing and validation trends, the use of advanced simulation tools is becoming increasingly important. As the industry continues to evolve, manufacturers must stay ahead of the curve by leveraging the latest simulation tools and technologies. By doing so, they can optimize electric motor performance, reduce development time and costs, and improve overall efficiency.

Real-World Examples: Electric Vehicle Testing and Validation Success Stories

Several companies in the automotive industry have successfully implemented advanced testing and validation methods for electric vehicles and electric motors. One such example is Tesla, which has developed a comprehensive testing and validation program for its electric motors. Tesla’s testing program includes a combination of simulation tools, testing protocols, and data analysis to ensure the reliability and efficiency of its electric motors.

Another example is Volkswagen, which has developed a testing and validation program for its electric vehicle batteries. Volkswagen’s program includes advanced testing methods such as battery management system testing, thermal testing, and vibration testing. These tests help to ensure the reliability and efficiency of the batteries, as well as the overall performance of the electric vehicle.

Other companies, such as General Motors and Nissan, have also implemented advanced testing and validation methods for their electric vehicles and electric motors. These companies have developed comprehensive testing programs that include a combination of simulation tools, testing protocols, and data analysis to ensure the reliability and efficiency of their electric motors.

The use of advanced testing and validation methods has helped these companies to improve the performance and efficiency of their electric vehicles and electric motors. For example, Tesla’s testing program has helped the company to improve the efficiency of its electric motors by up to 10%. Similarly, Volkswagen’s testing program has helped the company to improve the reliability of its electric vehicle batteries by up to 20%.

These success stories demonstrate the importance of advanced testing and validation methods in the development of electric vehicles and electric motors. By leveraging these methods, companies can improve the performance and efficiency of their products, reduce development time and costs, and improve overall customer satisfaction. Electric vehicle and electric motor testing and validation trends are evolving rapidly, and companies must stay ahead of the curve to remain competitive.

In addition to these success stories, there are several other examples of companies that have implemented advanced testing and validation methods for electric vehicles and electric motors. These companies include BMW, Mercedes-Benz, and Hyundai, among others. These companies have developed comprehensive testing programs that include a combination of simulation tools, testing protocols, and data analysis to ensure the reliability and efficiency of their electric motors.

Electric Motor Testing and Validation: A Deep Dive into Key Performance Indicators

Electric motor testing and validation involve evaluating the performance of electric motors against specific key performance indicators (KPIs). These KPIs include efficiency, power density, and thermal management, among others. In this section, we will delve into the details of these KPIs and explain how testing and validation methods can be used to optimize them.

Efficiency is a critical KPI for electric motors, as it directly affects the overall performance and range of electric vehicles. Testing and validation methods can be used to optimize efficiency by evaluating the motor’s ability to convert electrical energy into mechanical energy. This can be done using simulation tools, such as finite element analysis, and testing protocols, such as dynamometer testing.

Power density is another important KPI for electric motors, as it affects the motor’s ability to deliver power and torque. Testing and validation methods can be used to optimize power density by evaluating the motor’s ability to deliver power and torque under various operating conditions. This can be done using testing protocols, such as load testing and vibration testing.

Thermal management is also a critical KPI for electric motors, as it affects the motor’s ability to operate within a safe temperature range. Testing and validation methods can be used to optimize thermal management by evaluating the motor’s ability to dissipate heat under various operating conditions. This can be done using testing protocols, such as thermal testing and cooling system testing.

In addition to these KPIs, there are several other factors that can affect the performance of electric motors, including electromagnetic interference, vibration, and noise. Testing and validation methods can be used to optimize these factors by evaluating the motor’s ability to operate within a safe and reliable range.

The use of advanced testing and validation methods is essential for optimizing the performance of electric motors. By leveraging these methods, manufacturers can improve the efficiency, power density, and thermal management of their electric motors, leading to improved overall performance and range of electric vehicles. Electric vehicle and electric motor testing and validation trends are evolving rapidly, and manufacturers must stay ahead of the curve to remain competitive.

In conclusion, electric motor testing and validation involve evaluating the performance of electric motors against specific KPIs, including efficiency, power density, and thermal management. By leveraging advanced testing and validation methods, manufacturers can optimize these KPIs and improve the overall performance and range of electric vehicles.

The Impact of Electrification on Vehicle Testing and Validation: New Challenges and Opportunities

The increasing adoption of electric vehicles (EVs) is transforming the automotive industry, and vehicle testing and validation are no exception. Electrification brings new challenges and opportunities for testing and validation, requiring the development of advanced methodologies and tools. In this section, we will examine the impact of electrification on vehicle testing and validation, highlighting new challenges and opportunities.

One of the key challenges of electrification is the need for advanced battery testing and validation methodologies. EV batteries require specialized testing and validation protocols to ensure their safety, performance, and durability. This includes testing for battery management systems, thermal management, and electrical performance.

Another challenge is the need for advanced testing and validation methodologies for electric motors. Electric motors require specialized testing and validation protocols to ensure their performance, efficiency, and reliability. This includes testing for motor efficiency, power density, and thermal management.

Despite these challenges, electrification also brings new opportunities for vehicle testing and validation. For example, the use of advanced simulation tools and modeling techniques can help reduce physical prototyping and testing time, improving the overall efficiency of the testing and validation process.

Additionally, the use of data analytics and machine learning can help improve the accuracy and effectiveness of testing and validation. By analyzing data from various sources, including sensors, testing equipment, and simulation tools, manufacturers can gain valuable insights into the performance and behavior of their vehicles.

The impact of electrification on vehicle testing and validation is significant, and manufacturers must adapt to these changes to remain competitive. By developing advanced testing and validation methodologies and leveraging new technologies, manufacturers can ensure the safety, performance, and reliability of their electric vehicles.

In the context of electric vehicle and electric motor testing and validation trends, the impact of electrification is a critical factor. As the industry continues to evolve, manufacturers must stay ahead of the curve by developing advanced testing and validation methodologies and leveraging new technologies.

Overall, the impact of electrification on vehicle testing and validation is a complex and multifaceted issue. While it brings new challenges, it also brings new opportunities for innovation and improvement. By understanding these challenges and opportunities, manufacturers can develop effective testing and validation strategies that ensure the safety, performance, and reliability of their electric vehicles.

Best Practices for Electric Vehicle Testing and Validation: Lessons from Industry Experts

Electric vehicle testing and validation require a comprehensive approach that incorporates various testing tools and methodologies. Industry experts have developed best practices that can help streamline testing processes, reduce costs, and improve overall efficiency. In this section, we will discuss some of these best practices and provide insights into how they can be applied in electric vehicle testing and validation.

One of the key best practices in electric vehicle testing and validation is the use of advanced simulation tools. Simulation tools, such as finite element analysis and computational fluid dynamics, can help reduce physical prototyping and testing time, improving the overall efficiency of the testing process.

Another best practice is the use of testing protocols that are specifically designed for electric vehicles. These protocols can help ensure that electric vehicles are tested in a way that is relevant to their intended use, improving the accuracy and effectiveness of the testing process.

Industry experts also recommend the use of data analytics and machine learning in electric vehicle testing and validation. By analyzing data from various sources, including sensors, testing equipment, and simulation tools, manufacturers can gain valuable insights into the performance and behavior of their vehicles.

In addition to these best practices, industry experts also recommend the use of standardized testing methodologies. Standardized testing methodologies can help ensure that electric vehicles are tested in a consistent and repeatable way, improving the accuracy and effectiveness of the testing process.

Finally, industry experts recommend the use of collaboration and communication in electric vehicle testing and validation. Collaboration and communication between different teams and stakeholders can help ensure that testing and validation are done in a way that is efficient, effective, and relevant to the needs of the manufacturer.

By following these best practices, manufacturers can improve the efficiency and effectiveness of their electric vehicle testing and validation processes. Electric vehicle and electric motor testing and validation trends are evolving rapidly, and manufacturers must stay ahead of the curve to remain competitive.

In the context of electric vehicle and electric motor testing and validation trends, the use of best practices is critical. By leveraging these best practices, manufacturers can improve the accuracy and effectiveness of their testing and validation processes, reducing costs and improving overall efficiency.

Future Directions: Emerging Trends and Technologies in Electric Vehicle Testing and Validation

The electric vehicle industry is rapidly evolving, and testing and validation are critical components of this evolution. Emerging trends and technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT), are transforming the way electric vehicles are tested and validated. In this section, we will discuss these emerging trends and technologies and their potential impact on the industry.

Artificial intelligence (AI) is one of the most promising emerging trends in electric vehicle testing and validation. AI can be used to analyze data from various sources, including sensors, testing equipment, and simulation tools, to gain valuable insights into the performance and behavior of electric vehicles. This can help improve the accuracy and effectiveness of testing and validation, reducing costs and improving overall efficiency.

Machine learning is another emerging trend in electric vehicle testing and validation. Machine learning algorithms can be used to analyze data from various sources and identify patterns and trends that can help improve the performance and behavior of electric vehicles. This can help improve the accuracy and effectiveness of testing and validation, reducing costs and improving overall efficiency.

The Internet of Things (IoT) is also an emerging trend in electric vehicle testing and validation. IoT can be used to connect various devices and systems, including sensors, testing equipment, and simulation tools, to gain valuable insights into the performance and behavior of electric vehicles. This can help improve the accuracy and effectiveness of testing and validation, reducing costs and improving overall efficiency.

In addition to these emerging trends and technologies, there are several other factors that are driving innovation in electric vehicle testing and validation. These include the increasing use of advanced materials, such as lithium-ion batteries, and the development of new testing and validation methodologies, such as virtual testing and validation.

Overall, the future of electric vehicle testing and validation is exciting and rapidly evolving. Emerging trends and technologies, such as AI, machine learning, and IoT, are transforming the way electric vehicles are tested and validated, improving the accuracy and effectiveness of testing and validation, reducing costs, and improving overall efficiency.

In the context of electric vehicle and electric motor testing and validation trends, the use of emerging trends and technologies is critical. By leveraging these trends and technologies, manufacturers can improve the accuracy and effectiveness of testing and validation, reducing costs and improving overall efficiency.