Understanding the Synergy between Electric Motors and EVs

The integration of electric motors and electric vehicles (EVs) is a crucial aspect of the automotive industry’s transition towards sustainable and environmentally friendly transportation. Electric motor and electric vehicle integration is a complex process that requires careful consideration of various factors to achieve optimal performance, efficiency, and range. At its core, this integration involves the harmonious relationship between the electric motor, battery, power electronics, and control systems.

A well-designed electric motor and EV integration can significantly enhance the overall performance of the vehicle, providing faster acceleration, improved efficiency, and increased range. This is achieved through the optimization of power output, torque, and efficiency of the electric motor, as well as the careful management of energy flow between the motor, battery, and other components.

The benefits of electric motor and EV integration extend beyond performance and efficiency. It also enables the development of more sustainable and environmentally friendly vehicles, reducing greenhouse gas emissions and dependence on fossil fuels. Furthermore, the integration of electric motors and EVs can also improve the overall driving experience, providing a smoother and quieter ride.

However, achieving optimal electric motor and EV integration is a challenging task, requiring careful consideration of various technical and engineering aspects. It demands a deep understanding of the complex interactions between the electric motor, battery, power electronics, and control systems, as well as the ability to optimize these components for maximum performance and efficiency.

Despite these challenges, the rewards of successful electric motor and EV integration are significant, enabling the development of more efficient, sustainable, and environmentally friendly vehicles. As the automotive industry continues to evolve and transition towards electric vehicles, the importance of electric motor and EV integration will only continue to grow, driving innovation and advancements in this critical area of research and development.

How to Choose the Right Electric Motor for Your EV

Selecting the most suitable electric motor for an electric vehicle (EV) is a critical aspect of electric motor and electric vehicle integration. The right motor can significantly impact the performance, efficiency, and range of the vehicle, while a poorly chosen motor can lead to suboptimal performance and reduced lifespan.

When choosing an electric motor for an EV, several factors must be considered. Power output is a crucial consideration, as it directly affects the vehicle’s acceleration and top speed. Torque is also essential, as it influences the vehicle’s ability to handle different driving conditions, such as hills and heavy loads.

Efficiency is another critical factor, as it affects the vehicle’s overall energy consumption and range. A more efficient motor can help reduce energy losses and increase the vehicle’s range, making it a more attractive option for EV manufacturers and consumers.

Compatibility with the vehicle’s battery and control systems is also vital. The motor must be able to work seamlessly with the battery and control systems to ensure optimal performance and efficiency. This requires careful consideration of the motor’s voltage, current, and power output, as well as its compatibility with the vehicle’s electrical architecture.

In addition to these technical considerations, the motor’s size, weight, and cost must also be taken into account. A smaller, lighter motor can help reduce the vehicle’s overall weight and improve its power-to-weight ratio, while a more affordable motor can help reduce the vehicle’s production costs.

Some popular types of electric motors used in EVs include permanent magnet motors, induction motors, and switched reluctance motors. Each type has its advantages and disadvantages, and the choice of motor ultimately depends on the specific requirements of the vehicle and the manufacturer’s goals.

By carefully considering these factors and selecting the right electric motor for an EV, manufacturers can create vehicles that offer exceptional performance, efficiency, and range, while also reducing production costs and environmental impact.

The Role of Power Electronics in Electric Motor and EV Integration

Power electronics play a crucial role in electric motor and electric vehicle (EV) integration, enabling the efficient and reliable flow of electrical energy between the motor, battery, and other components. The power electronics system acts as an intermediary between the motor and battery, controlling the flow of energy and ensuring that the motor operates within its optimal range.

The power electronics system consists of several key components, including the inverter, converter, and controller. The inverter converts the DC power from the battery to AC power, which is then fed to the motor. The converter regulates the flow of energy between the battery and motor, while the controller monitors and controls the entire system, ensuring that it operates within safe and efficient parameters.

The power electronics system must be carefully designed and optimized to ensure efficient and reliable operation. This requires careful consideration of factors such as switching frequency, pulse width modulation, and thermal management. The system must also be able to handle the high currents and voltages associated with EV operation, while minimizing energy losses and heat generation.

Advances in power electronics have enabled the development of more efficient and compact EVs, with improved performance and range. The use of wide bandgap semiconductors, such as silicon carbide and gallium nitride, has enabled the creation of more efficient and reliable power electronics systems. These advances have also enabled the development of more sophisticated control systems, which can optimize the operation of the motor and battery in real-time.

The integration of power electronics with electric motors and EVs has also enabled the development of new features and functionalities, such as regenerative braking and torque vectoring. These features have improved the overall efficiency and performance of EVs, while also enhancing the driving experience.

In conclusion, power electronics play a vital role in electric motor and EV integration, enabling the efficient and reliable flow of electrical energy between the motor, battery, and other components. Advances in power electronics have enabled the development of more efficient and compact EVs, with improved performance and range.

Thermal Management Strategies for Electric Motor and EV Integration

Thermal management is a critical aspect of electric motor and electric vehicle (EV) integration, as it directly impacts the performance, efficiency, and longevity of the vehicle. The electric motor, battery, and other components generate heat during operation, which can lead to reduced efficiency, increased wear and tear, and even system failure if not properly managed. Effective thermal management strategies are essential to maintain optimal operating temperatures, ensuring reliable and efficient electric motor and EV integration.

One of the primary challenges in thermal management is cooling the electric motor. Electric motors can generate significant amounts of heat, particularly during high-torque or high-speed operations. To address this, various cooling techniques can be employed, such as air cooling, liquid cooling, or a combination of both. Air cooling systems use fans or blowers to circulate air through the motor, while liquid cooling systems utilize a coolant to absorb heat from the motor and transfer it to a heat exchanger.

In addition to motor cooling, battery thermal management is also crucial. Lithium-ion batteries, commonly used in EVs, have optimal operating temperature ranges. If the battery temperature exceeds these ranges, it can lead to reduced performance, capacity loss, and even thermal runaway. To mitigate this, battery thermal management systems can be designed to maintain optimal temperatures, using techniques such as air cooling, liquid cooling, or phase-change materials.

Other components, such as power electronics and control systems, also require thermal management. These components can generate heat during operation, which can impact their performance and reliability. Effective thermal management strategies, such as heat sinks, thermal interfaces, and cooling systems, can be employed to maintain optimal operating temperatures.

Advanced materials and technologies are being developed to enhance thermal management in electric motor and EV integration. For example, advanced composites and nanomaterials can be used to improve thermal conductivity and reduce weight. Additionally, innovative cooling systems, such as thermoelectric coolers and heat pipes, can be employed to efficiently manage heat.

In conclusion, thermal management is a critical aspect of electric motor and EV integration, requiring careful consideration of cooling techniques, materials, and system design. By implementing effective thermal management strategies, electric motor and EV manufacturers can ensure reliable and efficient operation, while also improving performance, range, and overall vehicle longevity.

Real-World Examples of Successful Electric Motor and EV Integration

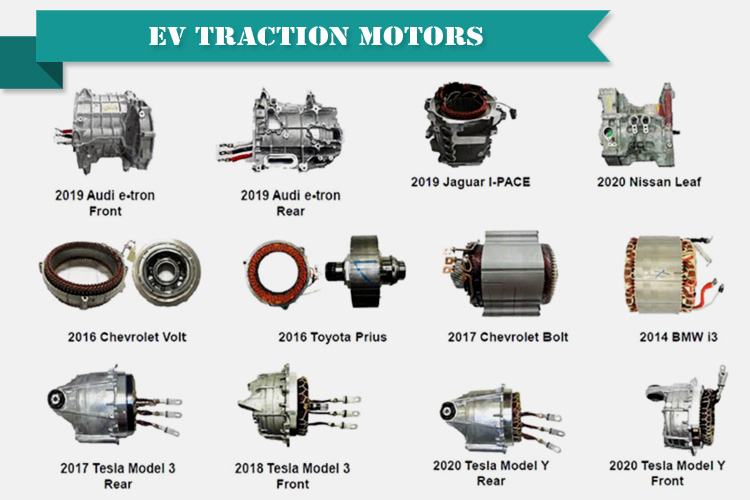

The integration of electric motors and electric vehicles (EVs) has led to the development of highly efficient and performance-driven vehicles. Several manufacturers have successfully integrated electric motors into their EVs, showcasing innovative approaches and benefits. This section highlights a few examples of successful electric motor and EV integration.

The Tesla Model S is a prime example of successful electric motor and EV integration. The Model S features a high-performance electric motor that produces 762 horsepower and 723 lb-ft of torque. The motor is powered by a 100 kWh battery pack, which provides an estimated range of up to 373 miles. Tesla’s innovative approach to electric motor and EV integration has enabled the Model S to achieve exceptional performance, efficiency, and range.

The Chevrolet Bolt is another example of successful electric motor and EV integration. The Bolt features a single electric motor that produces 200 horsepower and 266 lb-ft of torque. The motor is powered by a 60 kWh battery pack, which provides an estimated range of up to 259 miles. Chevrolet’s approach to electric motor and EV integration has enabled the Bolt to achieve exceptional efficiency and range, making it an attractive option for EV buyers.

The Nissan Leaf is a pioneering example of successful electric motor and EV integration. The Leaf features a high-torque electric motor that produces 147 horsepower and 236 lb-ft of torque. The motor is powered by a 40 kWh battery pack, which provides an estimated range of up to 147 miles. Nissan’s innovative approach to electric motor and EV integration has enabled the Leaf to achieve exceptional efficiency and range, making it one of the best-selling EVs of all time.

Other notable examples of successful electric motor and EV integration include the BMW i3, Volkswagen e-Golf, and Hyundai Kona Electric. These vehicles showcase innovative approaches to electric motor and EV integration, including advanced battery management systems, high-performance electric motors, and optimized power electronics.

These real-world examples demonstrate the importance of electric motor and EV integration in achieving exceptional performance, efficiency, and range. By understanding the successful approaches and benefits of these vehicles, manufacturers can develop more efficient and performance-driven EVs, driving the adoption of electric vehicles and reducing our reliance on fossil fuels.

Overcoming Challenges in Electric Motor and EV Integration

Electric motor and electric vehicle (EV) integration is a complex process that requires careful consideration of various factors to ensure reliable and efficient operation. Despite the many benefits of electric motor and EV integration, several challenges can arise during the integration process. This section discusses common challenges faced during electric motor and EV integration and provides solutions for mitigating these issues.

One of the primary challenges in electric motor and EV integration is electromagnetic interference (EMI). EMI can occur when the electric motor and other components in the vehicle generate electromagnetic fields that interfere with each other. To mitigate EMI, manufacturers can use shielding materials, filtering devices, and grounding techniques to reduce electromagnetic radiation.

Vibration and noise are another challenge in electric motor and EV integration. Electric motors can generate significant vibration and noise, particularly during high-speed operation. To address this, manufacturers can use vibration-damping materials, noise-reducing coatings, and optimized motor designs to minimize vibration and noise.

Thermal management is also a significant challenge in electric motor and EV integration. Electric motors and batteries can generate significant heat during operation, which can impact performance and longevity. To mitigate this, manufacturers can use advanced cooling systems, thermal interfaces, and heat sinks to manage heat and maintain optimal operating temperatures.

Another challenge in electric motor and EV integration is ensuring compatibility between the electric motor and other components in the vehicle. This includes ensuring compatibility with the battery management system, power electronics, and control systems. To address this, manufacturers can use standardized interfaces, modular designs, and software-based integration tools to ensure seamless communication between components.

Finally, ensuring reliability and durability is a critical challenge in electric motor and EV integration. Electric motors and batteries must be designed to withstand the rigors of daily use, including extreme temperatures, vibration, and electrical stress. To address this, manufacturers can use advanced materials, robust designs, and rigorous testing protocols to ensure reliable and durable operation.

By understanding these challenges and implementing effective solutions, manufacturers can overcome the obstacles associated with electric motor and EV integration. This enables the development of highly efficient, reliable, and performance-driven electric vehicles that meet the needs of consumers and reduce our reliance on fossil fuels.

Future Trends and Advancements in Electric Motor and EV Integration

The field of electric motor and electric vehicle (EV) integration is rapidly evolving, with emerging trends and technologies poised to shape the future of the industry. As the demand for efficient, reliable, and high-performance EVs continues to grow, manufacturers are investing heavily in research and development to stay ahead of the curve.

One of the most significant trends in electric motor and EV integration is the development of advanced materials and designs. New materials such as graphene, nanomaterials, and advanced ceramics are being explored for their potential to improve motor efficiency, reduce weight, and increase durability. Additionally, innovative designs such as axial flux motors, transverse flux motors, and modular motors are being developed to improve performance, reduce costs, and increase flexibility.

Another trend in electric motor and EV integration is the increasing use of advanced control systems and power electronics. The development of more sophisticated control algorithms, sensors, and power electronics is enabling the creation of more efficient, reliable, and high-performance EVs. Additionally, the use of advanced control systems is enabling the integration of multiple motors, batteries, and other components to create more complex and efficient EV systems.

The integration of artificial intelligence (AI) and machine learning (ML) is also becoming increasingly important in electric motor and EV integration. AI and ML algorithms can be used to optimize motor performance, predict maintenance needs, and improve overall system efficiency. Additionally, the use of AI and ML can enable the creation of more autonomous and connected EVs, which are poised to revolutionize the transportation industry.

Wireless charging is another emerging trend in electric motor and EV integration. Wireless charging technology enables the transfer of electrical energy between a transmitter and a receiver without the need for physical contact. This technology has the potential to greatly simplify the charging process, reduce infrastructure costs, and increase the convenience of EV ownership.

Finally, the development of more sustainable and environmentally friendly EVs is becoming increasingly important. The use of recycled materials, biodegradable materials, and sustainable manufacturing processes is becoming more prevalent in the industry. Additionally, the development of EVs that can be powered by renewable energy sources such as solar and wind power is becoming more important as the industry moves towards a more sustainable future.

These emerging trends and technologies are poised to shape the future of electric motor and EV integration, enabling the creation of more efficient, reliable, and high-performance EVs. As the industry continues to evolve, it is likely that we will see even more innovative and creative solutions to the challenges of electric motor and EV integration.

Best Practices for Ensuring Reliable and Efficient Electric Motor and EV Integration

Ensuring reliable and efficient electric motor and electric vehicle (EV) integration requires careful planning, testing, and validation. By following best practices and considering key factors, manufacturers can create high-performance EVs that meet the needs of consumers and reduce our reliance on fossil fuels.

One of the most important best practices for electric motor and EV integration is to carefully select the right electric motor for the vehicle. This involves considering factors such as power output, torque, efficiency, and compatibility with the vehicle’s battery and control systems. By selecting the right motor, manufacturers can ensure optimal performance, efficiency, and range.

Another key best practice is to ensure proper thermal management. This involves using techniques such as cooling and heating to maintain optimal temperatures for the motor, battery, and other components. By managing heat effectively, manufacturers can improve performance, efficiency, and longevity.

Power electronics play a crucial role in electric motor and EV integration, and manufacturers should carefully select and design power electronics systems to ensure efficient and reliable operation. This involves considering factors such as power output, efficiency, and compatibility with the vehicle’s battery and control systems.

Testing and validation are also critical best practices for electric motor and EV integration. Manufacturers should conduct thorough testing and validation to ensure that the electric motor and EV system meet performance, efficiency, and safety requirements. This involves testing the system under various operating conditions, including extreme temperatures, vibration, and electrical stress.

In addition to these best practices, manufacturers should also consider the importance of electromagnetic compatibility (EMC) and electromagnetic interference (EMI) mitigation. This involves designing the electric motor and EV system to minimize electromagnetic radiation and ensure compatibility with other components and systems.

Finally, manufacturers should prioritize the use of advanced materials and designs to improve performance, efficiency, and durability. This involves exploring new materials and technologies, such as graphene, nanomaterials, and advanced ceramics, to create more efficient and reliable electric motors and EV systems.

By following these best practices and considering key factors, manufacturers can create high-performance EVs that meet the needs of consumers and reduce our reliance on fossil fuels. As the industry continues to evolve, it is likely that we will see even more innovative and creative solutions to the challenges of electric motor and EV integration.