Unlocking the Potential of Electric Motors in EV Design

The electric motor is a crucial component in electric vehicle (EV) design and performance. As the EV industry continues to evolve, advancements in electric motor technology are driving innovation and transforming the way vehicles are designed and manufactured. Electric vehicle and electric motor product development teams are working tirelessly to create more efficient, powerful, and reliable electric motors that can meet the demands of the growing EV market.

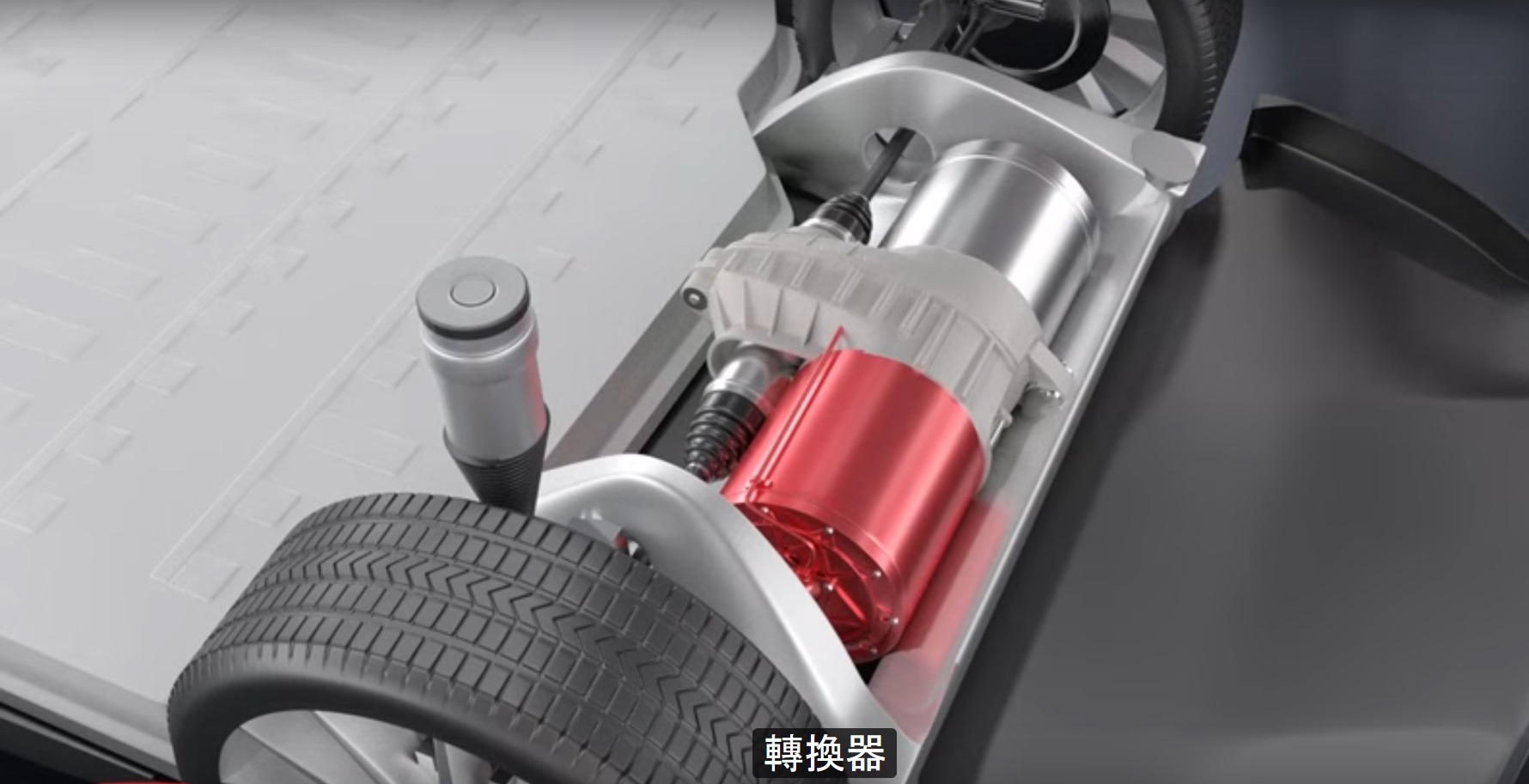

One of the key challenges in electric motor design is achieving optimal efficiency and performance while minimizing weight and cost. To address this challenge, manufacturers are exploring new materials and technologies, such as advanced magnetic materials and 3D printing. These innovations enable the creation of more complex motor geometries and optimized motor designs that can improve efficiency and reduce weight.

The development of electric motors for EV applications also requires careful consideration of the vehicle’s overall system architecture. Electric vehicle and electric motor product development teams must work closely together to ensure that the motor is optimized for the specific vehicle application and that the overall system is designed to meet the required performance and efficiency targets.

Advancements in electric motor technology are also driving innovation in other areas of EV design, such as battery management and power electronics. As electric motors become more efficient and powerful, they are enabling the development of more advanced battery management systems and power electronics that can optimize energy efficiency and reduce emissions.

Overall, the electric motor is a critical component in EV design and performance, and advancements in electric motor technology are driving innovation and transformation in the EV industry. As electric vehicle and electric motor product development teams continue to push the boundaries of what is possible, we can expect to see even more efficient, powerful, and reliable EVs in the future.

How to Develop High-Performance Electric Motors for EV Applications

Developing high-performance electric motors for electric vehicle (EV) applications requires careful consideration of several key factors, including motor design, materials, and testing. Electric vehicle and electric motor product development teams must work together to create motors that meet the demanding requirements of EVs, including high efficiency, reliability, and power density.

One of the most critical aspects of electric motor design is the selection of materials. The choice of materials can significantly impact the motor’s efficiency, reliability, and cost. For example, the use of rare-earth magnets can provide high power density and efficiency, but can also increase the motor’s cost. Electric vehicle and electric motor product development teams must carefully evaluate the trade-offs between different materials and select the best option for their specific application.

Another important consideration in electric motor design is the motor’s thermal management system. Electric motors can generate significant heat during operation, which can impact their efficiency and reliability. Electric vehicle and electric motor product development teams must design thermal management systems that can effectively cool the motor and maintain its optimal operating temperature.

Testing is also a critical aspect of electric motor development. Electric vehicle and electric motor product development teams must conduct thorough testing to ensure that the motor meets the required performance and efficiency targets. This includes testing the motor’s efficiency, power density, and reliability, as well as its thermal management system.

In addition to these technical considerations, electric vehicle and electric motor product development teams must also consider the motor’s manufacturability and cost. The motor must be designed to be manufactured efficiently and cost-effectively, while also meeting the required performance and efficiency targets.

By carefully considering these factors, electric vehicle and electric motor product development teams can create high-performance electric motors that meet the demanding requirements of EVs. This requires a deep understanding of electric motor design, materials, and testing, as well as a commitment to innovation and excellence.

Electric Vehicle Product Development: Trends, Challenges, and Opportunities

The electric vehicle (EV) industry is rapidly evolving, driven by government regulations, market demand, and technological advancements. Electric vehicle and electric motor product development teams must navigate these trends, challenges, and opportunities to create innovative and competitive products. In this section, we will examine the current state of the EV industry and explore the key factors shaping its future.

Government regulations are playing a significant role in driving the adoption of EVs. Many countries have set targets for EV adoption, and governments are offering incentives to encourage the development and purchase of EVs. For example, the European Union has set a target of having at least 50% of new car sales be electric by 2035. These regulations are creating a sense of urgency among automakers to develop and launch EVs, driving innovation and investment in electric vehicle and electric motor product development.

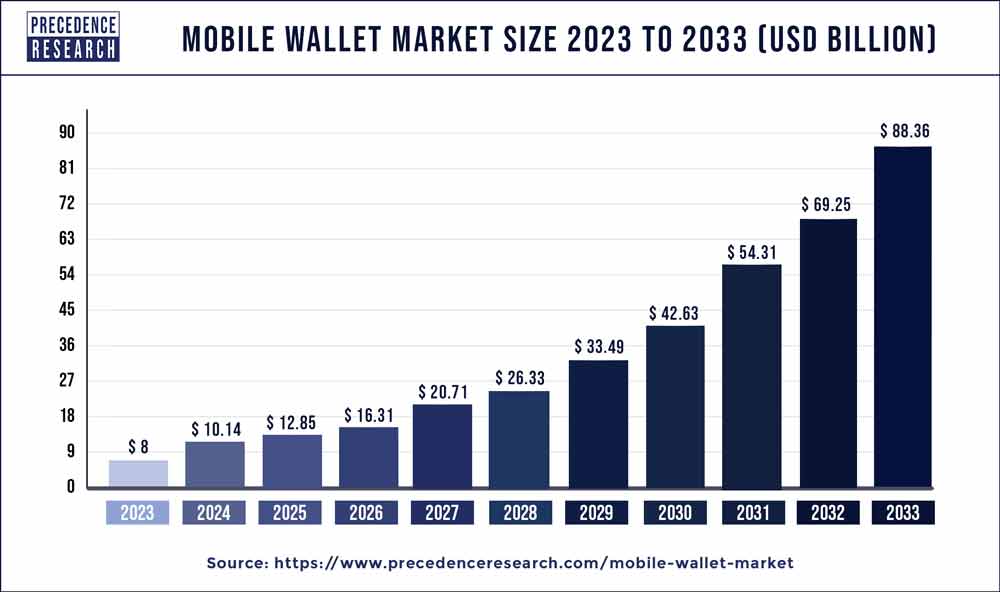

Market demand is also driving the growth of the EV industry. Consumers are increasingly interested in EVs, driven by concerns about climate change, air pollution, and energy efficiency. According to a recent survey, 75% of consumers consider the environmental impact of a vehicle when making a purchasing decision. This shift in consumer behavior is creating new opportunities for electric vehicle and electric motor product development teams to create innovative and appealing products.

Technological advancements are also transforming the EV industry. Advances in battery technology, electric motor design, and power electronics are enabling the development of more efficient, powerful, and affordable EVs. For example, the development of solid-state batteries promises to significantly improve the range and efficiency of EVs. Electric vehicle and electric motor product development teams must stay up-to-date with these technological advancements to remain competitive.

Despite these opportunities, the EV industry also faces significant challenges. One of the biggest challenges is the high cost of EVs, which is driven by the cost of batteries and electric motors. Electric vehicle and electric motor product development teams must work to reduce these costs while maintaining performance and efficiency. Another challenge is the lack of charging infrastructure, which can make it difficult for consumers to own and operate EVs. Governments and companies are investing heavily in charging infrastructure, but more work is needed to support the widespread adoption of EVs.

In conclusion, the EV industry is rapidly evolving, driven by government regulations, market demand, and technological advancements. Electric vehicle and electric motor product development teams must navigate these trends, challenges, and opportunities to create innovative and competitive products. By staying up-to-date with the latest technological advancements and addressing the challenges facing the industry, electric vehicle and electric motor product development teams can create a sustainable and successful future for the EV industry.

Real-World Examples: Successful Electric Vehicle and Electric Motor Products

The electric vehicle (EV) industry has seen significant growth in recent years, with many successful products hitting the market. In this section, we will examine some real-world examples of successful EVs and electric motors, and analyze their design, features, and market impact.

One of the most successful EVs on the market is the Tesla Model S. First introduced in 2012, the Model S has been a game-changer in the EV industry, offering a range of up to 373 miles on a single charge and a 0-60mph time of just 2.5 seconds. The Model S features a powerful electric motor, designed and developed by Tesla’s team of engineers. The motor uses a combination of permanent magnet and induction technologies to deliver exceptional efficiency and performance.

Another successful EV is the Nissan Leaf, which has been on the market since 2010. The Leaf features a compact electric motor, designed to provide exceptional efficiency and reliability. The motor uses a combination of permanent magnet and induction technologies, and is capable of delivering up to 147 horsepower. The Leaf has been a best-seller in the EV market, with over 400,000 units sold worldwide.

In addition to these successful EVs, there are also many successful electric motor products on the market. For example, the electric motor used in the BMW i3 is a highly efficient and compact design, capable of delivering up to 170 horsepower. The motor uses a combination of permanent magnet and induction technologies, and is designed to provide exceptional efficiency and reliability.

These real-world examples demonstrate the importance of electric vehicle and electric motor product development in the EV industry. By designing and developing high-performance electric motors, companies can create successful EVs that meet the needs of consumers and help to drive the growth of the industry.

In conclusion, the success of EVs like the Tesla Model S and the Nissan Leaf, and electric motor products like the BMW i3 motor, demonstrate the importance of electric vehicle and electric motor product development in the EV industry. By analyzing the design, features, and market impact of these successful products, we can gain a better understanding of the key factors that drive success in the EV industry.

Overcoming Technical Challenges in Electric Motor Design and Development

Electric motor design and development for electric vehicle (EV) applications can be a complex and challenging task. One of the most significant technical challenges is thermal management, as electric motors can generate a significant amount of heat during operation. This heat can impact the motor’s efficiency, reliability, and overall performance.

To overcome this challenge, electric vehicle and electric motor product development teams can use advanced materials and technologies, such as high-temperature magnets and advanced cooling systems. These solutions can help to reduce the motor’s temperature and improve its overall efficiency and reliability.

Another technical challenge in electric motor design and development is efficiency. Electric motors must be designed to operate at high efficiency to minimize energy losses and maximize the vehicle’s range. To achieve this, electric vehicle and electric motor product development teams can use advanced motor designs, such as permanent magnet motors and induction motors, which offer high efficiency and reliability.

Reliability is also a critical consideration in electric motor design and development. Electric motors must be designed to operate reliably over a wide range of temperatures and operating conditions. To achieve this, electric vehicle and electric motor product development teams can use advanced materials and technologies, such as high-reliability bearings and advanced motor windings.

In addition to these technical challenges, electric vehicle and electric motor product development teams must also consider the motor’s noise, vibration, and harshness (NVH) characteristics. Electric motors can generate significant noise and vibration during operation, which can impact the vehicle’s overall comfort and performance.

To overcome these challenges, electric vehicle and electric motor product development teams can use advanced simulation tools and testing techniques to optimize the motor’s design and performance. These tools and techniques can help to identify and mitigate potential issues early in the design process, reducing the risk of costly redesigns and rework.

In conclusion, electric motor design and development for EV applications can be a complex and challenging task. However, by using advanced materials and technologies, and by considering the motor’s thermal management, efficiency, reliability, and NVH characteristics, electric vehicle and electric motor product development teams can create high-performance electric motors that meet the demands of the EV industry.

Collaboration and Partnerships in Electric Vehicle Product Development

Collaboration and partnerships are essential in electric vehicle (EV) product development, as they enable companies to leverage the expertise and resources of multiple stakeholders to drive innovation and growth. Electric vehicle and electric motor product development teams can benefit from working with suppliers, startups, and research institutions to access new technologies, reduce development costs, and accelerate time-to-market.

One of the key benefits of collaboration and partnerships in EV product development is the ability to access new technologies and expertise. By working with suppliers and startups, electric vehicle and electric motor product development teams can gain access to cutting-edge technologies and innovative solutions that can help to drive innovation and growth.

Another benefit of collaboration and partnerships is the ability to reduce development costs. By sharing resources and expertise, electric vehicle and electric motor product development teams can reduce the costs associated with developing new products and technologies. This can help to make EVs more competitive in the market and increase their adoption rates.

Collaboration and partnerships can also help to accelerate time-to-market for EVs. By working together, electric vehicle and electric motor product development teams can reduce the time it takes to develop and launch new products, which can help to stay ahead of the competition and meet the growing demand for EVs.

Research institutions are also playing a critical role in EV product development, as they provide a source of innovative ideas and technologies. By partnering with research institutions, electric vehicle and electric motor product development teams can gain access to the latest research and development in EV technology, which can help to drive innovation and growth.

In addition to these benefits, collaboration and partnerships can also help to drive standardization in the EV industry. By working together, electric vehicle and electric motor product development teams can establish common standards and protocols for EVs, which can help to increase their adoption rates and reduce costs.

In conclusion, collaboration and partnerships are essential in electric vehicle product development, as they enable companies to leverage the expertise and resources of multiple stakeholders to drive innovation and growth. By working with suppliers, startups, and research institutions, electric vehicle and electric motor product development teams can access new technologies, reduce development costs, and accelerate time-to-market.

Electric Vehicle and Electric Motor Product Development: Future Outlook and Predictions

The electric vehicle (EV) industry is rapidly evolving, driven by advances in technology, changes in government regulations, and shifting market demand. As the industry continues to grow and mature, electric vehicle and electric motor product development teams must stay ahead of the curve to remain competitive.

One of the key trends shaping the future of the EV industry is the increasing focus on sustainability and environmental responsibility. As consumers become more aware of the environmental impact of their purchasing decisions, electric vehicle and electric motor product development teams must prioritize the development of sustainable and environmentally friendly products.

Another trend driving the future of the EV industry is the growing demand for autonomous vehicles. As autonomous technology continues to advance, electric vehicle and electric motor product development teams must integrate autonomous systems into their products to remain competitive.

In addition to these trends, the EV industry is also being shaped by emerging technologies such as advanced battery systems, electric motor technologies, and charging infrastructure. Electric vehicle and electric motor product development teams must stay up-to-date with these emerging technologies to remain competitive and drive innovation.

The market for EVs is also expected to shift in the coming years, driven by changes in government regulations and shifting consumer demand. Electric vehicle and electric motor product development teams must be prepared to adapt to these changes and develop products that meet the evolving needs of the market.

Despite these challenges, the future of the EV industry is bright, with many opportunities for growth and innovation. Electric vehicle and electric motor product development teams that prioritize sustainability, autonomous technology, and emerging technologies will be well-positioned to drive innovation and growth in the industry.

In conclusion, the future of electric vehicle and electric motor product development is shaped by a complex interplay of trends, technologies, and market shifts. By prioritizing sustainability, autonomous technology, and emerging technologies, electric vehicle and electric motor product development teams can drive innovation and growth in the industry.

Best Practices for Electric Vehicle and Electric Motor Product Development Teams

Electric vehicle and electric motor product development teams must follow best practices to ensure the successful development of high-performance electric vehicles and electric motors. In this section, we will discuss some of the key best practices and recommendations for electric vehicle and electric motor product development teams.

One of the most important best practices for electric vehicle and electric motor product development teams is to prioritize project management. This includes creating a clear project plan, setting realistic timelines, and allocating resources effectively. By prioritizing project management, electric vehicle and electric motor product development teams can ensure that their projects are completed on time, within budget, and to the required quality standards.

Another key best practice for electric vehicle and electric motor product development teams is to conduct thorough testing and validation. This includes testing the electric motor and electric vehicle under a range of operating conditions, including extreme temperatures, high speeds, and heavy loads. By conducting thorough testing and validation, electric vehicle and electric motor product development teams can ensure that their products meet the required performance and safety standards.

In addition to project management and testing, electric vehicle and electric motor product development teams must also prioritize collaboration and communication. This includes working closely with suppliers, startups, and research institutions to access new technologies and expertise. By prioritizing collaboration and communication, electric vehicle and electric motor product development teams can drive innovation and growth in the industry.

Electric vehicle and electric motor product development teams must also prioritize the development of sustainable and environmentally friendly products. This includes using recycled materials, minimizing waste, and reducing energy consumption. By prioritizing sustainability, electric vehicle and electric motor product development teams can reduce their environmental impact and contribute to a more sustainable future.

Finally, electric vehicle and electric motor product development teams must prioritize the development of products that meet the evolving needs of the market. This includes staying up-to-date with the latest trends and technologies, and being prepared to adapt to changes in government regulations and market demand. By prioritizing the development of products that meet the evolving needs of the market, electric vehicle and electric motor product development teams can drive innovation and growth in the industry.

In conclusion, electric vehicle and electric motor product development teams must follow best practices to ensure the successful development of high-performance electric vehicles and electric motors. By prioritizing project management, testing, collaboration, sustainability, and market-driven product development, electric vehicle and electric motor product development teams can drive innovation and growth in the industry.