Understanding the Role of Power Electronics in Electric Vehicles

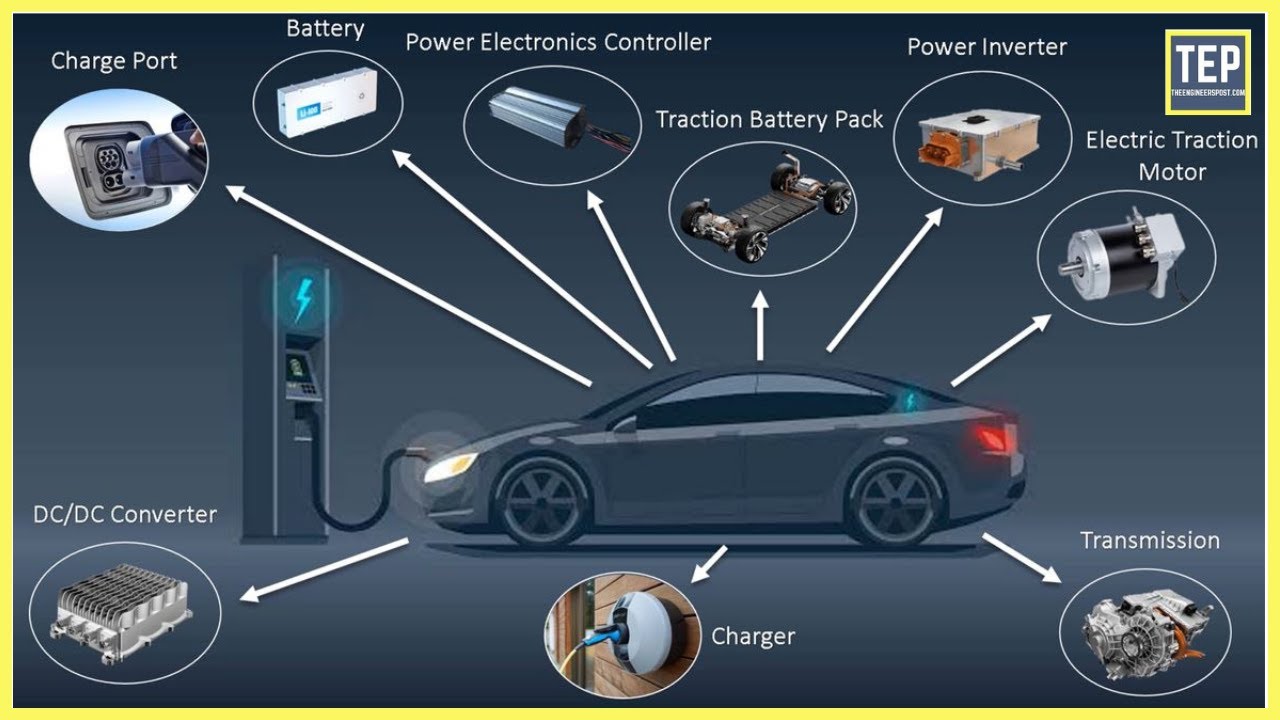

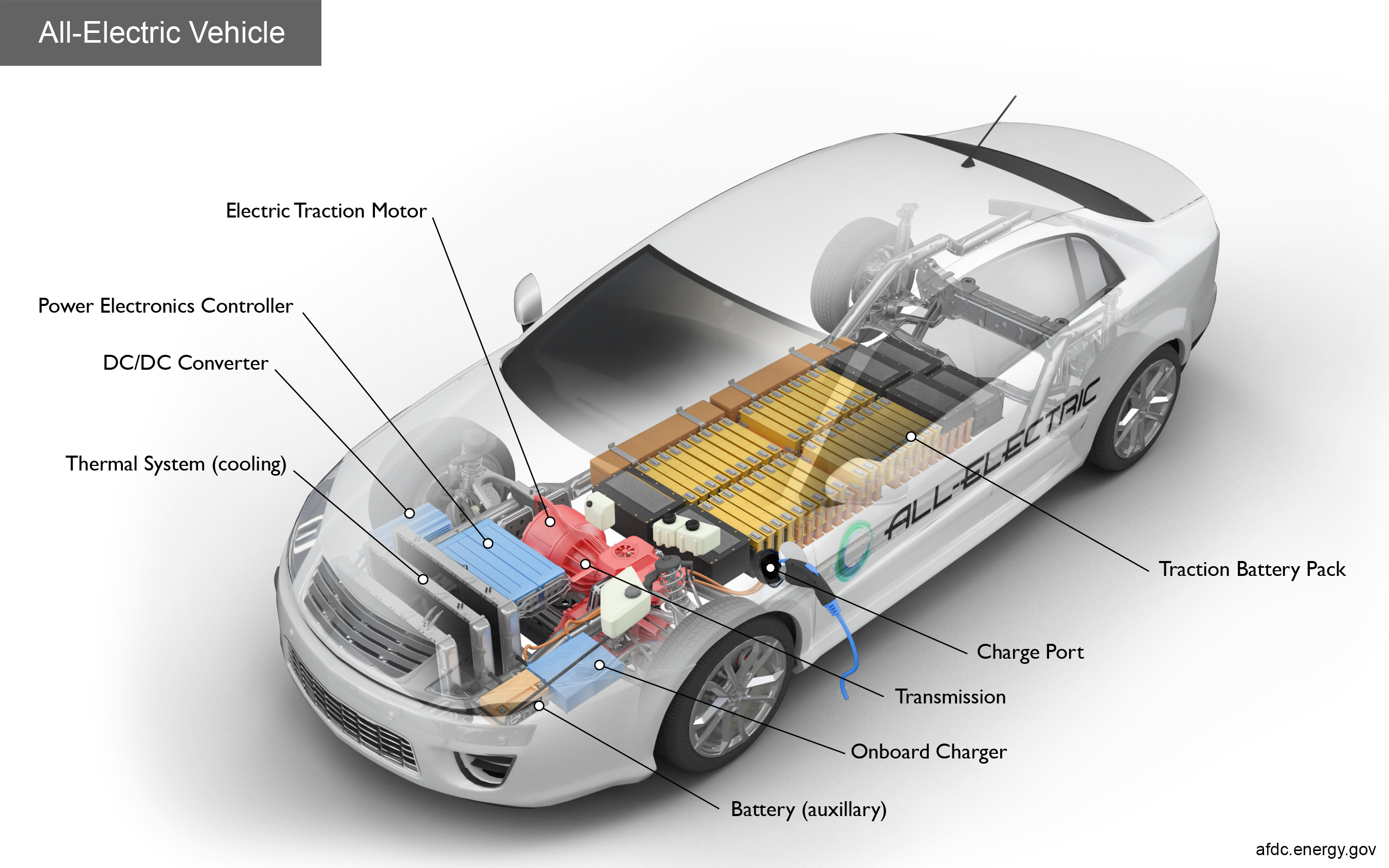

Power electronics play a crucial role in the operation of electric vehicles (EVs), enabling the efficient and reliable flow of electrical energy between the battery, motor, and other components. The importance of power electronics in EVs cannot be overstated, as they are responsible for controlling the flow of energy that powers the vehicle’s propulsion system. In essence, power electronics act as the “brain” of the EV, ensuring that the electrical energy is converted into mechanical energy in the most efficient manner possible.

The use of power electronics in EVs has numerous benefits, including improved efficiency, reliability, and performance. By optimizing the flow of electrical energy, power electronics can help reduce energy consumption, heat generation, and battery wear, ultimately leading to a longer vehicle lifespan. Furthermore, advancements in power electronics have enabled the development of more efficient and reliable EVs, with improved acceleration, range, and overall driving experience.

In an EV, power electronics are used to control the flow of electrical energy from the battery to the electric motor. This is achieved through the use of power modules, which are essentially high-power electronic switches that control the flow of electrical energy. The power modules are typically made up of power semiconductor devices, such as insulated gate bipolar transistors (IGBTs) or power MOSFETs, which are designed to handle high currents and voltages.

The integration of power electronics in EVs has also enabled the development of advanced vehicle features, such as regenerative braking and torque vectoring. Regenerative braking, for example, allows the vehicle to capture kinetic energy and convert it into electrical energy, which is then stored in the battery. This feature not only improves vehicle efficiency but also reduces wear on the braking system.

In addition to their technical benefits, power electronics have also played a crucial role in the widespread adoption of EVs. By enabling the development of more efficient and reliable EVs, power electronics have helped to reduce the cost and increase the appeal of EVs to consumers. As the demand for EVs continues to grow, the importance of power electronics in these vehicles will only continue to increase.

As the technology continues to evolve, it is likely that power electronics will play an even more critical role in the development of future EVs. With the increasing demand for higher efficiency, reliability, and performance, power electronics will be at the forefront of innovation in the EV industry. As such, it is essential to continue investing in research and development to improve the efficiency and reliability of power electronics in EVs.

How to Optimize Electric Motor Performance with Advanced Power Electronics

Optimizing electric motor performance is crucial for achieving high efficiency, reliability, and range in electric vehicles. Advanced power electronics play a vital role in this optimization, enabling the efficient control of electrical energy flow between the battery, motor, and other components. By leveraging high-performance power modules, advanced control algorithms, and thermal management systems, electric vehicle manufacturers can significantly improve motor performance and overall vehicle efficiency.

One key strategy for optimizing electric motor performance is the use of high-performance power modules. These modules, typically made up of power semiconductor devices such as IGBTs or power MOSFETs, are designed to handle high currents and voltages while minimizing energy losses. By selecting the right power module for the specific application, electric vehicle manufacturers can achieve higher efficiency, reliability, and power density.

Advanced control algorithms are another critical component of electric motor optimization. These algorithms, often implemented using digital signal processors (DSPs) or field-programmable gate arrays (FPGAs), enable the precise control of electrical energy flow and motor torque. By optimizing control algorithms for specific motor types and applications, electric vehicle manufacturers can achieve improved efficiency, reduced energy consumption, and enhanced vehicle performance.

Thermal management systems are also essential for optimizing electric motor performance. These systems, which typically include heat sinks, cooling fans, and thermal interface materials, help to dissipate heat generated by the motor and power electronics. By effectively managing thermal energy, electric vehicle manufacturers can prevent overheating, reduce energy losses, and ensure reliable motor operation.

In addition to these strategies, electric vehicle manufacturers can also leverage emerging technologies such as wide bandgap semiconductors and advanced magnetic materials to further optimize electric motor performance. These technologies offer improved efficiency, reliability, and power density, enabling the development of more efficient and reliable electric vehicles.

Simulation and testing are also critical components of electric motor optimization. By using simulation tools and testing methodologies, electric vehicle manufacturers can validate the performance of their power electronics and motor systems, identify areas for improvement, and optimize system design for maximum efficiency and reliability.

By combining these strategies and technologies, electric vehicle manufacturers can achieve significant improvements in electric motor performance, efficiency, and reliability. As the demand for electric vehicles continues to grow, the importance of optimizing electric motor performance will only continue to increase, driving innovation and advancement in the field of electric motor power electronics.

The Impact of Electric Motor Power Electronics on Vehicle Efficiency and Range

Electric motor power electronics play a crucial role in determining the efficiency and range of electric vehicles. The power electronics system, which includes the inverter, motor controller, and other components, is responsible for controlling the flow of electrical energy between the battery, motor, and other components. By optimizing the power electronics system, electric vehicle manufacturers can achieve significant improvements in vehicle efficiency and range.

One of the primary ways in which electric motor power electronics impact vehicle efficiency is by reducing energy losses. Energy losses occur when electrical energy is converted into heat, rather than being used to propel the vehicle. By using advanced power electronics technologies, such as high-performance power modules and advanced control algorithms, electric vehicle manufacturers can minimize energy losses and maximize efficiency.

Another way in which electric motor power electronics impact vehicle efficiency is by optimizing motor performance. The motor is the primary component responsible for propelling the vehicle, and its performance has a direct impact on vehicle efficiency. By using advanced power electronics technologies, such as field-oriented control and direct torque control, electric vehicle manufacturers can optimize motor performance and achieve significant improvements in vehicle efficiency.

In addition to their impact on vehicle efficiency, electric motor power electronics also play a critical role in determining vehicle range. Vehicle range is the distance that an electric vehicle can travel on a single charge, and it is a critical factor in determining the vehicle’s overall performance. By optimizing the power electronics system, electric vehicle manufacturers can achieve significant improvements in vehicle range, making electric vehicles a more viable option for consumers.

Advances in electric motor power electronics have enabled the development of more efficient and reliable electric vehicles. For example, the use of wide bandgap semiconductors, such as silicon carbide and gallium nitride, has enabled the development of more efficient and reliable power electronics systems. These advances have, in turn, enabled the development of electric vehicles with longer ranges and improved performance.

Real-world examples of the impact of electric motor power electronics on vehicle efficiency and range can be seen in popular electric vehicles, such as the Tesla Model S and the Chevrolet Bolt. These vehicles use advanced power electronics technologies, such as high-performance power modules and advanced control algorithms, to achieve significant improvements in vehicle efficiency and range.

In conclusion, electric motor power electronics play a critical role in determining the efficiency and range of electric vehicles. By optimizing the power electronics system, electric vehicle manufacturers can achieve significant improvements in vehicle efficiency and range, making electric vehicles a more viable option for consumers.

Real-World Examples: Power Electronics in Popular Electric Vehicles

Several popular electric vehicles have successfully integrated advanced power electronics technologies to achieve high performance, efficiency, and range. In this section, we will explore some real-world examples of power electronics in electric vehicles, including the Tesla Model S, Chevrolet Bolt, and Nissan Leaf.

The Tesla Model S is a prime example of a high-performance electric vehicle that relies heavily on advanced power electronics. The vehicle’s electric motor is powered by a high-performance inverter, which uses advanced power modules and control algorithms to optimize motor performance and efficiency. The Tesla Model S also features a sophisticated thermal management system, which helps to dissipate heat generated by the motor and power electronics.

The Chevrolet Bolt is another example of an electric vehicle that has successfully integrated advanced power electronics. The vehicle’s electric motor is powered by a high-performance inverter, which uses advanced power modules and control algorithms to optimize motor performance and efficiency. The Chevrolet Bolt also features a sophisticated battery management system, which helps to optimize battery performance and range.

The Nissan Leaf is a popular electric vehicle that has been in production for several years. The vehicle’s electric motor is powered by a high-performance inverter, which uses advanced power modules and control algorithms to optimize motor performance and efficiency. The Nissan Leaf also features a sophisticated thermal management system, which helps to dissipate heat generated by the motor and power electronics.

In addition to these examples, several other electric vehicles have also successfully integrated advanced power electronics technologies. For example, the BMW i3 and i8 models feature advanced power electronics systems that optimize motor performance and efficiency. The Volkswagen e-Golf and Audi e-tron models also feature advanced power electronics systems that optimize motor performance and efficiency.

These real-world examples demonstrate the importance of power electronics in electric vehicles. By integrating advanced power electronics technologies, electric vehicle manufacturers can achieve high performance, efficiency, and range, making electric vehicles a more viable option for consumers.

In conclusion, the use of advanced power electronics technologies is critical to the success of electric vehicles. By optimizing motor performance and efficiency, reducing energy losses, and improving thermal management, power electronics play a vital role in enabling the widespread adoption of electric vehicles.

The Future of Electric Motor Power Electronics: Trends and Innovations

The future of electric motor power electronics is exciting and rapidly evolving. Emerging trends and innovations are transforming the way electric vehicles are designed and developed, enabling the creation of more efficient, reliable, and high-performance vehicles. In this section, we will explore some of the key trends and innovations shaping the future of electric motor power electronics.

One of the most significant trends in electric motor power electronics is the use of wide bandgap semiconductors. These materials, such as silicon carbide and gallium nitride, offer improved efficiency, reliability, and power density compared to traditional silicon-based semiconductors. Wide bandgap semiconductors are being used in a range of electric vehicle applications, including power modules, inverters, and battery management systems.

Another trend in electric motor power electronics is the development of advanced magnetic materials. These materials, such as neodymium iron boron and samarium cobalt, offer improved magnetic properties and are being used in electric motor designs to improve efficiency and performance. Advanced magnetic materials are also being used in power electronics applications, such as inductors and transformers.

New power module architectures are also emerging, offering improved efficiency, reliability, and power density. These architectures, such as the use of multi-level converters and modular multilevel converters, are being used in a range of electric vehicle applications, including power electronics systems and battery management systems.

The use of advanced control algorithms is also becoming increasingly important in electric motor power electronics. These algorithms, such as model predictive control and machine learning, are being used to optimize motor performance, efficiency, and reliability. Advanced control algorithms are also being used in power electronics applications, such as inverter control and battery management.

In addition to these trends and innovations, there are also several emerging technologies that are expected to have a significant impact on the future of electric motor power electronics. These technologies, such as graphene and nanotechnology, offer improved efficiency, reliability, and power density and are being explored for use in a range of electric vehicle applications.

In conclusion, the future of electric motor power electronics is exciting and rapidly evolving. Emerging trends and innovations are transforming the way electric vehicles are designed and developed, enabling the creation of more efficient, reliable, and high-performance vehicles. As the demand for electric vehicles continues to grow, the importance of electric motor power electronics will only continue to increase, driving innovation and advancement in this field.

Designing and Developing Electric Motor Power Electronics for Electric Vehicles

Designing and developing electric motor power electronics for electric vehicles requires a deep understanding of the complex interactions between the power electronics, electric motor, and other components. In this section, we will provide guidance on designing and developing electric motor power electronics for electric vehicles, including the selection of power modules, control algorithms, and thermal management systems.

The selection of power modules is a critical aspect of designing electric motor power electronics for electric vehicles. Power modules are responsible for controlling the flow of electrical energy between the battery, motor, and other components. When selecting power modules, it is essential to consider factors such as power density, efficiency, and reliability. High-performance power modules, such as those using wide bandgap semiconductors, can offer improved efficiency and reliability.

Control algorithms are also a crucial aspect of designing electric motor power electronics for electric vehicles. Control algorithms are responsible for optimizing motor performance, efficiency, and reliability. Advanced control algorithms, such as model predictive control and machine learning, can offer improved performance and efficiency. When selecting control algorithms, it is essential to consider factors such as computational complexity, stability, and robustness.

Thermal management systems are also essential for designing electric motor power electronics for electric vehicles. Thermal management systems are responsible for dissipating heat generated by the power electronics and electric motor. When selecting thermal management systems, it is essential to consider factors such as heat transfer, thermal resistance, and cooling efficiency. Advanced thermal management systems, such as those using liquid cooling, can offer improved cooling efficiency and reliability.

Simulation and testing are also critical aspects of designing and developing electric motor power electronics for electric vehicles. Simulation tools, such as finite element analysis and circuit simulation, can be used to optimize power electronics design and performance. Testing, such as hardware-in-the-loop testing and vehicle testing, can be used to validate power electronics performance and reliability.

In addition to these considerations, it is also essential to consider the overall system architecture and integration when designing electric motor power electronics for electric vehicles. The power electronics system must be integrated with the electric motor, battery, and other components to optimize overall system performance and efficiency.

By following these guidelines and considering the complex interactions between the power electronics, electric motor, and other components, designers and developers can create high-performance electric motor power electronics for electric vehicles. These systems can offer improved efficiency, reliability, and performance, enabling the widespread adoption of electric vehicles.

Challenges and Opportunities in Electric Motor Power Electronics for Electric Vehicles

As the demand for electric vehicles (EVs) continues to grow, the importance of electric motor power electronics in enabling efficient, reliable, and high-performance EVs cannot be overstated. However, the development of electric motor power electronics for EVs is not without its challenges. In this section, we will discuss the challenges and opportunities in electric motor power electronics for EVs, and how advancements in this field can help address the challenges and enable the widespread adoption of EVs.

One of the primary challenges in electric motor power electronics for EVs is the need for higher power density. As EVs become increasingly popular, there is a growing demand for more powerful and efficient electric motors. However, this requires the development of power electronics that can handle higher power levels without compromising efficiency or reliability. To address this challenge, researchers are exploring new power module architectures, such as the use of wide bandgap semiconductors, which offer higher power density and efficiency than traditional silicon-based power modules.

Another challenge in electric motor power electronics for EVs is the need for improved efficiency. As EVs rely on batteries for power, minimizing energy consumption is crucial to maximizing range and reducing operating costs. To address this challenge, researchers are developing advanced control algorithms that optimize electric motor performance and minimize energy consumption. Additionally, the use of advanced magnetic materials and optimized motor designs can also help improve efficiency and reduce energy consumption.

Despite these challenges, there are also opportunities for innovation and advancement in electric motor power electronics for EVs. For example, the use of advanced power electronics can enable the development of more efficient and reliable EVs, which can help reduce greenhouse gas emissions and improve air quality. Additionally, the development of new power module architectures and control algorithms can also enable the creation of more affordable and accessible EVs, which can help increase adoption rates and reduce the environmental impact of transportation.

In conclusion, the development of electric motor power electronics for EVs is a complex and challenging field, but one that offers many opportunities for innovation and advancement. By addressing the challenges and leveraging the opportunities in this field, researchers and engineers can help enable the widespread adoption of EVs and create a more sustainable and environmentally-friendly transportation system.

Conclusion: The Critical Role of Electric Motor Power Electronics in Electric Vehicles

In conclusion, electric motor power electronics play a critical role in the performance, efficiency, and range of electric vehicles. The importance of power electronics in controlling the flow of electrical energy between the battery, motor, and other components cannot be overstated. As the demand for electric vehicles continues to grow, the need for advanced power electronics that can efficiently and reliably manage the flow of electrical energy will only continue to increase.

Throughout this article, we have discussed the various ways in which electric motor power electronics impact the performance and efficiency of electric vehicles. From the use of high-performance power modules and advanced control algorithms to the importance of thermal management systems, it is clear that power electronics are a crucial component of any electric vehicle. Additionally, we have highlighted real-world examples of power electronics in popular electric vehicles, such as the Tesla Model S and Chevrolet Bolt, and discussed the emerging trends and innovations that are shaping the future of electric motor power electronics.

As the electric vehicle market continues to evolve, it is likely that we will see even more advanced power electronics technologies emerge. The use of wide bandgap semiconductors, advanced magnetic materials, and new power module architectures are just a few examples of the innovations that are being developed to improve the performance and efficiency of electric vehicles. By continuing to advance the state-of-the-art in electric motor power electronics, we can enable the widespread adoption of electric vehicles and create a more sustainable and environmentally-friendly transportation system.

In order to achieve this vision, it is essential that researchers, engineers, and manufacturers continue to work together to develop and deploy advanced power electronics technologies. This will require a sustained investment in research and development, as well as a commitment to collaboration and knowledge-sharing across the industry. By working together, we can unlock the full potential of electric vehicles and create a more sustainable future for generations to come.

In summary, electric motor power electronics are a critical component of electric vehicles, and their impact on performance, efficiency, and range cannot be overstated. As the demand for electric vehicles continues to grow, the need for advanced power electronics will only continue to increase. By continuing to advance the state-of-the-art in electric motor power electronics, we can enable the widespread adoption of electric vehicles and create a more sustainable and environmentally-friendly transportation system.