Unlocking the Secrets of Electric Motor Design

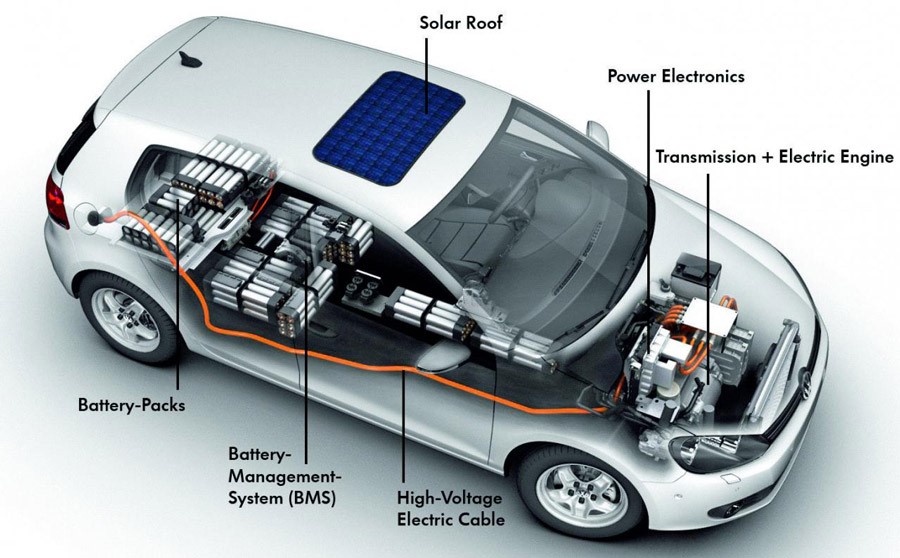

The electric vehicle (EV) industry has experienced rapid growth in recent years, driven by increasing demand for sustainable and environmentally friendly transportation solutions. At the heart of every EV lies a crucial component: the electric motor. The design of this motor, particularly the magnetic design, plays a vital role in determining the overall efficiency, performance, and driving experience of the vehicle. Electric vehicle magnetic design has become a critical area of focus for manufacturers seeking to improve their products’ range, acceleration, and reliability.

Advances in magnetic materials and design techniques have transformed the EV industry, enabling the creation of more efficient and powerful electric motors. The use of rare-earth magnets, for example, has become increasingly prevalent due to their exceptional strength and durability. However, the high cost and limited availability of these materials have driven researchers to explore alternative solutions, such as ferrite magnets and halbach arrays. These innovative approaches have not only reduced production costs but also improved the overall performance of electric motors.

The impact of magnetic design on EV performance cannot be overstated. A well-designed magnetic system can significantly improve the motor’s efficiency, reducing energy consumption and increasing the vehicle’s range. Moreover, a optimized magnetic field distribution can enhance the motor’s torque output, resulting in faster acceleration and a more responsive driving experience. As the EV industry continues to evolve, the importance of magnetic design will only continue to grow, driving innovation and improvement in this critical area.

In the following sections, we will delve deeper into the principles of magnetic field distribution, the role of magnet materials, and the key design considerations for electric motors. We will also examine the approaches taken by industry leaders, such as Tesla, and explore the emerging trends and advancements in electric vehicle magnetic design.

How to Optimize Magnetic Field Distribution for Improved EV Performance

Optimizing magnetic field distribution is crucial for achieving better performance, efficiency, and reliability in electric vehicles (EVs). The magnetic field distribution in an electric motor determines the motor’s torque output, efficiency, and overall performance. A well-designed magnetic field distribution can significantly improve the motor’s efficiency, reducing energy consumption and increasing the vehicle’s range.

One of the key principles behind magnetic field distribution is the concept of magnetic flux density. Magnetic flux density is the measure of the strength of the magnetic field in a given area. In an electric motor, the magnetic flux density is highest at the poles and decreases as you move towards the center of the motor. To optimize magnetic field distribution, designers must carefully balance the magnetic flux density across the motor to achieve maximum efficiency and performance.

Several techniques can be employed to optimize magnetic field distribution in EVs. One approach is to use a technique called “magnetic field shaping,” which involves designing the motor’s magnetic circuit to shape the magnetic field in a way that maximizes efficiency and performance. Another approach is to use advanced materials, such as rare-earth magnets, which have exceptional strength and durability.

In addition to these techniques, designers can also use computational tools, such as finite element analysis (FEA), to simulate and optimize magnetic field distribution in EVs. FEA allows designers to model and analyze the behavior of the magnetic field in the motor, enabling them to identify areas for improvement and optimize the design for maximum efficiency and performance.

By optimizing magnetic field distribution, EV manufacturers can achieve significant improvements in performance, efficiency, and reliability. For example, a well-designed magnetic field distribution can increase the motor’s torque output by up to 20%, while also reducing energy consumption by up to 15%. These improvements can have a significant impact on the overall performance and efficiency of the vehicle, making it more competitive in the market.

The Role of Magnet Materials in Electric Vehicle Design

Magnet materials play a crucial role in electric vehicle (EV) design, as they are used to create the magnetic fields that drive the electric motor. The choice of magnet material can significantly impact the performance, efficiency, and cost of the EV. In this section, we will discuss the different types of magnet materials used in EV design, including rare-earth magnets, ferrite magnets, and halbach arrays.

Rare-earth magnets, such as neodymium (NdFeB) and dysprosium (DyFeB), are widely used in EV design due to their exceptional strength and durability. These magnets have a high magnetic flux density, which enables them to produce a strong magnetic field. However, rare-earth magnets are also expensive and have limited availability, which can drive up the cost of EV production.

Ferrite magnets, on the other hand, are a more cost-effective option for EV design. These magnets have a lower magnetic flux density than rare-earth magnets but are still suitable for many EV applications. Ferrite magnets are also more widely available and have a lower environmental impact than rare-earth magnets.

Halbach arrays are another type of magnet material used in EV design. These arrays consist of a series of magnets arranged in a specific pattern to create a strong magnetic field. Halbach arrays are known for their high efficiency and are often used in high-performance EV applications.

The choice of magnet material depends on the specific requirements of the EV design. For example, rare-earth magnets may be used in high-performance EVs that require a strong magnetic field, while ferrite magnets may be used in more cost-sensitive applications. Halbach arrays may be used in EVs that require high efficiency and a strong magnetic field.

In addition to the type of magnet material, the design of the magnetic circuit also plays a crucial role in EV performance. The magnetic circuit design determines how the magnetic field is distributed throughout the motor, which can impact the motor’s efficiency and performance. A well-designed magnetic circuit can optimize the magnetic field distribution, resulting in improved EV performance and efficiency.

Electric Motor Design Considerations for Magnetic Field Optimization

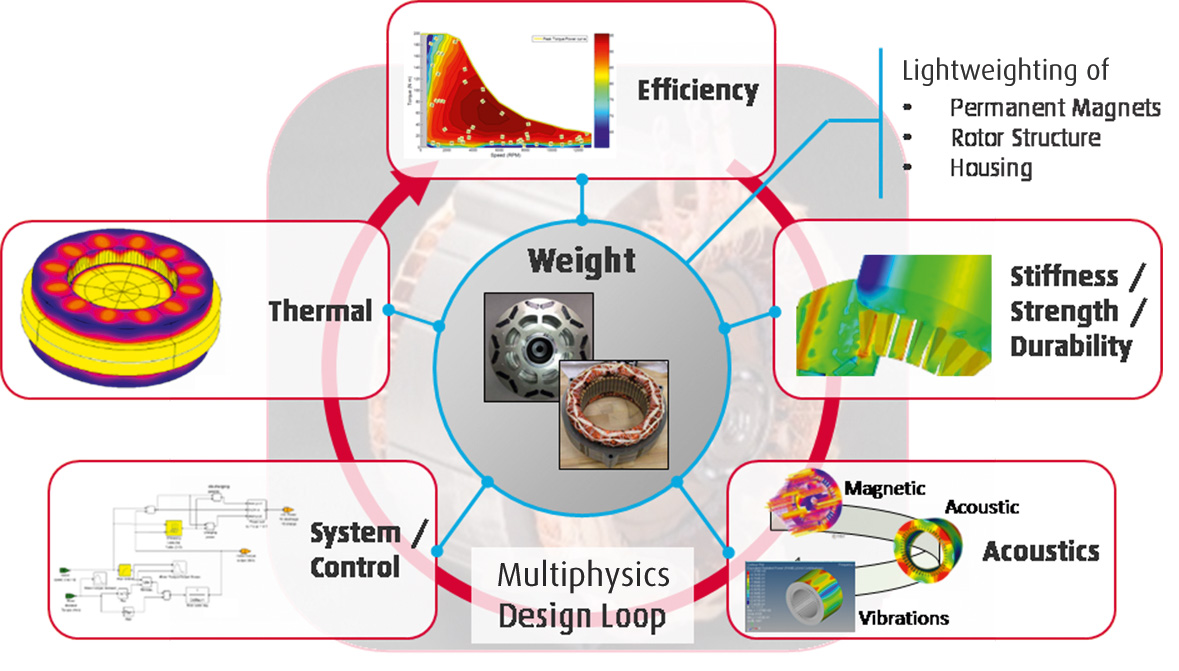

When designing an electric motor for an electric vehicle (EV), several key considerations must be taken into account to optimize the magnetic field distribution and achieve better performance, efficiency, and reliability. In this section, we will examine the key design considerations for electric motors, including winding configurations, pole pair combinations, and magnetic circuit design.

Winding configurations play a crucial role in determining the magnetic field distribution in an electric motor. The choice of winding configuration can impact the motor’s efficiency, torque output, and overall performance. For example, a concentrated winding configuration can provide a higher torque output, while a distributed winding configuration can offer better efficiency.

Pole pair combinations are another important design consideration for electric motors. The number of pole pairs can impact the motor’s speed, torque output, and efficiency. For example, a higher number of pole pairs can provide a higher torque output, while a lower number of pole pairs can offer better efficiency.

Magnetic circuit design is also critical for optimizing the magnetic field distribution in an electric motor. The magnetic circuit design determines how the magnetic field is distributed throughout the motor, which can impact the motor’s efficiency and performance. A well-designed magnetic circuit can optimize the magnetic field distribution, resulting in improved EV performance and efficiency.

In addition to these design considerations, the choice of magnet material and the design of the magnetic field distribution also play a crucial role in optimizing the performance of an electric motor. The use of advanced materials and design techniques, such as those used in Tesla’s electric motors, can provide significant improvements in performance, efficiency, and reliability.

By carefully considering these design factors, electric motor designers can create optimized magnetic field distributions that achieve better performance, efficiency, and reliability in EVs. This can result in improved driving experiences, increased range, and reduced energy consumption, making EVs more competitive in the market.

Case Study: Tesla’s Innovative Magnetic Design Approach

Tesla, a pioneer in the electric vehicle (EV) industry, has been at the forefront of magnetic design innovation. Their approach to magnetic design has been instrumental in achieving exceptional performance and efficiency in their vehicles. In this section, we will analyze Tesla’s approach to magnetic design, highlighting their use of advanced materials and design techniques.

Tesla’s magnetic design approach is centered around the use of advanced materials, such as rare-earth magnets and halbach arrays. These materials provide exceptional strength and durability, enabling Tesla’s electric motors to achieve high efficiency and performance. Additionally, Tesla’s design team has developed innovative design techniques, such as the use of 3D printing and finite element analysis (FEA), to optimize the magnetic field distribution in their motors.

One of the key benefits of Tesla’s magnetic design approach is its ability to achieve high efficiency and performance while minimizing the use of rare-earth materials. This is achieved through the use of advanced design techniques, such as the optimization of the magnetic circuit design and the use of alternative materials. As a result, Tesla’s electric motors are able to achieve exceptional performance and efficiency, making their vehicles highly competitive in the market.

However, Tesla’s approach to magnetic design also presents some challenges. For example, the use of rare-earth materials can be expensive and may have limited availability. Additionally, the complexity of Tesla’s magnetic design approach can make it difficult to manufacture and maintain their electric motors. Despite these challenges, Tesla’s innovative approach to magnetic design has been instrumental in achieving exceptional performance and efficiency in their vehicles.

Tesla’s approach to magnetic design serves as a model for the EV industry, demonstrating the potential for innovation and improvement in magnetic design. By adopting similar approaches, other EV manufacturers can achieve similar benefits, including improved performance, efficiency, and competitiveness in the market.

Magnetic Design Software and Tools for Electric Vehicle Development

The development of electric vehicles (EVs) requires the use of advanced software and tools to design and optimize magnetic fields and electric motors. In this section, we will introduce the various software and tools used in magnetic design for EVs, including finite element analysis (FEA) and computational fluid dynamics (CFD).

Finite element analysis (FEA) is a powerful tool used in magnetic design to simulate and analyze the behavior of magnetic fields and electric motors. FEA allows designers to model and analyze the magnetic field distribution, electromagnetic forces, and thermal behavior of electric motors, enabling them to optimize the design for better performance, efficiency, and reliability.

Computational fluid dynamics (CFD) is another important tool used in magnetic design for EVs. CFD allows designers to simulate and analyze the fluid dynamics and heat transfer behavior of electric motors, enabling them to optimize the design for better cooling and thermal management.

In addition to FEA and CFD, other software and tools used in magnetic design for EVs include magnetic field simulation software, such as COMSOL and ANSYS, and computer-aided design (CAD) software, such as SolidWorks and CATIA. These tools enable designers to create and optimize magnetic field designs, simulate and analyze their behavior, and validate their performance.

The use of these software and tools has revolutionized the field of magnetic design for EVs, enabling designers to create more efficient, reliable, and high-performance electric motors. By leveraging these tools, designers can optimize the magnetic field distribution, reduce energy losses, and improve the overall performance of EVs.

In the next section, we will discuss the emerging trends and advancements in magnetic design for EVs, including the use of new materials, design techniques, and manufacturing processes. We will also speculate on how these developments will shape the future of the EV industry.

Future Trends and Advancements in Electric Vehicle Magnetic Design

The field of electric vehicle (EV) magnetic design is rapidly evolving, with emerging trends and advancements in materials, design techniques, and manufacturing processes. In this section, we will discuss some of the future trends and advancements in EV magnetic design and speculate on how they will shape the future of the EV industry.

One of the most significant trends in EV magnetic design is the development of new materials with improved magnetic properties. For example, researchers are exploring the use of new rare-earth materials, such as neodymium and dysprosium, which offer improved magnetic strength and durability. Additionally, advancements in nanotechnology are enabling the development of new magnetic materials with unique properties.

Another trend in EV magnetic design is the use of advanced design techniques, such as topology optimization and machine learning algorithms. These techniques enable designers to create complex magnetic field distributions and optimize the design of electric motors for better performance, efficiency, and reliability.

Manufacturing processes are also evolving, with the adoption of new technologies such as 3D printing and additive manufacturing. These technologies enable the creation of complex magnetic field distributions and the production of electric motors with improved performance and efficiency.

As the EV industry continues to evolve, we can expect to see significant advancements in magnetic design. For example, the use of new materials and design techniques will enable the creation of electric motors with improved performance, efficiency, and reliability. Additionally, advancements in manufacturing processes will enable the production of electric motors with reduced costs and improved quality.

In the next section, we will summarize the key takeaways from this article and provide best practices for implementing magnetic design in electric vehicle development. We will also offer guidance on how to balance performance, efficiency, and cost considerations when designing magnetic systems for EVs.

Best Practices for Implementing Magnetic Design in Electric Vehicle Development

In this article, we have discussed the importance of magnetic design in electric vehicles, highlighting its impact on efficiency, performance, and overall driving experience. We have also explored the principles behind magnetic field distribution, the role of magnet materials, and the key design considerations for electric motors. Additionally, we have analyzed Tesla’s innovative magnetic design approach and discussed the emerging trends and advancements in magnetic design for electric vehicles.

When implementing magnetic design in electric vehicle development, there are several best practices to keep in mind. First, it is essential to balance performance, efficiency, and cost considerations when designing magnetic systems for EVs. This can be achieved by selecting the right magnet materials, optimizing the magnetic field distribution, and using advanced design techniques such as finite element analysis (FEA) and computational fluid dynamics (CFD).

Second, it is crucial to consider the thermal management of the electric motor, as high temperatures can affect the performance and efficiency of the motor. This can be achieved by using advanced cooling systems, such as liquid cooling or air cooling, and optimizing the design of the motor for better heat dissipation.

Third, it is essential to ensure that the magnetic design is compatible with the overall vehicle design and architecture. This can be achieved by collaborating with other teams, such as the electrical and mechanical engineering teams, to ensure that the magnetic design is integrated with the overall vehicle design.

Finally, it is crucial to stay up-to-date with the latest advancements in magnetic design and electric vehicle technology. This can be achieved by attending industry conferences, reading industry publications, and participating in online forums and discussions.

By following these best practices, electric vehicle manufacturers can create magnetic designs that optimize performance, efficiency, and cost, while also ensuring the overall quality and reliability of the vehicle.