The Crucial Role of Electric Motor Testing and Validation

Electric motor testing and validation are critical components of the electric vehicle development process. The reliability and performance of electric vehicles depend heavily on the efficiency and effectiveness of their electric motors. Thorough testing and validation of electric motors help identify potential issues, optimize motor efficiency, and ensure compliance with regulatory requirements.

Electric motor testing and validation involve simulating real-world conditions to evaluate motor performance under various loads, temperatures, and operating conditions. This process enables manufacturers to detect potential problems, such as overheating, vibration, or electromagnetic interference, and make necessary design changes to improve motor efficiency and reliability.

The importance of electric motor testing and validation cannot be overstated. Electric motors are a critical component of electric vehicles, and their performance directly impacts the overall efficiency, range, and safety of the vehicle. By conducting comprehensive testing and validation, manufacturers can ensure that their electric motors meet the required standards and specifications, reducing the risk of costly recalls, warranty claims, and damage to their reputation.

Electric motor testing and validation also play a critical role in ensuring vehicle safety. Electric motors must be designed and tested to withstand various operating conditions, including extreme temperatures, vibrations, and electrical stresses. By conducting thorough testing and validation, manufacturers can ensure that their electric motors meet the required safety standards, reducing the risk of electrical shocks, fires, and other safety hazards.

In addition to optimizing motor performance and ensuring vehicle safety, electric motor testing and validation are essential for ensuring compliance with regulatory requirements. Governments and regulatory bodies have established strict standards and guidelines for electric vehicle safety, performance, and emissions. By conducting comprehensive testing and validation, manufacturers can ensure that their electric motors meet these requirements, avoiding costly fines, penalties, and reputational damage.

Electric vehicle and electric motor testing and validation are critical components of the electric vehicle development process. By prioritizing thorough testing and validation, manufacturers can ensure the reliability, performance, and safety of their electric vehicles, while also optimizing motor efficiency, reducing energy consumption, and improving overall vehicle efficiency.

Key Challenges in Electric Motor Testing and Validation

Electric motor testing and validation for electric vehicles pose several challenges that must be addressed to ensure the reliability, performance, and safety of the vehicle. One of the primary challenges is ensuring accurate simulation of real-world conditions. Electric motors must be tested under various operating conditions, including extreme temperatures, vibrations, and electrical stresses, to ensure that they can withstand the demands of real-world driving.

Another challenge is managing high-power testing. Electric motors for electric vehicles are designed to operate at high power levels, which can be difficult to replicate in a testing environment. High-power testing requires specialized equipment and facilities, and can be costly and time-consuming. However, it is essential to ensure that the electric motor can handle the high power levels required for electric vehicle operation.

Electromagnetic compatibility (EMC) issues are also a significant challenge in electric motor testing and validation. Electric motors can generate electromagnetic interference (EMI) that can affect other components in the vehicle, such as the battery management system, the power electronics, and the communication systems. Ensuring that the electric motor meets the required EMC standards is critical to prevent malfunctions and ensure safe operation.

In addition to these challenges, electric motor testing and validation for electric vehicles also require specialized equipment and facilities. Dynamometers, thermal chambers, and vibration testing equipment are just a few examples of the specialized equipment required to test electric motors. These facilities and equipment can be costly and require significant investment.

Furthermore, electric motor testing and validation for electric vehicles require a high degree of expertise and knowledge. Engineers and technicians must have a deep understanding of electric motor design, testing, and validation to ensure that the motor meets the required standards and specifications. This expertise can be difficult to find and retain, and can be a significant challenge for manufacturers.

Despite these challenges, electric motor testing and validation are critical components of the electric vehicle development process. By addressing these challenges and ensuring that electric motors are thoroughly tested and validated, manufacturers can ensure the reliability, performance, and safety of their electric vehicles.

How to Develop a Comprehensive Electric Motor Testing and Validation Strategy

Developing a comprehensive electric motor testing and validation strategy is crucial to ensure the reliability, performance, and safety of electric vehicles. A well-planned strategy helps to identify potential issues, optimize motor efficiency, and ensure compliance with regulatory requirements. Here is a step-by-step guide to develop a comprehensive electric motor testing and validation strategy:

Step 1: Define Test Objectives

The first step in developing a comprehensive electric motor testing and validation strategy is to define the test objectives. This involves identifying the specific requirements and standards that the electric motor must meet, such as efficiency, power output, and reliability. The test objectives should be clearly defined and aligned with the overall goals of the electric vehicle development program.

Step 2: Select Test Methods

Once the test objectives are defined, the next step is to select the test methods. This involves choosing the appropriate testing techniques and tools to evaluate the electric motor’s performance, efficiency, and reliability. Common test methods include dynamometer testing, thermal testing, and vibration testing. The selected test methods should be capable of simulating real-world operating conditions and evaluating the electric motor’s performance under various loads and temperatures.

Step 3: Establish Validation Criteria

Establishing validation criteria is critical to ensure that the electric motor meets the required standards and specifications. The validation criteria should be based on the test objectives and should include specific metrics and targets for performance, efficiency, and reliability. The validation criteria should also include acceptance criteria for the test results, such as pass/fail criteria or tolerance limits.

Step 4: Develop a Test Plan

Developing a test plan is essential to ensure that the electric motor testing and validation process is well-planned and executed. The test plan should include a detailed description of the test methods, test procedures, and test schedules. The test plan should also include a list of required test equipment, personnel, and facilities.

Step 5: Conduct Testing and Validation

Conducting testing and validation is the final step in the electric motor testing and validation process. This involves executing the test plan and evaluating the electric motor’s performance, efficiency, and reliability under various operating conditions. The test results should be analyzed and compared to the validation criteria to determine if the electric motor meets the required standards and specifications.

By following these steps, electric vehicle manufacturers can develop a comprehensive electric motor testing and validation strategy that ensures the reliability, performance, and safety of their electric vehicles.

Electric Motor Testing and Validation Techniques for Electric Vehicles

Electric motor testing and validation for electric vehicles involve various techniques to ensure the reliability, performance, and safety of the motor. Some of the common testing and validation techniques used for electric motors in electric vehicles include:

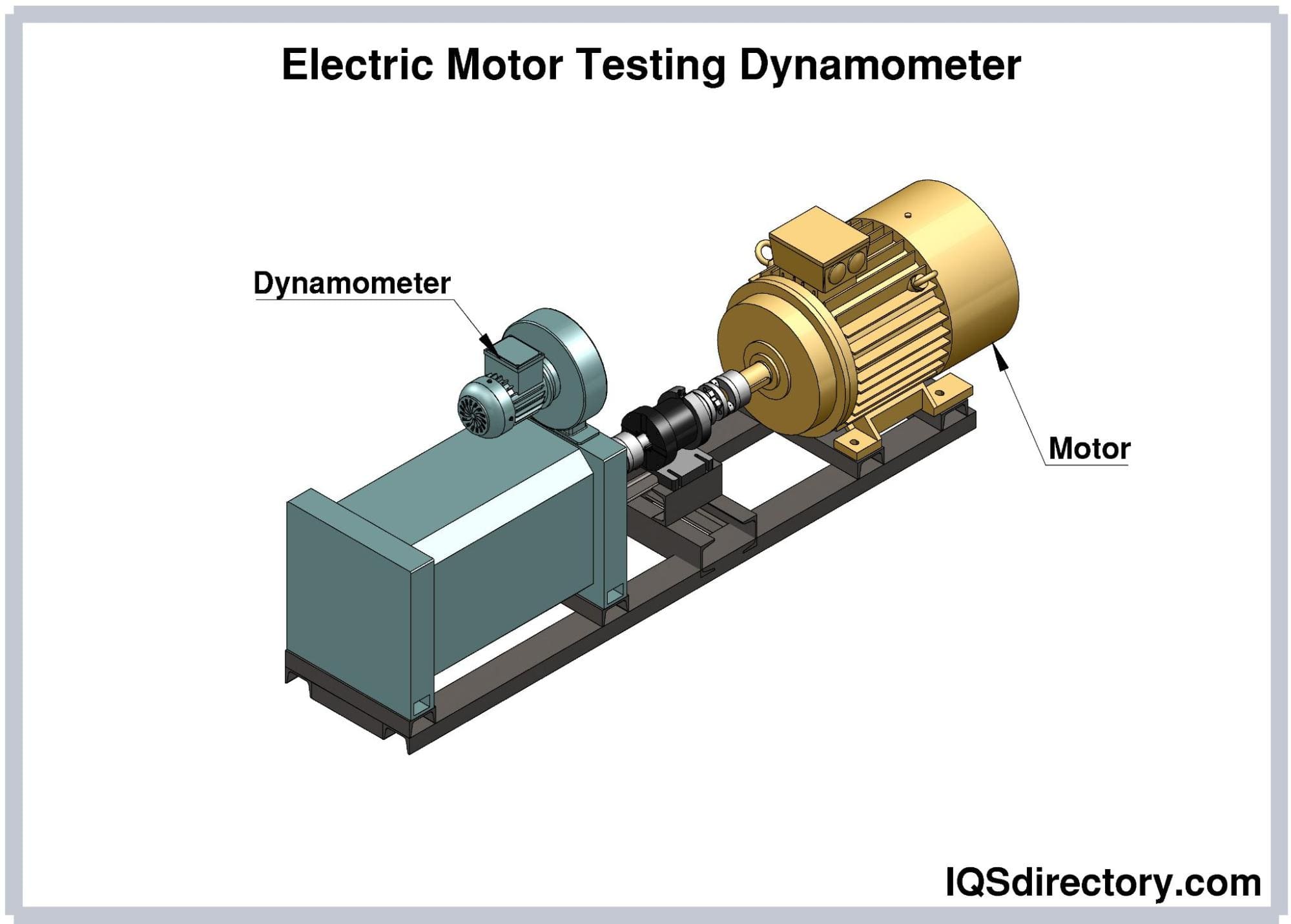

Dynamometer Testing

Dynamometer testing is a widely used technique for testing electric motors in electric vehicles. This technique involves using a dynamometer to simulate the load conditions that the motor would experience in real-world driving. The dynamometer is connected to the motor and applies a load to the motor, allowing the motor’s performance to be evaluated under various operating conditions.

Thermal Testing

Thermal testing is another important technique used for electric motor testing and validation in electric vehicles. This technique involves testing the motor’s performance under various temperature conditions to ensure that it can operate efficiently and reliably in extreme temperatures. Thermal testing can be performed using thermal chambers or other specialized equipment.

Vibration Testing

Vibration testing is a technique used to evaluate the motor’s performance under various vibration conditions. This technique involves using specialized equipment to apply vibrations to the motor and evaluate its performance under these conditions. Vibration testing is important to ensure that the motor can withstand the vibrations that it would experience in real-world driving.

Electromagnetic Compatibility (EMC) Testing

EMC testing is a technique used to evaluate the motor’s electromagnetic compatibility with other components in the electric vehicle. This technique involves testing the motor’s electromagnetic emissions and susceptibility to ensure that it does not interfere with other components in the vehicle.

Simulation Testing

Simulation testing is a technique used to evaluate the motor’s performance under various operating conditions using simulation software. This technique involves creating a virtual model of the motor and testing its performance under various conditions, such as different temperatures, loads, and speeds. Simulation testing is a cost-effective and efficient way to evaluate the motor’s performance without the need for physical testing.

These are just a few examples of the testing and validation techniques used for electric motors in electric vehicles. By using these techniques, electric vehicle manufacturers can ensure that their motors are reliable, efficient, and safe, and meet the required standards and specifications.

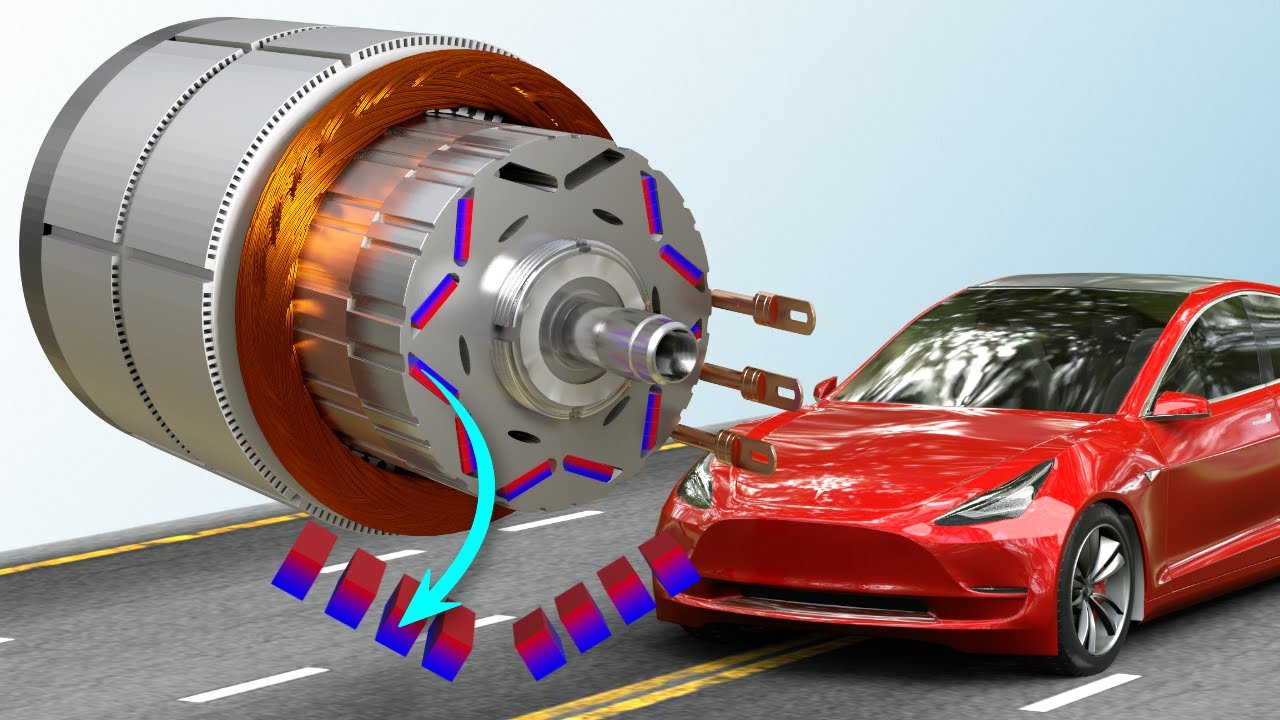

Case Study: Electric Motor Testing and Validation for the Tesla Model S

The Tesla Model S is a luxury electric vehicle that has been widely acclaimed for its performance, range, and reliability. One of the key factors that contribute to the Model S’s success is the rigorous electric motor testing and validation process that Tesla employs. In this case study, we will examine the electric motor testing and validation process used by Tesla for the Model S, highlighting the testing methods used, challenges faced, and lessons learned.

Testing Methods Used

Tesla uses a combination of simulation testing, dynamometer testing, and on-road testing to validate the electric motor for the Model S. Simulation testing is used to evaluate the motor’s performance under various operating conditions, such as different temperatures, loads, and speeds. Dynamometer testing is used to evaluate the motor’s performance under controlled laboratory conditions, while on-road testing is used to evaluate the motor’s performance in real-world driving conditions.

Challenges Faced

One of the biggest challenges faced by Tesla during the electric motor testing and validation process for the Model S was ensuring accurate simulation of real-world conditions. To address this challenge, Tesla developed advanced simulation tools that could accurately model the motor’s behavior under various operating conditions. Another challenge faced by Tesla was managing high-power testing, which required specialized equipment and facilities.

Lessons Learned

Through the electric motor testing and validation process for the Model S, Tesla learned several valuable lessons. One of the key lessons learned was the importance of rigorous testing and validation in ensuring the reliability and performance of electric motors. Tesla also learned the value of using advanced simulation tools to evaluate motor performance under various operating conditions. Finally, Tesla learned the importance of collaboration between different teams, including engineering, testing, and manufacturing, to ensure that the electric motor meets the required standards and specifications.

Conclusion

The electric motor testing and validation process used by Tesla for the Model S is a prime example of the importance of rigorous testing and validation in ensuring the reliability and performance of electric motors. By using a combination of simulation testing, dynamometer testing, and on-road testing, Tesla was able to validate the electric motor for the Model S and ensure its reliability and performance. The lessons learned from this case study can be applied to other electric vehicle manufacturers to improve the reliability and performance of their electric motors.

Best Practices for Electric Motor Testing and Validation in Electric Vehicles

Electric motor testing and validation are critical components of the electric vehicle development process. To ensure the reliability, performance, and safety of electric vehicles, it is essential to follow best practices for electric motor testing and validation. Here are some best practices to consider:

Ensure Proper Test Equipment Calibration

Proper calibration of test equipment is essential to ensure accurate and reliable test results. This includes calibrating dynamometers, thermal chambers, and other test equipment to ensure that they are functioning correctly.

Use Simulation Tools

Simulation tools can be used to evaluate electric motor performance under various operating conditions, reducing the need for physical testing. Simulation tools can also be used to optimize motor design and performance.

Conduct Regular Maintenance

Regular maintenance is essential to ensure that electric motors continue to operate reliably and efficiently. This includes regular inspections, cleaning, and replacement of worn or damaged components.

Use Advanced Testing Techniques

Advanced testing techniques, such as vibration testing and electromagnetic compatibility testing, can be used to evaluate electric motor performance and identify potential issues.

Collaborate with Suppliers and Partners

Collaboration with suppliers and partners is essential to ensure that electric motors meet the required standards and specifications. This includes working with suppliers to ensure that components meet the required specifications and collaborating with partners to ensure that electric motors are integrated correctly into the vehicle.

Continuously Monitor and Improve

Continuous monitoring and improvement are essential to ensure that electric motor testing and validation processes are optimized. This includes regularly reviewing test results, identifying areas for improvement, and implementing changes to optimize the testing and validation process.

By following these best practices, electric vehicle manufacturers can ensure that their electric motors are reliable, efficient, and safe, and meet the required standards and specifications.

Future Trends in Electric Motor Testing and Validation for Electric Vehicles

The electric vehicle industry is rapidly evolving, and electric motor testing and validation are critical components of this evolution. As the industry continues to grow and mature, we can expect to see several future trends and advancements in electric motor testing and validation for electric vehicles.

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are expected to play a significant role in electric motor testing and validation in the future. AI and ML can be used to analyze large amounts of data from electric motor testing, identify patterns and trends, and optimize motor performance.

Advanced Simulation Tools

Advanced simulation tools are also expected to play a significant role in electric motor testing and validation in the future. These tools can be used to simulate electric motor performance under various operating conditions, reducing the need for physical testing and improving the accuracy of test results.

Increased Use of Electromagnetic Compatibility Testing

Electromagnetic compatibility (EMC) testing is expected to become more prevalent in electric motor testing and validation in the future. EMC testing is used to ensure that electric motors do not interfere with other components in the vehicle, and that they can operate safely and efficiently in a variety of environments.

Greater Emphasis on Thermal Testing

Thermal testing is expected to become more important in electric motor testing and validation in the future. Thermal testing is used to evaluate the thermal performance of electric motors, and to ensure that they can operate safely and efficiently in a variety of temperatures and environments.

Increased Use of Vibration Testing

Vibration testing is expected to become more prevalent in electric motor testing and validation in the future. Vibration testing is used to evaluate the vibration performance of electric motors, and to ensure that they can operate safely and efficiently in a variety of environments.

These are just a few examples of the future trends and advancements that we can expect to see in electric motor testing and validation for electric vehicles. As the industry continues to evolve and mature, we can expect to see even more innovative and effective testing and validation techniques emerge.

Conclusion: The Importance of Electric Motor Testing and Validation in Electric Vehicles

In conclusion, electric motor testing and validation are critical components of the electric vehicle development process. These processes help to ensure the reliability, performance, and safety of electric vehicles, and are essential for identifying potential issues and optimizing motor efficiency.

As the electric vehicle industry continues to evolve and mature, the importance of electric motor testing and validation will only continue to grow. By understanding the key challenges and best practices associated with electric motor testing and validation, electric vehicle manufacturers can ensure that their vehicles meet the required standards and specifications, and provide a safe and reliable driving experience for consumers.

In this article, we have discussed the importance of electric motor testing and validation in electric vehicles, and have provided a comprehensive overview of the key challenges and best practices associated with these processes. We have also presented a case study on the electric motor testing and validation process for the Tesla Model S, and have discussed future trends and advancements in electric motor testing and validation for electric vehicles.

By following the best practices and guidelines outlined in this article, electric vehicle manufacturers can ensure that their electric motors are thoroughly tested and validated, and that their vehicles meet the required standards and specifications. This will help to ensure the reliability, performance, and safety of electric vehicles, and will provide a safe and reliable driving experience for consumers.

In summary, electric motor testing and validation are critical components of the electric vehicle development process, and are essential for ensuring the reliability, performance, and safety of electric vehicles. By understanding the key challenges and best practices associated with these processes, electric vehicle manufacturers can ensure that their vehicles meet the required standards and specifications, and provide a safe and reliable driving experience for consumers.