What Makes an Electric Motor Reliable?

Reliability is a critical aspect of electric vehicles, as it directly impacts the overall efficiency and safety of the vehicle. The electric motor is a crucial component of an electric vehicle, and its reliability is essential to ensure the vehicle’s performance and longevity. So, what makes an electric motor reliable?

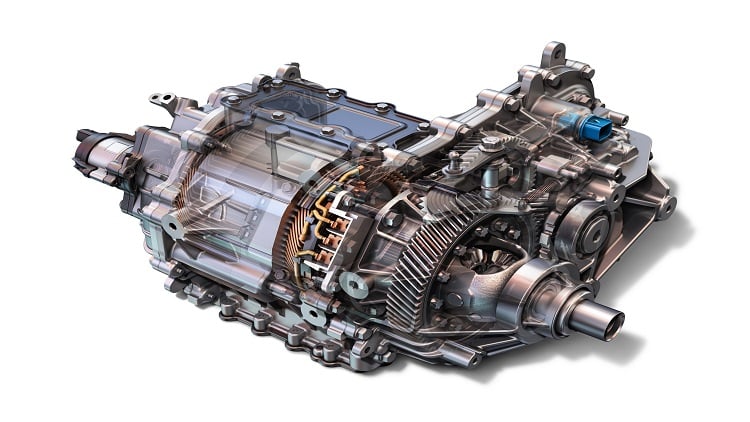

Several key factors contribute to an electric motor’s reliability, including design, materials, and testing. A well-designed electric motor should be able to withstand various environmental conditions, such as extreme temperatures, vibrations, and electromagnetic interference. The choice of materials is also crucial, as it can affect the motor’s durability and performance. For instance, the use of high-quality magnets and bearings can significantly improve the motor’s reliability.

In addition to design and materials, testing is also a critical aspect of ensuring electric motor reliability. Manufacturers should conduct rigorous testing, including environmental testing, durability testing, and performance testing, to identify potential issues and ensure that the motor meets the required standards. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established reliability standards for electric vehicles, which provide a framework for manufacturers to follow.

Electric vehicle and electric motor reliability standards are essential to ensure the safety and performance of electric vehicles. By following these standards, manufacturers can ensure that their electric motors are reliable, efficient, and safe. As the demand for electric vehicles continues to grow, the importance of reliability standards will only increase. In the next section, we will delve deeper into the various reliability standards for electric vehicles and explore how they ensure the safety and performance of these vehicles.

Understanding Electric Vehicle Reliability Standards

Electric vehicle reliability standards play a crucial role in ensuring the safety and performance of electric vehicles. These standards are established by organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) to provide a framework for manufacturers to follow. The IEC, for example, has developed a series of standards for electric vehicles, including IEC 62660, which covers the safety requirements for lithium-ion batteries, and IEC 60364, which covers the electrical safety of electric vehicles.

The SAE has also developed a range of standards for electric vehicles, including SAE J2954, which covers the testing and validation of electric vehicle charging systems, and SAE J3016, which covers the cybersecurity of electric vehicles. These standards help to ensure that electric vehicles are designed and manufactured with safety and reliability in mind, and that they meet the required performance and efficiency standards.

Electric vehicle and electric motor reliability standards also cover aspects such as electromagnetic compatibility (EMC), which ensures that electric vehicles do not interfere with other electrical systems, and environmental testing, which ensures that electric vehicles can operate safely in a range of environmental conditions. By following these standards, manufacturers can ensure that their electric vehicles meet the required safety and performance standards, and that they are reliable and efficient.

In addition to the IEC and SAE standards, other organizations such as the National Highway Traffic Safety Administration (NHTSA) and the European New Car Assessment Programme (Euro NCAP) also play a role in establishing electric vehicle reliability standards. These organizations conduct testing and evaluation of electric vehicles to ensure that they meet the required safety and performance standards.

Overall, electric vehicle reliability standards are essential to ensuring the safety and performance of electric vehicles. By following these standards, manufacturers can ensure that their electric vehicles are reliable, efficient, and safe, and that they meet the required performance and efficiency standards.

How to Evaluate Electric Motor Reliability in EVs

Evaluating the reliability of an electric motor in an electric vehicle (EV) is crucial to ensure the overall performance and safety of the vehicle. To assess the reliability of an electric motor, several factors need to be considered, including motor type, power output, and efficiency. In this section, we will provide a step-by-step guide on how to evaluate electric motor reliability in EVs.

Step 1: Identify the Motor Type

The first step in evaluating electric motor reliability is to identify the type of motor used in the EV. There are several types of electric motors, including permanent magnet motors, induction motors, and switched reluctance motors. Each type of motor has its own strengths and weaknesses, and understanding the motor type is essential to evaluating its reliability.

Step 2: Assess the Power Output

The power output of the electric motor is another critical factor to consider when evaluating its reliability. The power output of the motor should be sufficient to meet the demands of the vehicle, including acceleration, hill climbing, and cruising. A motor with insufficient power output may not be able to handle the demands of the vehicle, leading to reduced reliability.

Step 3: Evaluate the Efficiency

The efficiency of the electric motor is also an important factor to consider when evaluating its reliability. A motor with high efficiency will be able to convert more of the electrical energy into mechanical energy, reducing the risk of overheating and increasing the overall reliability of the motor.

Step 4: Conduct Testing and Validation

Once the motor type, power output, and efficiency have been evaluated, the next step is to conduct testing and validation. This includes performing tests such as environmental testing, durability testing, and performance testing to ensure that the motor meets the required reliability standards.

Tools and Methods for Evaluating Electric Motor Reliability

Several tools and methods can be used to evaluate electric motor reliability, including:

Motor simulation software: This software can be used to simulate the performance of the motor under various operating conditions, including temperature, humidity, and vibration.

Testing equipment: This includes equipment such as dynamometers, oscilloscopes, and thermal imaging cameras, which can be used to measure the performance of the motor and identify potential issues.

Reliability modeling: This involves using statistical models to predict the reliability of the motor based on factors such as usage patterns, environmental conditions, and maintenance schedules.

By following these steps and using these tools and methods, it is possible to evaluate the reliability of an electric motor in an EV and ensure that it meets the required reliability standards.

Real-World Examples: Electric Vehicle Reliability in Practice

Several electric vehicles have demonstrated high reliability in real-world applications, providing valuable insights into the design and testing processes that contribute to their reliability. Two notable examples are the Tesla Model 3 and the Nissan Leaf.

Tesla Model 3: The Tesla Model 3 is a compact luxury sedan that has been in production since 2017. It has been praised for its exceptional reliability, with many owners reporting low maintenance costs and few mechanical issues. Tesla’s approach to reliability includes rigorous testing and validation, including environmental testing, durability testing, and performance testing. Additionally, Tesla’s use of advanced materials and manufacturing techniques, such as aluminum and steel construction, has helped to reduce the risk of mechanical failures.

Nissan Leaf: The Nissan Leaf is a compact electric hatchback that has been in production since 2010. It has been praised for its reliability, with many owners reporting low maintenance costs and few mechanical issues. Nissan’s approach to reliability includes rigorous testing and validation, including environmental testing, durability testing, and performance testing. Additionally, Nissan’s use of advanced materials and manufacturing techniques, such as lithium-ion batteries and regenerative braking, has helped to reduce the risk of mechanical failures.

Design and Testing Processes: Both Tesla and Nissan have implemented robust design and testing processes to ensure the reliability of their electric vehicles. These processes include:

Computer-aided design (CAD) and simulation: Both companies use CAD and simulation tools to design and test their electric vehicles, reducing the risk of mechanical failures and improving overall reliability.

Prototyping and testing: Both companies build and test prototypes of their electric vehicles, identifying and addressing potential issues before production.

Manufacturing quality control: Both companies have implemented robust quality control processes in their manufacturing facilities, ensuring that every vehicle meets strict reliability and safety standards.

Warranty and maintenance: Both companies offer comprehensive warranties and maintenance programs, providing owners with peace of mind and protecting their investment in the vehicle.

By examining the design and testing processes of these two companies, we can gain valuable insights into the importance of reliability in electric vehicles and the steps that manufacturers can take to ensure the reliability of their products.

The Role of Testing in Ensuring Electric Motor Reliability

Testing plays a crucial role in ensuring the reliability of electric motors in electric vehicles. Testing helps to identify potential issues and ensures that the motor meets the required reliability standards. There are several types of tests that can be conducted to ensure the reliability of electric motors, including:

Environmental Testing: Environmental testing involves subjecting the motor to various environmental conditions, such as temperature, humidity, and vibration, to ensure that it can operate reliably in different environments.

Durability Testing: Durability testing involves subjecting the motor to repeated stress and strain to ensure that it can withstand the rigors of repeated use.

Performance Testing: Performance testing involves testing the motor’s performance under various operating conditions, such as speed, torque, and efficiency, to ensure that it meets the required performance standards.

Electromagnetic Compatibility (EMC) Testing: EMC testing involves testing the motor’s electromagnetic compatibility with other electrical systems in the vehicle to ensure that it does not interfere with other systems.

Thermal Testing: Thermal testing involves testing the motor’s thermal performance to ensure that it can operate reliably in high-temperature environments.

Benefits of Testing: Testing provides several benefits, including:

Identification of potential issues: Testing helps to identify potential issues with the motor, such as design flaws or manufacturing defects, which can be addressed before the motor is put into production.

Improved reliability: Testing helps to ensure that the motor meets the required reliability standards, which improves the overall reliability of the vehicle.

Reduced maintenance costs: Testing helps to identify potential issues with the motor, which can reduce maintenance costs over the life of the vehicle.

Improved performance: Testing helps to ensure that the motor meets the required performance standards, which improves the overall performance of the vehicle.

Best Practices for Testing: To ensure the reliability of electric motors, manufacturers should follow best practices for testing, including:

Developing a comprehensive testing plan: Manufacturers should develop a comprehensive testing plan that includes all the necessary tests to ensure the reliability of the motor.

Using advanced testing equipment: Manufacturers should use advanced testing equipment, such as dynamometers and oscilloscopes, to ensure that the motor is tested accurately and reliably.

Conducting regular testing: Manufacturers should conduct regular testing to ensure that the motor continues to meet the required reliability standards over time.

By following these best practices for testing, manufacturers can ensure the reliability of their electric motors and provide high-quality vehicles to their customers.

Designing for Reliability: Best Practices for Electric Motor Manufacturers

Designing electric motors for reliability is crucial to ensure the overall performance and safety of electric vehicles. Electric motor manufacturers can follow best practices to minimize the risk of motor failure and optimize efficiency. Here are some key considerations for designing reliable electric motors:

Material selection is critical in electric motor design. Manufacturers should choose materials that can withstand the high temperatures and stresses associated with electric motor operation. For example, using high-temperature-resistant magnets and insulation materials can help prevent motor failure due to overheating.

Thermal management is another essential aspect of electric motor design. Manufacturers should ensure that the motor is designed to dissipate heat efficiently, using techniques such as heat sinks, cooling fins, or liquid cooling systems. This helps to prevent overheating, which can reduce motor lifespan and affect overall vehicle performance.

Electromagnetic design is also critical in ensuring electric motor reliability. Manufacturers should optimize the motor’s electromagnetic design to minimize losses and reduce the risk of demagnetization. This can be achieved through techniques such as finite element analysis and simulation tools.

In addition to these design considerations, manufacturers should also follow established electric vehicle and electric motor reliability standards, such as those set by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). These standards provide guidelines for designing and testing electric motors to ensure reliability and safety.

Furthermore, manufacturers should consider implementing design for manufacturability (DFM) principles to ensure that the motor is designed for efficient and reliable production. This includes considerations such as component sourcing, assembly processes, and testing procedures.

By following these best practices, electric motor manufacturers can design reliable motors that meet the demands of electric vehicle applications. This not only ensures the safety and performance of the vehicle but also helps to build customer trust and loyalty in the brand.

Electric Vehicle Reliability Standards: Future Developments and Trends

The electric vehicle industry is rapidly evolving, with emerging trends and technologies that will impact the development of electric vehicle and electric motor reliability standards. As the industry continues to grow, it is essential to stay ahead of the curve and anticipate the reliability challenges that will arise from these advancements.

One of the most significant trends in the electric vehicle industry is the development of autonomous driving technology. Autonomous vehicles will require even higher levels of reliability and safety, as they will be operating without human intervention. This will necessitate the development of new reliability standards that address the unique challenges of autonomous vehicles, such as the need for redundant systems and advanced sensor technologies.

Another trend that will impact electric vehicle reliability standards is the growth of vehicle-to-grid (V2G) technology. V2G technology allows electric vehicles to act as energy storage devices and supply electricity back to the grid. This will require new reliability standards that address the unique demands of V2G operation, such as the need for advanced battery management systems and high-power charging infrastructure.

In addition to these trends, there are also emerging technologies that will impact electric vehicle reliability standards. For example, the development of advanced materials and manufacturing techniques, such as 3D printing, will enable the creation of more efficient and reliable electric motors. Similarly, the use of artificial intelligence and machine learning algorithms will enable the development of more sophisticated reliability testing and validation methods.

To address these emerging trends and technologies, organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) are already working on developing new electric vehicle and electric motor reliability standards. These standards will provide a framework for ensuring the safety and performance of electric vehicles, even as the technology continues to evolve.

For example, the IEC is currently developing a new standard for the reliability of electric vehicle batteries, which will address the unique challenges of battery operation in electric vehicles. Similarly, the SAE is working on a new standard for the reliability of autonomous vehicle systems, which will provide a framework for ensuring the safety and performance of these systems.

As the electric vehicle industry continues to evolve, it is essential to stay ahead of the curve and anticipate the reliability challenges that will arise from emerging trends and technologies. By developing new electric vehicle and electric motor reliability standards, we can ensure the safety and performance of these vehicles, even as the technology continues to advance.

Conclusion: The Importance of Electric Vehicle Reliability Standards

In conclusion, electric vehicle and electric motor reliability standards play a critical role in ensuring the safety and performance of electric vehicles. As the industry continues to evolve, it is essential to prioritize reliability when selecting an electric vehicle or designing electric motors.

Throughout this article, we have discussed the importance of reliability in electric vehicles, the various reliability standards for electric vehicles, and the key factors that contribute to an electric motor’s reliability. We have also examined real-world examples of electric vehicles that have demonstrated high reliability and discussed the role of testing in ensuring electric motor reliability.

As the electric vehicle industry continues to grow, it is essential to stay ahead of the curve and anticipate the reliability challenges that will arise from emerging trends and technologies. By prioritizing reliability and adhering to established electric vehicle and electric motor reliability standards, manufacturers can ensure the safety and performance of their vehicles, even as the technology continues to advance.

Ultimately, the importance of electric vehicle and electric motor reliability standards cannot be overstated. By prioritizing reliability, manufacturers can build trust with their customers, reduce the risk of costly recalls, and contribute to a safer and more sustainable transportation ecosystem.

As the industry continues to evolve, it is essential to remain vigilant and proactive in addressing the reliability challenges that arise. By working together to develop and implement robust electric vehicle and electric motor reliability standards, we can ensure a safer, more efficient, and more sustainable future for electric vehicles.