Why Validation is Crucial for Electric Motor and Vehicle Performance

Electric motor and electric vehicle validation is a critical process that ensures the reliability, efficiency, and safety of electric motors and vehicles. Validation helps to identify and address potential issues before they become major problems, reducing the risk of costly recalls, warranty claims, and damage to a manufacturer’s reputation. By validating electric motor and vehicle systems, manufacturers can ensure that their products meet the required safety and performance standards, comply with regulatory requirements, and provide a high level of customer satisfaction.

The importance of validation cannot be overstated, as it plays a crucial role in the development and production of electric motors and vehicles. Validation involves a series of tests and evaluations that are designed to verify the performance, safety, and reliability of electric motor and vehicle systems. These tests may include electromagnetic compatibility testing, thermal management testing, and vibration testing, among others. By conducting these tests, manufacturers can identify potential issues and make necessary adjustments to ensure that their products meet the required standards.

Furthermore, validation helps to reduce the risk of product failures, which can have serious consequences for manufacturers and consumers alike. Product failures can result in costly repairs, warranty claims, and damage to a manufacturer’s reputation. By validating electric motor and vehicle systems, manufacturers can minimize the risk of product failures and ensure that their products provide a high level of performance, safety, and reliability.

In addition, validation is essential for ensuring compliance with regulatory requirements. Electric motor and vehicle manufacturers must comply with a range of regulatory requirements, including safety standards, emissions standards, and performance standards. By validating their products, manufacturers can ensure that they meet these requirements and avoid costly fines and penalties.

Overall, electric motor and electric vehicle validation is a critical process that ensures the reliability, efficiency, and safety of electric motors and vehicles. By validating their products, manufacturers can minimize the risk of product failures, ensure compliance with regulatory requirements, and provide a high level of customer satisfaction.

Understanding the Key Components of Electric Motor Validation

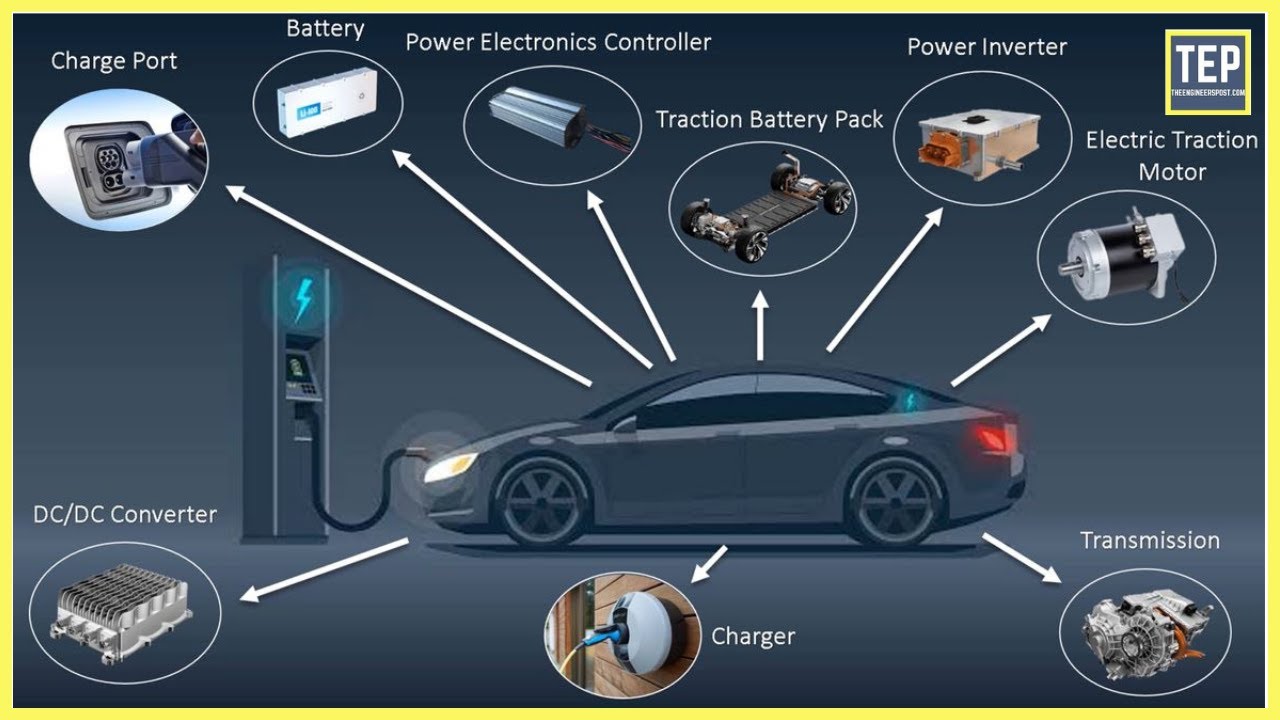

Electric motor and electric vehicle validation is a critical process that ensures the reliability, efficiency, and safety of electric motors and vehicles. One of the key components of electric motor validation is electromagnetic compatibility (EMC) testing. EMC testing evaluates the motor’s ability to function as intended in the presence of electromagnetic interference (EMI) from other electrical systems. This is crucial in electric vehicles, where multiple electrical systems are integrated into a single platform.

Thermal management is another critical component of electric motor validation. Electric motors generate heat during operation, which can affect their performance and lifespan. Thermal management testing evaluates the motor’s ability to dissipate heat and maintain a stable operating temperature. This is particularly important in electric vehicles, where high-performance motors are often used.

Vibration testing is also an essential component of electric motor validation. Vibration can affect the motor’s performance, efficiency, and lifespan. Vibration testing evaluates the motor’s ability to withstand various types of vibration, including those caused by road conditions and other external factors.

Other key components of electric motor validation include testing for insulation resistance, dielectric strength, and partial discharge. These tests evaluate the motor’s electrical insulation and its ability to withstand electrical stress.

In addition to these components, electric motor validation also involves testing for performance, efficiency, and reliability. This includes evaluating the motor’s torque, speed, and power output, as well as its ability to operate under various environmental conditions.

By validating these key components, manufacturers can ensure that their electric motors and vehicles meet the required standards for performance, efficiency, and safety. This is critical in the electric vehicle industry, where reliability and safety are paramount.

Electric motor and electric vehicle validation is a complex process that requires specialized expertise and equipment. By understanding the key components of electric motor validation, manufacturers can develop more efficient and effective testing protocols that ensure the reliability and safety of their products.

How to Validate Electric Vehicle Systems for Optimal Performance

Validating electric vehicle systems is a complex process that requires a structured approach to ensure optimal performance. The following step-by-step guide outlines the key steps involved in validating electric vehicle systems, including the use of simulation tools, testing protocols, and data analysis techniques.

Step 1: Define Validation Objectives and Requirements

The first step in validating electric vehicle systems is to define the validation objectives and requirements. This involves identifying the key performance indicators (KPIs) that need to be measured and the validation protocols that need to be followed. The validation objectives and requirements should be aligned with the overall vehicle performance and safety standards.

Step 2: Develop Simulation Models and Tools

Simulation models and tools play a critical role in electric vehicle system validation. They enable engineers to simulate various scenarios and test the vehicle’s performance under different conditions. The simulation models and tools should be validated against experimental data to ensure accuracy and reliability.

Step 3: Design and Implement Testing Protocols

Testing protocols are designed to validate the electric vehicle system’s performance under various conditions. The testing protocols should include a combination of laboratory and field tests to ensure that the vehicle meets the required performance and safety standards.

Step 4: Conduct Data Analysis and Interpretation

Data analysis and interpretation are critical steps in electric vehicle system validation. The data collected during testing should be analyzed to identify trends, patterns, and correlations. The results should be interpreted in the context of the validation objectives and requirements.

Step 5: Refine and Iterate the Validation Process

The validation process is iterative, and refinement is an ongoing process. The results of the validation process should be used to refine the simulation models, testing protocols, and data analysis techniques. This ensures that the electric vehicle system meets the required performance and safety standards.

Step 6: Collaborate with Suppliers and Regulatory Bodies

Collaboration with suppliers and regulatory bodies is essential in electric vehicle system validation. Suppliers can provide valuable insights into the performance and safety of their components, while regulatory bodies can provide guidance on compliance with safety standards.

By following these steps, electric vehicle manufacturers can ensure that their vehicles meet the required performance and safety standards. Electric motor and electric vehicle validation is a critical process that requires a structured approach to ensure optimal performance. By incorporating simulation tools, testing protocols, and data analysis techniques, manufacturers can validate their electric vehicle systems and ensure compliance with safety standards.

Iterative testing and refinement are essential in electric vehicle system validation. The validation process should be ongoing, with continuous refinement and iteration to ensure that the vehicle meets the required performance and safety standards. By adopting this approach, electric vehicle manufacturers can ensure that their vehicles are safe, efficient, and reliable.

Real-World Examples of Electric Vehicle Validation: Lessons from Tesla and BMW

Tesla and BMW are two leading manufacturers in the electric vehicle (EV) industry, and their approaches to electric motor and electric vehicle validation offer valuable insights into the importance of rigorous testing and validation. Both companies have faced challenges in ensuring the reliability, efficiency, and safety of their EVs, but their solutions have helped to establish them as leaders in the industry.

Tesla’s Approach to Electric Motor Validation

Tesla’s approach to electric motor validation is centered around its proprietary motor design, which is optimized for high-performance and efficiency. The company uses advanced simulation tools, such as finite element analysis and computational fluid dynamics, to validate its motor design and ensure that it meets the required performance and safety standards.

In addition to simulation tools, Tesla also conducts extensive testing of its motors, including dynamometer testing and road testing. The company’s testing protocols are designed to simulate real-world driving conditions, including extreme temperatures, high speeds, and heavy loads.

BMW’s Approach to Electric Vehicle Validation

BMW’s approach to electric vehicle validation is focused on ensuring the reliability and safety of its EVs. The company uses a combination of simulation tools and physical testing to validate its EVs, including crash testing, durability testing, and performance testing.

BMW also places a strong emphasis on testing its EVs in real-world conditions, including extreme temperatures, high altitudes, and heavy loads. The company’s testing protocols are designed to simulate the diverse range of driving conditions that its EVs may encounter in the real world.

Lessons Learned from Tesla and BMW

Both Tesla and BMW have learned valuable lessons from their experiences with electric motor and electric vehicle validation. One key takeaway is the importance of rigorous testing and validation in ensuring the reliability, efficiency, and safety of EVs.

Another key lesson is the value of using advanced simulation tools to validate motor design and performance. Simulation tools can help to reduce testing time and costs, while also improving the accuracy and reliability of test results.

Finally, both Tesla and BMW have emphasized the importance of collaboration with suppliers and regulatory bodies in ensuring compliance with safety standards. By working closely with suppliers and regulatory bodies, manufacturers can ensure that their EVs meet the required safety standards and are reliable, efficient, and safe for consumers.

Electric motor and electric vehicle validation is a critical process that requires a structured approach to ensure optimal performance. By learning from the experiences of leading manufacturers like Tesla and BMW, manufacturers can develop more effective validation processes and ensure that their EVs are reliable, efficient, and safe for consumers.

The Role of Advanced Simulation Tools in Electric Motor Validation

Advanced simulation tools play a crucial role in electric motor validation, enabling manufacturers to test and optimize their designs without the need for physical prototypes. These tools use complex algorithms and mathematical models to simulate the behavior of electric motors under various operating conditions, allowing manufacturers to identify and address potential issues before they become major problems.

Finite Element Analysis (FEA) is one of the most widely used simulation tools in electric motor validation. FEA uses numerical methods to simulate the behavior of electric motors under various loads and operating conditions, allowing manufacturers to optimize their designs for performance, efficiency, and reliability.

Computational Fluid Dynamics (CFD) is another advanced simulation tool used in electric motor validation. CFD uses numerical methods to simulate the behavior of fluids and gases within electric motors, allowing manufacturers to optimize their designs for thermal management and cooling.

The benefits of using advanced simulation tools in electric motor validation are numerous. These tools can help reduce testing time and costs, improve design accuracy and reliability, and enable manufacturers to optimize their designs for performance and efficiency.

However, advanced simulation tools also have limitations. They require significant computational resources and expertise to use effectively, and may not always accurately predict the behavior of electric motors under real-world operating conditions.

Despite these limitations, advanced simulation tools are becoming increasingly important in electric motor validation. As electric vehicles become more widespread, manufacturers are under pressure to deliver high-performance, efficient, and reliable electric motors that meet the demands of consumers.

By using advanced simulation tools, manufacturers can optimize their designs for performance, efficiency, and reliability, and ensure that their electric motors meet the required safety and regulatory standards.

In addition to FEA and CFD, other advanced simulation tools are also being used in electric motor validation, including multi-body dynamics and electromagnetic simulation. These tools enable manufacturers to simulate the behavior of electric motors under various operating conditions, and optimize their designs for performance, efficiency, and reliability.

Electric motor and electric vehicle validation is a critical process that requires the use of advanced simulation tools. By leveraging these tools, manufacturers can optimize their designs for performance, efficiency, and reliability, and ensure that their electric motors meet the required safety and regulatory standards.

As the demand for electric vehicles continues to grow, the importance of advanced simulation tools in electric motor validation will only continue to increase. By investing in these tools, manufacturers can stay ahead of the competition and deliver high-performance, efficient, and reliable electric motors that meet the demands of consumers.

Ensuring Compliance with Electric Vehicle Safety Standards through Validation

Ensuring compliance with electric vehicle safety standards is a critical aspect of electric motor and electric vehicle validation. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) and the International Electrotechnical Commission (IEC) set strict safety standards for electric vehicles, and manufacturers must ensure that their vehicles meet these standards.

Validation plays a crucial role in ensuring compliance with electric vehicle safety standards. By validating electric motor and vehicle systems, manufacturers can identify and address potential safety issues before they become major problems. This includes testing for electromagnetic compatibility, thermal management, and vibration, as well as ensuring that vehicles meet safety standards for crashworthiness, fire resistance, and electrical safety.

The NHTSA sets safety standards for electric vehicles in the United States, including standards for crashworthiness, fire resistance, and electrical safety. The IEC sets international safety standards for electric vehicles, including standards for electromagnetic compatibility, thermal management, and vibration.

Manufacturers must ensure that their electric vehicles meet these safety standards through a combination of testing and validation. This includes physical testing, such as crash testing and fire testing, as well as simulation testing, such as finite element analysis and computational fluid dynamics.

Validation also involves ensuring that electric vehicles meet safety standards for electrical safety, including standards for insulation, grounding, and electrical shock protection. This includes testing for electrical safety under various operating conditions, including normal operation, fault conditions, and environmental extremes.

In addition to meeting safety standards, manufacturers must also ensure that their electric vehicles meet regulatory requirements for labeling, documentation, and certification. This includes providing documentation and labeling that meets regulatory requirements, as well as obtaining certification from regulatory bodies.

Electric motor and electric vehicle validation is a critical process that ensures compliance with safety standards and regulatory requirements. By validating electric motor and vehicle systems, manufacturers can ensure that their vehicles are safe, reliable, and efficient, and meet the required safety and regulatory standards.

Ensuring compliance with electric vehicle safety standards through validation is an ongoing process that requires continuous testing and refinement. Manufacturers must stay up-to-date with changing safety standards and regulatory requirements, and ensure that their vehicles meet these standards through ongoing validation and testing.

By prioritizing validation and compliance, manufacturers can ensure that their electric vehicles meet the required safety and regulatory standards, and provide safe and reliable transportation for consumers.

Best Practices for Electric Motor and Vehicle Validation: A Manufacturer’s Perspective

Electric motor and electric vehicle validation is a critical process that requires careful planning, execution, and analysis. Experienced manufacturers have developed best practices for validation, including tips on testing protocols, data analysis, and collaboration with suppliers and regulatory bodies.

One of the most important best practices for electric motor and vehicle validation is to develop a comprehensive testing protocol. This protocol should include a range of tests, including electromagnetic compatibility, thermal management, and vibration testing, as well as performance and efficiency testing.

Another key best practice is to use advanced simulation tools, such as finite element analysis and computational fluid dynamics, to validate electric motor and vehicle designs. These tools can help reduce testing time and costs, while also improving the accuracy and reliability of test results.

Data analysis is also a critical component of electric motor and vehicle validation. Manufacturers should use advanced data analysis techniques, such as machine learning and artificial intelligence, to analyze test data and identify trends and patterns.

Collaboration with suppliers and regulatory bodies is also essential for electric motor and vehicle validation. Manufacturers should work closely with suppliers to ensure that components meet required safety and performance standards, and with regulatory bodies to ensure compliance with safety and regulatory requirements.

Experienced manufacturers also emphasize the importance of iterative testing and refinement. Electric motor and vehicle validation is an ongoing process that requires continuous testing and refinement to ensure that vehicles meet required safety and performance standards.

Finally, manufacturers should prioritize validation and testing throughout the development process. This includes conducting regular testing and validation, as well as incorporating feedback from testing and validation into the design and development process.

By following these best practices, manufacturers can ensure that their electric motors and vehicles meet required safety and performance standards, and provide safe and reliable transportation for consumers.

Electric motor and electric vehicle validation is a complex and ongoing process that requires careful planning, execution, and analysis. By prioritizing validation and testing, and by following best practices for testing protocols, data analysis, and collaboration, manufacturers can ensure that their vehicles meet required safety and performance standards.

As the demand for electric vehicles continues to grow, the importance of electric motor and electric vehicle validation will only continue to increase. By prioritizing validation and testing, manufacturers can stay ahead of the competition and provide safe and reliable transportation for consumers.

Future Directions in Electric Motor and Vehicle Validation: Trends and Opportunities

The electric motor and electric vehicle validation landscape is rapidly evolving, with emerging trends and opportunities that are transforming the way manufacturers approach validation. One of the most significant trends is the increasing use of artificial intelligence (AI) and machine learning (ML) in validation.

AI and ML can be used to analyze large datasets and identify patterns and trends that may not be apparent through traditional testing methods. This can help manufacturers to identify potential issues earlier in the development process, and to optimize their designs for better performance and efficiency.

Another trend is the growing use of the Internet of Things (IoT) in validation. IoT sensors and devices can be used to collect data from vehicles in real-time, providing manufacturers with valuable insights into how their vehicles are performing in the field.

The use of advanced simulation tools, such as finite element analysis and computational fluid dynamics, is also becoming more widespread in electric motor and vehicle validation. These tools can help manufacturers to reduce testing time and costs, while also improving the accuracy and reliability of their test results.

In addition to these trends, there are also several opportunities for innovation in electric motor and vehicle validation. One area of opportunity is the development of new testing protocols and methodologies that can help manufacturers to validate their vehicles more efficiently and effectively.

Another area of opportunity is the integration of electric motor and vehicle validation with other areas of the development process, such as design and manufacturing. This can help manufacturers to identify potential issues earlier in the development process, and to optimize their designs for better performance and efficiency.

Finally, there is also an opportunity for manufacturers to use electric motor and vehicle validation as a competitive differentiator. By investing in advanced validation technologies and methodologies, manufacturers can demonstrate their commitment to quality and performance, and differentiate themselves from their competitors.

Electric motor and electric vehicle validation is a critical process that is essential for ensuring the reliability, efficiency, and safety of electric vehicles. By staying up-to-date with the latest trends and opportunities in validation, manufacturers can optimize their designs, reduce testing time and costs, and improve overall vehicle performance.

The future of electric motor and vehicle validation is exciting and rapidly evolving. As manufacturers continue to innovate and invest in new technologies and methodologies, we can expect to see significant improvements in the performance, efficiency, and safety of electric vehicles.

By embracing these trends and opportunities, manufacturers can stay ahead of the competition and provide safe and reliable transportation for consumers. The future of electric motor and vehicle validation is bright, and it will be exciting to see the innovations and advancements that emerge in the coming years.