Unlocking the Secrets of Efficient Electric Motor Performance

Electric motor magnetic design plays a crucial role in determining the efficiency, power density, and overall performance of electric motors. A well-designed magnetic system can lead to significant improvements in motor operation, resulting in increased productivity, reduced energy consumption, and lower maintenance costs. In the context of electric motor magnetic design, the goal is to create a magnetic field that efficiently converts electrical energy into mechanical energy.

The importance of magnetic design in electric motors cannot be overstated. A poorly designed magnetic system can lead to reduced motor efficiency, increased energy losses, and decreased overall performance. On the other hand, a well-designed magnetic system can result in improved motor efficiency, increased power density, and enhanced overall performance. As such, electric motor magnetic design is a critical aspect of electric motor development and optimization.

In the field of electric motor magnetic design, engineers and designers employ various techniques and tools to create efficient and effective magnetic systems. These techniques include the use of finite element analysis (FEA) software, computational fluid dynamics (CFD) simulations, and experimental testing. By leveraging these tools and techniques, designers can optimize the magnetic design of electric motors, resulting in improved performance, increased efficiency, and reduced energy consumption.

One of the key challenges in electric motor magnetic design is balancing the competing demands of efficiency, power density, and cost. Designers must carefully consider the trade-offs between these factors, selecting materials and design configurations that optimize performance while minimizing costs. Additionally, designers must also consider the impact of magnetic design on other aspects of motor performance, such as thermal management, vibration, and noise reduction.

Despite the challenges, advances in electric motor magnetic design have led to significant improvements in motor efficiency and performance. For example, the development of high-efficiency magnetic materials, such as neodymium iron boron (NdFeB) and ferrite, has enabled the creation of more efficient and compact electric motors. Similarly, advances in simulation tools and experimental techniques have enabled designers to optimize magnetic design with greater precision and accuracy.

In conclusion, electric motor magnetic design is a critical aspect of electric motor development and optimization. By leveraging advanced techniques and tools, designers can create efficient and effective magnetic systems that improve motor performance, increase efficiency, and reduce energy consumption. As the demand for more efficient and sustainable electric motors continues to grow, the importance of electric motor magnetic design will only continue to increase.

How to Optimize Magnetic Field Distribution for Enhanced Motor Efficiency

Magnetic field distribution is a critical aspect of electric motor magnetic design, as it directly affects the motor’s efficiency, power density, and overall performance. Optimizing magnetic field distribution requires a deep understanding of the underlying principles and the use of advanced simulation tools and experimental methods.

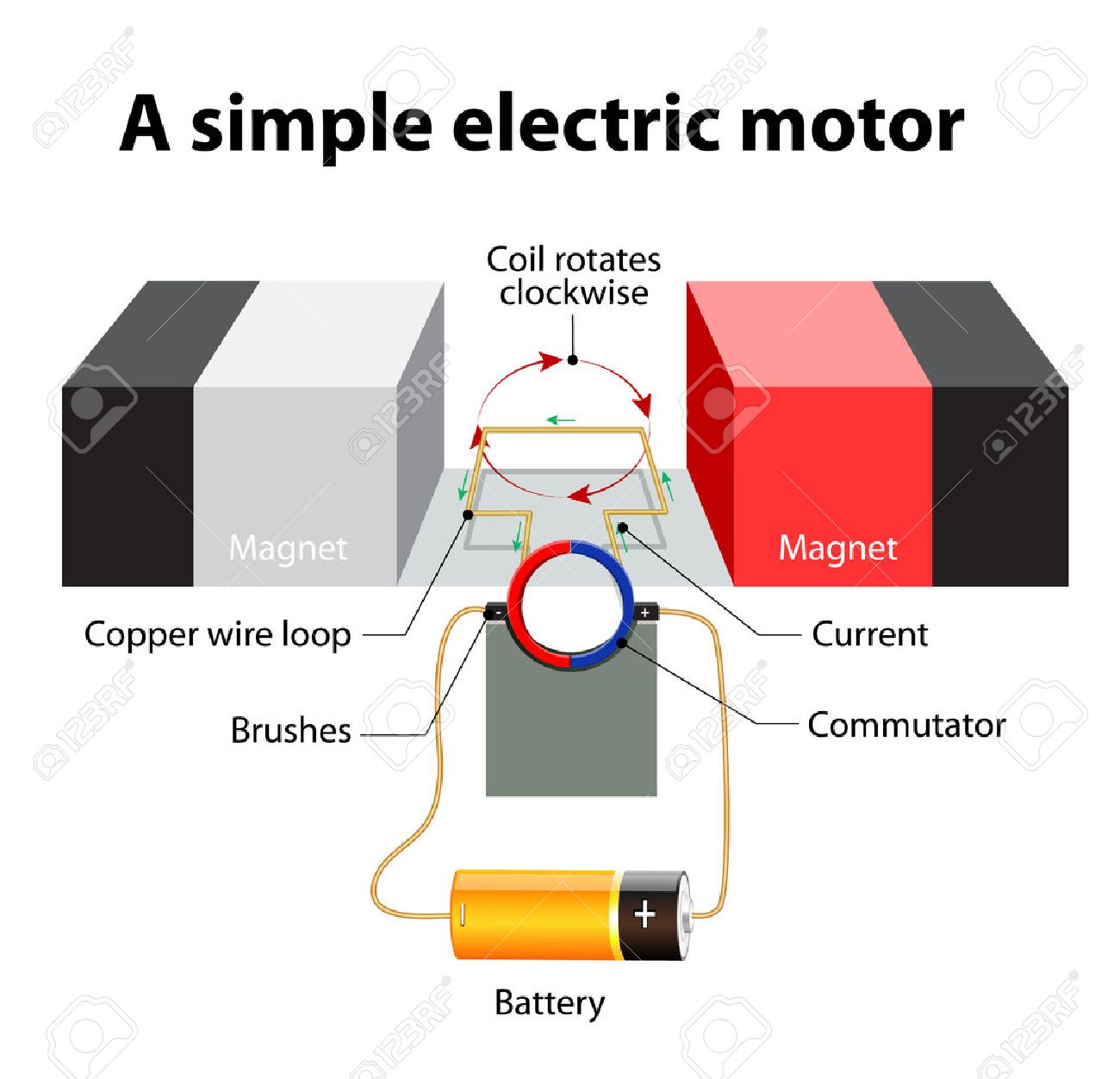

The magnetic field distribution in an electric motor is influenced by several factors, including the type of magnetic material used, the coil design, and the geometry of the motor. Magnetic materials with high permeability and low core loss are essential for efficient magnetic field distribution. Coil design also plays a crucial role, as it determines the magnetic field pattern and the resulting torque and power output.

Geometry is another critical factor in magnetic field distribution, as it affects the magnetic flux density and the resulting motor performance. The use of finite element analysis (FEA) software and computational fluid dynamics (CFD) simulations can help designers optimize the geometry of the motor and the magnetic field distribution.

Practical tips for optimizing magnetic field distribution include using simulation tools to analyze the magnetic field pattern and identify areas for improvement. Experimental methods, such as magnetic field measurements and motor performance testing, can also be used to validate the simulation results and optimize the motor design.

Some of the key benefits of optimizing magnetic field distribution in electric motors include improved efficiency, increased power density, and reduced energy losses. By optimizing the magnetic field distribution, designers can create more efficient and compact electric motors that meet the demands of modern applications.

In electric motor magnetic design, the use of advanced simulation tools and experimental methods is essential for optimizing magnetic field distribution. By leveraging these tools and techniques, designers can create more efficient and effective magnetic systems that improve motor performance and reduce energy consumption.

For example, the use of FEA software can help designers optimize the magnetic field distribution in an electric motor by analyzing the magnetic flux density and the resulting torque and power output. CFD simulations can also be used to analyze the thermal management of the motor and optimize the cooling system.

By combining advanced simulation tools and experimental methods, designers can create more efficient and effective electric motors that meet the demands of modern applications. The optimization of magnetic field distribution is a critical aspect of electric motor magnetic design, and its importance will only continue to grow as the demand for more efficient and sustainable electric motors increases.

The Role of Magnetization in Electric Motor Design: A Deep Dive

Magnetization is a fundamental concept in electric motor design, playing a crucial role in determining the motor’s performance, efficiency, and overall behavior. In the context of electric motor magnetic design, magnetization refers to the process of creating a magnetic field within the motor, which is essential for converting electrical energy into mechanical energy.

There are several types of magnetization, including permanent magnetization, electromagnetic induction, and magnetization curves. Permanent magnetization involves the use of permanent magnets, which are made from materials that retain their magnetic field forever. Electromagnetic induction, on the other hand, involves the use of coils and electrical currents to generate a magnetic field. Magnetization curves, also known as B-H curves, describe the relationship between the magnetic field strength and the magnetic flux density.

The impact of magnetization on motor performance is significant, affecting the motor’s torque, power, and efficiency. A well-designed magnetization system can result in improved motor efficiency, increased power density, and enhanced overall performance. Conversely, a poorly designed magnetization system can lead to reduced motor efficiency, decreased power density, and compromised overall performance.

In electric motor magnetic design, the choice of magnetization type and design depends on the specific application and requirements. For example, permanent magnetization is often used in high-performance applications, such as electric vehicles and industrial machinery, where high torque and power density are required. Electromagnetic induction, on the other hand, is often used in lower-performance applications, such as household appliances and power tools, where lower torque and power density are sufficient.

The design of the magnetization system also depends on the type of magnetic material used. Different magnetic materials have different properties and characteristics, such as permeability, coercivity, and remanence, which affect the magnetization process. For example, neodymium iron boron (NdFeB) magnets are known for their high permeability and coercivity, making them suitable for high-performance applications.

In addition to the type of magnetization and magnetic material, the design of the magnetization system also depends on the motor’s geometry and configuration. The shape and size of the motor, as well as the arrangement of the coils and magnets, can affect the magnetization process and the resulting motor performance.

By understanding the principles of magnetization and its impact on motor performance, designers can create more efficient and effective electric motors that meet the demands of modern applications. The role of magnetization in electric motor design is critical, and its importance will only continue to grow as the demand for more efficient and sustainable electric motors increases.

Designing Electric Motors with High-Efficiency Magnetic Materials

The selection of magnetic materials is a critical aspect of electric motor magnetic design, as it directly affects the motor’s efficiency, power density, and overall performance. High-efficiency magnetic materials are essential for creating electric motors that meet the demands of modern applications, including electric vehicles, industrial machinery, and renewable energy systems.

Neodymium iron boron (NdFeB) magnets are a popular choice for electric motor magnetic design due to their high permeability, coercivity, and remanence. These magnets are known for their high energy density and are often used in high-performance applications, such as electric vehicles and industrial machinery. However, NdFeB magnets can be expensive and may require additional processing steps to achieve optimal performance.

Ferrite magnets are another type of high-efficiency magnetic material that is commonly used in electric motor magnetic design. Ferrite magnets are known for their high permeability and low core loss, making them suitable for applications where high efficiency is required. Ferrite magnets are also less expensive than NdFeB magnets and can be easily processed to achieve optimal performance.

Other high-efficiency magnetic materials that are used in electric motor magnetic design include samarium-cobalt (SmCo) magnets and aluminum-nickel-cobalt (AlNiCo) magnets. SmCo magnets are known for their high temperature stability and are often used in high-temperature applications, such as aerospace and defense. AlNiCo magnets are known for their high coercivity and are often used in applications where high magnetic field strength is required.

When selecting a magnetic material for electric motor magnetic design, it is essential to consider the specific requirements of the application. Factors such as temperature, vibration, and corrosion resistance must be taken into account to ensure that the magnetic material can withstand the operating conditions. Additionally, the magnetic material must be compatible with the motor’s geometry and configuration to ensure optimal performance.

In addition to the type of magnetic material, the design of the magnetic circuit is also critical in electric motor magnetic design. The magnetic circuit must be designed to optimize the magnetic field distribution and minimize energy losses. This can be achieved through the use of simulation tools and experimental methods, such as finite element analysis (FEA) and magnetic field measurements.

By selecting the right magnetic material and designing an optimal magnetic circuit, electric motor designers can create high-efficiency motors that meet the demands of modern applications. The use of high-efficiency magnetic materials and advanced design techniques can result in improved motor efficiency, increased power density, and enhanced overall performance.

Electric Motor Design Software: A Review of Popular Tools and Techniques

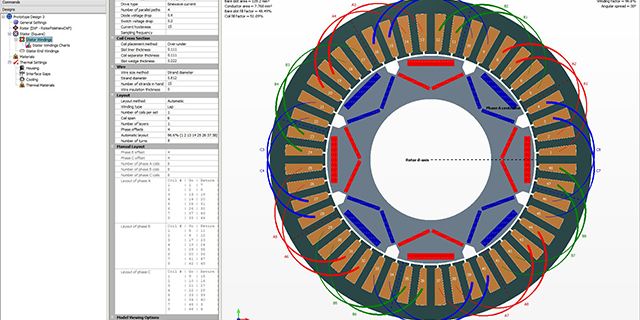

Electric motor design software is a crucial tool for engineers and designers working on electric motor magnetic design. These software tools enable designers to create, simulate, and optimize electric motor designs, reducing the need for physical prototyping and testing. In this article, we will review popular electric motor design software, including finite element analysis (FEA) tools and computer-aided design (CAD) programs.

Finite Element Analysis (FEA) tools are widely used in electric motor design to simulate and analyze the behavior of magnetic fields, thermal performance, and structural integrity. FEA tools, such as ANSYS and COMSOL, provide a detailed understanding of the motor’s performance under various operating conditions, enabling designers to optimize the design for improved efficiency, power density, and reliability.

Computer-Aided Design (CAD) programs, such as SolidWorks and Autodesk Inventor, are used to create and modify electric motor designs. CAD programs provide a graphical interface for designers to create and edit 2D and 3D models of the motor, including the magnetic circuit, coils, and other components. CAD programs also enable designers to perform simulations and analysis of the motor’s performance, including thermal and structural analysis.

Other popular electric motor design software includes Motor-CAD, which is a specialized tool for designing and optimizing electric motors. Motor-CAD provides a comprehensive set of tools for designing and analyzing electric motors, including FEA and CAD capabilities. Another popular tool is JMAG, which is a software tool for designing and optimizing electric motors and generators.

When selecting electric motor design software, designers should consider the specific requirements of their project, including the type of motor, operating conditions, and performance requirements. Designers should also consider the software’s capabilities, including FEA and CAD capabilities, as well as its user interface and ease of use.

In addition to the software itself, designers should also consider the level of support and training provided by the software vendor. Many software vendors offer training and support programs to help designers get started with the software and optimize their designs.

By using electric motor design software, designers can create optimized electric motor designs that meet the demands of modern applications. These software tools enable designers to simulate and analyze the behavior of magnetic fields, thermal performance, and structural integrity, reducing the need for physical prototyping and testing.

In conclusion, electric motor design software is a crucial tool for engineers and designers working on electric motor magnetic design. By selecting the right software and using it effectively, designers can create optimized electric motor designs that meet the demands of modern applications.

Case Study: Optimizing Electric Motor Design for a Real-World Application

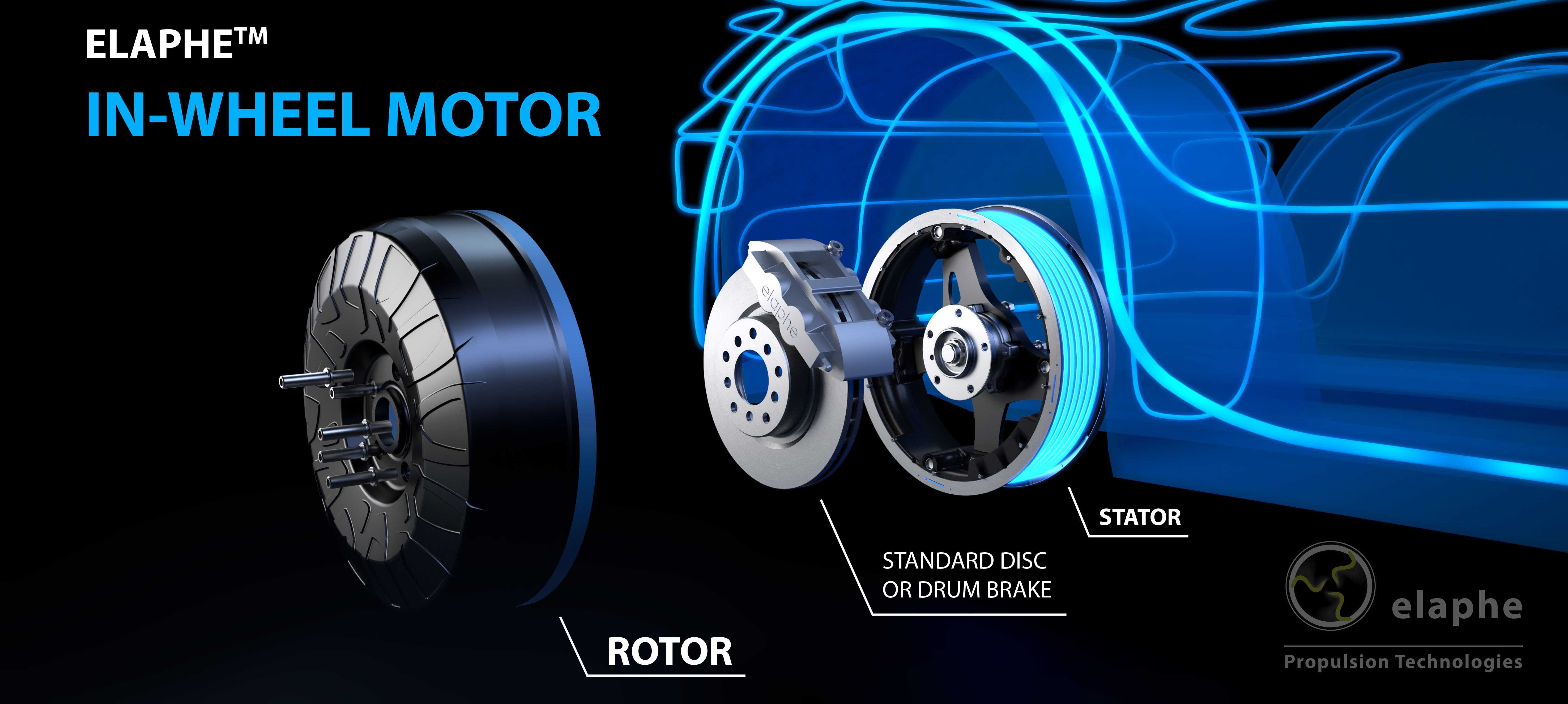

In this case study, we will present a real-world example of electric motor design optimization for a specific application. The application is a high-performance electric vehicle (EV) that requires a high-torque and high-efficiency electric motor. The motor design must meet the requirements of the EV’s powertrain system, including high power density, high efficiency, and low noise.

The design requirements for the electric motor include a power output of 100 kW, a torque output of 200 Nm, and an efficiency of 95%. The motor must also meet the requirements of the EV’s powertrain system, including a high power density and low noise.

To optimize the electric motor design, we used a combination of simulation tools and experimental methods. We used finite element analysis (FEA) software to simulate the magnetic field distribution and thermal performance of the motor. We also used computer-aided design (CAD) software to create and modify the motor design.

The simulation results showed that the original motor design had a number of limitations, including a low power density and high core loss. To address these limitations, we optimized the motor design by changing the magnetic material, coil design, and geometry. We also used a new cooling system to improve the thermal performance of the motor.

The experimental results showed that the optimized motor design met the requirements of the EV’s powertrain system, including high power density, high efficiency, and low noise. The motor also showed a significant improvement in performance compared to the original design.

This case study demonstrates the importance of electric motor design optimization for real-world applications. By using a combination of simulation tools and experimental methods, we were able to optimize the motor design and meet the requirements of the EV’s powertrain system. The optimized motor design also showed a significant improvement in performance compared to the original design.

The key takeaways from this case study are the importance of using simulation tools and experimental methods to optimize electric motor design, and the need to consider the specific requirements of the application when designing the motor. By following these best practices, designers can create optimized electric motor designs that meet the demands of modern applications.

Best Practices for Electric Motor Magnetic Design: Lessons Learned from Industry Experts

Electric motor magnetic design is a complex and nuanced field, requiring a deep understanding of magnetic principles, materials, and design techniques. To achieve optimal motor performance and efficiency, designers must follow best practices and avoid common pitfalls. In this article, we will gather insights from industry experts on best practices for electric motor magnetic design, highlighting common mistakes to avoid and tips for achieving optimal motor performance.

One of the most critical best practices in electric motor magnetic design is to carefully select the magnetic material. The choice of magnetic material can significantly impact motor performance, efficiency, and cost. Industry experts recommend selecting materials with high permeability, low core loss, and high temperature stability. Neodymium iron boron (NdFeB) and ferrite are popular choices for electric motor magnetic design due to their high efficiency and low cost.

Another best practice is to optimize the magnetic circuit design. The magnetic circuit design should be optimized to minimize energy losses and maximize motor efficiency. Industry experts recommend using finite element analysis (FEA) software to simulate and analyze the magnetic field distribution and thermal performance of the motor. This can help identify areas for improvement and optimize the design for optimal performance.

Coil design is also a critical aspect of electric motor magnetic design. The coil design should be optimized to minimize energy losses and maximize motor efficiency. Industry experts recommend using computer-aided design (CAD) software to create and modify the coil design, and to simulate and analyze the magnetic field distribution and thermal performance of the coil.

Geometry is also an important consideration in electric motor magnetic design. The geometry of the motor should be optimized to minimize energy losses and maximize motor efficiency. Industry experts recommend using FEA software to simulate and analyze the magnetic field distribution and thermal performance of the motor, and to optimize the geometry for optimal performance.

Finally, industry experts recommend testing and validating the motor design using experimental methods. This can help identify areas for improvement and optimize the design for optimal performance. Experimental methods can also help validate the simulation results and ensure that the motor design meets the required specifications.

By following these best practices and avoiding common pitfalls, designers can create optimized electric motor magnetic designs that meet the demands of modern applications. The key takeaways from this article are the importance of selecting the right magnetic material, optimizing the magnetic circuit design, coil design, and geometry, and testing and validating the motor design using experimental methods.

Future Directions in Electric Motor Magnetic Design: Emerging Trends and Technologies

The field of electric motor magnetic design is constantly evolving, with new trends and technologies emerging to improve motor performance, efficiency, and cost. In this article, we will explore some of the emerging trends and technologies in electric motor magnetic design, including advancements in magnetic materials, coil design, and simulation tools.

One of the most significant emerging trends in electric motor magnetic design is the development of new magnetic materials with improved properties. For example, researchers are working on developing new rare-earth-free magnetic materials that can match the performance of traditional rare-earth-based materials. These new materials have the potential to reduce the cost and environmental impact of electric motor production.

Another emerging trend in electric motor magnetic design is the use of advanced coil design techniques. For example, researchers are working on developing new coil designs that can improve motor efficiency and reduce energy losses. These new coil designs use advanced materials and manufacturing techniques to create coils with improved thermal and electrical properties.

Simulation tools are also playing an increasingly important role in electric motor magnetic design. Advanced simulation tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), are being used to simulate and optimize motor performance. These tools can help designers to identify areas for improvement and optimize the design for optimal performance.

Artificial intelligence (AI) and machine learning (ML) are also being used in electric motor magnetic design to improve motor performance and efficiency. AI and ML algorithms can be used to analyze large amounts of data and identify patterns and trends that can inform design decisions. These algorithms can also be used to optimize motor performance in real-time, allowing for more efficient and effective motor operation.

The Internet of Things (IoT) is also having an impact on electric motor magnetic design. The IoT allows for the connection of motors and other devices to the internet, enabling real-time monitoring and control. This can help to improve motor performance and efficiency, as well as reduce maintenance costs.

In conclusion, the field of electric motor magnetic design is constantly evolving, with new trends and technologies emerging to improve motor performance, efficiency, and cost. By staying up-to-date with the latest developments and advancements, designers can create optimized electric motor magnetic designs that meet the demands of modern applications.