Unlocking the Power of Virtual Prototyping for Electric Vehicles

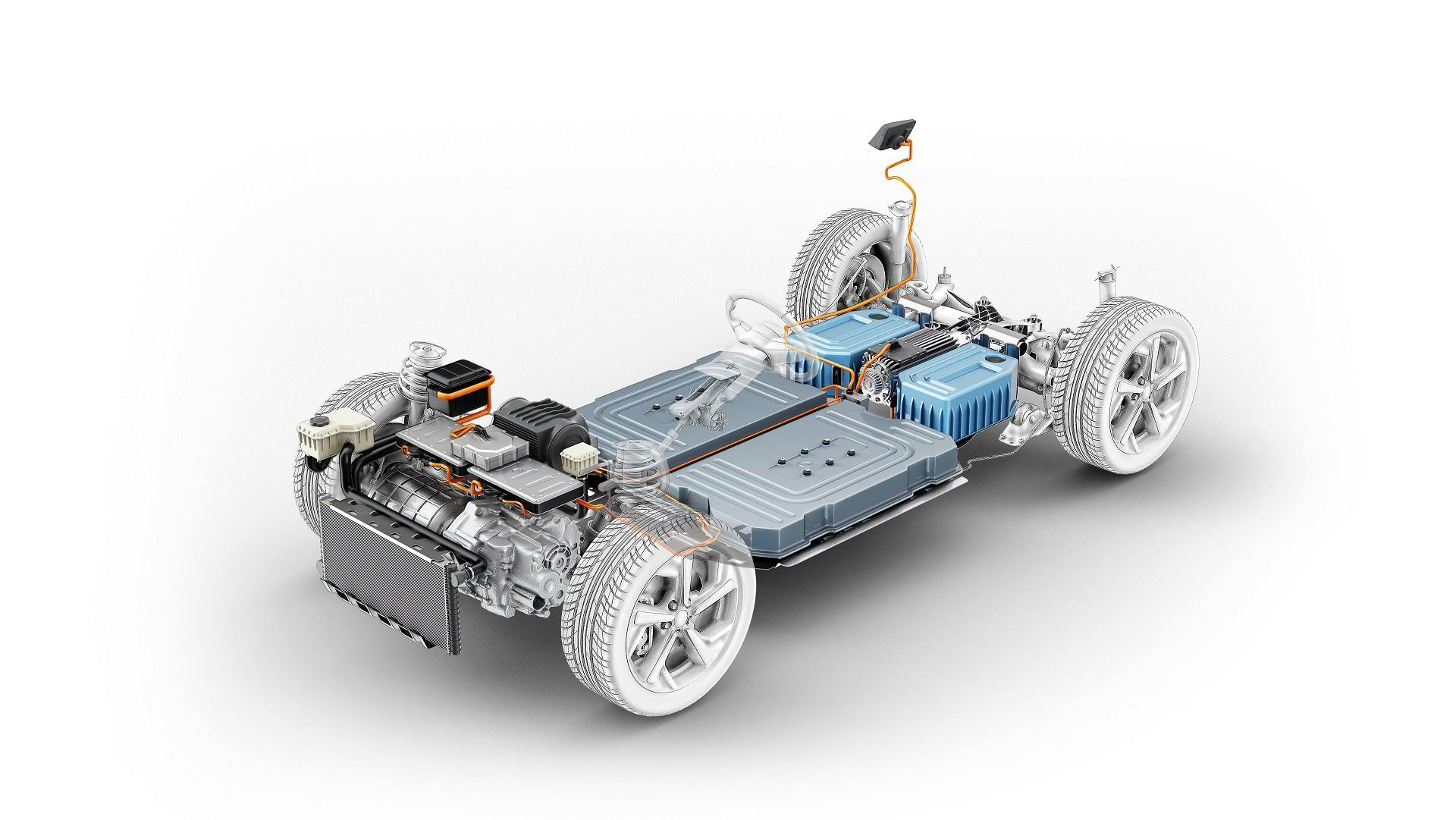

The automotive industry is undergoing a significant transformation with the growing importance of electric vehicles (EVs). As governments and consumers increasingly demand more sustainable and environmentally friendly transportation options, manufacturers are under pressure to develop and bring to market innovative EV solutions. Advanced modeling and simulation techniques, including electric vehicle modeling and simulation, play a crucial role in accelerating EV innovation and reducing development time.

Virtual prototyping has emerged as a game-changer in the EV development process. By creating digital models of EVs and simulating their behavior under various operating conditions, manufacturers can test and validate different design configurations, reducing the need for physical prototypes and minimizing the risk of costly rework. This approach enables the optimization of EV performance, efficiency, and reliability, while also improving overall development efficiency.

The use of advanced modeling and simulation techniques is critical to the success of virtual prototyping. These techniques enable the accurate modeling of complex EV systems, including battery management, electric motor control, and vehicle dynamics. By simulating the behavior of these systems, manufacturers can identify potential issues and optimize EV performance, reducing energy consumption and improving vehicle range.

The benefits of virtual prototyping for EV development are numerous. It enables manufacturers to reduce development time and costs, improve product quality, and enhance innovation. By leveraging advanced modeling and simulation techniques, manufacturers can create more efficient, sustainable, and environmentally friendly EVs that meet the growing demands of consumers and governments.

How to Build Accurate Electric Vehicle Models for Simulation

Building accurate electric vehicle models for simulation is a critical step in the electric vehicle development process. Advanced modeling and simulation techniques, including electric vehicle modeling and simulation, require accurate models to produce reliable results. In this section, we will provide a step-by-step guide on building accurate electric vehicle models for simulation.

Step 1: Selecting Modeling Tools

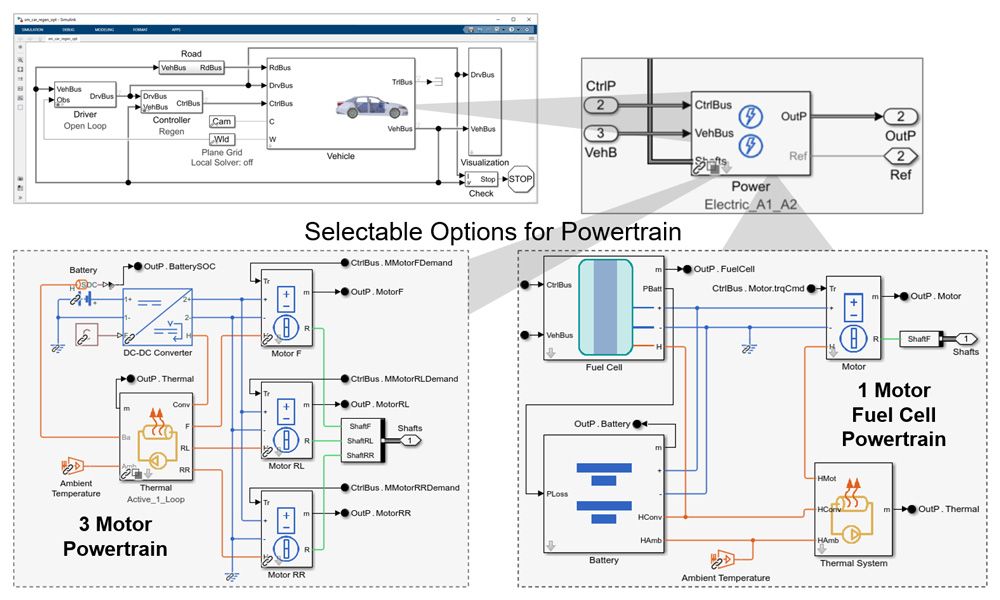

The first step in building accurate electric vehicle models is to select the right modeling tools. There are several modeling tools available, including MATLAB, Simulink, and Modelica. The choice of modeling tool depends on the specific requirements of the project and the expertise of the modeling team.

Step 2: Defining Model Parameters

Once the modeling tool is selected, the next step is to define the model parameters. This includes defining the physical parameters of the electric vehicle, such as the battery chemistry, electric motor characteristics, and vehicle dynamics. The model parameters should be based on real-world data and should be validated through experimentation and testing.

Step 3: Validating Model Accuracy

The final step in building accurate electric vehicle models is to validate the model accuracy. This involves comparing the simulation results with real-world data and experimentation results. The model should be validated for different operating conditions, including different drive cycles, temperatures, and battery states of charge.

Factors to Consider

When building accurate electric vehicle models, there are several factors to consider. These include:

Battery Chemistry: The battery chemistry should be accurately modeled, including the battery’s state of charge, state of health, and internal resistance.

Electric Motor Characteristics: The electric motor characteristics should be accurately modeled, including the motor’s efficiency, torque, and speed.

Vehicle Dynamics: The vehicle dynamics should be accurately modeled, including the vehicle’s mass, inertia, and aerodynamics.

By following these steps and considering these factors, accurate electric vehicle models can be built for simulation. These models can be used to optimize electric vehicle performance and efficiency, reduce energy consumption, and improve vehicle range.

Leveraging Simulation to Optimize Electric Vehicle Performance and Efficiency

Simulation plays a crucial role in optimizing electric vehicle (EV) performance and efficiency. By using advanced modeling and simulation techniques, such as electric vehicle modeling and simulation, manufacturers can analyze different drive cycles, evaluate battery management strategies, and optimize electric motor control algorithms. This enables the development of more efficient, sustainable, and environmentally friendly EVs that meet the growing demands of consumers and governments.

Analysis of Different Drive Cycles

Simulation allows manufacturers to analyze different drive cycles, including urban, highway, and combined cycles. This enables the evaluation of EV performance and efficiency under various operating conditions, including different temperatures, road types, and traffic patterns. By analyzing these drive cycles, manufacturers can optimize EV performance and efficiency, reducing energy consumption and improving vehicle range.

Evaluation of Battery Management Strategies

Simulation also enables the evaluation of different battery management strategies, including charging and discharging profiles, state of charge management, and battery health monitoring. By optimizing battery management strategies, manufacturers can improve EV efficiency, reduce energy consumption, and extend battery life.

Optimization of Electric Motor Control Algorithms

Simulation allows manufacturers to optimize electric motor control algorithms, including torque control, speed control, and efficiency optimization. By optimizing these algorithms, manufacturers can improve EV performance, reduce energy consumption, and improve overall efficiency.

Benefits of Using Simulation

The use of simulation in EV development offers several benefits, including:

Reduced Energy Consumption: Simulation enables the optimization of EV performance and efficiency, reducing energy consumption and improving vehicle range.

Improved Vehicle Range: By optimizing battery management strategies and electric motor control algorithms, manufacturers can improve vehicle range and reduce the need for frequent charging.

Increased Efficiency: Simulation enables the optimization of EV performance and efficiency, reducing energy consumption and improving overall efficiency.

By leveraging simulation in EV development, manufacturers can create more efficient, sustainable, and environmentally friendly EVs that meet the growing demands of consumers and governments.

Case Study: Simulation-Driven Development of a High-Performance Electric Vehicle

A leading automotive manufacturer recently developed a high-performance electric vehicle using advanced modeling and simulation techniques. The vehicle, which features a state-of-the-art electric powertrain and advanced battery management system, was designed to deliver exceptional performance, efficiency, and range.

Simulation-Driven Development Process

The development process for the vehicle was heavily reliant on simulation, with the manufacturer using advanced modeling and simulation tools to optimize the vehicle’s performance, efficiency, and range. The simulation-driven development process involved the creation of detailed models of the vehicle’s powertrain, battery, and electrical systems, as well as the simulation of various operating conditions, including different drive cycles, temperatures, and road types.

Role of Simulation in Optimizing Vehicle Performance

Simulation played a critical role in optimizing the vehicle’s performance, with the manufacturer using advanced modeling and simulation techniques to evaluate and optimize the vehicle’s powertrain, battery, and electrical systems. The simulation results were used to inform design decisions and optimize the vehicle’s performance, efficiency, and range.

Benefits of Simulation-Driven Development

The use of simulation-driven development for the high-performance electric vehicle delivered several benefits, including:

Reduced Development Time: The simulation-driven development process enabled the manufacturer to reduce development time and costs, while also improving the vehicle’s performance, efficiency, and range.

Improved Vehicle Performance: The simulation results were used to optimize the vehicle’s powertrain, battery, and electrical systems, resulting in improved vehicle performance, efficiency, and range.

Increased Efficiency: The simulation-driven development process enabled the manufacturer to optimize the vehicle’s efficiency, resulting in reduced energy consumption and improved overall efficiency.

By leveraging advanced modeling and simulation techniques, the manufacturer was able to develop a high-performance electric vehicle that delivers exceptional performance, efficiency, and range. The use of simulation-driven development also enabled the manufacturer to reduce development time and costs, while also improving the vehicle’s overall efficiency and performance.

Integrating Simulation with Physical Testing for Electric Vehicle Development

Integrating simulation with physical testing is a crucial step in the electric vehicle development process. By combining simulation and physical testing, manufacturers can validate physical test results, reduce testing time, and improve overall vehicle reliability. In this section, we will discuss the importance of integrating simulation with physical testing and explain how simulation can be used to support physical testing.

Benefits of Integrating Simulation with Physical Testing

Integrating simulation with physical testing offers several benefits, including:

Validation of Physical Test Results: Simulation can be used to validate physical test results, ensuring that the test results are accurate and reliable.

Reduction of Testing Time: Simulation can be used to reduce testing time, allowing manufacturers to test and validate vehicle performance more quickly and efficiently.

Improvement of Vehicle Reliability: Simulation can be used to improve vehicle reliability, by identifying and addressing potential issues before they become major problems.

How Simulation Supports Physical Testing

Simulation can be used to support physical testing in several ways, including:

Predicting Vehicle Performance: Simulation can be used to predict vehicle performance, allowing manufacturers to identify potential issues and optimize vehicle design before physical testing.

Optimizing Test Procedures: Simulation can be used to optimize test procedures, reducing testing time and improving the accuracy of test results.

Validating Test Results: Simulation can be used to validate test results, ensuring that the test results are accurate and reliable.

By integrating simulation with physical testing, manufacturers can improve the efficiency and effectiveness of the electric vehicle development process, reducing development time and costs while improving overall vehicle reliability.

https://www.youtube.com/watch?v=tLGKy_Qebu0

Overcoming Challenges in Electric Vehicle Modeling and Simulation

Electric vehicle modeling and simulation can be a complex and challenging task, requiring the consideration of multiple factors and the use of advanced techniques. In this section, we will discuss some of the common challenges associated with electric vehicle modeling and simulation, and provide tips and best practices for overcoming these challenges.

Modeling Complex Battery Behavior

One of the biggest challenges in electric vehicle modeling and simulation is modeling complex battery behavior. Batteries are complex systems that can exhibit non-linear behavior, making it difficult to accurately model their performance. To overcome this challenge, it is recommended to use advanced modeling techniques, such as electrochemical modeling, and to validate the model using experimental data.

Simulating High-Speed Electric Motor Dynamics

Another challenge in electric vehicle modeling and simulation is simulating high-speed electric motor dynamics. Electric motors can operate at high speeds, making it difficult to accurately model their behavior. To overcome this challenge, it is recommended to use advanced modeling techniques, such as finite element analysis, and to validate the model using experimental data.

Ensuring Model Accuracy

Ensuring model accuracy is critical in electric vehicle modeling and simulation. To overcome this challenge, it is recommended to use a combination of modeling techniques, such as empirical modeling and physics-based modeling, and to validate the model using experimental data.

Tips and Best Practices

Here are some tips and best practices for overcoming the challenges associated with electric vehicle modeling and simulation:

Use advanced modeling techniques, such as electrochemical modeling and finite element analysis, to accurately model complex battery behavior and high-speed electric motor dynamics.

Validate the model using experimental data to ensure accuracy and reliability.

Use a combination of modeling techniques, such as empirical modeling and physics-based modeling, to ensure model accuracy and reliability.

By following these tips and best practices, engineers and researchers can overcome the challenges associated with electric vehicle modeling and simulation, and develop accurate and reliable models that can be used to optimize electric vehicle performance and efficiency.

Future Directions in Electric Vehicle Modeling and Simulation

The field of electric vehicle modeling and simulation is rapidly evolving, with new technologies and techniques emerging all the time. In this section, we will discuss some of the future directions in electric vehicle modeling and simulation, including the integration of artificial intelligence and machine learning, the use of cloud-based simulation platforms, and the development of more advanced modeling tools.

Integration of Artificial Intelligence and Machine Learning

One of the most exciting developments in electric vehicle modeling and simulation is the integration of artificial intelligence (AI) and machine learning (ML) techniques. AI and ML can be used to improve the accuracy and efficiency of electric vehicle models, and to enable the simulation of complex systems and behaviors. For example, AI and ML can be used to optimize electric vehicle control systems, and to predict and prevent faults and failures.

Use of Cloud-Based Simulation Platforms

Another future direction in electric vehicle modeling and simulation is the use of cloud-based simulation platforms. Cloud-based simulation platforms can provide a scalable and flexible way to perform simulations, and can enable the collaboration and sharing of models and results. For example, cloud-based simulation platforms can be used to simulate the behavior of electric vehicles in different environments and scenarios, and to optimize their performance and efficiency.

Development of More Advanced Modeling Tools

The development of more advanced modeling tools is also an important future direction in electric vehicle modeling and simulation. More advanced modeling tools can provide a more accurate and detailed representation of electric vehicle systems and behaviors, and can enable the simulation of complex phenomena and effects. For example, more advanced modeling tools can be used to simulate the behavior of electric vehicle batteries and electric motors, and to optimize their performance and efficiency.

Benefits of Future Directions

The future directions in electric vehicle modeling and simulation have the potential to bring many benefits, including:

Improved accuracy and efficiency of electric vehicle models

Enhanced collaboration and sharing of models and results

Increased scalability and flexibility of simulation platforms

Improved optimization of electric vehicle performance and efficiency

By embracing these future directions, the field of electric vehicle modeling and simulation can continue to evolve and improve, and can play an increasingly important role in the development of electric vehicles.

Conclusion: Accelerating Electric Vehicle Innovation through Advanced Modeling and Simulation

In conclusion, advanced modeling and simulation techniques are playing a crucial role in accelerating electric vehicle innovation and reducing development time. By leveraging these techniques, manufacturers can optimize electric vehicle performance and efficiency, reduce energy consumption, and improve vehicle range. The use of virtual prototyping, simulation-driven development, and integration of simulation with physical testing are just a few examples of how advanced modeling and simulation techniques can be applied to electric vehicle development.

Key Takeaways

The following are the key takeaways from this article:

Advanced modeling and simulation techniques are essential for accelerating electric vehicle innovation and reducing development time.

Virtual prototyping can be used to optimize electric vehicle performance and efficiency, and to reduce the need for physical prototypes.

Simulation-driven development can be used to optimize electric vehicle performance and efficiency, and to reduce development time.

Integration of simulation with physical testing can be used to validate physical test results, reduce testing time, and improve overall vehicle reliability.

Future Directions

The future of electric vehicle modeling and simulation is exciting, with new technologies and techniques emerging all the time. The integration of artificial intelligence and machine learning, the use of cloud-based simulation platforms, and the development of more advanced modeling tools are just a few examples of the future directions in electric vehicle modeling and simulation.

Importance of Advanced Modeling and Simulation Techniques

Advanced modeling and simulation techniques are critical for accelerating electric vehicle innovation and reducing development time. By leveraging these techniques, manufacturers can optimize electric vehicle performance and efficiency, reduce energy consumption, and improve vehicle range. The use of advanced modeling and simulation techniques can also help to reduce the environmental impact of electric vehicles, by optimizing their performance and efficiency.