Unlocking the Full Potential of EV Batteries

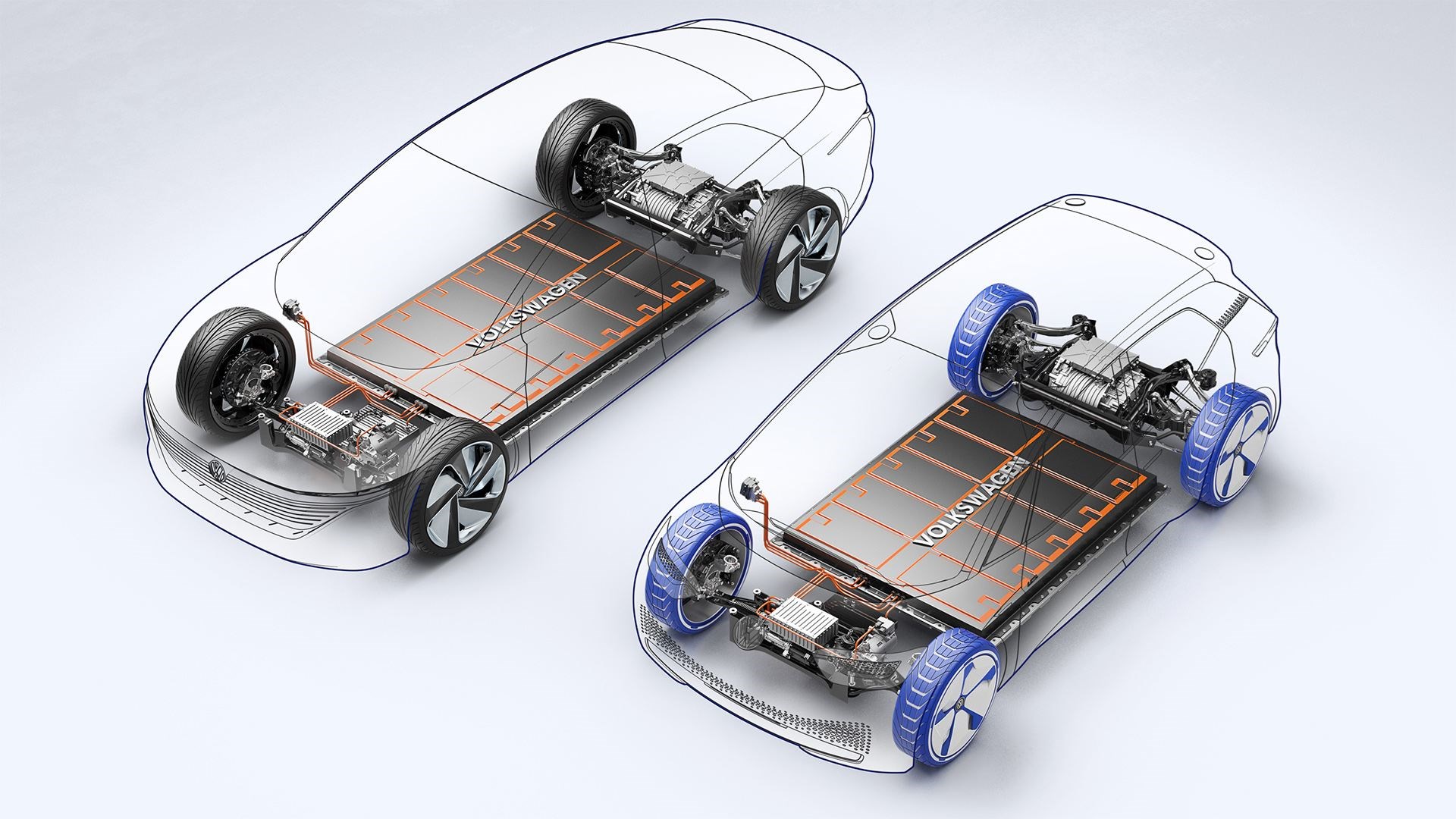

Electric vehicle battery management systems (BMS) play a crucial role in optimizing the performance, range, and overall efficiency of electric vehicles (EVs). A well-designed BMS can significantly impact the driving experience, making it essential for EV manufacturers to invest in advanced battery management technologies. By optimizing battery health, reducing charging time, and improving overall efficiency, electric vehicle battery management systems can unlock the full potential of EV batteries.

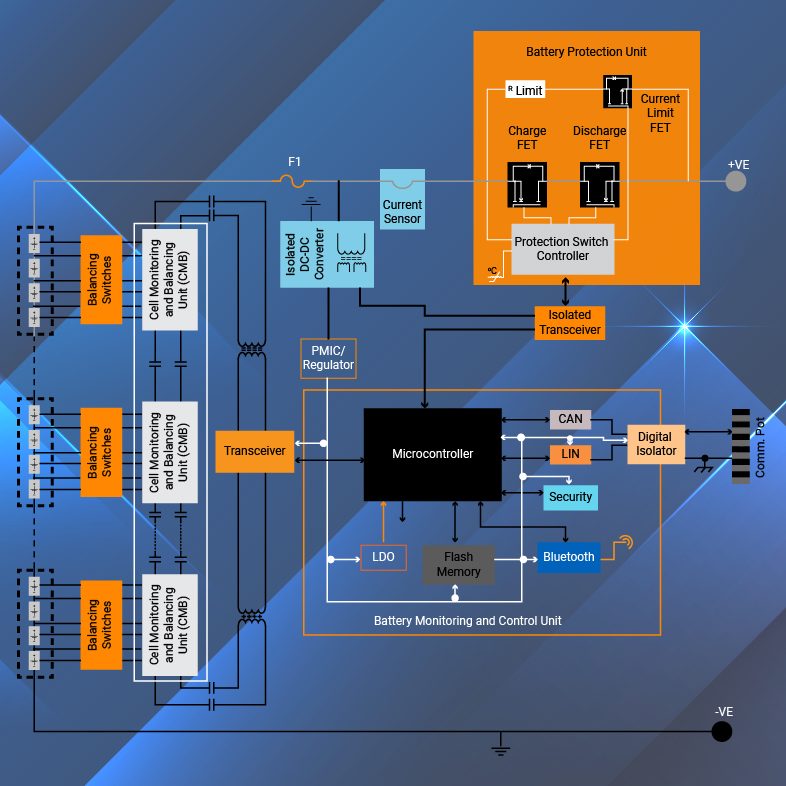

The importance of BMS in EVs cannot be overstated. A BMS is responsible for monitoring and controlling the battery’s state of charge, voltage, and temperature, ensuring that the battery operates within a safe and efficient range. Advanced BMS can also detect and correct cell imbalances, reducing the risk of battery degradation and prolonging its lifespan. Furthermore, a well-designed BMS can optimize charging and discharging strategies, reducing charging time and improving overall efficiency.

Electric vehicle battery management systems can also have a significant impact on the environment. By optimizing battery performance and reducing energy consumption, EVs can minimize their carbon footprint and contribute to a more sustainable transportation sector. Moreover, advanced BMS can enable the integration of renewable energy sources, such as solar and wind power, into the EV’s energy mix, further reducing the vehicle’s environmental impact.

In addition to their technical benefits, electric vehicle battery management systems can also provide economic advantages. By reducing energy consumption and prolonging battery lifespan, EVs can lower operating costs and reduce the need for frequent battery replacements. This can result in significant cost savings for EV owners and operators, making EVs a more attractive option for those looking to reduce their transportation costs.

As the demand for electric vehicles continues to grow, the importance of advanced battery management systems will only continue to increase. By investing in innovative BMS technologies, EV manufacturers can unlock the full potential of EV batteries, providing a better driving experience, reducing environmental impact, and improving economic efficiency. As the EV industry continues to evolve, it is likely that electric vehicle battery management systems will play an increasingly critical role in shaping the future of sustainable transportation.

How to Choose the Right Battery Management System for Your Electric Vehicle

Selecting the ideal battery management system (BMS) for an electric vehicle (EV) is a critical decision that can significantly impact the vehicle’s performance, range, and overall efficiency. With the numerous BMS options available, it can be challenging to determine which one is best suited for a particular EV. In this article, we will provide a comprehensive guide on choosing the right BMS for electric vehicles, including factors to consider and the pros and cons of different BMS architectures and topologies.

One of the primary factors to consider when selecting a BMS is the type of battery used in the EV. Different battery chemistries, such as lithium-ion, nickel-metal hydride, and lead-acid, require specific BMS configurations to optimize their performance and lifespan. For example, lithium-ion batteries require a BMS that can accurately monitor and control their state of charge, voltage, and temperature to prevent overheating and degradation.

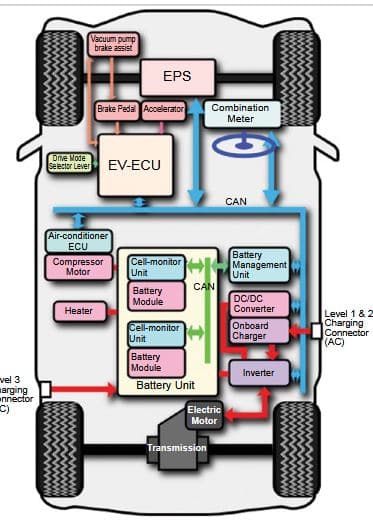

Another crucial factor to consider is the vehicle’s specifications, including its power output, torque, and driving range. A BMS that is designed for a high-performance EV will require more advanced features, such as high-speed charging and regenerative braking, than a BMS designed for a low-range EV. Additionally, the BMS should be compatible with the vehicle’s onboard computer and communication protocols to ensure seamless integration and data exchange.

Driving habits and patterns are also essential considerations when selecting a BMS. For example, an EV used for frequent short trips may require a BMS that can optimize battery performance for short-range driving, while an EV used for long-distance driving may require a BMS that can optimize battery performance for extended driving ranges.

There are several BMS architectures and topologies available, each with its pros and cons. For example, centralized BMS architectures are commonly used in high-performance EVs, as they offer advanced features and high-speed processing capabilities. However, they can be more expensive and complex to implement than decentralized BMS architectures, which are often used in low-range EVs.

Another BMS topology is the modular BMS, which consists of multiple modules that can be easily integrated and scaled to meet the specific needs of an EV. Modular BMS offer flexibility and scalability, but can be more expensive than centralized or decentralized BMS architectures.

In conclusion, selecting the right BMS for an electric vehicle requires careful consideration of several factors, including battery type, vehicle specifications, driving habits, and BMS architecture and topology. By understanding these factors and the pros and cons of different BMS options, EV manufacturers and owners can choose a BMS that optimizes the performance, range, and overall efficiency of their electric vehicle.

The Role of Cell Balancing in Electric Vehicle Battery Management

Cell balancing is a critical component of electric vehicle battery management systems (BMS), playing a vital role in maintaining optimal battery performance, prolonging battery lifespan, and ensuring safe operation. In this article, we will delve into the significance of cell balancing in EV battery management, discussing the consequences of imbalance and the benefits of active cell balancing.

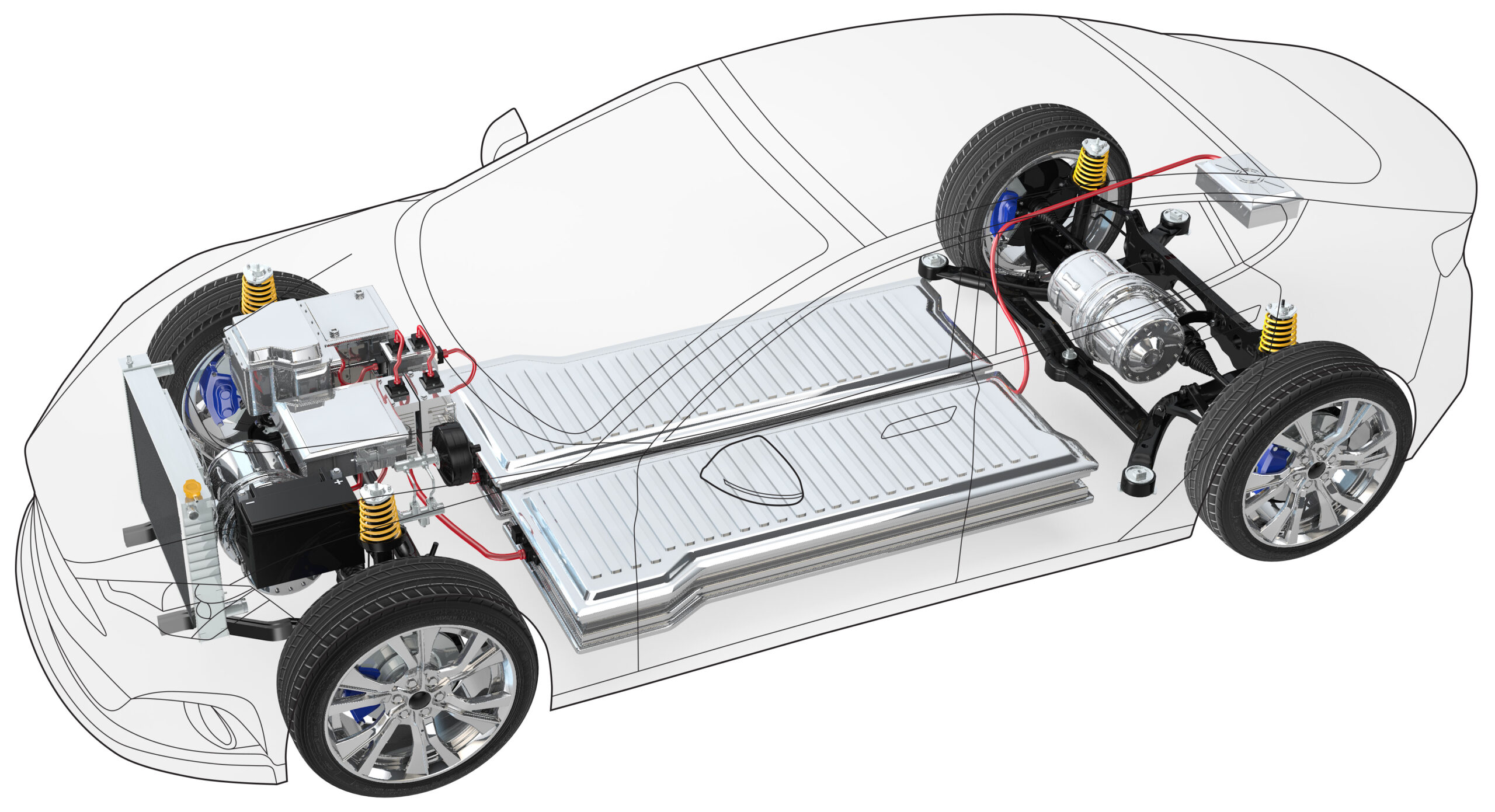

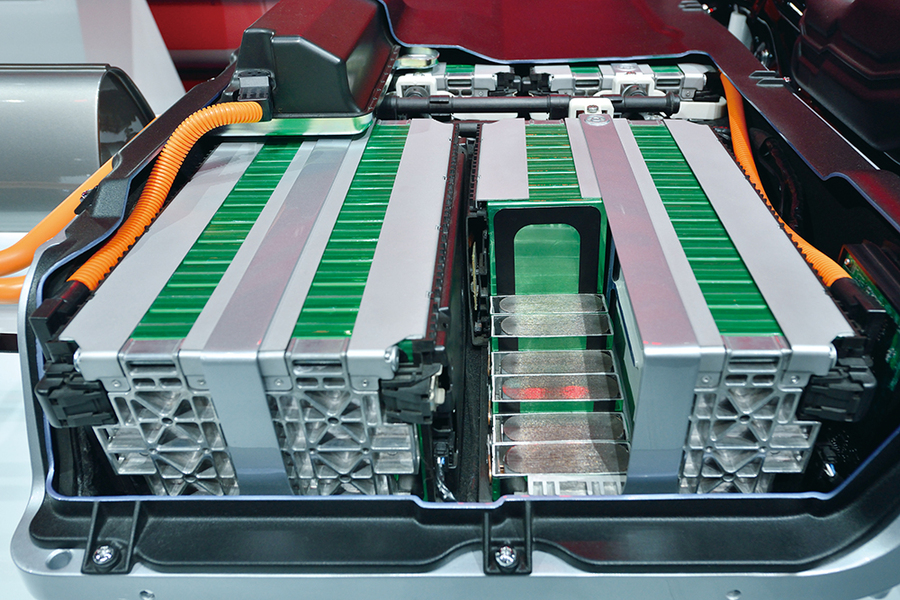

In an electric vehicle battery pack, multiple cells are connected in series and parallel to achieve the desired voltage and capacity. However, due to manufacturing variations, temperature differences, and aging, cells can become imbalanced, leading to reduced battery performance, decreased range, and increased risk of battery failure. Cell imbalance can occur in two forms: voltage imbalance and state of charge (SOC) imbalance.

Voltage imbalance occurs when the voltage of individual cells deviates from the average voltage of the battery pack. This can lead to overcharging or over-discharging of certain cells, causing damage to the battery and reducing its lifespan. SOC imbalance, on the other hand, occurs when the SOC of individual cells deviates from the average SOC of the battery pack. This can lead to reduced battery capacity, decreased range, and increased risk of battery failure.

Active cell balancing is a technique used in advanced BMS to detect and correct cell imbalances in real-time. This involves monitoring the voltage and SOC of individual cells and adjusting the charging and discharging currents to balance the cells. Active cell balancing can be achieved through various methods, including passive balancing, active balancing, and hybrid balancing.

Passive balancing involves dissipating excess energy from overcharged cells through resistors or other dissipative elements. This method is simple and cost-effective but can lead to energy losses and reduced battery efficiency. Active balancing, on the other hand, involves transferring energy from overcharged cells to undercharged cells through power electronics or other energy transfer mechanisms. This method is more efficient and effective but can be more complex and expensive.

Hybrid balancing combines the benefits of passive and active balancing, using a combination of dissipative elements and power electronics to balance the cells. This method offers a compromise between energy efficiency and complexity, making it a popular choice for many EV manufacturers.

In conclusion, cell balancing is a critical component of electric vehicle battery management systems, playing a vital role in maintaining optimal battery performance, prolonging battery lifespan, and ensuring safe operation. By understanding the consequences of cell imbalance and the benefits of active cell balancing, EV manufacturers and owners can optimize their battery management systems to achieve better performance, range, and overall efficiency.

Real-World Examples: Tesla’s Battery Management System and the Nissan Leaf’s BMS

Tesla and Nissan are two of the leading electric vehicle (EV) manufacturers that have developed advanced battery management systems (BMS) to optimize the performance, range, and overall efficiency of their vehicles. In this article, we will examine the BMS used in the Tesla Model S and the Nissan Leaf, analyzing their strengths, weaknesses, and innovative features.

Tesla’s BMS is considered one of the most advanced in the industry, with a sophisticated architecture that integrates multiple components, including battery management, thermal management, and power electronics. The system uses a combination of hardware and software to monitor and control the battery’s state of charge, voltage, and temperature, ensuring optimal performance and longevity.

One of the key features of Tesla’s BMS is its ability to balance the battery cells in real-time, using a technique called “active balancing.” This involves transferring energy from overcharged cells to undercharged cells, ensuring that all cells are operating within a safe and efficient range. Tesla’s BMS also includes advanced thermal management features, such as liquid cooling and heating, to maintain optimal battery temperatures and extend lifespan.

The Nissan Leaf’s BMS, on the other hand, uses a more traditional architecture, with a focus on simplicity and cost-effectiveness. The system uses a combination of hardware and software to monitor and control the battery’s state of charge, voltage, and temperature, but does not include advanced features like active balancing or liquid cooling.

Despite these differences, both Tesla’s and Nissan’s BMS have been successful in optimizing the performance and range of their vehicles. Tesla’s Model S, for example, has a range of up to 373 miles on a single charge, while the Nissan Leaf has a range of up to 147 miles. Both vehicles have also received high praise for their smooth and quiet operation, thanks in part to their advanced BMS.

In conclusion, the BMS used in the Tesla Model S and the Nissan Leaf are two examples of the innovative solutions being developed to optimize the performance, range, and overall efficiency of electric vehicles. By analyzing the strengths and weaknesses of these systems, we can gain a better understanding of the importance of advanced BMS in the EV industry and the potential for future innovation and improvement.

Thermal Management in Electric Vehicle Battery Management Systems

Thermal management is a critical component of electric vehicle battery management systems (BMS), playing a vital role in maintaining battery health and performance. Temperature affects battery chemistry and lifespan, and improper thermal management can lead to reduced battery performance, decreased range, and increased risk of battery failure.

Battery temperature affects the chemical reactions that occur within the battery, influencing its performance and lifespan. High temperatures can cause the battery to degrade faster, while low temperatures can reduce its performance and range. Therefore, it is essential to maintain the battery within a safe and optimal temperature range.

There are several strategies for effective thermal management in electric vehicle BMS, including cooling systems and thermal modeling. Cooling systems can be used to remove heat from the battery, while thermal modeling can be used to predict and optimize battery temperature.

Cooling systems can be classified into two main categories: active and passive. Active cooling systems use external energy sources, such as fans or pumps, to remove heat from the battery. Passive cooling systems, on the other hand, rely on natural convection or radiation to dissipate heat.

Thermal modeling is a critical component of thermal management, allowing engineers to predict and optimize battery temperature. Thermal models can be used to simulate various thermal scenarios, including different ambient temperatures, driving patterns, and battery configurations.

Advanced thermal management systems can also be integrated with other BMS components, such as battery management and power electronics. This allows for real-time monitoring and control of battery temperature, ensuring optimal performance and longevity.

In conclusion, thermal management is a critical component of electric vehicle BMS, playing a vital role in maintaining battery health and performance. By understanding the importance of thermal management and implementing effective strategies, such as cooling systems and thermal modeling, engineers can optimize battery performance and lifespan, ensuring a safe and efficient driving experience.

Advances in Battery Management System Technology: Trends and Future Directions

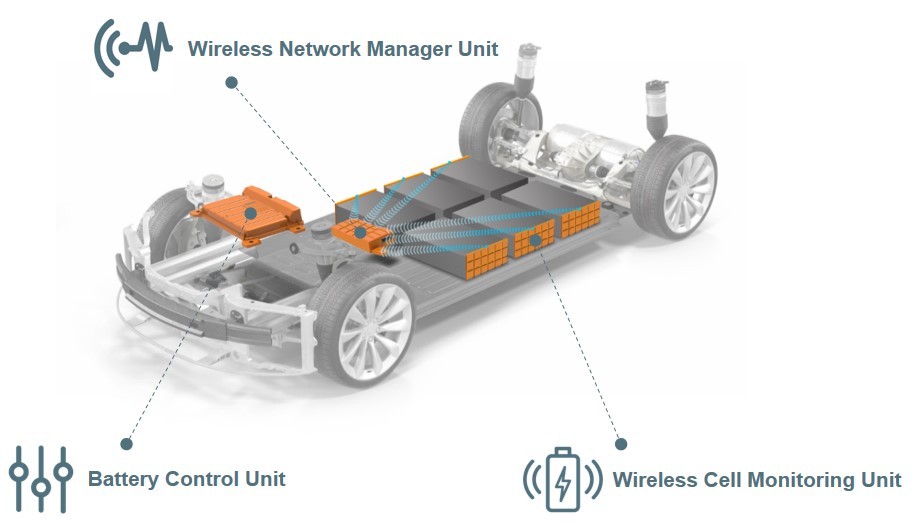

The electric vehicle battery management system (BMS) market is rapidly evolving, driven by advances in technology and increasing demand for electric vehicles. In this article, we will explore the latest advancements in BMS technology, including the integration of artificial intelligence, machine learning, and IoT connectivity.

One of the most significant trends in BMS technology is the integration of artificial intelligence (AI) and machine learning (ML) algorithms. These algorithms can be used to optimize battery performance, predict battery health, and detect potential faults. AI and ML can also be used to improve the accuracy of battery state of charge (SOC) and state of health (SOH) estimates, enabling more efficient battery management.

Another trend in BMS technology is the adoption of IoT connectivity. IoT connectivity enables the exchange of data between the BMS and other systems, such as the vehicle’s onboard computer and the cloud. This enables real-time monitoring and control of battery performance, as well as remote software updates and diagnostics.

Solid-state batteries are another emerging trend in BMS technology. Solid-state batteries replace the traditional liquid electrolyte with a solid material, enhancing safety, energy density, and charging speeds. Solid-state batteries also offer improved thermal management, reduced self-discharge, and increased cycle life.

Advanced battery chemistries, such as lithium-air and sodium-ion, are also being developed. These chemistries offer improved energy density, reduced costs, and enhanced safety. However, they also present new challenges, such as the need for advanced BMS algorithms and thermal management systems.

In conclusion, the BMS market is rapidly evolving, driven by advances in technology and increasing demand for electric vehicles. The integration of AI, ML, and IoT connectivity, as well as the adoption of solid-state batteries and advanced battery chemistries, are just a few of the trends shaping the future of BMS technology.

Best Practices for Electric Vehicle Battery Maintenance and Repair

Proper maintenance and repair of electric vehicle batteries are crucial to ensure optimal performance, extend lifespan, and prevent costly repairs. In this article, we will provide practical advice on maintaining and repairing electric vehicle batteries, including tips on charging habits, storage, and troubleshooting common issues.

Charging habits play a significant role in maintaining battery health. It is essential to follow the manufacturer’s recommended charging schedule and avoid overcharging or undercharging the battery. Overcharging can cause the battery to heat up, reducing its lifespan, while undercharging can lead to reduced performance and range.

Storage is another critical factor in maintaining battery health. Electric vehicle batteries should be stored in a cool, dry place, away from direct sunlight and moisture. It is also essential to keep the battery charged to the recommended level, as specified by the manufacturer.

Troubleshooting common issues is also essential to prevent costly repairs. Common issues include reduced battery performance, decreased range, and error messages. By identifying and addressing these issues promptly, electric vehicle owners can prevent more severe problems from developing.

Regular maintenance is also crucial to extend battery lifespan. This includes checking the battery’s state of charge, state of health, and temperature. By monitoring these parameters, electric vehicle owners can identify potential issues before they become major problems.

In addition to regular maintenance, it is also essential to follow proper repair procedures when issues arise. This includes using the correct tools and equipment, following the manufacturer’s instructions, and seeking professional help when necessary.

In conclusion, proper maintenance and repair of electric vehicle batteries are essential to ensure optimal performance, extend lifespan, and prevent costly repairs. By following the tips and best practices outlined in this article, electric vehicle owners can keep their batteries in top condition and enjoy a safe and efficient driving experience.

The Future of Electric Vehicle Battery Management Systems

In conclusion, the significance of advanced battery management systems in electric vehicles cannot be overstated. As the electric vehicle industry continues to evolve, the development of sophisticated BMS will play a crucial role in unlocking the full potential of EV batteries. By optimizing battery health, reducing charging time, and improving overall driving experience, advanced BMS will be instrumental in driving the widespread adoption of electric vehicles.

As we look to the future, it is clear that electric vehicle battery management systems will continue to advance, driven by innovations in technologies such as artificial intelligence, machine learning, and IoT connectivity. The integration of these technologies will enable BMS to become even more sophisticated, allowing for real-time monitoring, predictive maintenance, and optimized performance.

Furthermore, the development of new battery chemistries and solid-state batteries will require the creation of even more advanced BMS. These systems will need to be capable of managing the unique characteristics of these new battery types, ensuring optimal performance, safety, and lifespan.

As the demand for electric vehicles continues to grow, the importance of advanced battery management systems will only continue to increase. By investing in the development of sophisticated BMS, manufacturers can ensure that their electric vehicles remain competitive, efficient, and sustainable.

Ultimately, the future of electric vehicle battery management systems holds much promise. As technology continues to advance, we can expect to see even more innovative solutions that will help to drive the widespread adoption of electric vehicles. By prioritizing the development of advanced BMS, we can create a more sustainable, efficient, and environmentally friendly transportation system for generations to come.