Why Data-Driven Decision Making is Crucial for PCB Success

In the rapidly evolving world of printed circuit board (PCB) design and manufacturing, staying ahead of the competition requires more than just intuition and experience. Data-driven decision making has become essential for PCB startups to make informed decisions, optimize processes, and drive business growth. By leveraging data analytics and insights, PCB startups can unlock new opportunities, reduce costs, and improve overall efficiency.

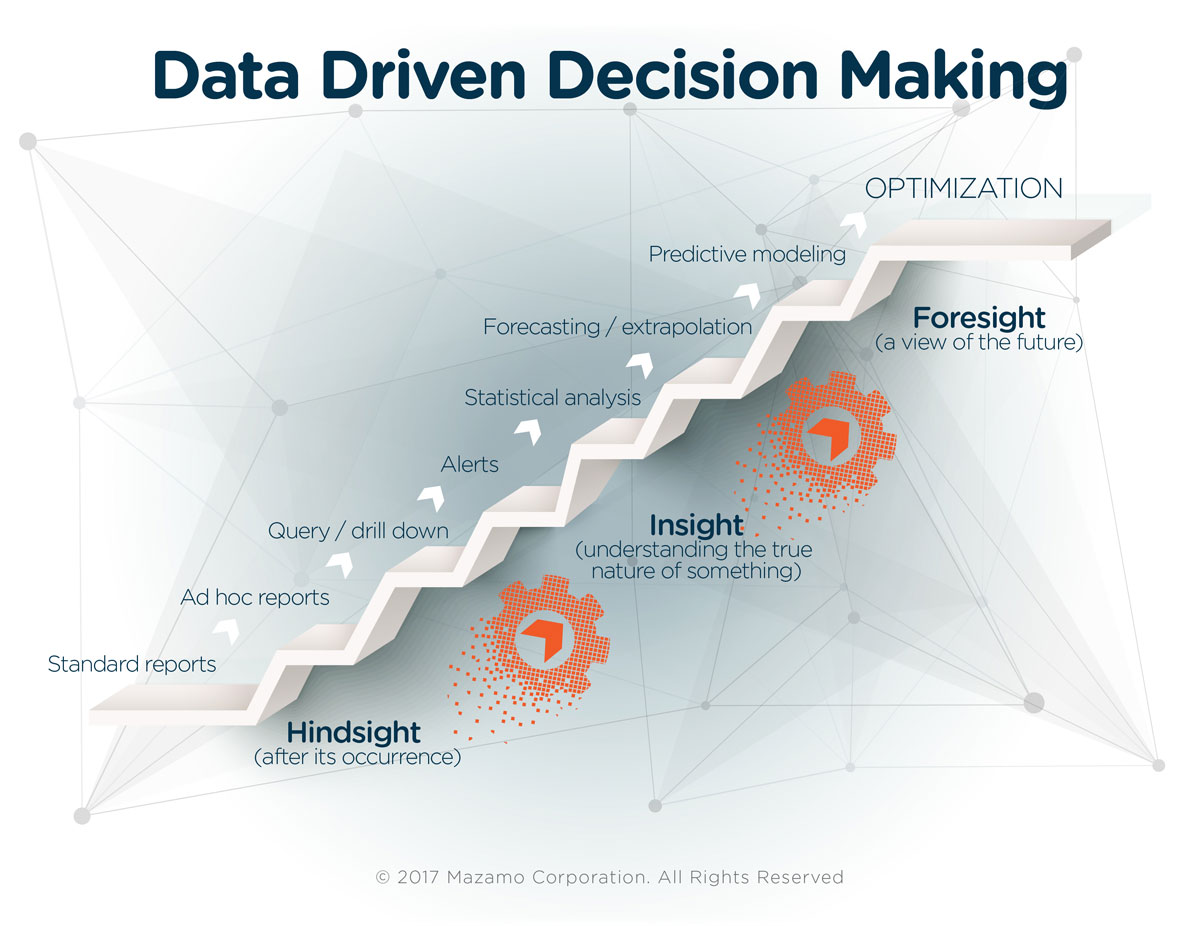

Data-driven decision making involves using data and analytics to inform design, manufacturing, and business decisions. This approach enables PCB startups to move beyond traditional methods, which often rely on guesswork and trial-and-error. By analyzing data from various sources, including design files, manufacturing processes, and customer feedback, PCB startups can identify trends, patterns, and correlations that inform strategic decisions.

One of the primary benefits of data-driven decision making for PCB startups is improved design optimization. By analyzing data from simulation tools, thermal analysis, and signal integrity analysis, designers can identify potential issues and optimize their designs for better performance, reliability, and manufacturability. This approach enables PCB startups to reduce design iterations, lower production costs, and improve time-to-market.

Data-driven decision making also plays a critical role in PCB manufacturing and quality control. By analyzing data from production processes, PCB startups can identify areas for improvement, predict defects, and optimize production workflows. This approach enables PCB startups to improve manufacturing efficiency, reduce waste, and enhance overall product quality.

Furthermore, data-driven decision making can inform business decisions in the PCB industry, including market research, customer segmentation, and supply chain optimization. By analyzing data from various sources, including market trends, customer feedback, and supplier performance, PCB startups can identify new business opportunities, optimize their supply chains, and improve customer satisfaction.

By embracing data-driven decision making, PCB startups can gain a competitive edge in the market, drive business growth, and improve overall efficiency. As the PCB industry continues to evolve, data-driven decision making will become increasingly essential for startups to stay ahead of the curve and achieve long-term success.

How to Leverage Data Analytics for PCB Design Optimization

Data analytics plays a crucial role in optimizing PCB design, enabling designers to create high-performance, reliable, and manufacturable boards. By leveraging data analytics, PCB startups can reduce design iterations, lower production costs, and improve time-to-market. In this section, we will explore how to leverage data analytics for PCB design optimization, including the use of simulation tools, thermal analysis, and signal integrity analysis.

Simulation tools are a key component of data-driven PCB design optimization. These tools enable designers to simulate the behavior of their designs, identifying potential issues and optimizing performance. For example, simulation tools can be used to analyze the thermal performance of a PCB, identifying hotspots and optimizing thermal management. Similarly, simulation tools can be used to analyze the signal integrity of a PCB, identifying potential issues and optimizing signal transmission.

Thermal analysis is another critical aspect of PCB design optimization. By analyzing thermal data, designers can identify potential thermal issues, such as hotspots and thermal gradients. This information can be used to optimize thermal management, reducing the risk of thermal-related failures. Thermal analysis can also be used to optimize the placement of components, reducing thermal stress and improving overall reliability.

Signal integrity analysis is also essential for PCB design optimization. By analyzing signal integrity data, designers can identify potential issues, such as signal attenuation and distortion. This information can be used to optimize signal transmission, reducing the risk of signal-related failures. Signal integrity analysis can also be used to optimize the placement of components, reducing signal stress and improving overall reliability.

To leverage data analytics for PCB design optimization, PCB startups should follow these best practices:

- Use simulation tools to analyze the behavior of your designs

- Conduct thermal analysis to identify potential thermal issues

- Perform signal integrity analysis to identify potential signal-related issues

- Use data analytics to optimize component placement and thermal management

- Continuously monitor and analyze data to identify areas for improvement

By following these best practices, PCB startups can leverage data analytics to optimize their PCB designs, reducing design iterations, lowering production costs, and improving time-to-market.

The Role of Big Data in PCB Manufacturing and Quality Control

Big data plays a significant role in PCB manufacturing and quality control, enabling PCB startups to optimize production processes, predict defects, and improve overall efficiency. By leveraging big data analytics, PCB startups can gain valuable insights into their manufacturing processes, identify areas for improvement, and make data-driven decisions to drive business growth.

One of the key applications of big data in PCB manufacturing is predictive maintenance. By analyzing data from sensors and machines, PCB startups can predict when equipment is likely to fail, schedule maintenance, and reduce downtime. This approach enables PCB startups to minimize the risk of equipment failure, reduce maintenance costs, and improve overall productivity.

Big data analytics can also be used to optimize production processes, such as PCB assembly and testing. By analyzing data from production lines, PCB startups can identify bottlenecks, optimize workflows, and improve overall efficiency. This approach enables PCB startups to reduce production costs, improve product quality, and increase customer satisfaction.

Machine learning algorithms are also being used in PCB manufacturing to predict defects and optimize production processes. By analyzing data from production lines, machine learning algorithms can identify patterns and anomalies, predict defects, and optimize production processes. This approach enables PCB startups to reduce the risk of defects, improve product quality, and increase customer satisfaction.

Furthermore, big data analytics can be used to improve supply chain management, enabling PCB startups to optimize inventory levels, reduce lead times, and improve overall efficiency. By analyzing data from suppliers, PCB startups can identify trends and patterns, predict demand, and optimize inventory levels. This approach enables PCB startups to reduce inventory costs, improve product availability, and increase customer satisfaction.

To leverage big data analytics in PCB manufacturing and quality control, PCB startups should follow these best practices:

- Implement a data management system to collect and analyze data from production lines

- Use machine learning algorithms to predict defects and optimize production processes

- Implement predictive maintenance to reduce downtime and improve overall productivity

- Use big data analytics to optimize supply chain management and improve overall efficiency

- Continuously monitor and analyze data to identify areas for improvement

By following these best practices, PCB startups can leverage big data analytics to optimize their manufacturing processes, predict defects, and improve overall efficiency.

Using Data to Inform Business Decisions in the PCB Industry

Data-driven decision making is not only crucial for PCB design and manufacturing, but also for business decisions. By leveraging data analytics, PCB startups can gain valuable insights into their business operations, identify areas for improvement, and make informed decisions to drive growth and profitability.

Market research is a critical aspect of business decision making in the PCB industry. By analyzing data from market trends, customer behavior, and competitor analysis, PCB startups can identify opportunities and threats, and develop strategies to stay ahead of the competition. For example, data analytics can help PCB startups identify emerging trends in the market, such as the increasing demand for IoT devices, and develop products and services to meet that demand.

Customer segmentation is another important application of data analytics in the PCB industry. By analyzing data from customer interactions, PCB startups can identify patterns and trends, and develop targeted marketing campaigns to reach their ideal customers. For example, data analytics can help PCB startups identify customers who are likely to purchase high-volume orders, and develop targeted marketing campaigns to reach those customers.

Supply chain optimization is also a critical aspect of business decision making in the PCB industry. By analyzing data from suppliers, PCB startups can identify trends and patterns, and develop strategies to optimize their supply chain. For example, data analytics can help PCB startups identify suppliers who are likely to experience delays or disruptions, and develop contingency plans to mitigate those risks.

Furthermore, data analytics can be used to inform pricing decisions, inventory management, and product development. By analyzing data from sales trends, customer behavior, and market research, PCB startups can develop pricing strategies that balance revenue goals with customer demand. Data analytics can also be used to optimize inventory levels, reducing waste and improving product availability.

To leverage data analytics for business decision making, PCB startups should follow these best practices:

- Implement a data management system to collect and analyze data from various sources

- Use data analytics to inform market research, customer segmentation, and supply chain optimization

- Develop targeted marketing campaigns to reach ideal customers

- Use data analytics to optimize pricing decisions, inventory management, and product development

- Continuously monitor and analyze data to identify areas for improvement

By following these best practices, PCB startups can leverage data analytics to inform their business decisions, drive growth and profitability, and stay ahead of the competition.

Case Study: How a PCB Startup Used Data-Driven Decision Making to Achieve Success

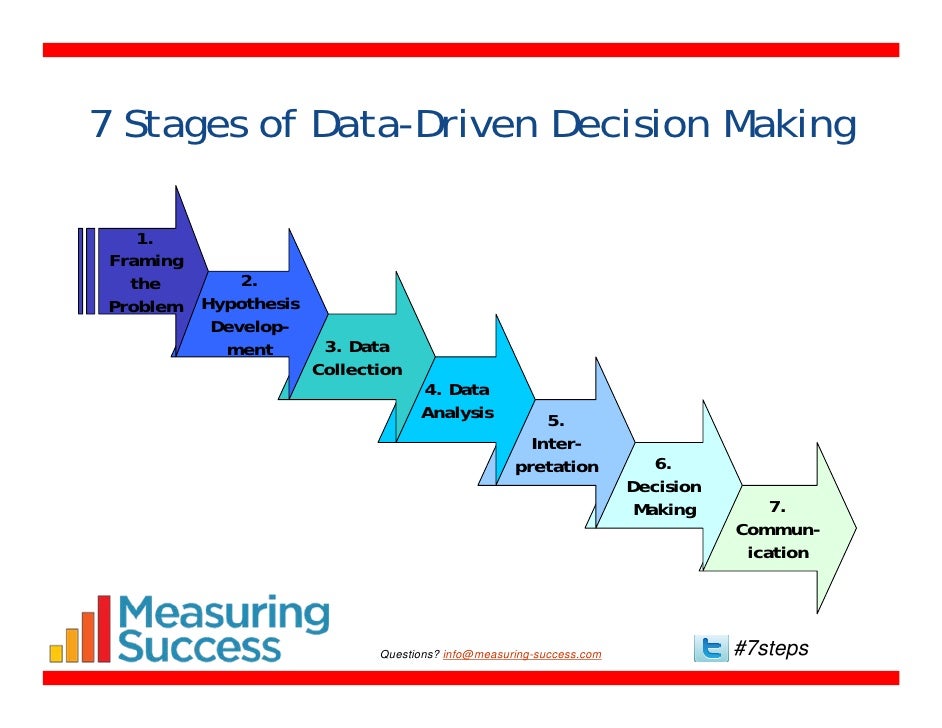

XYZ PCB, a startup based in California, was facing significant challenges in their manufacturing process. They were experiencing high defect rates, long lead times, and high production costs. To address these challenges, they decided to implement data-driven decision making in their organization.

The first step was to collect and analyze data from their manufacturing process. They used sensors and machines to collect data on production times, defect rates, and material usage. They also collected data from their suppliers, including lead times, pricing, and quality ratings.

Next, they used data analytics tools to analyze the data and identify trends and patterns. They discovered that their defect rates were highest during peak production periods, and that their suppliers were experiencing delays in delivering materials.

Armed with this information, XYZ PCB made several changes to their manufacturing process. They implemented a new quality control process that reduced defect rates by 30%. They also renegotiated their contracts with suppliers to reduce lead times and improve material quality.

The results were impressive. XYZ PCB saw a 25% reduction in production costs, a 30% reduction in lead times, and a 20% increase in customer satisfaction. They were able to increase their production capacity without increasing their workforce, and they were able to reduce their environmental impact by reducing waste and energy consumption.

XYZ PCB’s success with data-driven decision making can be attributed to several factors. First, they had a clear understanding of their business goals and objectives. Second, they had a strong data management system in place that allowed them to collect and analyze data from various sources. Third, they had a culture of continuous improvement that encouraged experimentation and innovation.

XYZ PCB’s experience demonstrates the power of data-driven decision making in the PCB industry. By leveraging data analytics and machine learning algorithms, PCB startups can gain valuable insights into their manufacturing process, identify areas for improvement, and make informed decisions to drive growth and profitability.

Key takeaways from XYZ PCB’s case study include:

- Collect and analyze data from various sources to gain valuable insights into your manufacturing process

- Use data analytics tools to identify trends and patterns in your data

- Make data-driven decisions to drive growth and profitability

- Continuously monitor and analyze data to identify areas for improvement

By following these best practices, PCB startups can achieve similar success with data-driven decision making and stay ahead of the competition in the rapidly evolving PCB industry.

Best Practices for Implementing Data-Driven Decision Making in Your PCB Startup

Implementing data-driven decision making in a PCB startup requires a strategic approach. Here are some best practices to help you get started:

1. Define Your Goals and Objectives: Clearly define what you want to achieve with data-driven decision making. Identify the key performance indicators (KPIs) that will help you measure success.

2. Collect and Integrate Data: Collect data from various sources, including design files, manufacturing processes, and customer feedback. Integrate this data into a single platform to enable easy analysis and visualization.

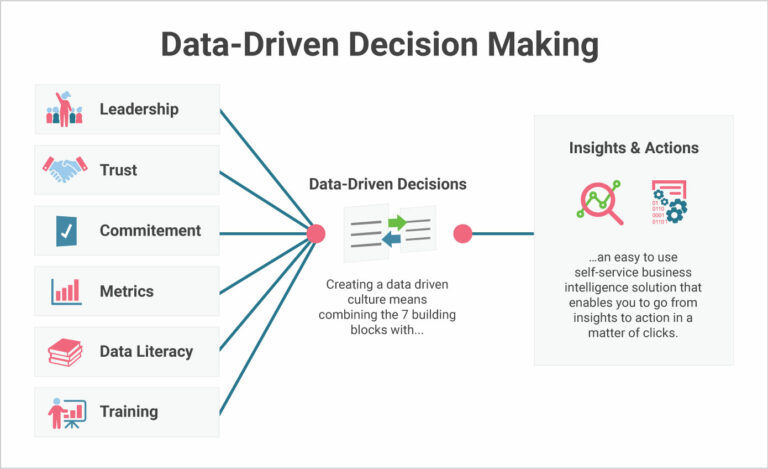

3. Develop a Data-Driven Culture: Encourage a culture of data-driven decision making within your organization. Provide training and resources to help employees understand the importance of data-driven decision making and how to use data to inform their decisions.

4. Use Data Analytics Tools: Use data analytics tools to analyze and visualize your data. These tools can help you identify trends and patterns, and provide insights into your design, manufacturing, and business processes.

5. Monitor and Analyze Data Continuously: Continuously monitor and analyze your data to identify areas for improvement. Use this data to inform your decisions and drive business growth.

6. Communicate Insights and Recommendations: Communicate insights and recommendations to stakeholders, including employees, customers, and investors. Use data visualization techniques to present complex data in a clear and concise manner.

7. Establish a Data Governance Framework: Establish a data governance framework to ensure data quality, security, and compliance. This framework should include policies and procedures for data management, data security, and data compliance.

8. Continuously Evaluate and Improve: Continuously evaluate and improve your data-driven decision making processes. Use feedback from employees, customers, and stakeholders to identify areas for improvement and implement changes as needed.

By following these best practices, PCB startups can implement data-driven decision making and achieve significant benefits, including improved design quality, reduced manufacturing costs, and increased business growth.

Additionally, PCB startups can use the following tools and technologies to support their data-driven decision making efforts:

- Data analytics platforms, such as Tableau or Power BI

- Machine learning algorithms, such as TensorFlow or PyTorch

- Cloud-based data storage solutions, such as AWS or Google Cloud

- Data visualization tools, such as D3.js or Matplotlib

By leveraging these tools and technologies, PCB startups can gain a competitive advantage and achieve success in the rapidly evolving PCB industry.

Common Challenges and Pitfalls to Avoid in Data-Driven Decision Making

While data-driven decision making can bring numerous benefits to PCB startups, there are also common challenges and pitfalls to avoid. Here are some of the most common ones:

1. Data Quality Issues: Poor data quality can lead to inaccurate insights and decisions. PCB startups should ensure that their data is accurate, complete, and consistent.

2. Analysis Paralysis: With the abundance of data available, PCB startups can get overwhelmed and struggle to make decisions. To avoid analysis paralysis, PCB startups should focus on the most critical data points and use data visualization techniques to present complex data in a clear and concise manner.

3. Lack of Stakeholder Buy-in: Data-driven decision making requires stakeholder buy-in and support. PCB startups should ensure that all stakeholders are aligned with the data-driven decision making approach and understand the benefits of using data to inform decisions.

4. Insufficient Data: PCB startups may not have access to sufficient data to make informed decisions. To overcome this challenge, PCB startups can use data from external sources, such as market research reports or industry benchmarks.

5. Overreliance on Data: While data is essential for informed decision making, PCB startups should not overrely on data. They should also consider other factors, such as industry trends, customer feedback, and market conditions.

6. Lack of Data Governance: PCB startups should establish a data governance framework to ensure data quality, security, and compliance. This framework should include policies and procedures for data management, data security, and data compliance.

7. Insufficient Resources: Data-driven decision making requires significant resources, including data analytics tools, personnel, and training. PCB startups should ensure that they have the necessary resources to support their data-driven decision making efforts.

By being aware of these common challenges and pitfalls, PCB startups can take steps to avoid them and ensure successful implementation of data-driven decision making.

To overcome these challenges, PCB startups can use the following strategies:

- Establish a data governance framework to ensure data quality, security, and compliance

- Use data visualization techniques to present complex data in a clear and concise manner

- Focus on the most critical data points and avoid analysis paralysis

- Ensure stakeholder buy-in and support for data-driven decision making

- Use data from external sources to supplement internal data

By using these strategies, PCB startups can overcome common challenges and pitfalls and achieve success with data-driven decision making.

Conclusion: Empowering PCB Startups with Data-Driven Decision Making

Data-driven decision making is a crucial aspect of success for PCB startups. By leveraging data analytics and machine learning algorithms, PCB startups can gain valuable insights into their design, manufacturing, and business processes, and make informed decisions to drive growth and profitability.

In this article, we have discussed the importance of data-driven decision making for PCB startups, and provided an overview of how data analytics can be used to optimize PCB design, manufacturing, and business decisions. We have also highlighted the role of big data in PCB manufacturing and quality control, and provided a case study of a PCB startup that successfully implemented data-driven decision making.

Additionally, we have offered best practices for implementing data-driven decision making in a PCB startup, including tips on data collection, data analysis, and data visualization. We have also discussed common challenges and pitfalls to avoid in data-driven decision making, and provided advice on how to overcome these challenges and ensure successful implementation.

By following the guidelines and best practices outlined in this article, PCB startups can empower themselves with data-driven insights and achieve success in the rapidly evolving PCB industry. Remember, data-driven decision making is a journey, not a destination, and it requires continuous effort and improvement to stay ahead of the competition.

Start your data-driven journey today and discover the power of data-driven decision making for your PCB startup. With the right tools, techniques, and mindset, you can unlock new opportunities, drive growth and profitability, and achieve success in the PCB industry.

As you embark on your data-driven journey, keep in mind the following key takeaways:

- Data-driven decision making is crucial for PCB startups to stay competitive and improve their bottom line.

- Data analytics and machine learning algorithms can be used to optimize PCB design, manufacturing, and business decisions.

- Big data plays a critical role in PCB manufacturing and quality control, and can be used to predict defects and optimize production processes.

- Creating a data-driven culture within the organization is essential for successful implementation of data-driven decision making.

- Common challenges and pitfalls to avoid in data-driven decision making include data quality issues, analysis paralysis, and lack of stakeholder buy-in.

By following these key takeaways and best practices, PCB startups can empower themselves with data-driven insights and achieve success in the PCB industry.