Unlocking the Secrets of Efficient Electric Motor Design

Electric motor design plays a crucial role in the performance, efficiency, and overall quality of electric vehicles. As the demand for electric vehicles continues to grow, the importance of efficient electric motor design has become increasingly evident. Advances in materials science and computer-aided design have driven innovation in electric motor development, enabling manufacturers to create more efficient, reliable, and cost-effective motors.

One of the key factors in efficient electric motor design is the use of advanced materials. Rare-earth magnets, for example, offer higher magnetic strength and durability compared to traditional magnets, resulting in improved motor efficiency and reduced weight. High-temperature superconductors are another example of advanced materials being used in electric motor design, enabling the creation of more efficient and compact motors.

Computer-aided design (CAD) software has also revolutionized the electric motor design process, allowing manufacturers to simulate and test various design configurations before physical prototyping. This approach enables the optimization of motor design for specific applications, reducing the risk of costly redesigns and improving overall efficiency.

The impact of efficient electric motor design on electric vehicle performance cannot be overstated. A well-designed motor can improve vehicle range, reduce energy consumption, and enhance overall driving experience. Furthermore, efficient motor design can also reduce the environmental impact of electric vehicles, making them a more sustainable option for the future.

As the electric vehicle industry continues to evolve, the importance of efficient electric motor design will only continue to grow. Manufacturers must stay at the forefront of innovation, leveraging advances in materials science and computer-aided design to create more efficient, reliable, and cost-effective motors. By doing so, they can ensure that their electric vehicles meet the demands of a rapidly changing market, while also contributing to a more sustainable future.

In the context of electric vehicle and electric motor quality management trends, efficient motor design is a critical aspect of ensuring overall vehicle quality and reliability. By prioritizing motor design and leveraging advances in materials science and computer-aided design, manufacturers can create electric vehicles that meet the highest standards of performance, efficiency, and sustainability.

How to Optimize Electric Vehicle Manufacturing for Quality and Reliability

The electric vehicle manufacturing process is complex and involves multiple stages, from design and prototyping to production and testing. To ensure the quality and reliability of electric vehicles, manufacturers must implement effective quality management strategies throughout the production process. One approach to achieving this is by adopting lean manufacturing principles, which aim to minimize waste and maximize efficiency.

Lean manufacturing involves identifying and eliminating non-value-added activities, streamlining processes, and implementing continuous improvement initiatives. By applying lean principles, electric vehicle manufacturers can reduce production costs, improve product quality, and enhance overall efficiency. For example, implementing a just-in-time (JIT) inventory system can help reduce inventory costs and minimize waste.

Total productive maintenance (TPM) is another quality control strategy that can be applied to electric vehicle manufacturing. TPM involves proactive maintenance activities, such as regular equipment inspections and maintenance, to prevent equipment failures and reduce downtime. By implementing TPM, manufacturers can improve equipment reliability, reduce maintenance costs, and enhance overall productivity.

In addition to lean manufacturing and TPM, electric vehicle manufacturers can also implement other quality control strategies, such as statistical process control (SPC) and failure mode and effects analysis (FMEA). SPC involves monitoring and controlling production processes to ensure that they are operating within predetermined limits, while FMEA involves identifying and mitigating potential failures in the production process.

By implementing these quality control strategies, electric vehicle manufacturers can ensure that their products meet the highest standards of quality and reliability. This is particularly important in the context of electric vehicle and electric motor quality management trends, where the demand for high-quality and reliable electric vehicles is increasing rapidly.

Furthermore, electric vehicle manufacturers can also benefit from implementing digital technologies, such as Industry 4.0 and the Internet of Things (IoT), to enhance their quality management capabilities. These technologies can provide real-time data and insights on production processes, enabling manufacturers to identify areas for improvement and optimize their quality control strategies.

In conclusion, optimizing electric vehicle manufacturing for quality and reliability requires a comprehensive approach that involves implementing effective quality management strategies throughout the production process. By adopting lean manufacturing principles, TPM, SPC, FMEA, and digital technologies, electric vehicle manufacturers can ensure that their products meet the highest standards of quality and reliability, and stay ahead of the competition in the rapidly evolving electric vehicle market.

The Role of Advanced Materials in Enhancing Electric Motor Quality

Advanced materials play a crucial role in enhancing the quality and performance of electric motors in electric vehicles. The use of advanced materials such as rare-earth magnets, high-temperature superconductors, and advanced composites can significantly improve the efficiency, reliability, and durability of electric motors.

Rare-earth magnets, for example, offer higher magnetic strength and durability compared to traditional magnets, resulting in improved motor efficiency and reduced weight. High-temperature superconductors, on the other hand, enable the creation of more efficient and compact motors by reducing energy losses and increasing power density.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to enhance the quality and performance of electric motors. These materials offer improved strength-to-weight ratios, reduced vibration, and increased thermal stability, resulting in improved motor reliability and durability.

The use of advanced materials in electric motor design is a key trend in electric vehicle and electric motor quality management. As the demand for electric vehicles continues to grow, the importance of using advanced materials to enhance motor quality and performance will only continue to increase.

In addition to improving motor efficiency and reliability, advanced materials can also help reduce production costs and environmental impact. For example, the use of recycled materials and sustainable manufacturing processes can help reduce waste and minimize the environmental footprint of electric motor production.

Furthermore, the use of advanced materials can also enable the creation of more innovative and efficient electric motor designs. For example, the use of 3D printing and additive manufacturing techniques can enable the creation of complex motor geometries and structures that cannot be produced using traditional manufacturing methods.

In the context of electric vehicle and electric motor quality management trends, the use of advanced materials is a critical aspect of ensuring the quality and performance of electric motors. By leveraging the latest advancements in materials science and technology, electric vehicle manufacturers can create more efficient, reliable, and sustainable electric motors that meet the demands of a rapidly changing market.

As the electric vehicle industry continues to evolve, the importance of using advanced materials to enhance electric motor quality and performance will only continue to grow. By staying at the forefront of materials science and technology, electric vehicle manufacturers can ensure that their products meet the highest standards of quality, reliability, and sustainability, and stay ahead of the competition in the rapidly evolving electric vehicle market.

Electric Vehicle Testing and Validation: Ensuring Quality and Performance

Testing and validation are critical components of electric vehicle development, ensuring that vehicles meet the required standards of quality, performance, and safety. Electric vehicle manufacturers must conduct a range of tests to validate the performance of their vehicles, including dynamometer testing, environmental testing, and durability testing.

Dynamometer testing involves testing the vehicle’s powertrain and electric motor under controlled conditions, simulating various driving scenarios and loads. This type of testing helps to validate the vehicle’s performance, efficiency, and reliability. Environmental testing, on the other hand, involves testing the vehicle’s performance in various environmental conditions, such as extreme temperatures, humidity, and altitude.

Durability testing involves testing the vehicle’s components and systems over an extended period, simulating real-world driving conditions. This type of testing helps to validate the vehicle’s reliability and durability, ensuring that it can withstand the rigors of daily use. In addition to these tests, electric vehicle manufacturers must also conduct simulation-based testing, using advanced software tools to simulate various driving scenarios and conditions.

Simulation-based testing can help reduce testing time and costs, while also improving the accuracy and reliability of test results. By leveraging advanced simulation tools and techniques, electric vehicle manufacturers can optimize their testing and validation processes, ensuring that their vehicles meet the highest standards of quality and performance.

In the context of electric vehicle and electric motor quality management trends, testing and validation are critical components of ensuring the quality and performance of electric vehicles. By conducting a range of tests and validations, electric vehicle manufacturers can ensure that their vehicles meet the required standards of quality, performance, and safety, and stay ahead of the competition in the rapidly evolving electric vehicle market.

Furthermore, testing and validation can also help electric vehicle manufacturers to identify and address potential quality issues early in the development process, reducing the risk of costly recalls and warranty claims. By prioritizing testing and validation, electric vehicle manufacturers can ensure that their vehicles meet the highest standards of quality and performance, and provide a safe and reliable driving experience for their customers.

In conclusion, testing and validation are critical components of electric vehicle development, ensuring that vehicles meet the required standards of quality, performance, and safety. By leveraging advanced testing and validation techniques, electric vehicle manufacturers can optimize their development processes, ensure the quality and performance of their vehicles, and stay ahead of the competition in the rapidly evolving electric vehicle market.

Real-World Examples: Tesla’s Quality Management Strategies for Electric Motor Production

Tesla is a pioneer in the electric vehicle industry, and its quality management strategies for electric motor production are a key factor in its success. Tesla’s approach to design for manufacturability, supply chain management, and continuous improvement has enabled the company to produce high-quality electric motors that meet the demands of its customers.

Tesla’s design for manufacturability approach involves designing electric motors that are easy to manufacture and assemble. This approach has enabled the company to reduce production costs and improve product quality. Tesla’s supply chain management strategy involves working closely with its suppliers to ensure that they meet the company’s quality and reliability standards.

Tesla’s continuous improvement approach involves continually monitoring and improving its production processes to ensure that they meet the company’s quality and reliability standards. This approach has enabled the company to identify and address potential quality issues early in the production process, reducing the risk of costly recalls and warranty claims.

Tesla’s quality management strategies have enabled the company to produce high-quality electric motors that meet the demands of its customers. The company’s approach to design for manufacturability, supply chain management, and continuous improvement has reduced production costs and improved product quality, enabling Tesla to stay ahead of the competition in the rapidly evolving electric vehicle market.

In the context of electric vehicle and electric motor quality management trends, Tesla’s quality management strategies are a best practice example of how to produce high-quality electric motors that meet the demands of customers. By adopting a similar approach, other electric vehicle manufacturers can improve their product quality and reliability, reducing the risk of costly recalls and warranty claims.

Furthermore, Tesla’s quality management strategies have enabled the company to improve its overall efficiency and productivity. By reducing production costs and improving product quality, Tesla has been able to increase its market share and stay ahead of the competition in the rapidly evolving electric vehicle market.

In conclusion, Tesla’s quality management strategies for electric motor production are a key factor in its success. By adopting a similar approach, other electric vehicle manufacturers can improve their product quality and reliability, reducing the risk of costly recalls and warranty claims. Tesla’s quality management strategies are a best practice example of how to produce high-quality electric motors that meet the demands of customers.

Electric Motor Quality Management in the Age of Electrification

The automotive industry is undergoing a significant transformation with the increasing demand for electric vehicles. As the industry shifts towards electrification, the importance of electric motor quality management is becoming more pronounced. Electric motor quality management is critical to ensuring the performance, reliability, and safety of electric vehicles.

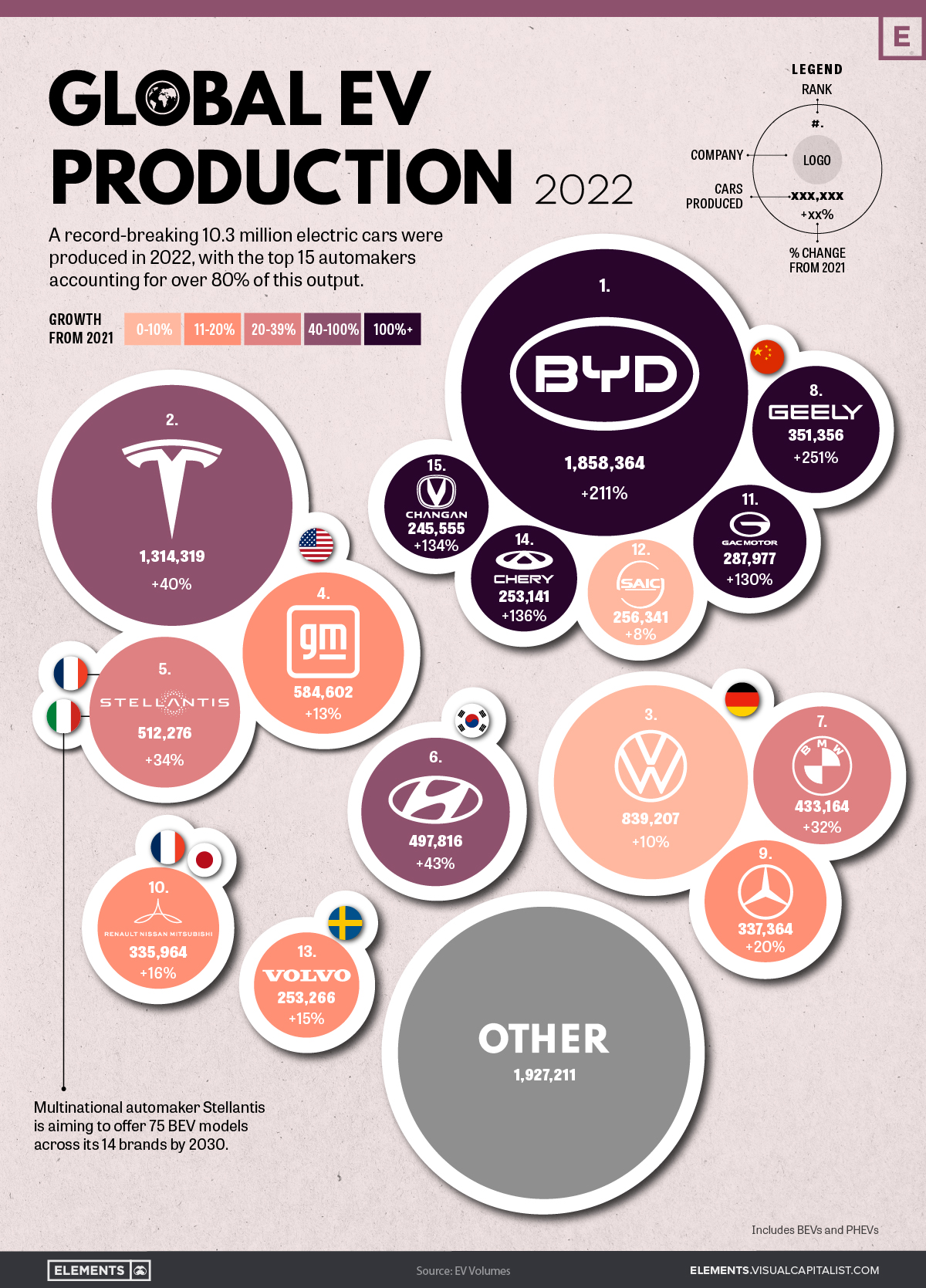

The growing demand for electric vehicles has led to an increase in the production volume of electric motors. However, this increase in production volume also brings new challenges for electric motor quality management. Electric motor manufacturers must adapt their quality management strategies to meet the challenges of high-volume production, while also ensuring that their products meet the required standards of quality and reliability.

One of the key challenges in electric motor quality management is ensuring the consistency of product quality across large production volumes. Electric motor manufacturers must implement robust quality control processes to ensure that their products meet the required standards of quality and reliability. This includes implementing advanced testing and validation methodologies, such as dynamometer testing and simulation-based testing.

Another challenge in electric motor quality management is ensuring the reliability of electric motors over their entire lifespan. Electric motor manufacturers must implement robust reliability testing and validation methodologies to ensure that their products meet the required standards of reliability. This includes implementing advanced testing and validation methodologies, such as accelerated life testing and reliability modeling.

In the context of electric vehicle and electric motor quality management trends, the importance of electric motor quality management is becoming more pronounced. Electric motor manufacturers must adapt their quality management strategies to meet the challenges of high-volume production, while also ensuring that their products meet the required standards of quality and reliability.

Furthermore, electric motor manufacturers must also consider the impact of electrification on the automotive industry as a whole. The increasing demand for electric vehicles is driving innovation in electric motor design and development, and electric motor manufacturers must stay at the forefront of this innovation to remain competitive.

In conclusion, electric motor quality management is critical to ensuring the performance, reliability, and safety of electric vehicles. Electric motor manufacturers must adapt their quality management strategies to meet the challenges of high-volume production, while also ensuring that their products meet the required standards of quality and reliability. By prioritizing electric motor quality management, electric motor manufacturers can ensure that their products meet the demands of the rapidly evolving electric vehicle market.

Future-Proofing Electric Vehicle Quality Management: Emerging Trends and Technologies

The electric vehicle industry is rapidly evolving, and quality management strategies must adapt to meet the challenges of high-volume production. Emerging trends and technologies, such as artificial intelligence, machine learning, and the Internet of Things (IoT), are transforming the way electric vehicle manufacturers approach quality management.

Artificial intelligence and machine learning are being used to improve predictive maintenance and quality control in electric vehicle manufacturing. These technologies enable manufacturers to analyze large amounts of data and identify potential quality issues before they occur. This approach can help reduce the risk of costly recalls and warranty claims, while also improving overall vehicle reliability.

The Internet of Things (IoT) is also playing a critical role in electric vehicle quality management. IoT sensors and devices can be used to monitor and control various aspects of the manufacturing process, including temperature, humidity, and vibration. This data can be used to optimize production processes and improve overall product quality.

In addition to these emerging trends and technologies, electric vehicle manufacturers are also leveraging advanced simulation tools and modeling techniques to improve quality management. These tools enable manufacturers to simulate various production scenarios and identify potential quality issues before they occur.

In the context of electric vehicle and electric motor quality management trends, the use of emerging trends and technologies is becoming increasingly important. Electric vehicle manufacturers must stay at the forefront of these trends and technologies to remain competitive and ensure the quality and reliability of their products.

Furthermore, the use of emerging trends and technologies can also help electric vehicle manufacturers to improve their overall efficiency and productivity. By leveraging advanced simulation tools and modeling techniques, manufacturers can optimize their production processes and reduce waste and costs.

In conclusion, emerging trends and technologies are transforming the way electric vehicle manufacturers approach quality management. By leveraging artificial intelligence, machine learning, IoT, and advanced simulation tools, manufacturers can improve predictive maintenance and quality control, reduce the risk of costly recalls and warranty claims, and improve overall vehicle reliability.

Conclusion: The Road Ahead for Electric Vehicle and Electric Motor Quality Management

In conclusion, the importance of quality management in ensuring the performance, reliability, and safety of electric vehicles cannot be overstated. As the demand for electric vehicles continues to grow, the need for effective quality management strategies will only continue to increase.

Electric vehicle manufacturers must prioritize quality management and invest in the latest technologies and trends to stay ahead of the competition. This includes leveraging emerging trends and technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) to improve predictive maintenance and quality control.

Furthermore, electric vehicle manufacturers must also focus on improving their overall efficiency and productivity. By implementing lean manufacturing principles, total productive maintenance, and other quality control strategies, manufacturers can reduce waste and costs, while also improving overall vehicle reliability.

In the context of electric vehicle and electric motor quality management trends, the future looks bright. With the increasing demand for electric vehicles and the growing importance of electric motor quality management, there are many opportunities for innovation and growth.

However, there are also challenges that lie ahead. Electric vehicle manufacturers must navigate the complexities of high-volume production, while also ensuring that their products meet the required standards of quality and reliability.

Despite these challenges, the future of electric vehicle and electric motor quality management is exciting. With the latest technologies and trends, electric vehicle manufacturers can improve their products, reduce costs, and stay ahead of the competition.

In the end, the key to success in electric vehicle and electric motor quality management is to prioritize quality and invest in the latest technologies and trends. By doing so, electric vehicle manufacturers can ensure that their products meet the required standards of quality and reliability, while also staying ahead of the competition in the rapidly evolving electric vehicle market.