Mastering the Fundamentals of Electric Motor Management

Effective electric motor management is crucial for optimizing the performance, efficiency, and overall driving experience of electric vehicles. The electric motor is the heart of an electric vehicle, responsible for converting electrical energy into mechanical energy to propel the vehicle forward. To achieve optimal performance, it is essential to understand the key components of electric motor operations and their role in electric vehicle and electric motor operations management.

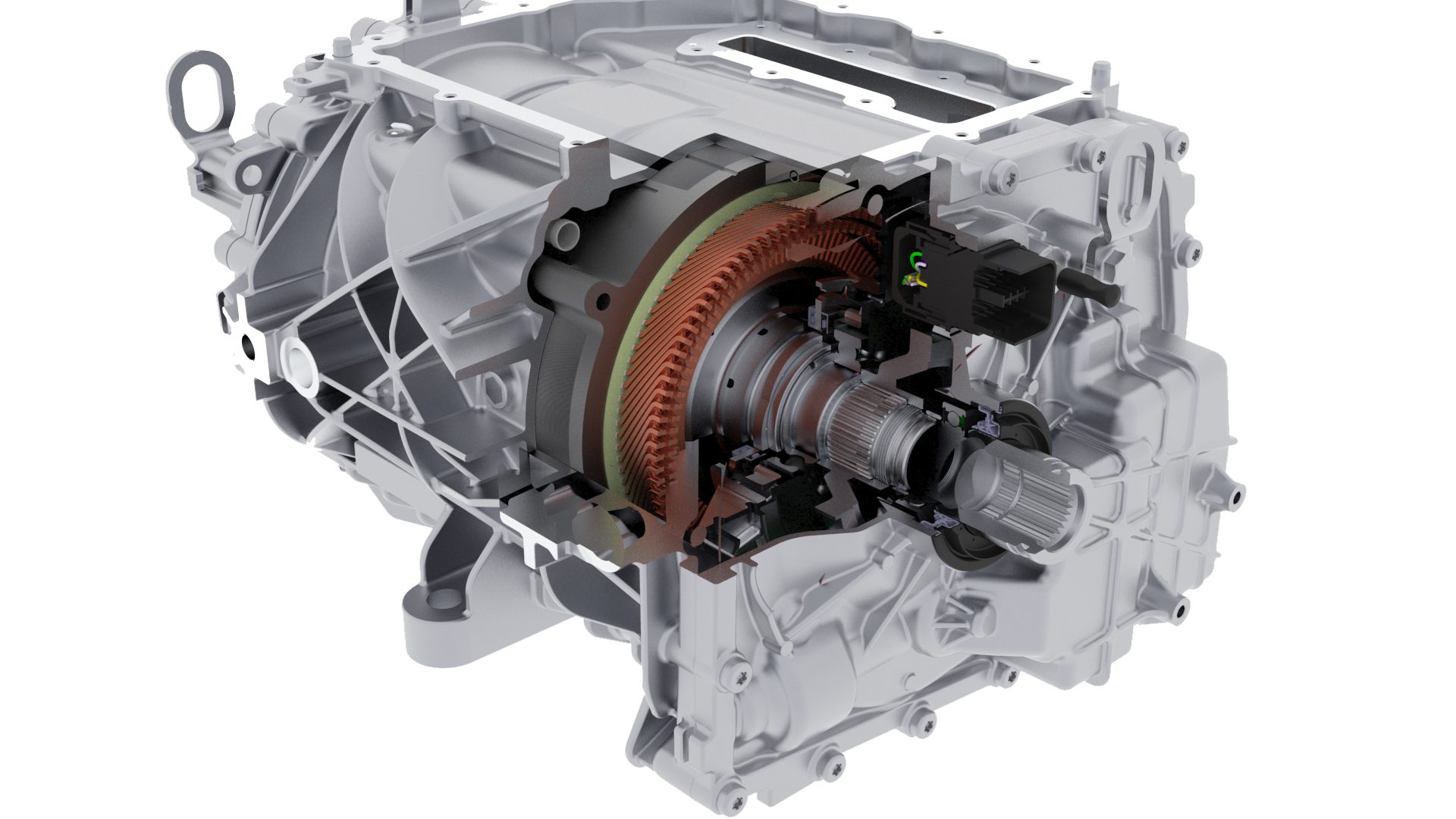

The electric motor consists of several critical components, including the rotor, stator, and power electronics. The rotor is the moving part of the motor, while the stator is the stationary part. The power electronics control the flow of electrical energy to the motor, regulating the speed and torque of the vehicle. Understanding how these components interact and impact motor performance is vital for efficient electric motor operations management.

In addition to the motor components, other factors such as motor design, driving habits, and environmental conditions also affect electric motor efficiency and energy consumption. For instance, aggressive driving habits can reduce motor efficiency, while extreme temperatures can impact motor performance. By understanding these factors and implementing strategies to mitigate their impact, electric vehicle owners and operators can optimize motor performance and reduce energy consumption.

Furthermore, advances in electric motor technologies have led to the development of more efficient and powerful motors. For example, the use of permanent magnet motors and induction motors has improved motor efficiency and reduced energy consumption. However, these advances also require sophisticated electric motor operations management strategies to optimize performance and efficiency.

In the context of electric vehicle and electric motor operations management, it is essential to consider the interplay between the electric motor, power electronics, and other vehicle systems. By optimizing the performance of these systems, electric vehicle owners and operators can achieve improved efficiency, reduced energy consumption, and enhanced overall driving experience. In the next section, we will explore the importance of monitoring and maintaining electric motor health to prevent motor failure and reduce downtime.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance are crucial for ensuring the optimal performance and longevity of electric vehicle motors. By implementing proactive maintenance strategies, electric vehicle owners and operators can prevent motor failure, reduce downtime, and optimize electric vehicle and electric motor operations management.

One of the most effective ways to monitor electric motor health is through the use of diagnostic tools. These tools can detect potential issues before they become major problems, allowing for prompt maintenance and repair. Some common diagnostic tools include motor condition monitoring systems, thermal imaging cameras, and vibration analysis equipment.

In addition to diagnostic tools, regular checks and inspections are also essential for maintaining electric motor health. These checks should include visual inspections of the motor and its components, as well as checks of the motor’s electrical and mechanical systems. By identifying potential issues early, electric vehicle owners and operators can take proactive steps to prevent motor failure and optimize performance.

Troubleshooting techniques are also critical for maintaining electric motor health. By understanding the common causes of motor failure and how to troubleshoot them, electric vehicle owners and operators can quickly identify and resolve issues, minimizing downtime and optimizing electric vehicle and electric motor operations management.

Some common causes of motor failure include overheating, overloading, and electrical surges. By understanding how to prevent and troubleshoot these issues, electric vehicle owners and operators can optimize motor performance and extend the lifespan of their electric vehicle motors.

Best practices for monitoring and maintaining electric motor health include regular maintenance schedules, prompt repair of issues, and ongoing training and education for maintenance personnel. By implementing these best practices, electric vehicle owners and operators can optimize electric vehicle and electric motor operations management, reducing downtime and improving overall performance.

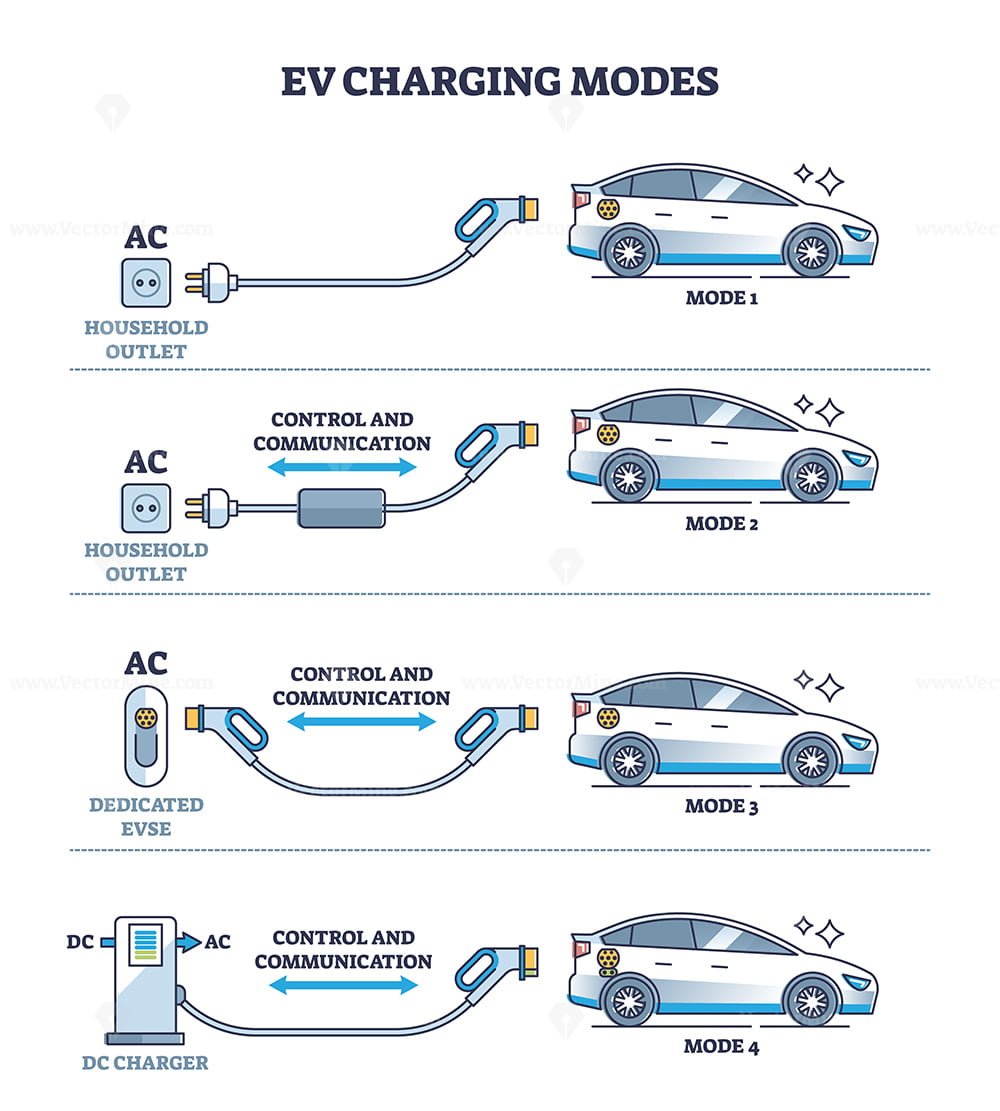

Electric Vehicle Charging Strategies for Optimal Motor Performance

Electric vehicle charging strategies play a crucial role in optimizing motor performance and overall driving experience. The type of charging method used can significantly impact the efficiency and longevity of the electric motor, making it essential to choose the right charging strategy for your vehicle and driving habits.

There are three main types of electric vehicle charging methods: Level 1, Level 2, and DC Fast Charging. Level 1 charging uses a standard 120-volt household outlet and is the slowest method, taking up to 24 hours to fully charge a depleted battery. Level 2 charging uses a 240-volt charging station and can charge a depleted battery in 4-8 hours. DC Fast Charging is the fastest method, capable of charging a depleted battery to 80% in under 30 minutes.

The choice of charging method depends on several factors, including the type of electric vehicle, driving habits, and access to charging infrastructure. For example, Level 1 charging may be suitable for drivers with short commutes and access to a household outlet, while Level 2 charging may be more suitable for drivers with longer commutes or limited access to charging infrastructure. DC Fast Charging is ideal for long-distance driving or emergency situations.

In addition to the type of charging method, the frequency and timing of charging also impact motor performance. It is recommended to charge the battery when it is partially depleted, rather than waiting until it is fully depleted. This helps to maintain the health of the battery and optimize motor performance.

Electric vehicle manufacturers also provide guidance on charging strategies to optimize motor performance. For example, some manufacturers recommend avoiding deep discharging of the battery, while others recommend keeping the battery level between 20% and 80% charged. By following these guidelines and choosing the right charging strategy, electric vehicle owners and operators can optimize motor performance and extend the lifespan of their electric vehicle motors.

Effective electric vehicle and electric motor operations management also involves monitoring and adjusting charging strategies based on driving habits and environmental conditions. By doing so, electric vehicle owners and operators can optimize energy consumption, reduce waste, and improve overall driving experience.

Understanding Electric Motor Efficiency and Energy Consumption

Electric motor efficiency and energy consumption are critical factors in optimizing electric vehicle performance and overall driving experience. Several factors affect electric motor efficiency and energy consumption, including motor design, driving habits, and environmental conditions.

Motor design plays a significant role in determining electric motor efficiency. The type of motor used, such as an induction motor or a permanent magnet motor, can impact efficiency. Additionally, the motor’s power rating, torque output, and speed range can also affect efficiency. Electric vehicle manufacturers often optimize motor design to achieve a balance between efficiency, performance, and cost.

Driving habits also significantly impact electric motor efficiency and energy consumption. Aggressive driving, such as rapid acceleration and braking, can reduce motor efficiency and increase energy consumption. Conversely, smooth and moderate driving can help optimize motor efficiency and reduce energy consumption.

Environmental conditions, such as temperature and altitude, can also affect electric motor efficiency and energy consumption. Extreme temperatures, for example, can impact motor performance and efficiency. Similarly, high altitudes can reduce motor efficiency due to the lower air density.

To optimize energy consumption and reduce waste, electric vehicle owners and operators can implement several strategies. One approach is to adjust driving habits to optimize motor efficiency. This can include driving smoothly, avoiding rapid acceleration and braking, and maintaining a moderate speed. Additionally, electric vehicle owners and operators can also optimize motor performance by adjusting the vehicle’s settings, such as the regenerative braking system.

Electric vehicle manufacturers also provide guidance on optimizing energy consumption and reducing waste. For example, some manufacturers recommend using the vehicle’s built-in energy management system to optimize energy consumption. Others recommend adjusting the vehicle’s settings to optimize motor performance in different environmental conditions.

Effective electric vehicle and electric motor operations management requires a comprehensive understanding of the factors that affect electric motor efficiency and energy consumption. By optimizing motor design, driving habits, and environmental conditions, electric vehicle owners and operators can optimize energy consumption, reduce waste, and improve overall driving experience.

Real-World Examples: Electric Motor Operations in Popular EV Models

Several popular electric vehicle (EV) models have demonstrated exceptional electric motor operations, showcasing the importance of effective electric vehicle and electric motor operations management. In this section, we will explore the unique features and technologies used in the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf to optimize motor performance.

The Tesla Model 3, for example, features a permanent magnet motor that provides exceptional efficiency and performance. The motor’s design allows for a high power-to-weight ratio, enabling the vehicle to accelerate quickly and smoothly. Additionally, the Model 3’s advanced battery management system helps to optimize energy consumption and reduce waste.

The Chevrolet Bolt, on the other hand, uses a dual electric motor setup to provide exceptional torque and acceleration. The motors are designed to work together to optimize performance and efficiency, and the vehicle’s advanced transmission system helps to minimize energy loss. The Bolt’s regenerative braking system also helps to capture kinetic energy and convert it into electrical energy, further optimizing motor performance.

The Nissan Leaf, one of the best-selling EVs of all time, features a synchronous motor that provides exceptional efficiency and reliability. The motor’s design allows for a high power output while minimizing energy consumption, and the vehicle’s advanced battery management system helps to optimize energy storage and release. The Leaf’s regenerative braking system also helps to capture kinetic energy and convert it into electrical energy, further optimizing motor performance.

These examples demonstrate the importance of effective electric vehicle and electric motor operations management in optimizing motor performance and overall driving experience. By understanding the unique features and technologies used in these popular EV models, electric vehicle owners and operators can gain valuable insights into how to optimize their own vehicle’s performance and efficiency.

Furthermore, these examples also highlight the importance of ongoing research and development in the field of electric motor operations. As new technologies and innovations emerge, electric vehicle manufacturers will continue to push the boundaries of what is possible in terms of motor performance and efficiency.

Advanced Electric Motor Technologies: What’s on the Horizon

The electric motor industry is constantly evolving, with new technologies and innovations emerging regularly. In this section, we will explore some of the latest advancements in electric motor technologies and their potential impact on electric vehicle and electric motor operations management.

One of the most promising new technologies is the use of advanced materials in electric motor design. For example, the use of rare earth magnets and high-temperature superconductors is allowing for the development of more efficient and powerful electric motors. Additionally, the use of advanced composites and 3D printing is enabling the creation of complex motor geometries and optimized motor designs.

Another area of innovation is in the development of new motor designs, such as the axial flux motor and the transverse flux motor. These designs offer improved efficiency and power density, making them ideal for use in electric vehicles. Furthermore, the development of advanced power electronics and control systems is enabling the creation of more efficient and optimized motor control systems.

The use of artificial intelligence (AI) and machine learning (ML) is also becoming increasingly prevalent in electric motor operations management. AI and ML can be used to optimize motor performance, predict maintenance needs, and detect potential faults. This can help to improve overall efficiency and reduce downtime.

While these emerging technologies offer many potential benefits, they also present several challenges. For example, the use of advanced materials and new motor designs can increase costs and complexity. Additionally, the integration of AI and ML into electric motor operations management can require significant investment in new infrastructure and training.

Despite these challenges, the potential benefits of these emerging technologies make them an exciting area of development in the field of electric vehicle and electric motor operations management. As these technologies continue to evolve and mature, we can expect to see significant improvements in efficiency, performance, and overall driving experience.

Electric Vehicle Motor Operations in Extreme Environments

Electric vehicles are designed to operate in a variety of environments, but extreme temperatures, high altitudes, and other challenging conditions can impact motor performance and overall driving experience. In this section, we will discuss the challenges of operating electric vehicles in extreme environments and provide tips and strategies for optimizing motor performance in these conditions.

High temperatures can impact electric motor performance by reducing efficiency and increasing the risk of overheating. To mitigate this, electric vehicle manufacturers often use advanced cooling systems and thermal management techniques to keep the motor at a safe operating temperature. Additionally, drivers can take steps to reduce the impact of high temperatures, such as avoiding rapid acceleration and braking, and keeping the vehicle in a shaded area when not in use.

Low temperatures can also impact electric motor performance by reducing efficiency and increasing the risk of battery drain. To mitigate this, electric vehicle manufacturers often use advanced battery management systems and thermal management techniques to keep the battery at a safe operating temperature. Additionally, drivers can take steps to reduce the impact of low temperatures, such as keeping the vehicle in a warm area when not in use, and using a block heater to warm up the engine before driving.

High altitudes can also impact electric motor performance by reducing efficiency and increasing the risk of overheating. To mitigate this, electric vehicle manufacturers often use advanced cooling systems and thermal management techniques to keep the motor at a safe operating temperature. Additionally, drivers can take steps to reduce the impact of high altitudes, such as avoiding rapid acceleration and braking, and keeping the vehicle in a shaded area when not in use.

Other extreme environments, such as high humidity and exposure to saltwater, can also impact electric motor performance. To mitigate this, electric vehicle manufacturers often use advanced corrosion protection techniques and waterproofing materials to protect the motor and other electrical components.

By understanding the challenges of operating electric vehicles in extreme environments, drivers can take steps to optimize motor performance and reduce the risk of damage. This includes following the manufacturer’s recommendations for maintenance and repair, and taking steps to mitigate the impact of extreme temperatures, high altitudes, and other challenging conditions.

Best Practices for Electric Vehicle Motor Operations Management

Effective electric vehicle and electric motor operations management is crucial for optimizing motor performance, reducing energy consumption, and extending the lifespan of the vehicle. In this section, we will summarize the key takeaways from the article and