Mastering the Fundamentals of Electric Motor Management

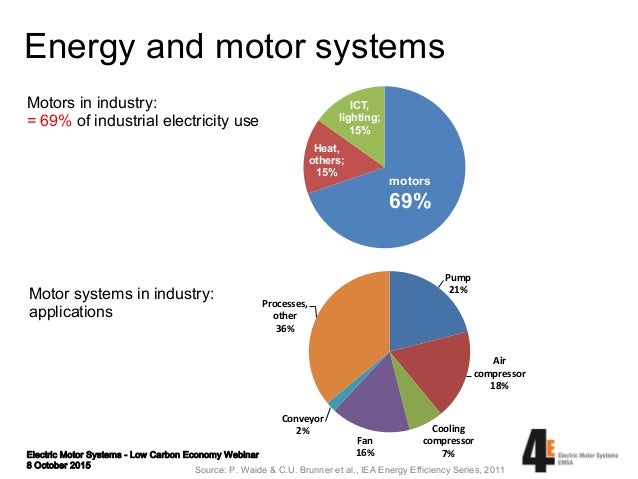

Effective electric motor management is crucial for optimizing the performance, efficiency, and lifespan of electric vehicles. As the demand for electric vehicles continues to grow, the importance of efficient electric motor operations management cannot be overstated. Electric motor management encompasses a range of key components, including power electronics, motor control, and thermal management. By understanding these fundamental elements, fleet managers and operators can unlock the full potential of their electric vehicles.

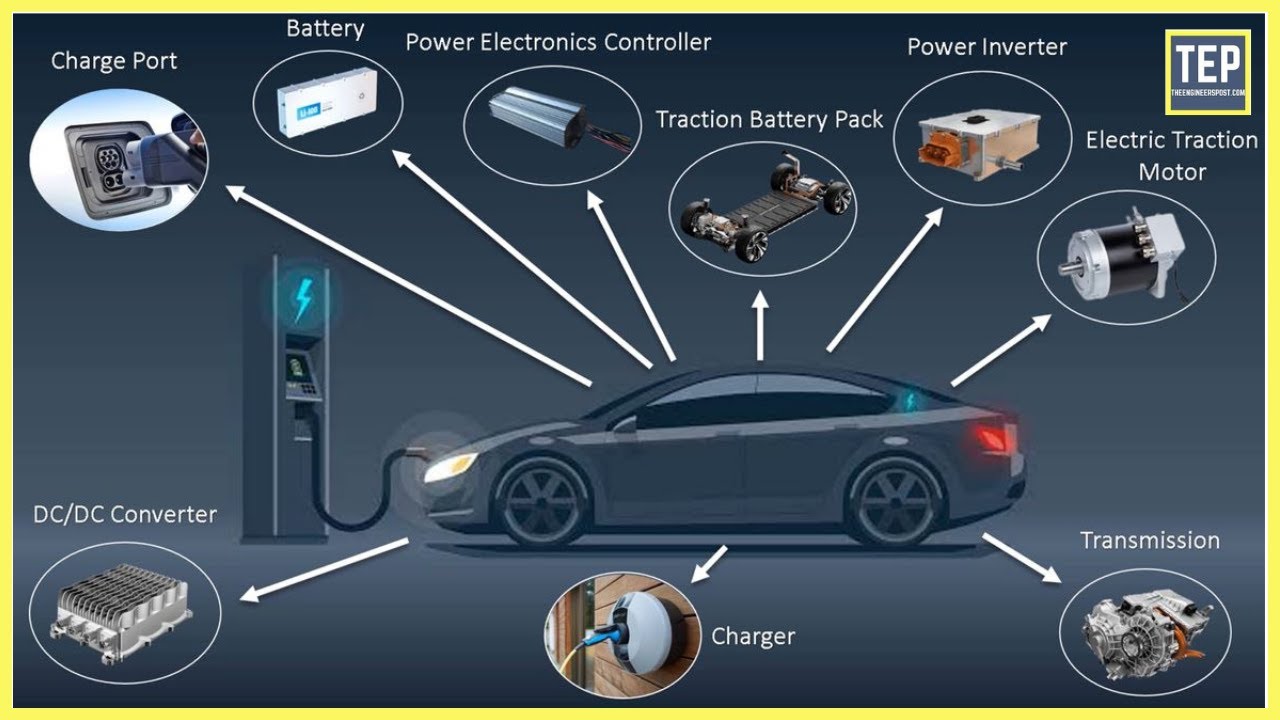

Power electronics play a vital role in electric motor management, enabling efficient and reliable motor operations. The use of advanced power electronic devices, such as inverters, converters, and battery management systems, allows for precise control over motor performance. This, in turn, enables electric vehicles to achieve optimal efficiency, range, and performance. Furthermore, power electronics facilitate the integration of renewable energy sources, such as solar and wind power, into the electric vehicle ecosystem.

Motor control is another critical aspect of electric motor management. By employing advanced control algorithms, such as field-oriented control and direct torque control, electric vehicles can achieve precise and efficient motor control. This enables optimal performance, reduced energy consumption, and extended motor lifespan. Additionally, motor control systems can be optimized for specific driving conditions, such as urban or highway driving, to further enhance efficiency and performance.

Thermal management is also essential for efficient electric motor operations. Electric motors generate heat during operation, which can impact efficiency, lifespan, and performance. By employing effective thermal management strategies, such as air cooling, liquid cooling, and heat exchangers, electric vehicles can maintain optimal motor temperatures. This, in turn, enables efficient motor operations, reduced energy consumption, and extended motor lifespan.

In the context of electric vehicle and electric motor operations management, it is essential to consider the interplay between these fundamental components. By optimizing power electronics, motor control, and thermal management, fleet managers and operators can unlock the full potential of their electric vehicles. This, in turn, enables efficient, reliable, and high-performance electric motor operations, which are critical for achieving optimal range, efficiency, and lifespan.

As the electric vehicle market continues to evolve, the importance of efficient electric motor operations management will only continue to grow. By mastering the fundamentals of electric motor management, fleet managers and operators can stay ahead of the curve, optimizing their electric vehicles for optimal performance, efficiency, and lifespan. Whether you are a seasoned fleet manager or an operator looking to optimize your electric vehicle, understanding the fundamentals of electric motor management is essential for achieving success in the electric vehicle market.

How to Monitor and Analyze Electric Motor Performance in Real-Time

Real-time monitoring and analysis of electric motor performance is crucial for optimizing electric vehicle efficiency, performance, and lifespan. By leveraging data analytics and IoT sensors, fleet managers and operators can gain valuable insights into motor operations, enabling data-driven decision-making and predictive maintenance. This approach is particularly important in electric vehicle and electric motor operations management, where optimal performance and efficiency are critical.

IoT sensors can be used to collect data on various parameters, such as motor temperature, voltage, current, and power output. This data can be transmitted to a cloud-based platform or an on-premise server for analysis and processing. Advanced data analytics tools can then be applied to identify trends, patterns, and anomalies in motor performance, enabling fleet managers and operators to take proactive measures to optimize motor operations.

Real-time monitoring and analysis can also be used to predict maintenance needs, reducing downtime and extending motor lifespan. By analyzing data on motor performance, fleet managers and operators can identify potential issues before they become major problems, enabling proactive maintenance and minimizing the risk of unexpected failures.

Furthermore, real-time monitoring and analysis can be used to optimize electric vehicle charging and discharging strategies, reducing energy consumption and improving overall efficiency. By analyzing data on motor performance and energy usage, fleet managers and operators can identify opportunities to optimize charging and discharging strategies, reducing energy costs and minimizing the environmental impact of electric vehicle operations.

In addition to these benefits, real-time monitoring and analysis can also be used to improve driver training and behavior, reducing energy consumption and improving overall efficiency. By analyzing data on driver behavior and motor performance, fleet managers and operators can identify areas for improvement and provide targeted training and feedback to drivers, enabling them to optimize their driving habits and reduce energy consumption.

Overall, real-time monitoring and analysis of electric motor performance is a critical component of electric vehicle and electric motor operations management. By leveraging data analytics and IoT sensors, fleet managers and operators can gain valuable insights into motor operations, enabling data-driven decision-making and predictive maintenance. This approach can help to optimize electric vehicle efficiency, performance, and lifespan, reducing energy consumption and improving overall efficiency.

The Role of Power Electronics in Electric Vehicle Motor Operations

Power electronics play a vital role in electric vehicle motor operations, enabling efficient and reliable electric motor performance. The use of advanced power electronic devices, such as inverters, converters, and battery management systems, allows for precise control over motor performance, optimizing efficiency, range, and overall vehicle performance.

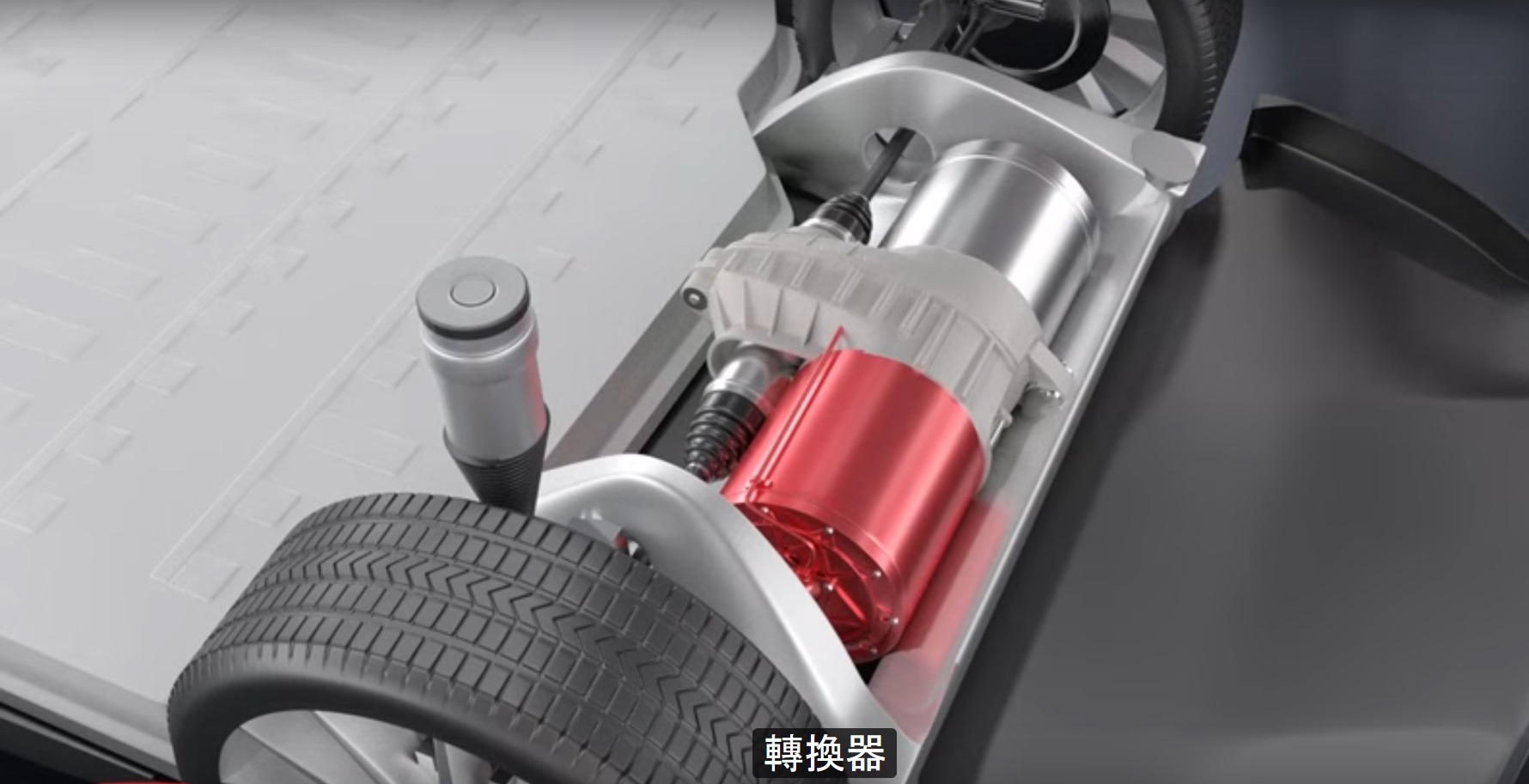

In electric vehicle and electric motor operations management, power electronics are responsible for converting DC power from the battery to AC power for the electric motor. This process involves the use of power electronic devices, such as inverters, which convert DC power to AC power, and converters, which convert AC power to DC power. Battery management systems also play a critical role in power electronics, ensuring that the battery is operating within a safe and efficient range.

The use of power electronics in electric vehicle motor operations offers several benefits, including improved efficiency, increased range, and enhanced overall vehicle performance. By optimizing power electronic devices, electric vehicle manufacturers can improve the efficiency of their vehicles, reducing energy consumption and increasing range. Additionally, power electronics enable the use of advanced motor control algorithms, such as field-oriented control and direct torque control, which optimize motor performance and efficiency.

There are several types of power electronic devices used in electric vehicle motor operations, including insulated gate bipolar transistors (IGBTs), power MOSFETs, and thyristors. IGBTs are commonly used in electric vehicle inverters due to their high switching frequency and low losses. Power MOSFETs are also used in electric vehicle applications due to their high efficiency and reliability. Thyristors are used in electric vehicle converters due to their high power handling capability and low losses.

In addition to the types of power electronic devices used, the design and implementation of power electronics in electric vehicle motor operations are also critical. The design of power electronic devices must take into account the specific requirements of electric vehicle motor operations, including high efficiency, reliability, and thermal management. The implementation of power electronics must also be carefully considered, with attention paid to the integration of power electronic devices with other electric vehicle systems, such as the battery management system and motor control system.

Overall, power electronics play a critical role in electric vehicle motor operations, enabling efficient and reliable electric motor performance. The use of advanced power electronic devices, such as inverters, converters, and battery management systems, allows for precise control over motor performance, optimizing efficiency, range, and overall vehicle performance. As electric vehicle technology continues to evolve, the importance of power electronics in electric vehicle motor operations will only continue to grow.

Thermal Management Strategies for Electric Vehicle Motors

Thermal management is a critical aspect of electric vehicle motor operations, as excessive heat can reduce motor efficiency, lifespan, and performance. In electric vehicle and electric motor operations management, thermal management strategies play a vital role in maintaining optimal motor temperatures, ensuring efficient and reliable motor operations.

There are several thermal management strategies used in electric vehicle motors, including air cooling, liquid cooling, and heat exchangers. Air cooling is a common method used in electric vehicles, where a cooling fan is used to circulate air through the motor, dissipating heat. Liquid cooling is another method used in electric vehicles, where a coolant is pumped through the motor, absorbing heat and transferring it to a radiator, where it is dissipated.

Heat exchangers are also used in electric vehicle motors, where a heat exchanger is used to transfer heat from the motor to a coolant, which is then dissipated through a radiator. Heat exchangers are commonly used in electric vehicles, as they offer high efficiency and reliability. Additionally, heat exchangers can be used in conjunction with air cooling or liquid cooling systems, providing a hybrid thermal management solution.

The choice of thermal management strategy depends on several factors, including the type of electric vehicle, the motor design, and the operating conditions. For example, air cooling may be suitable for small electric vehicles with low power motors, while liquid cooling or heat exchangers may be more suitable for larger electric vehicles with high power motors.

In addition to the choice of thermal management strategy, the design and implementation of thermal management systems are also critical. The design of thermal management systems must take into account the specific requirements of electric vehicle motor operations, including high efficiency, reliability, and thermal management. The implementation of thermal management systems must also be carefully considered, with attention paid to the integration of thermal management systems with other electric vehicle systems, such as the motor control system and battery management system.

Overall, thermal management is a critical aspect of electric vehicle motor operations, and the choice of thermal management strategy depends on several factors. By understanding the different thermal management strategies available, electric vehicle manufacturers and operators can optimize their thermal management systems, ensuring efficient and reliable motor operations.

In electric vehicle and electric motor operations management, thermal management strategies play a vital role in maintaining optimal motor temperatures, ensuring efficient and reliable motor operations. By incorporating innovative and creative thermal management solutions, electric vehicle manufacturers and operators can improve the efficiency, reliability, and performance of their electric vehicles, reducing energy consumption and emissions.

Electric Motor Control Systems: A Deep Dive

Electric motor control systems are a critical component of electric vehicle motor operations, enabling efficient and precise motor control. In electric vehicle and electric motor operations management, motor control systems play a vital role in optimizing motor performance, efficiency, and lifespan.

There are several types of motor control algorithms used in electric vehicles, including field-oriented control (FOC) and direct torque control (DTC). FOC is a widely used algorithm that controls the motor by regulating the magnetic field and torque. DTC is another popular algorithm that controls the motor by directly regulating the torque and flux.

Motor control systems also rely on software and programming to optimize motor performance. Advanced software algorithms can be used to optimize motor control, taking into account factors such as motor temperature, speed, and torque. Programming languages such as C++ and Python are commonly used in motor control systems, allowing developers to create customized control algorithms and optimize motor performance.

In addition to software and programming, motor control systems also rely on hardware components such as sensors, actuators, and power electronics. Sensors such as encoders and resolvers are used to measure motor speed and position, while actuators such as motors and gearboxes are used to control motor torque and speed. Power electronics such as inverters and converters are used to control the flow of electrical energy to the motor.

The design and implementation of motor control systems are critical in electric vehicle motor operations. The design of motor control systems must take into account the specific requirements of electric vehicle motor operations, including high efficiency, reliability, and thermal management. The implementation of motor control systems must also be carefully considered, with attention paid to the integration of motor control systems with other electric vehicle systems, such as the battery management system and thermal management system.

Overall, electric motor control systems are a critical component of electric vehicle motor operations, enabling efficient and precise motor control. By understanding the different types of motor control algorithms and the role of software and programming in motor control, electric vehicle manufacturers and operators can optimize their motor control systems, improving motor performance, efficiency, and lifespan.

In electric vehicle and electric motor operations management, motor control systems play a vital role in optimizing motor performance, efficiency, and lifespan. By incorporating innovative and creative motor control solutions, electric vehicle manufacturers and operators can improve the efficiency, reliability, and performance of their electric vehicles, reducing energy consumption and emissions.

Real-World Examples of Electric Vehicle Motor Operations Management

Several companies have successfully implemented efficient electric motor operations management in their electric vehicles, resulting in improved performance, efficiency, and reduced costs. Tesla, for example, has optimized its electric motor operations through the use of advanced power electronics and motor control systems. The company’s electric vehicles are equipped with high-performance electric motors that are designed to provide exceptional efficiency and reliability.

Nissan has also implemented efficient electric motor operations management in its electric vehicles, including the Leaf. The company’s electric vehicles are equipped with advanced motor control systems that optimize motor performance and efficiency. Nissan has also implemented a range of thermal management strategies to ensure optimal motor performance and lifespan.

BMW has also optimized its electric motor operations through the use of advanced power electronics and motor control systems. The company’s electric vehicles, such as the i3 and iX3, are equipped with high-performance electric motors that are designed to provide exceptional efficiency and reliability. BMW has also implemented a range of thermal management strategies to ensure optimal motor performance and lifespan.

These companies have achieved significant improvements in electric motor performance and efficiency through the implementation of efficient electric motor operations management. By optimizing power electronics, motor control, and thermal management, these companies have been able to reduce energy consumption, improve motor lifespan, and enhance overall vehicle performance.

In addition to these examples, there are several other companies that have successfully implemented efficient electric motor operations management in their electric vehicles. These companies have achieved significant improvements in electric motor performance and efficiency, resulting in reduced costs and improved overall vehicle performance.

Overall, the implementation of efficient electric motor operations management is critical for electric vehicle manufacturers and operators. By optimizing power electronics, motor control, and thermal management, companies can achieve significant improvements in electric motor performance and efficiency, resulting in reduced costs and improved overall vehicle performance.

In electric vehicle and electric motor operations management, the implementation of efficient electric motor operations is critical for achieving optimal performance, efficiency, and lifespan. By incorporating innovative and creative motor operations management solutions, electric vehicle manufacturers and operators can improve the efficiency, reliability, and performance of their electric vehicles, reducing energy consumption and emissions.

Future Trends and Innovations in Electric Vehicle Motor Operations

The future of electric vehicle motor operations is exciting and rapidly evolving. Emerging trends and innovations, such as advanced materials, new motor designs, and autonomous vehicles, are expected to shape the future of electric vehicle motor operations management.

Advanced materials, such as rare-earth magnets and high-temperature superconductors, are being developed to improve the efficiency and performance of electric motors. These materials have the potential to increase the power density and efficiency of electric motors, enabling electric vehicles to travel further and faster.

New motor designs, such as axial flux motors and transverse flux motors, are also being developed to improve the efficiency and performance of electric motors. These motor designs have the potential to increase the power density and efficiency of electric motors, enabling electric vehicles to travel further and faster.

Autonomous vehicles are also expected to play a major role in the future of electric vehicle motor operations. Autonomous vehicles will require advanced electric motor control systems that can optimize motor performance and efficiency in real-time. This will require the development of advanced software and programming algorithms that can analyze data from various sensors and optimize motor performance accordingly.

In addition to these trends and innovations, there are several other developments that are expected to shape the future of electric vehicle motor operations. These include the development of advanced battery management systems, the integration of electric vehicles with the grid, and the development of new charging technologies.

Overall, the future of electric vehicle motor operations is exciting and rapidly evolving. Emerging trends and innovations, such as advanced materials, new motor designs, and autonomous vehicles, are expected to shape the future of electric vehicle motor operations management. By incorporating these trends and innovations into their electric vehicle motor operations, manufacturers and operators can improve the efficiency, performance, and reliability of their electric vehicles.

In electric vehicle and electric motor operations management, the future is all about innovation and improvement. By staying ahead of the curve and incorporating emerging trends and innovations into their electric vehicle motor operations, manufacturers and operators can improve the efficiency, performance, and reliability of their electric vehicles, reducing energy consumption and emissions.

Implementing Efficient Electric Motor Operations in Your Fleet

Implementing efficient electric motor operations in your fleet requires a comprehensive approach that includes regular maintenance, data analysis, and driver training. By following these best practices, fleet managers and operators can optimize motor performance, reduce costs, and improve overall vehicle efficiency.

Regular maintenance is critical to ensuring efficient electric motor operations. This includes routine checks on motor temperature, voltage, and current, as well as regular maintenance of power electronics and motor control systems. By identifying and addressing potential issues early, fleet managers and operators can prevent costly repairs and downtime.

Data analysis is also essential to optimizing electric motor operations. By analyzing data from various sensors and systems, fleet managers and operators can identify trends and patterns that can inform maintenance and optimization strategies. This includes analyzing data on motor performance, energy consumption, and driver behavior.

Driver training is also critical to optimizing electric motor operations. By educating drivers on best practices for electric vehicle operation, fleet managers and operators can improve driver behavior and reduce energy consumption. This includes training on optimal acceleration and braking techniques, as well as strategies for minimizing energy consumption.

In addition to these best practices, fleet managers and operators can also implement various technologies to optimize electric motor operations. This includes advanced power electronics, motor control systems, and thermal management systems. By leveraging these technologies, fleet managers and operators can improve motor performance, reduce costs, and improve overall vehicle efficiency.

Overall, implementing efficient electric motor operations in your fleet requires a comprehensive approach that includes regular maintenance, data analysis, and driver training. By following these best practices and leveraging advanced technologies, fleet managers and operators can optimize motor performance, reduce costs, and improve overall vehicle efficiency.

In electric vehicle and electric motor operations management, implementing efficient electric motor operations is critical to achieving optimal performance, efficiency, and lifespan. By incorporating innovative and creative motor operations management solutions, fleet managers and operators can improve the efficiency, reliability, and performance of their electric vehicles, reducing energy consumption and emissions.