Unlocking the Potential of Electric Motors

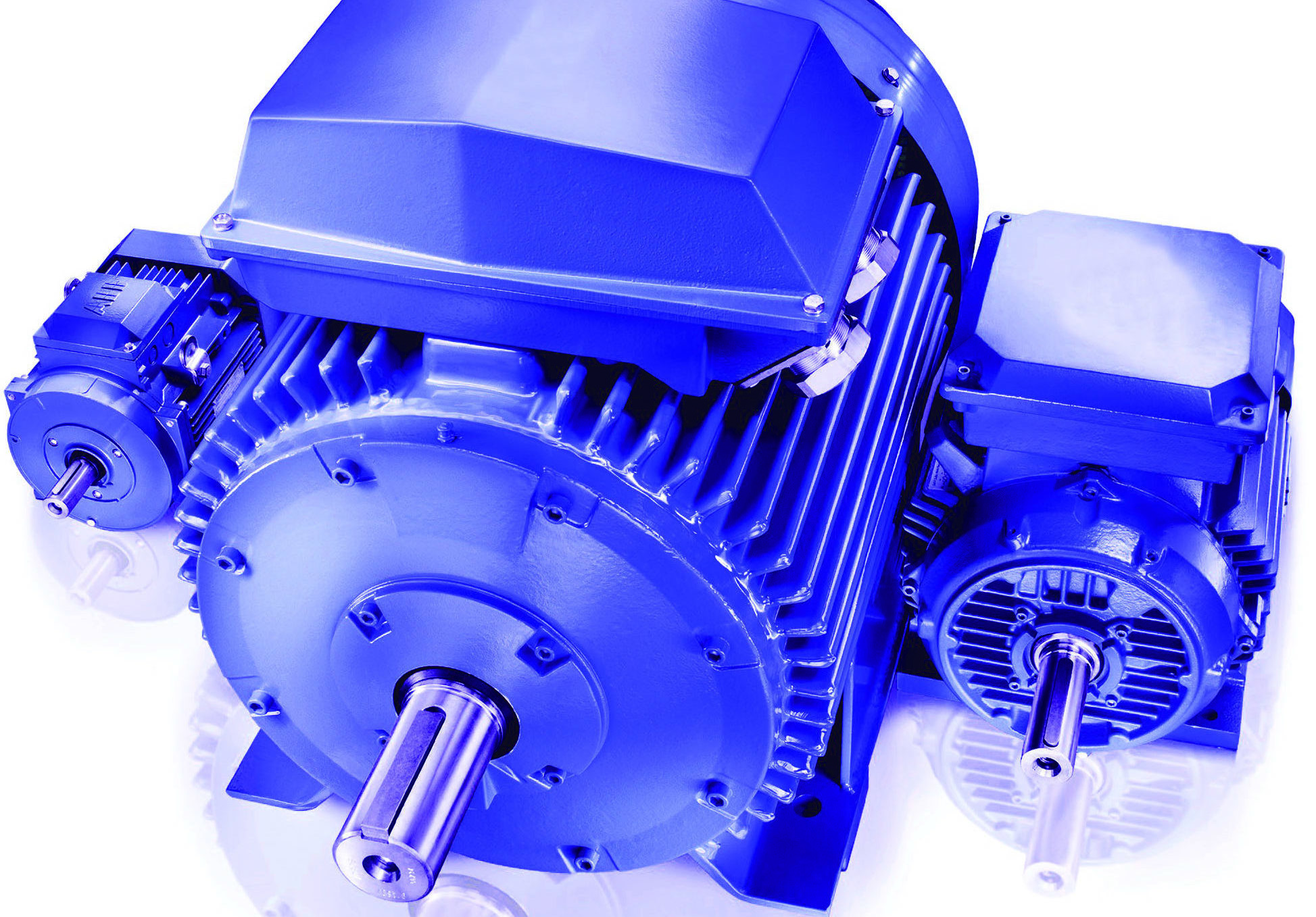

Electric motor technology has made significant strides in recent years, transforming the electric vehicle (EV) industry. The current state of electric motor technology is characterized by improved efficiency, reduced emissions, and increased power density. These advancements have been driven by the development of new materials, designs, and manufacturing processes.

One of the key benefits of electric motors is their improved efficiency compared to traditional internal combustion engines. Electric motors can achieve efficiency rates of 90% or higher, compared to 30-40% for internal combustion engines. This increased efficiency, combined with the reduced emissions, makes electric motors an attractive option for EV manufacturers.

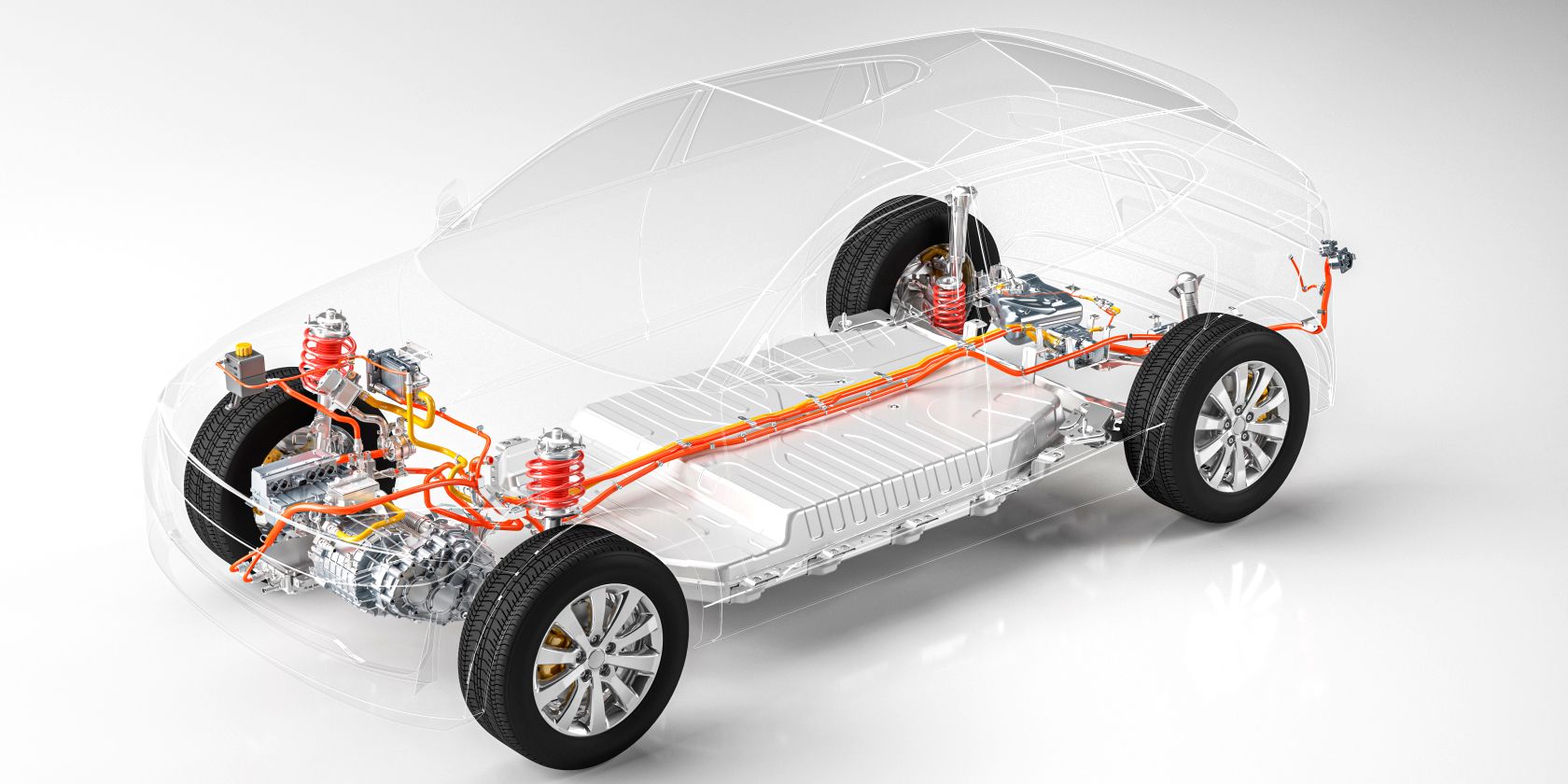

The applications of electric motors in EVs are diverse, ranging from passenger vehicles to commercial trucks and buses. Electric motors are also being used in hybrid vehicles, which combine the benefits of electric and internal combustion engines. As the demand for EVs continues to grow, the importance of electric motor innovation will only increase.

Electric motor and electric vehicle innovation strategies are critical to the development of the EV industry. By investing in research and development, manufacturers can improve the efficiency, range, and affordability of EVs. This, in turn, will drive adoption and help to reduce greenhouse gas emissions.

How to Drive Innovation in Electric Vehicle Design

Innovation in electric vehicle (EV) design is crucial for the widespread adoption of EVs. Several key factors are driving innovation in EV design, including advances in battery technology, aerodynamics, and lightweight materials. These advancements are enabling EV manufacturers to improve the range, efficiency, and affordability of their vehicles.

Advances in battery technology are a major driver of innovation in EV design. New battery chemistries, such as lithium-air and solid-state batteries, are being developed to improve energy density and reduce costs. These advancements are enabling EV manufacturers to increase the range of their vehicles while reducing their weight and cost.

Aerodynamics is another key area of innovation in EV design. EV manufacturers are using advanced computer simulations and wind tunnel testing to optimize the aerodynamics of their vehicles. This is enabling them to reduce drag, improve range, and enhance the overall efficiency of their vehicles.

Lightweight materials are also playing a critical role in EV design innovation. EV manufacturers are using advanced materials, such as carbon fiber and aluminum, to reduce the weight of their vehicles. This is enabling them to improve the range and efficiency of their vehicles while reducing their environmental impact.

Electric motor and electric vehicle innovation strategies are essential for driving innovation in EV design. By investing in research and development, EV manufacturers can stay ahead of the curve and develop vehicles that meet the needs of consumers. This includes investing in new technologies, such as autonomous driving and advanced mobility solutions.

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these

The Role of Advanced Materials in Electric Motor Development

Advanced materials are playing a crucial role in the development of electric motors, enabling the creation of more efficient, compact, and powerful motors. Rare-earth magnets, high-temperature superconductors, and advanced composites are some of the materials being used to improve electric motor performance.

Rare-earth magnets, such as neodymium and dysprosium, are being used to create high-performance electric motors. These magnets offer high magnetic strength, corrosion resistance, and durability, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited supply, and environmental concerns.

High-temperature superconductors are another advanced material being used in electric motor development. These materials can operate at high temperatures, reducing the need for cooling systems and increasing motor efficiency. High-temperature superconductors also offer high current density, enabling the creation of more compact and powerful motors.

Advanced composites, such as carbon fiber and nanomaterials, are also being used to improve electric motor performance. These materials offer high strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in electric motor components. Advanced composites can also be used to create complex geometries and shapes, enabling the creation of more efficient and compact motors.

The use of advanced materials in electric motor development is a key aspect of electric motor and electric vehicle innovation strategies. By leveraging these