Mastering the Fundamentals of Electric Motor Management

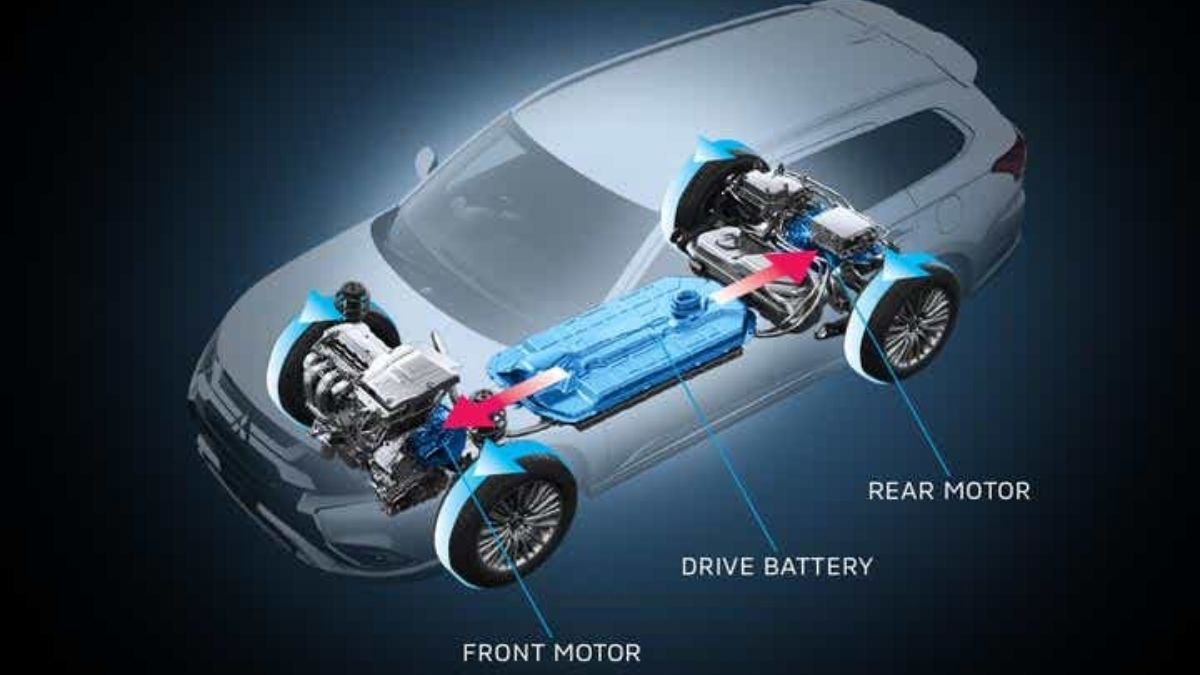

Effective electric motor management is crucial for optimizing electric vehicle performance, efficiency, and overall driving experience. Electric motor operations play a vital role in determining the vehicle’s acceleration, top speed, and range. The key components of electric motor operations include the motor itself, power electronics, and control systems. These components work together to convert electrical energy into mechanical energy, propelling the vehicle forward.

The electric motor is the heart of an electric vehicle, responsible for converting electrical energy into torque and propulsion. The power electronics system, comprising the inverter and other components, controls the flow of electrical energy to the motor. The control system, including the vehicle control unit and motor control unit, regulates the operation of the motor and power electronics, ensuring optimal performance and efficiency.

Electric vehicle manufacturers employ various electric motor technologies, including permanent magnet, induction, and switched reluctance motors. Each technology has its strengths and weaknesses, and the choice of motor type depends on the specific application and requirements. For instance, permanent magnet motors offer high efficiency and power density, making them suitable for high-performance electric vehicles.

In addition to the motor technology, the design and configuration of the electric motor operations system also impact performance and efficiency. Factors such as motor winding, magnet material, and cooling system design can significantly influence the motor’s efficiency, reliability, and lifespan. Furthermore, the integration of advanced technologies, such as regenerative braking and torque vectoring, can enhance the overall driving experience and efficiency of the electric vehicle.

By understanding the fundamentals of electric motor management, electric vehicle manufacturers and operators can optimize motor operations to achieve improved performance, efficiency, and reliability. This, in turn, can lead to increased customer satisfaction, reduced maintenance costs, and a competitive edge in the market. As the electric vehicle industry continues to evolve, the importance of effective electric motor management will only continue to grow.

Electric vehicle and electric motor operations management is a critical aspect of the electric vehicle ecosystem, and its impact on performance, efficiency, and overall driving experience cannot be overstated. By mastering the fundamentals of electric motor management, stakeholders can unlock the full potential of electric vehicles and drive the transition to a more sustainable and efficient transportation sector.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance are crucial for ensuring the optimal performance and longevity of electric vehicle motors. Neglecting motor health can lead to reduced efficiency, decreased performance, and even costly repairs. By following a proactive maintenance schedule, electric vehicle owners and operators can prevent common issues and ensure their motors continue to operate at peak levels.

One of the most important aspects of motor maintenance is regular checks. This includes inspecting the motor for signs of wear and tear, such as excessive vibration, noise, or heat. Additionally, monitoring the motor’s electrical performance, including voltage, current, and power factor, can help identify potential issues before they become major problems.

Troubleshooting common issues is also essential for maintaining electric motor health. This includes identifying and addressing problems such as overheating, overloading, and electrical faults. By understanding the root causes of these issues, electric vehicle owners and operators can take corrective action to prevent them from occurring in the future.

Routine maintenance tasks, such as cleaning and lubricating the motor, are also critical for ensuring optimal performance. Regular cleaning can help prevent the buildup of debris and dust, which can reduce motor efficiency and increase the risk of overheating. Lubricating the motor’s moving parts can help reduce friction and wear, extending the motor’s lifespan.

In addition to regular checks and maintenance tasks, electric vehicle owners and operators can also utilize advanced technologies to monitor and maintain motor health. This includes the use of condition monitoring systems, which can provide real-time data on motor performance and health. By leveraging these technologies, electric vehicle owners and operators can optimize motor performance, reduce downtime, and extend the lifespan of their motors.

Effective electric vehicle and electric motor operations management requires a proactive approach to maintenance and monitoring. By following a regular maintenance schedule and utilizing advanced technologies, electric vehicle owners and operators can ensure their motors continue to operate at peak levels, reducing the risk of costly repairs and downtime. By prioritizing motor health, electric vehicle owners and operators can optimize performance, efficiency, and reliability, and get the most out of their electric vehicles.

Electric Vehicle Charging Strategies for Optimal Motor Performance

Electric vehicle charging strategies play a crucial role in optimizing motor performance, efficiency, and overall driving experience. With various charging methods available, it’s essential to understand the benefits and drawbacks of each to choose the best strategy for specific driving needs and habits.

Level 1 charging, also known as trickle charging, is the slowest and most basic method. It uses a standard 120-volt household outlet and is suitable for drivers who have a short commute or don’t drive frequently. However, Level 1 charging can take up to 24 hours to fully charge an electric vehicle, making it less convenient for drivers who need to charge their vehicle quickly.

Level 2 charging, on the other hand, is a faster and more popular method. It uses a 240-volt charging station and can charge an electric vehicle in 4-8 hours. Level 2 charging is ideal for drivers who have a moderate commute or drive frequently, as it provides a faster charging time without the need for expensive equipment.

DC Fast Charging is the fastest method, capable of charging an electric vehicle to 80% in just 30 minutes. However, it requires specialized equipment and is typically more expensive than Level 1 and Level 2 charging. DC Fast Charging is best suited for drivers who need to charge their vehicle quickly, such as those on long road trips or with limited charging time.

When choosing a charging strategy, it’s essential to consider factors such as driving habits, commute distance, and charging infrastructure. For example, drivers with a short commute may prefer Level 1 charging, while those with a longer commute may prefer Level 2 or DC Fast Charging. Additionally, drivers should consider the type of electric vehicle they own, as some models may be more compatible with certain charging methods.

Effective electric vehicle and electric motor operations management requires a deep understanding of charging strategies and their impact on motor performance. By choosing the right charging strategy, drivers can optimize their electric vehicle’s performance, efficiency, and overall driving experience. Moreover, manufacturers and charging infrastructure providers can design and implement charging systems that cater to the diverse needs of electric vehicle owners, promoting widespread adoption and sustainability.

In conclusion, electric vehicle charging strategies are a critical aspect of electric motor operations management. By understanding the benefits and drawbacks of each charging method, drivers can make informed decisions that optimize their electric vehicle’s performance, efficiency, and overall driving experience.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric motor operations, as excessive heat can significantly impact efficiency, performance, and lifespan. Electric vehicles rely on electric motors to propel the vehicle, and these motors generate heat as a byproduct of operation. If not properly managed, this heat can lead to reduced motor efficiency, decreased performance, and even premature failure.

To mitigate these effects, various thermal management techniques are employed in electric vehicles. One common approach is the use of cooling systems, which circulate a coolant through the motor to absorb heat. This coolant is then dissipated through a heat exchanger, such as a radiator, to maintain a stable motor temperature.

Another technique is thermal shielding, which involves using materials with high thermal resistance to reduce heat transfer between the motor and surrounding components. This can include the use of thermal interface materials, such as thermal pads or tapes, to minimize heat transfer between the motor and other components.

In addition to these techniques, some electric vehicles employ advanced thermal management systems, such as liquid cooling or air cooling systems. These systems use a combination of fans, heat exchangers, and coolant to maintain a stable motor temperature, even in extreme operating conditions.

The importance of thermal management in electric motor operations cannot be overstated. By maintaining a stable motor temperature, electric vehicles can optimize motor efficiency, performance, and lifespan. This, in turn, can lead to improved overall vehicle efficiency, reduced maintenance costs, and enhanced driving experience.

Effective electric vehicle and electric motor operations management requires a deep understanding of thermal management techniques and their impact on motor efficiency. By incorporating these techniques into electric vehicle design and operation, manufacturers can create vehicles that are more efficient, reliable, and sustainable.

In the context of electric vehicle and electric motor operations management, thermal management is a critical aspect that cannot be ignored. By prioritizing thermal management, manufacturers and operators can optimize motor performance, efficiency, and lifespan, leading to improved overall vehicle efficiency and reduced maintenance costs.

Electric Motor Control Systems: Understanding the Technology

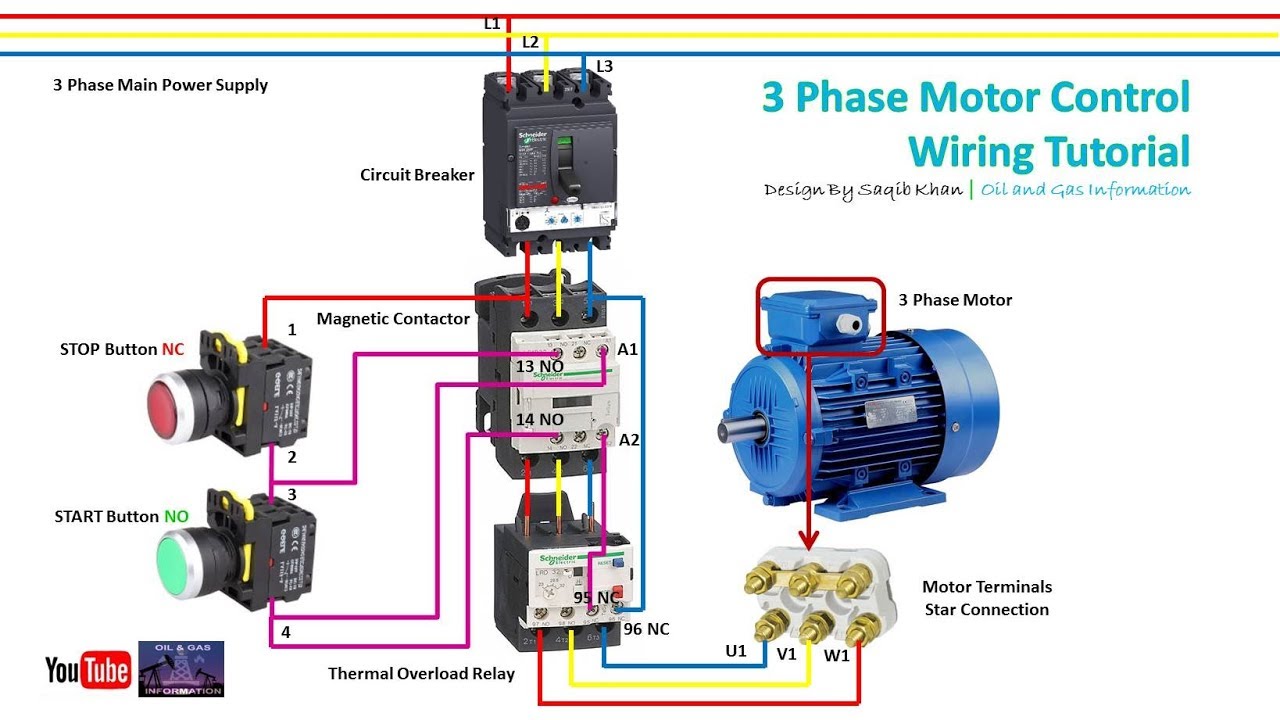

Electric motor control systems are a critical component of electric vehicle motor operations, as they play a crucial role in optimizing motor performance, efficiency, and reliability. These systems consist of various controllers, sensors, and software that work together to regulate the flow of electrical energy to the motor.

There are two primary types of electric motor controllers: AC and DC controllers. AC controllers are used in induction motors and are responsible for controlling the frequency and amplitude of the AC power supplied to the motor. DC controllers, on the other hand, are used in permanent magnet motors and control the flow of DC power to the motor.

In addition to these controllers, electric motor control systems also include various sensors and software that monitor and adjust motor performance in real-time. These sensors can include temperature sensors, current sensors, and position sensors, which provide critical data on motor performance and health.

The software component of electric motor control systems is also essential, as it enables the system to optimize motor performance and efficiency based on various parameters, such as speed, torque, and temperature. This software can include advanced algorithms and machine learning techniques that enable the system to adapt to changing operating conditions and optimize motor performance accordingly.

Effective electric vehicle and electric motor operations management requires a deep understanding of electric motor control systems and their role in optimizing motor performance. By selecting the right controller and software for specific motor applications, manufacturers and operators can optimize motor efficiency, performance, and reliability, leading to improved overall vehicle efficiency and reduced maintenance costs.

In the context of electric vehicle and electric motor operations management, electric motor control systems are a critical aspect that cannot be ignored. By prioritizing the development and implementation of advanced electric motor control systems, manufacturers and operators can optimize motor performance, efficiency, and reliability, leading to improved overall vehicle efficiency and reduced maintenance costs.

As the electric vehicle industry continues to evolve, the importance of electric motor control systems will only continue to grow. By staying at the forefront of this technology, manufacturers and operators can ensure that their electric vehicles remain competitive and efficient, while also providing a superior driving experience for their customers.

Real-World Examples of Electric Vehicle Motor Operations Management

Electric vehicle motor operations management is a critical aspect of ensuring optimal performance, efficiency, and reliability in electric vehicles. In this section, we will explore real-world examples of electric vehicle motor operations management in action, including case studies of successful implementations and lessons learned.

One notable example is the Tesla Model S, which features a advanced electric motor control system that optimizes motor performance and efficiency. The system uses a combination of sensors and software to monitor and adjust motor performance in real-time, ensuring optimal efficiency and performance.

Another example is the Nissan Leaf, which features a thermal management system that optimizes motor temperature and efficiency. The system uses a combination of cooling systems and thermal shielding to maintain optimal motor temperature, even in extreme operating conditions.

In addition to these examples, there are many other successful implementations of electric vehicle motor operations management in various industries and applications. For instance, the electric bus manufacturer, BYD, has implemented an advanced motor control system that optimizes motor performance and efficiency in their electric buses.

These real-world examples demonstrate the importance of electric vehicle motor operations management in ensuring optimal performance, efficiency, and reliability in electric vehicles. By implementing effective motor operations management strategies, manufacturers and operators can optimize motor performance, reduce maintenance costs, and improve overall vehicle efficiency.

Lessons learned from these examples include the importance of ongoing monitoring and maintenance, the need for advanced motor control systems, and the benefits of thermal management techniques. By incorporating these lessons into their own motor operations management strategies, manufacturers and operators can optimize motor performance and efficiency, leading to improved overall vehicle efficiency and reduced maintenance costs.

As the electric vehicle industry continues to evolve, the importance of electric vehicle motor operations management will only continue to grow. By staying at the forefront of this technology, manufacturers and operators can ensure that their electric vehicles remain competitive and efficient, while also providing a superior driving experience for their customers.

Future Developments in Electric Motor Technology

The electric motor technology is rapidly evolving, with new advancements and innovations emerging regularly. In this section, we will discuss the latest developments and future trends in electric motor technology, and how they will impact electric vehicle performance, efficiency, and overall driving experience.

One of the most significant developments in electric motor technology is the use of advanced materials and designs. For example, the use of rare-earth magnets in electric motors has improved efficiency and reduced weight. Additionally, the development of new motor designs, such as the axial flux motor, has improved performance and efficiency.

Another area of development is the use of advanced control systems and software. For example, the use of model predictive control (MPC) algorithms has improved motor efficiency and performance. Additionally, the development of advanced software tools has enabled the optimization of motor design and operation.

Furthermore, the use of electric motors in hybrid and fuel cell vehicles is becoming increasingly popular. These vehicles use electric motors in combination with traditional internal combustion engines or fuel cells to improve efficiency and reduce emissions.

In the future, we can expect to see even more advanced electric motor technologies emerge. For example, the use of advanced materials, such as graphene and nanomaterials, is expected to improve motor efficiency and performance. Additionally, the development of new motor designs, such as the transverse flux motor, is expected to improve performance and efficiency.

These advancements in electric motor technology will have a significant impact on electric vehicle performance, efficiency, and overall driving experience. For example, improved motor efficiency will enable electric vehicles to travel longer distances on a single charge, while improved performance will enable faster acceleration and better handling.

In conclusion, the future of electric motor technology is exciting and rapidly evolving. As new advancements and innovations emerge, we can expect to see significant improvements in electric vehicle performance, efficiency, and overall driving experience.

Effective electric vehicle and electric motor operations management will be critical to ensuring that these advancements are realized. By staying at the forefront of this technology, manufacturers and operators can optimize motor performance, efficiency, and reliability, leading to improved overall vehicle efficiency and reduced maintenance costs.

Best Practices for Electric Vehicle Motor Operations Management

Effective electric vehicle motor operations management is crucial for ensuring optimal performance, efficiency, and reliability. In this section, we will summarize the key takeaways from the article and provide a comprehensive list of best practices for electric vehicle motor operations management.

Regular monitoring and maintenance are essential for preventing costly repairs and ensuring optimal performance. This includes regular checks on motor temperature, voltage, and current, as well as troubleshooting common issues and performing routine maintenance tasks.

Proper charging strategies are also critical for optimal motor performance. This includes choosing the right charging method for specific driving needs and habits, such as Level 1, Level 2, or DC Fast Charging.

Thermal management is also essential for electric motor efficiency. This includes using cooling systems and thermal shielding to maintain optimal motor temperature, even in extreme operating conditions.

Electric motor control systems are also critical for optimizing motor performance, efficiency, and reliability. This includes understanding the different types of controllers, such as AC and DC controllers, and their functions.

Real-world examples of electric vehicle motor operations management in action can provide valuable insights and lessons learned. This includes case studies of successful implementations and challenges faced in various industries and applications.

Staying up-to-date with the latest advancements and future developments in electric motor technology is also essential for effective electric vehicle motor operations management. This includes emerging trends, innovations, and breakthroughs that will impact electric vehicle performance, efficiency, and overall driving experience.

In conclusion, effective electric vehicle motor operations management requires a comprehensive approach that includes regular monitoring and maintenance, proper charging strategies, thermal management, electric motor control systems, and staying up-to-date with the latest advancements and future developments in electric motor technology.

By following these best practices, manufacturers and operators can optimize motor performance, efficiency, and reliability, leading to improved overall vehicle efficiency and reduced maintenance costs.

Effective electric vehicle and electric motor operations management is critical for ensuring optimal performance, efficiency, and reliability. By prioritizing these best practices, manufacturers and operators can optimize motor performance, efficiency, and reliability, leading to improved overall vehicle efficiency and reduced maintenance costs.