Unlocking the Potential of Electric Motors: Understanding the Basics

Electric vehicle and electric motor operations management is a critical aspect of the electric vehicle (EV) industry, as it directly impacts the performance, efficiency, and lifespan of EVs. Optimized electric motor operations can lead to significant benefits, including reduced energy consumption, extended lifespan, and improved overall efficiency. To achieve these benefits, it is essential to understand the fundamental principles of electric motors and their role in EVs.

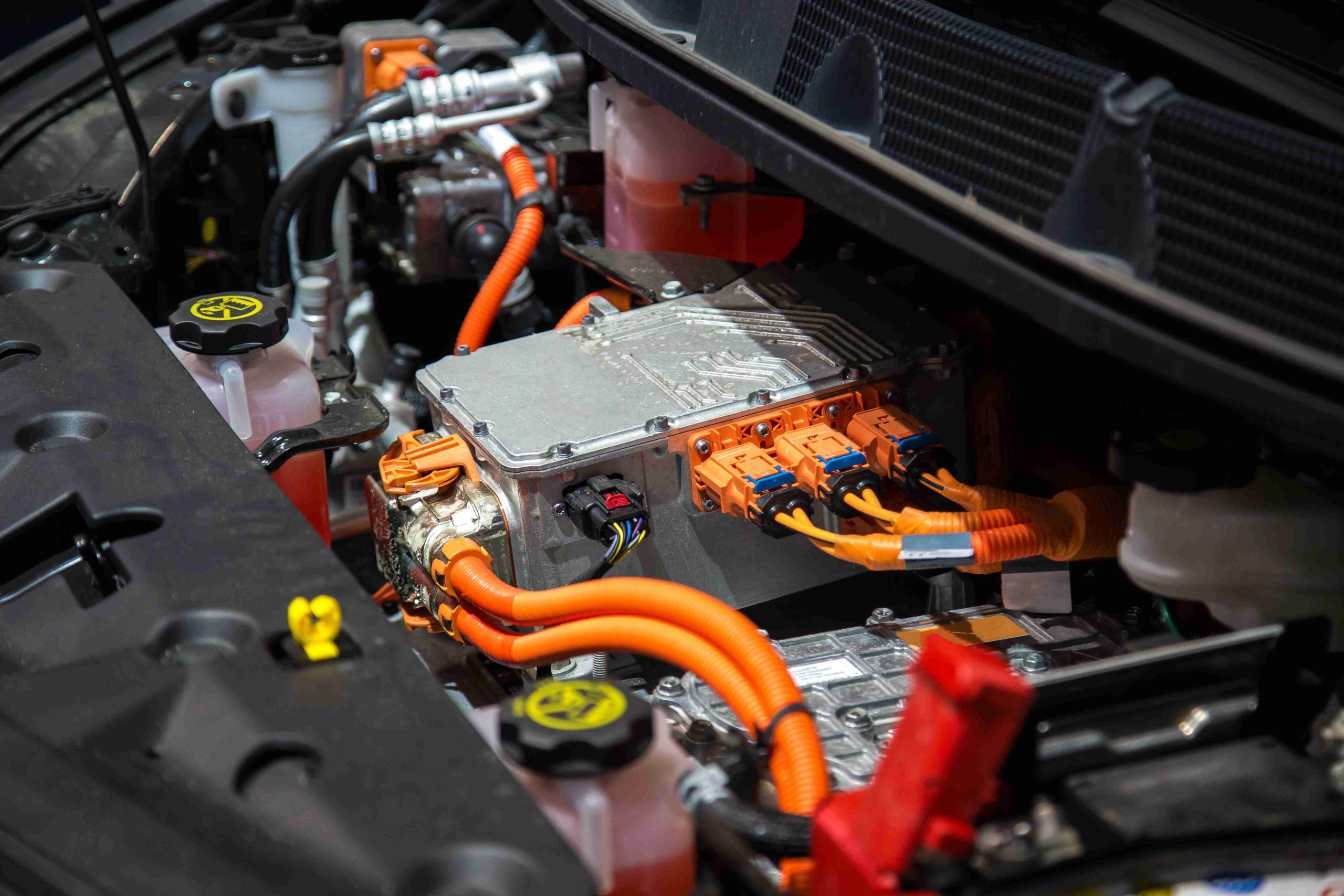

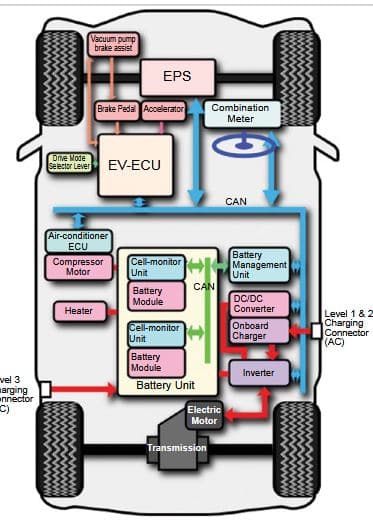

Electric motors are the heart of EVs, converting electrical energy into mechanical energy to propel the vehicle. The most common type of electric motor used in EVs is the permanent magnet synchronous motor (PMSM), which offers high efficiency, reliability, and durability. However, electric motors are not without their challenges, and effective operations management is crucial to mitigate issues such as overheating, vibration, and reduced performance.

Effective electric vehicle and electric motor operations management involves a range of strategies, including monitoring and maintaining electric motor health, optimizing charging strategies, and implementing advanced control systems. By understanding the basics of electric motors and their role in EVs, operators can take the first step towards optimizing electric motor operations and unlocking the full potential of their EVs.

In the context of electric vehicle and electric motor operations management, it is essential to consider the interplay between the electric motor, power electronics, and control systems. By optimizing these components, operators can achieve significant improvements in efficiency, performance, and lifespan. Furthermore, the use of advanced technologies such as regenerative braking and torque vectoring can further enhance the efficiency and performance of EVs.

As the EV industry continues to evolve, the importance of electric vehicle and electric motor operations management will only continue to grow. By understanding the basics of electric motors and their role in EVs, operators can stay ahead of the curve and optimize their electric motor operations for improved efficiency, performance, and lifespan.

How to Monitor and Maintain Electric Motor Health for Peak Performance

Regular monitoring and maintenance of electric motor health is crucial for ensuring peak performance, preventing downtime, and reducing repair costs in electric vehicle and electric motor operations management. Effective monitoring and maintenance involve a range of strategies, including temperature management, vibration analysis, and condition-based maintenance.

Temperature management is critical for electric motor health, as excessive heat can lead to reduced performance, increased energy consumption, and premature wear. Operators can use temperature sensors and monitoring systems to track electric motor temperature and identify potential issues before they become major problems. Regular cleaning and maintenance of electric motor cooling systems can also help to prevent overheating.

Vibration analysis is another key aspect of electric motor health monitoring. Excessive vibration can lead to reduced performance, increased energy consumption, and premature wear. Operators can use vibration sensors and analysis software to identify potential issues and take corrective action. Regular balancing and alignment of electric motor components can also help to reduce vibration and improve overall performance.

Condition-based maintenance is a proactive approach to electric motor maintenance that involves monitoring electric motor condition and performing maintenance only when necessary. This approach can help to reduce maintenance costs, improve overall efficiency, and extend electric motor lifespan. Operators can use condition-based maintenance software and sensors to track electric motor condition and schedule maintenance accordingly.

In addition to these strategies, operators can also use data analytics and machine learning algorithms to predict electric motor maintenance needs and optimize overall performance. By analyzing data from electric motor sensors and monitoring systems, operators can identify potential issues before they become major problems and take corrective action to prevent downtime and reduce repair costs.

Effective electric motor monitoring and maintenance are critical components of electric vehicle and electric motor operations management. By implementing these strategies, operators can ensure peak performance, prevent downtime, and reduce repair costs. Regular monitoring and maintenance can also help to extend electric motor lifespan, improve overall efficiency, and reduce energy consumption.

Electric Vehicle Charging Strategies for Efficient Operations

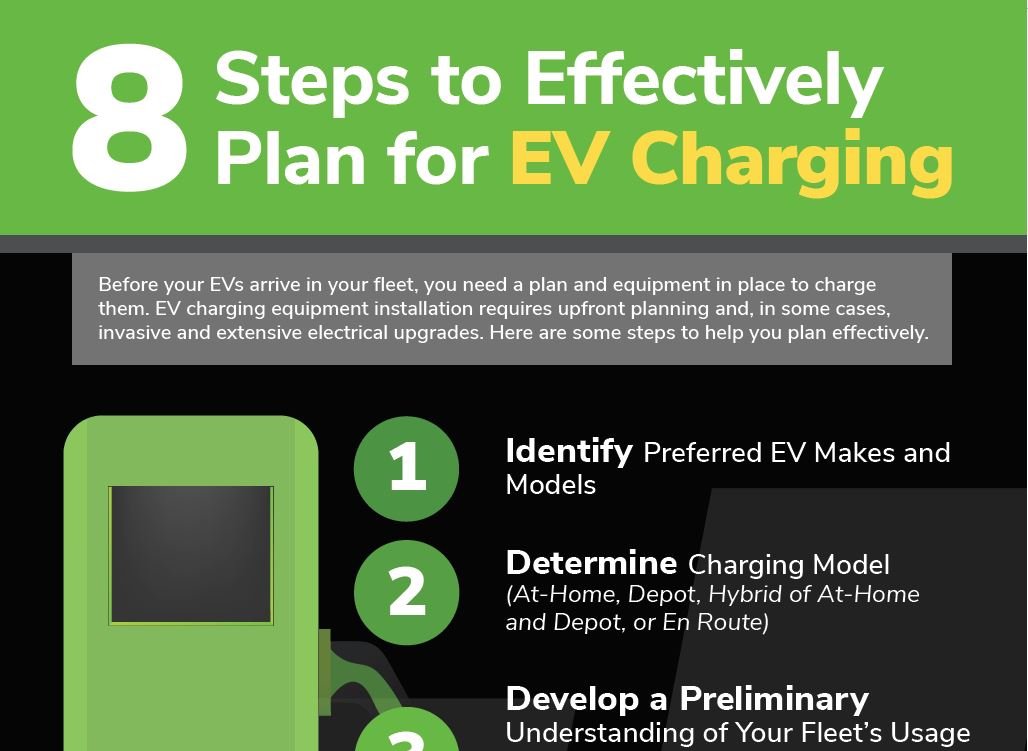

Electric vehicle charging is a critical aspect of electric vehicle and electric motor operations management, as it directly impacts the efficiency, performance, and overall cost of EV ownership. With the increasing adoption of electric vehicles, it is essential to understand the different charging strategies available and how to select the most efficient approach for specific use cases.

Level 1 charging is the most basic form of electric vehicle charging, using a standard 120-volt outlet to charge the vehicle. This method is suitable for vehicles with small batteries and low power requirements, but it can take up to 24 hours to fully charge a vehicle. Level 1 charging is often used for overnight charging at home or in low-usage applications.

Level 2 charging is a more advanced form of electric vehicle charging, using a 240-volt charging station to charge the vehicle. This method is faster than Level 1 charging, taking around 4-8 hours to fully charge a vehicle. Level 2 charging is often used for home charging, workplace charging, and public charging stations.

DC Fast Charging is the fastest form of electric vehicle charging, using a high-power charging station to charge the vehicle to 80% in under 30 minutes. This method is often used for long-distance driving, highway rest stops, and high-usage applications.

When selecting a charging strategy, it is essential to consider the specific use case and requirements of the vehicle. For example, a vehicle used for short-distance driving may only require Level 1 charging, while a vehicle used for long-distance driving may require DC Fast Charging. Additionally, the cost of charging, the availability of charging infrastructure, and the impact on the electrical grid must also be considered.

In electric vehicle and electric motor operations management, the selection of a charging strategy can have a significant impact on the overall efficiency and performance of the vehicle. By understanding the different charging strategies available and selecting the most efficient approach for specific use cases, operators can optimize their EV operations and reduce costs.

Furthermore, the use of advanced charging technologies, such as smart charging and vehicle-to-grid (V2G) technology, can also optimize EV operations and reduce costs. Smart charging allows operators to optimize their charging schedule based on energy demand and availability, while V2G technology enables vehicles to supply energy back to the grid, reducing the strain on the electrical grid and generating revenue for operators.

Optimizing Electric Motor Control Systems for Improved Efficiency

Electric motor control systems play a crucial role in electric vehicle and electric motor operations management, as they directly impact the efficiency, performance, and overall cost of EV ownership. Optimizing electric motor control systems can lead to significant improvements in efficiency, reduced energy consumption, and extended lifespan.

Power electronics are a critical component of electric motor control systems, as they enable the efficient conversion of electrical energy into mechanical energy. Advanced power electronics, such as insulated gate bipolar transistors (IGBTs) and power MOSFETs, offer high efficiency, reliability, and durability. However, the selection of power electronics must be carefully considered, as it can impact the overall performance and efficiency of the electric motor.

Motor drives are another essential component of electric motor control systems, as they enable the efficient control of electric motor speed and torque. Advanced motor drives, such as field-oriented control (FOC) and direct torque control (DTC), offer high efficiency, reliability, and durability. However, the selection of motor drives must be carefully considered, as it can impact the overall performance and efficiency of the electric motor.

Control algorithms are a critical component of electric motor control systems, as they enable the efficient control of electric motor speed and torque. Advanced control algorithms, such as model predictive control (MPC) and adaptive control, offer high efficiency, reliability, and durability. However, the selection of control algorithms must be carefully considered, as it can impact the overall performance and efficiency of the electric motor.

Regenerative braking is a key feature of electric motor control systems, as it enables the recovery of kinetic energy during braking. Advanced regenerative braking systems, such as brake-by-wire (BBW) and regenerative braking control (RBC), offer high efficiency, reliability, and durability. However, the selection of regenerative braking systems must be carefully considered, as it can impact the overall performance and efficiency of the electric motor.

Torque vectoring is another key feature of electric motor control systems, as it enables the efficient control of electric motor torque. Advanced torque vectoring systems, such as torque vectoring control (TVC) and torque vectoring optimization (TVO), offer high efficiency, reliability, and durability. However, the selection of torque vectoring systems must be carefully considered, as it can impact the overall performance and efficiency of the electric motor.

In electric vehicle and electric motor operations management, the optimization of electric motor control systems can have a significant impact on the overall efficiency and performance of the vehicle. By selecting the right power electronics, motor drives, control algorithms, regenerative braking systems, and torque vectoring systems, operators can optimize their EV operations and reduce costs.

Real-World Examples of Electric Vehicle Operations Management in Action

Electric vehicle operations management is a critical aspect of the electric vehicle (EV) industry, as it directly impacts the efficiency, performance, and overall cost of EV ownership. To illustrate the importance of electric vehicle operations management, let’s examine some real-world examples of successful EV operations management from companies like Tesla, Nissan, and BMW.

Tesla, a pioneer in the EV industry, has implemented a range of innovative strategies to optimize its EV operations. One notable example is its use of advanced data analytics to predict maintenance needs and optimize vehicle performance. Tesla’s data analytics platform collects data from its vehicles, including battery health, charging patterns, and driving habits, to identify potential issues before they become major problems.

Nissan, another leading EV manufacturer, has also implemented a range of strategies to optimize its EV operations. One notable example is its use of advanced charging infrastructure to support its EV fleet. Nissan has partnered with charging infrastructure providers to install high-power charging stations along highways and in urban areas, enabling its EVs to charge quickly and efficiently.

BMW, a luxury EV manufacturer, has also implemented a range of strategies to optimize its EV operations. One notable example is its use of advanced driver training programs to educate drivers on how to optimize their EV’s performance and efficiency. BMW’s driver training programs include tips on how to drive efficiently, how to charge the vehicle, and how to maintain the vehicle’s battery health.

These real-world examples illustrate the importance of electric vehicle operations management in optimizing EV performance and efficiency. By implementing innovative strategies like advanced data analytics, charging infrastructure, and driver training programs, EV manufacturers can reduce costs, improve efficiency, and enhance the overall driving experience.

In electric vehicle and electric motor operations management, the use of data analytics, charging infrastructure, and driver training programs can have a significant impact on the overall efficiency and performance of EVs. By analyzing data from EVs, optimizing charging infrastructure, and educating drivers on how to optimize their EV’s performance, operators can optimize their EV operations and reduce costs.

Furthermore, the use of advanced technologies like autonomous vehicles, vehicle-to-grid (V2G) technology, and advanced battery management systems can also optimize EV operations and reduce costs. Autonomous vehicles, for example, can optimize their own performance and efficiency by adjusting their speed and acceleration to minimize energy consumption.

The Role of Data Analytics in Electric Vehicle Operations Management

Data analytics plays a crucial role in electric vehicle and electric motor operations management, as it enables operators to optimize performance, predict maintenance needs, and improve overall efficiency. By analyzing data from various sources, including telematics, IoT sensors, and charging infrastructure, operators can gain valuable insights into their EV operations and make data-driven decisions to optimize their fleet.

Telematics is a key source of data for electric vehicle operations management, as it provides real-time information on vehicle location, speed, and battery state of charge. By analyzing telematics data, operators can optimize their routing and scheduling, reduce energy consumption, and improve overall efficiency.

IoT sensors are another important source of data for electric vehicle operations management, as they provide real-time information on vehicle performance, battery health, and charging patterns. By analyzing IoT sensor data, operators can predict maintenance needs, reduce downtime, and improve overall efficiency.

Charging infrastructure data is also critical for electric vehicle operations management, as it provides information on charging patterns, energy consumption, and charging station utilization. By analyzing charging infrastructure data, operators can optimize their charging strategies, reduce energy consumption, and improve overall efficiency.

Advanced data analytics tools and platforms, such as machine learning and artificial intelligence, can also be used to analyze data from various sources and provide valuable insights into electric vehicle operations. By using these tools, operators can optimize their EV operations, reduce costs, and improve overall efficiency.

In electric vehicle and electric motor operations management, the use of data analytics can have a significant impact on the overall efficiency and performance of EVs. By analyzing data from various sources, operators can optimize their EV operations, reduce costs, and improve overall efficiency.

Furthermore, the use of data analytics can also enable operators to predict maintenance needs, reduce downtime, and improve overall efficiency. By analyzing data from telematics, IoT sensors, and charging infrastructure, operators can identify potential issues before they become major problems and take corrective action to prevent downtime and reduce repair costs.

Best Practices for Electric Vehicle Fleet Management

Electric vehicle fleet management is a critical aspect of electric vehicle and electric motor operations management, as it enables operators to optimize their EV fleet operations, reduce costs, and improve overall efficiency. To achieve these goals, operators must follow best practices for vehicle selection, charging infrastructure planning, and driver training.

Vehicle selection is a critical aspect of electric vehicle fleet management, as it directly impacts the overall efficiency and performance of the EV fleet. Operators should select vehicles that meet their specific needs and requirements, taking into account factors such as range, payload capacity, and charging time.

Charging infrastructure planning is another critical aspect of electric vehicle fleet management, as it enables operators to optimize their EV charging operations and reduce costs.

Best Practices for Electric Vehicle Fleet Management

Electric vehicle fleet management is a critical aspect of electric vehicle and electric motor operations management, as it enables operators to optimize their EV fleet operations, reduce costs, and improve overall efficiency. To achieve these goals, operators must follow best practices for vehicle selection, charging infrastructure planning, and driver training.

Vehicle selection is a critical aspect of electric vehicle fleet management, as it directly impacts the overall efficiency and performance of the EV fleet. Operators should select vehicles that meet their specific needs and requirements, taking into account factors such as range, payload capacity, and charging time.

Charging infrastructure planning is another critical aspect of electric vehicle fleet management, as it enables operators to optimize their EV charging operations and reduce costs.