Mastering the Fundamentals of Electric Motor Management

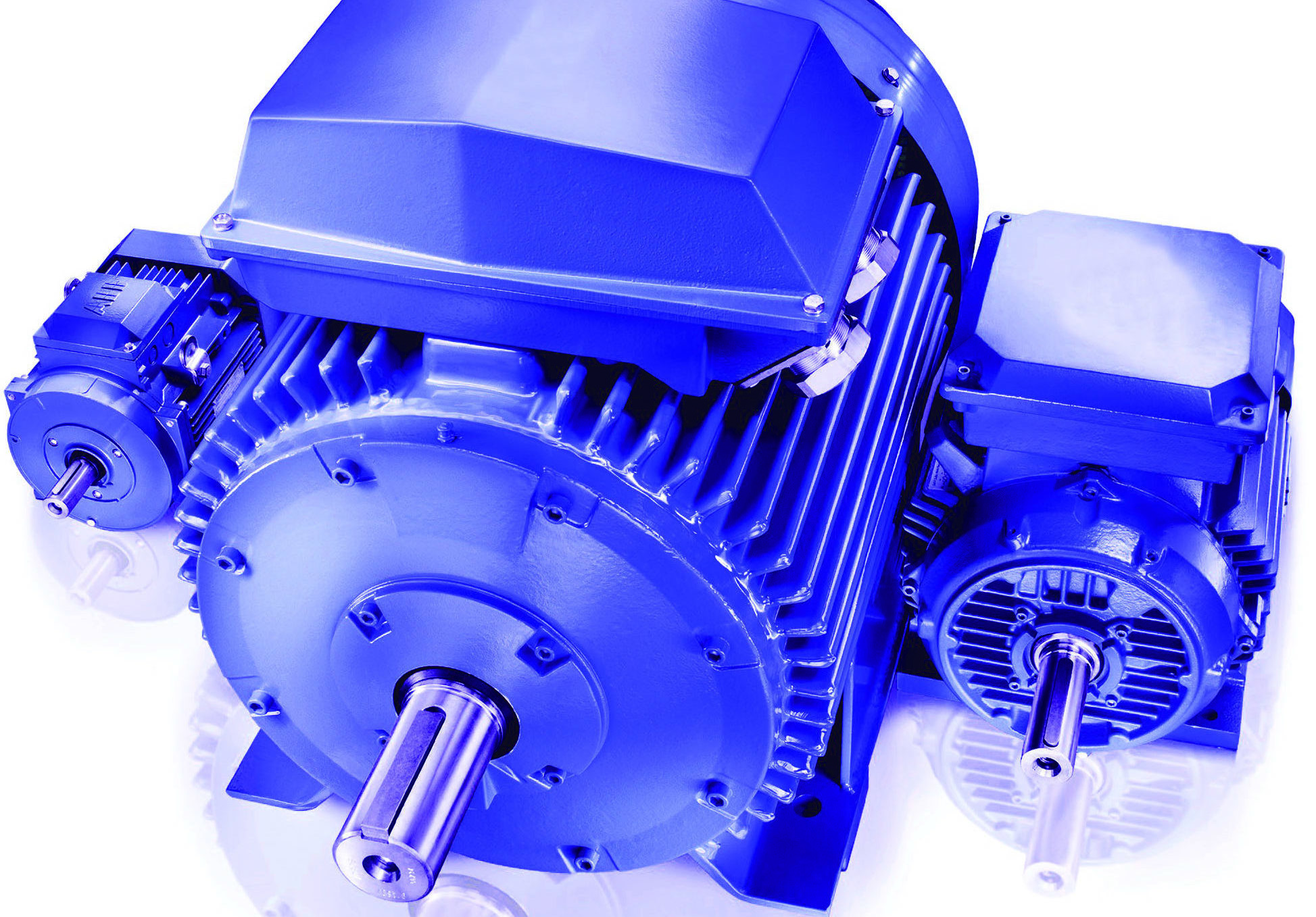

Effective electric motor management is crucial for optimizing electric vehicle performance, efficiency, and lifespan. Electric motor operations management involves the coordination of various components, including power electronics, thermal management, and control systems, to ensure seamless and efficient motor performance. The importance of electric motor management cannot be overstated, as it directly impacts the overall performance, efficiency, and lifespan of electric vehicles.

In the context of electric vehicle and electric motor operations management, understanding the key components of electric motor operations is essential. Power electronics play a vital role in enabling efficient and reliable electric motor operations. Thermal management strategies, such as air cooling, liquid cooling, and heat exchangers, are also critical in maintaining optimal motor temperatures, thereby ensuring efficient performance and prolonging motor lifespan.

Control systems, including motor control units, traction control systems, and vehicle control units, work in tandem to optimize motor performance, efficiency, and safety. These systems enable real-time monitoring and analysis of electric motor performance, allowing for predictive maintenance and optimization of motor operations. By mastering the fundamentals of electric motor management, electric vehicle manufacturers and operators can unlock significant improvements in performance, efficiency, and lifespan.

The integration of electric motor management with other vehicle systems, such as battery management and transmission control, is also crucial for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

As the electric vehicle market continues to evolve, the importance of effective electric motor management will only continue to grow. By prioritizing electric motor management and investing in the development of advanced technologies and strategies, electric vehicle manufacturers and operators can stay ahead of the curve and reap the benefits of optimized performance, efficiency, and lifespan.

How to Monitor and Analyze Electric Motor Performance in Real-Time

Real-time monitoring and analysis of electric motor performance is crucial for optimizing electric vehicle efficiency, performance, and lifespan. The use of data analytics and IoT sensors enables electric vehicle manufacturers and operators to gain valuable insights into motor operations, allowing for predictive maintenance, optimization of motor performance, and improvement of overall vehicle efficiency.

In the context of electric vehicle and electric motor operations management, real-time monitoring and analysis of electric motor performance involves the collection and analysis of data from various sources, including motor control units, traction control systems, and vehicle control units. This data can be used to identify trends, patterns, and anomalies in motor performance, enabling proactive maintenance and optimization of motor operations.

IoT sensors play a critical role in real-time monitoring and analysis of electric motor performance, providing real-time data on motor temperature, vibration, and other key performance indicators. This data can be used to optimize motor performance, predict maintenance needs, and improve overall vehicle efficiency. By leveraging advanced data analytics and IoT sensors, electric vehicle manufacturers and operators can unlock significant improvements in motor performance, efficiency, and lifespan.

Real-time monitoring and analysis of electric motor performance also enables the implementation of condition-based maintenance, where maintenance tasks are performed based on the actual condition of the motor, rather than on a fixed schedule. This approach can help reduce maintenance costs, improve motor reliability, and extend motor lifespan.

Furthermore, real-time monitoring and analysis of electric motor performance can provide valuable insights into the overall performance and efficiency of the electric vehicle. By analyzing data from various sources, electric vehicle manufacturers and operators can identify areas for improvement, optimize vehicle performance, and improve overall efficiency.

The integration of real-time monitoring and analysis of electric motor performance with other vehicle systems, such as battery management and transmission control, is also critical for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

The Role of Power Electronics in Electric Vehicle Motor Operations

Power electronics play a vital role in enabling efficient and reliable electric motor operations in electric vehicles. These electronic devices convert electrical energy from the vehicle’s battery into a form that can be used by the electric motor, allowing for efficient and reliable operation. In the context of electric vehicle and electric motor operations management, power electronics are a critical component, enabling the optimization of motor performance, efficiency, and lifespan.

There are several types of power electronic devices used in electric vehicles, including inverters, converters, and battery management systems. Inverters convert DC power from the battery into AC power for the electric motor, while converters convert AC power from the motor back into DC power for the battery. Battery management systems, on the other hand, monitor and control the battery’s state of charge, voltage, and temperature, ensuring optimal performance and lifespan.

The use of power electronics in electric vehicle motor operations enables the implementation of advanced motor control strategies, such as field-oriented control and direct torque control. These strategies allow for the optimization of motor performance, efficiency, and lifespan, and are critical for achieving exceptional motor efficiency and performance in electric vehicles.

Furthermore, power electronics enable the integration of electric vehicles with other systems, such as regenerative braking and traction control. Regenerative braking, for example, captures kinetic energy from the vehicle’s wheels and converts it into electrical energy, which is then stored in the battery. Traction control, on the other hand, uses power electronics to control the flow of electrical energy to the motor, ensuring optimal traction and stability.

The design and development of power electronics for electric vehicle motor operations require careful consideration of several factors, including efficiency, reliability, and cost. The use of advanced materials and technologies, such as silicon carbide and gallium nitride, can help improve the efficiency and reliability of power electronics, while reducing costs.

In addition, the integration of power electronics with other vehicle systems, such as battery management and thermal management, is critical for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Thermal Management Strategies for Electric Vehicle Motors

Thermal management is a critical aspect of electric vehicle motor operations, as excessive temperatures can significantly impact motor efficiency, lifespan, and performance. In the context of electric vehicle and electric motor operations management, thermal management strategies play a vital role in ensuring optimal motor performance and efficiency.

There are several thermal management strategies used in electric vehicle motors, including air cooling, liquid cooling, and heat exchangers. Air cooling is a common method used in many electric vehicles, where air is circulated through the motor to dissipate heat. Liquid cooling, on the other hand, uses a liquid coolant to absorb heat from the motor and transfer it to a heat exchanger, where it is dissipated.

Heat exchangers are also used in electric vehicle motors to dissipate heat. These devices transfer heat from the motor to a coolant, which is then dissipated through a radiator or other heat dissipation system. Heat exchangers can be designed to operate in various modes, including air-cooled, liquid-cooled, or a combination of both.

The choice of thermal management strategy depends on several factors, including the type of electric motor, the operating conditions, and the desired level of performance and efficiency. For example, high-performance electric vehicles may require more advanced thermal management strategies, such as liquid cooling or heat exchangers, to maintain optimal motor performance and efficiency.

In addition to these strategies, electric vehicle manufacturers are also exploring new technologies and materials to improve thermal management in electric vehicle motors. For example, advanced materials such as graphene and nanomaterials are being developed to improve heat dissipation and reduce thermal resistance.

The integration of thermal management strategies with other vehicle systems, such as battery management and power electronics, is also critical for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Furthermore, thermal management strategies can also impact the overall efficiency and performance of the electric vehicle. For example, a well-designed thermal management system can help reduce energy losses and improve the overall efficiency of the vehicle. This, in turn, can lead to improved range and performance, making electric vehicles more appealing to consumers.

Control Systems for Electric Vehicle Motor Operations: A Deep Dive

Control systems play a crucial role in electric vehicle motor operations, enabling the optimization of motor performance, efficiency, and safety. In the context of electric vehicle and electric motor operations management, control systems are responsible for managing the flow of electrical energy to the motor, ensuring optimal performance and efficiency.

There are several types of control systems used in electric vehicle motor operations, including motor control units, traction control systems, and vehicle control units. Motor control units are responsible for controlling the flow of electrical energy to the motor, while traction control systems manage the distribution of torque to the wheels. Vehicle control units, on the other hand, oversee the overall operation of the vehicle, including the motor, transmission, and brakes.

These control systems work together to optimize motor performance, efficiency, and safety. For example, motor control units can adjust the flow of electrical energy to the motor in real-time, ensuring optimal performance and efficiency. Traction control systems can manage the distribution of torque to the wheels, improving stability and control. Vehicle control units can oversee the overall operation of the vehicle, ensuring safe and efficient operation.

The use of advanced control systems in electric vehicle motor operations enables the implementation of advanced motor control strategies, such as field-oriented control and direct torque control. These strategies allow for the optimization of motor performance, efficiency, and safety, and are critical for achieving exceptional motor efficiency and performance in electric vehicles.

In addition to these control systems, electric vehicle manufacturers are also exploring new technologies and innovations to improve motor control and efficiency. For example, the use of artificial intelligence and machine learning algorithms can enable real-time optimization of motor performance and efficiency, while the use of advanced sensors and IoT technologies can provide real-time data on motor performance and efficiency.

The integration of control systems with other vehicle systems, such as power electronics and thermal management, is also critical for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Furthermore, control systems can also impact the overall efficiency and performance of the electric vehicle. For example, a well-designed control system can help reduce energy losses and improve the overall efficiency of the vehicle. This, in turn, can lead to improved range and performance, making electric vehicles more appealing to consumers.

Electric Vehicle Motor Maintenance and Repair: Best Practices

Regular maintenance and repair are crucial for ensuring the optimal performance and efficiency of electric vehicle motors. In the context of electric vehicle and electric motor operations management, maintenance and repair play a vital role in extending the lifespan of the motor, reducing downtime, and improving overall vehicle efficiency.

One of the most important aspects of electric vehicle motor maintenance is troubleshooting common issues. This includes identifying and addressing problems such as overheating, vibration, and noise. By troubleshooting these issues, electric vehicle owners and operators can prevent more serious problems from developing and ensure optimal motor performance.

Performing routine maintenance tasks is also essential for maintaining the health and efficiency of electric vehicle motors. This includes tasks such as cleaning and inspecting the motor, checking and replacing worn-out components, and updating software and firmware. By performing these tasks regularly, electric vehicle owners and operators can ensure optimal motor performance and extend the lifespan of the motor.

Replacing worn-out components is also a critical aspect of electric vehicle motor maintenance and repair. This includes replacing components such as bearings, seals, and windings. By replacing these components regularly, electric vehicle owners and operators can ensure optimal motor performance and prevent more serious problems from developing.

In addition to these best practices, electric vehicle manufacturers are also developing new technologies and innovations to improve motor maintenance and repair. For example, the use of advanced sensors and IoT technologies can provide real-time data on motor performance and efficiency, enabling predictive maintenance and repair. The use of artificial intelligence and machine learning algorithms can also enable real-time optimization of motor performance and efficiency.

The integration of maintenance and repair with other vehicle systems, such as power electronics and thermal management, is also critical for achieving optimal performance and efficiency. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Furthermore, maintenance and repair can also impact the overall efficiency and performance of the electric vehicle. For example, a well-maintained motor can help reduce energy losses and improve the overall efficiency of the vehicle. This, in turn, can lead to improved range and performance, making electric vehicles more appealing to consumers.

Real-World Examples of Efficient Electric Vehicle Motor Operations

Several electric vehicle manufacturers have achieved exceptional motor efficiency and performance through the implementation of advanced technologies and strategies. In the context of electric vehicle and electric motor operations management, these examples demonstrate the potential for optimized motor performance and efficiency.

One notable example is the Tesla Model S, which features a highly efficient electric motor that achieves exceptional performance and range. The motor is designed to optimize efficiency and performance, with a unique combination of power electronics, thermal management, and control systems. The result is a vehicle that can achieve up to 373 miles of range on a single charge, making it one of the most efficient electric vehicles on the market.

Another example is the Nissan Leaf, which features a highly efficient electric motor that achieves exceptional performance and range. The motor is designed to optimize efficiency and performance, with a unique combination of power electronics, thermal management, and control systems. The result is a vehicle that can achieve up to 147 miles of range on a single charge, making it one of the most efficient electric vehicles in its class.

Other notable examples include the BMW i3, the Volkswagen e-Golf, and the Hyundai Kona Electric, all of which feature highly efficient electric motors that achieve exceptional performance and range. These vehicles demonstrate the potential for optimized motor performance and efficiency, and highlight the importance of advanced technologies and strategies in achieving exceptional electric vehicle performance.

The integration of advanced technologies and strategies, such as power electronics, thermal management, and control systems, is critical for achieving exceptional electric vehicle performance. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Furthermore, these examples demonstrate the potential for electric vehicles to achieve exceptional performance and efficiency, making them a viable alternative to traditional gasoline-powered vehicles. As the demand for electric vehicles continues to grow, the importance of optimized motor performance and efficiency will only continue to increase, driving innovation and advancement in the field of electric vehicle and electric motor operations management.

Future Trends in Electric Vehicle Motor Operations Management

The future of electric vehicle motor operations management is exciting and rapidly evolving. Emerging technologies like artificial intelligence, blockchain, and the Internet of Things (IoT) are transforming the way electric vehicles are designed, manufactured, and operated. In the context of electric vehicle and electric motor operations management, these technologies have the potential to revolutionize the industry.

Artificial intelligence (AI) is one of the most promising emerging technologies in electric vehicle motor operations management. AI can be used to optimize motor performance, predict maintenance needs, and improve overall vehicle efficiency. For example, AI-powered predictive maintenance can help identify potential issues before they occur, reducing downtime and improving overall vehicle reliability.

Blockchain is another emerging technology that has the potential to transform electric vehicle motor operations management. Blockchain can be used to create a secure and transparent record of vehicle data, including motor performance, maintenance history, and ownership. This can help improve vehicle safety, reduce the risk of fraud, and create new business models.

The Internet of Things (IoT) is also playing a critical role in the future of electric vehicle motor operations management. IoT sensors and devices can be used to monitor and control motor performance in real-time, enabling predictive maintenance and improving overall vehicle efficiency. IoT can also be used to create new business models, such as vehicle-to-grid (V2G) charging, where electric vehicles can sell excess energy back to the grid.

Other emerging technologies, such as 5G networks and edge computing, are also expected to play a critical role in the future of electric vehicle motor operations management. These technologies can enable faster and more reliable data transfer, improving the overall efficiency and performance of electric vehicles.

The integration of these emerging technologies with existing technologies, such as power electronics, thermal management, and control systems, is critical for achieving exceptional electric vehicle performance. By adopting a holistic approach to electric vehicle and electric motor operations management, stakeholders can unlock the full potential of electric vehicles and drive the transition towards a more sustainable and efficient transportation sector.

Furthermore, the future of electric vehicle motor operations management is not just about technology, but also about sustainability and environmental impact. As the demand for electric vehicles continues to grow, the importance of sustainable and environmentally friendly motor operations will only continue to increase. Emerging technologies like AI, blockchain, and IoT can help reduce the environmental impact of electric vehicles, making them a more viable alternative to traditional gasoline-powered vehicles.