Unlocking the Potential of Electric Motors and EVs

The development of electric vehicles (EVs) and electric motors is a rapidly evolving field, driven by the need for sustainable and efficient transportation solutions. As the demand for EVs continues to grow, the importance of rigorous testing and validation cannot be overstated. Electric motor and electric vehicle testing are critical components of the development process, enabling manufacturers to ensure the performance, efficiency, and safety of their products.

Through comprehensive testing, manufacturers can identify and address potential issues early in the development cycle, reducing the risk of costly rework and recalls. Moreover, testing enables the optimization of electric motor and EV performance, leading to improved fuel efficiency, increased range, and enhanced overall driving experience.

The benefits of rigorous testing extend beyond the development phase, as it also plays a crucial role in ensuring compliance with regulatory requirements and industry standards. By conducting thorough testing, manufacturers can demonstrate the safety and efficacy of their products, building trust with consumers and stakeholders.

Furthermore, electric motor and electric vehicle testing provide valuable insights into the behavior of these complex systems, enabling the development of more sophisticated and efficient technologies. As the industry continues to evolve, the importance of testing and validation will only continue to grow, driving innovation and progress in the field of electric mobility.

By prioritizing electric motor and electric vehicle testing, manufacturers can unlock the full potential of these technologies, delivering high-performance, efficient, and safe products that meet the needs of an increasingly demanding market. As the world transitions towards a more sustainable and electrified transportation ecosystem, the role of testing and validation will be instrumental in shaping the future of the industry.

How to Ensure Reliable Electric Motor Performance

Electric motor performance is a critical aspect of electric vehicle (EV) development, as it directly impacts the overall efficiency, range, and safety of the vehicle. To ensure reliable electric motor performance, manufacturers must consider several key factors, including temperature, vibration, and electromagnetic interference.

Temperature is a significant factor in electric motor performance, as excessive heat can lead to reduced efficiency, increased wear, and even motor failure. To mitigate this risk, manufacturers can use advanced materials and cooling systems, such as liquid cooling or air cooling, to maintain optimal operating temperatures.

Vibration is another critical factor, as it can cause mechanical stress, reduce motor lifespan, and affect overall vehicle performance. To minimize vibration, manufacturers can use advanced mounting systems, balance motors, and optimize motor design.

Electromagnetic interference (EMI) is also a significant concern, as it can affect motor performance, safety, and overall vehicle reliability. To mitigate EMI, manufacturers can use shielding, filtering, and grounding techniques to minimize electromagnetic radiation.

To design and test electric motors for optimal reliability, manufacturers can use advanced simulation tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD). These tools enable manufacturers to simulate various operating conditions, predict motor behavior, and optimize design parameters.

In addition to simulation tools, manufacturers can use testing protocols, such as accelerated life testing (ALT) and highly accelerated life testing (HALT), to validate motor performance and reliability. These protocols involve subjecting motors to extreme operating conditions, such as high temperatures, vibrations, and EMI, to identify potential failures and optimize design.

By considering these key factors and using advanced simulation tools and testing protocols, manufacturers can ensure reliable electric motor performance, improve overall vehicle efficiency and safety, and reduce the risk of costly rework and recalls.

Electric Vehicle Testing: A Comprehensive Approach

Electric vehicle (EV) testing is a complex and multifaceted process that requires a comprehensive approach to ensure the safety, performance, and efficiency of these vehicles. To validate the performance of EVs, manufacturers must conduct a range of tests, including dynamic testing, static testing, and environmental testing.

Dynamic testing involves simulating real-world driving conditions, such as acceleration, braking, and cornering, to evaluate the vehicle’s performance and handling. This type of testing is critical to ensure that the vehicle can operate safely and efficiently in a variety of driving scenarios.

Static testing, on the other hand, involves evaluating the vehicle’s performance under stationary conditions, such as when the vehicle is parked or idling. This type of testing is important to ensure that the vehicle’s systems, such as the battery management system and electric motor, are functioning properly.

Environmental testing involves evaluating the vehicle’s performance in various environmental conditions, such as extreme temperatures, humidity, and altitude. This type of testing is critical to ensure that the vehicle can operate safely and efficiently in a variety of environmental conditions.

In addition to these types of testing, manufacturers must also conduct testing to validate the performance of specific components, such as the electric motor, battery, and power electronics. This type of testing is critical to ensure that these components are functioning properly and can operate safely and efficiently.

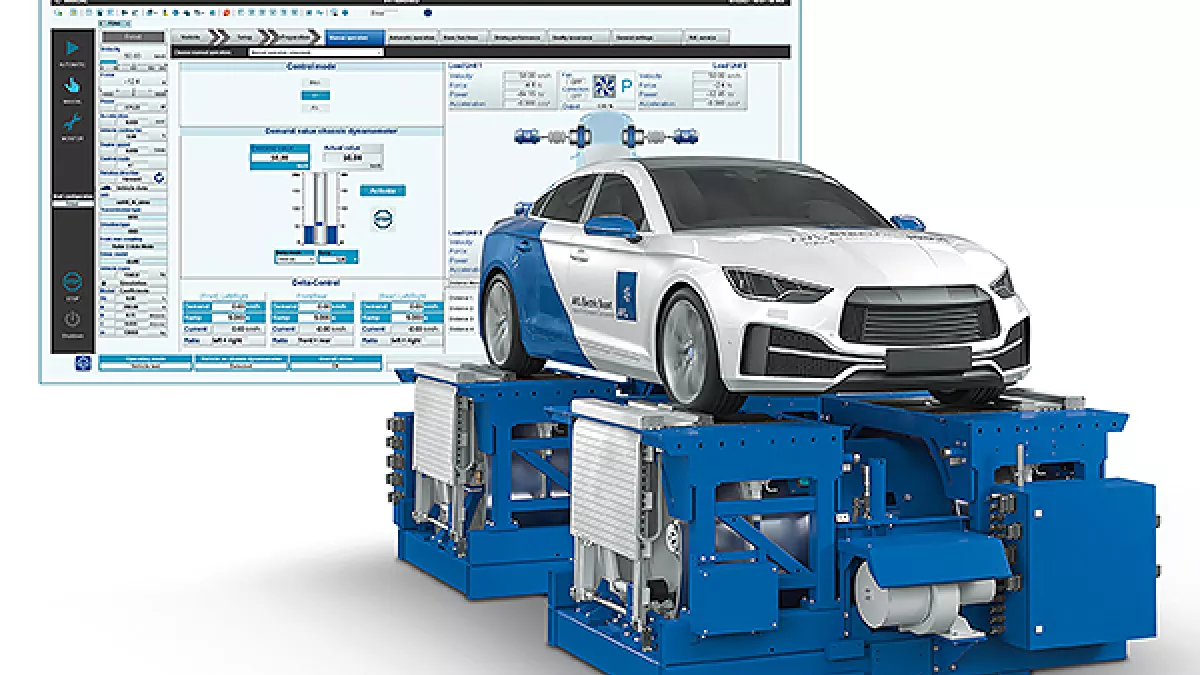

Simulating real-world driving conditions is also an important aspect of EV testing. This can be achieved through the use of advanced testing tools, such as chassis dynamometers and battery test equipment. These tools enable manufacturers to simulate a wide range of driving scenarios, including urban, highway, and off-road driving.

By conducting a comprehensive range of tests, manufacturers can ensure that their EVs are safe, efficient, and reliable. This is critical to building consumer confidence in these vehicles and to ensuring their widespread adoption.

Electric motor and electric vehicle testing are critical components of the EV development process. By conducting rigorous testing, manufacturers can ensure that their vehicles are safe, efficient, and reliable, and can help to drive the widespread adoption of EVs.

Real-World Examples: Testing the Tesla Model 3 and Chevrolet Bolt

The Tesla Model 3 and Chevrolet Bolt are two examples of electric vehicles that have undergone rigorous testing to ensure their safety, performance, and efficiency. Both vehicles have been tested using a variety of protocols, including dynamic testing, static testing, and environmental testing.

Tesla, for example, uses a comprehensive testing program that includes simulation testing, laboratory testing, and on-road testing. The company’s testing program is designed to validate the performance of its electric motors, batteries, and other components, as well as to ensure the overall safety and efficiency of its vehicles.

The Chevrolet Bolt, on the other hand, has undergone extensive testing at General Motors’ (GM) proving grounds in Michigan. The testing program includes a variety of tests, such as acceleration, braking, and cornering, to evaluate the vehicle’s performance and handling.

Both Tesla and GM have also used advanced testing tools, such as data analytics and machine learning algorithms, to improve the efficiency and accuracy of their testing programs. These tools enable the companies to analyze large amounts of data and identify potential issues before they become major problems.

The results of these testing programs have been impressive. The Tesla Model 3, for example, has been rated as one of the safest vehicles on the road, with a 5-star safety rating from the National Highway Traffic Safety Administration (NHTSA). The Chevrolet Bolt has also received high marks for its safety and performance, with a 5-star overall safety rating from the NHTSA.

These real-world examples demonstrate the importance of rigorous testing in the development of electric vehicles. By using a comprehensive testing program and advanced testing tools, manufacturers can ensure that their vehicles are safe, efficient, and reliable, and can help to drive the widespread adoption of electric vehicles.

Electric motor and electric vehicle testing are critical components of the EV development process. By conducting rigorous testing, manufacturers can ensure that their vehicles are safe, efficient, and reliable, and can help to drive the widespread adoption of EVs.

Advancements in Electric Motor Testing Technology

The electric motor testing technology has undergone significant advancements in recent years, driven by the increasing demand for efficient and reliable electric vehicles. One of the key advancements is the use of simulation tools, which enable manufacturers to test and validate electric motor performance in a virtual environment.

Simulation tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), allow manufacturers to model and simulate various operating conditions, including temperature, vibration, and electromagnetic interference. This enables them to optimize electric motor design and performance, reducing the need for physical prototyping and testing.

Data analytics is another area of advancement in electric motor testing technology. By analyzing large amounts of data from various sources, including sensors, testing equipment, and simulation tools, manufacturers can gain valuable insights into electric motor performance and identify areas for improvement.

Machine learning algorithms are also being used to improve electric motor testing efficiency and accuracy. These algorithms can analyze data from various sources and identify patterns and trends, enabling manufacturers to predict electric motor performance and identify potential issues before they occur.

The use of simulation tools, data analytics, and machine learning algorithms has improved the efficiency and accuracy of electric motor testing, enabling manufacturers to develop more efficient and reliable electric vehicles. These advancements have also reduced the time and cost associated with electric motor testing, making it more feasible for manufacturers to test and validate their products.

Electric motor and electric vehicle testing are critical components of the EV development process. By leveraging these advancements in testing technology, manufacturers can ensure that their vehicles are safe, efficient, and reliable, and can help to drive the widespread adoption of electric vehicles.

The future of electric motor testing technology holds much promise, with ongoing research and development focused on improving testing efficiency and accuracy. As the demand for electric vehicles continues to grow, the importance of electric motor testing will only continue to increase, driving innovation and progress in this field.

Overcoming the Challenges of Electric Vehicle Testing

Electric vehicle testing is a complex and challenging process that requires careful planning, execution, and analysis. Despite the importance of testing, there are several challenges that manufacturers face during the testing process.

One of the common challenges is ensuring safety during testing. Electric vehicles have high-voltage electrical systems that can be hazardous if not handled properly. Manufacturers must take necessary precautions to ensure the safety of test personnel and equipment.

Another challenge is managing test data. Electric vehicle testing generates vast amounts of data that must be collected, analyzed, and interpreted. Manufacturers must have robust data management systems in place to handle this data and ensure that it is accurate and reliable.

Maintaining test equipment is also a significant challenge. Electric vehicle testing requires specialized equipment that must be calibrated and maintained regularly. Manufacturers must have a robust maintenance program in place to ensure that test equipment is functioning properly.

To overcome these challenges, manufacturers can adopt best practices such as standardizing testing protocols, collaborating with other manufacturers and suppliers, and continuously improving testing procedures. By adopting these best practices, manufacturers can ensure that their electric vehicles are safe, efficient, and reliable.

Electric motor and electric vehicle testing are critical components of the EV development process. By overcoming the challenges of testing, manufacturers can ensure that their vehicles meet the required safety and performance standards, and can help to drive the widespread adoption of electric vehicles.

Manufacturers can also leverage advanced technologies such as simulation tools, data analytics, and machine learning algorithms to improve testing efficiency and accuracy. These technologies can help manufacturers to identify potential issues earlier in the testing process, reducing the risk of costly rework and recalls.

Best Practices for Electric Motor and EV Testing

Electric motor and electric vehicle testing are critical components of the EV development process. To ensure that EVs are safe, efficient, and reliable, manufacturers must adopt best practices for testing. Here are some recommendations for testing protocols and procedures:

Standardization is key to ensuring that testing is consistent and reliable. Manufacturers should adopt standardized testing protocols and procedures to ensure that all EVs are tested to the same standards.

Collaboration is also essential for effective testing. Manufacturers should work with suppliers, testing equipment manufacturers, and other stakeholders to ensure that testing is comprehensive and accurate.

Continuous improvement is also critical for effective testing. Manufacturers should continuously monitor and improve their testing protocols and procedures to ensure that they are keeping pace with the latest technological advancements.

Simulation tools, data analytics, and machine learning algorithms can also be used to improve testing efficiency and accuracy. These technologies can help manufacturers to identify potential issues earlier in the testing process, reducing the risk of costly rework and recalls.

Electric motor and electric vehicle testing are critical components of the EV development process. By adopting best practices for testing, manufacturers can ensure that their EVs are safe, efficient, and reliable, and can help to drive the widespread adoption of electric vehicles.

Manufacturers should also consider the following testing protocols and procedures:

Dynamic testing: This type of testing involves simulating real-world driving conditions to evaluate the performance and efficiency of EVs.

Static testing: This type of testing involves evaluating the performance and efficiency of EVs under stationary conditions.

Environmental testing: This type of testing involves evaluating the performance and efficiency of EVs in various environmental conditions, such as extreme temperatures and humidity.

By adopting these best practices and testing protocols, manufacturers can ensure that their EVs are safe, efficient, and reliable, and can help to drive the widespread adoption of electric vehicles.

The Future of Electric Vehicle Testing: Trends and Opportunities

The future of electric vehicle testing is exciting and rapidly evolving. As the demand for electric vehicles continues to grow, the importance of rigorous testing will only continue to increase. Here are some trends and opportunities that are shaping the future of electric vehicle testing:

The growth of autonomous vehicles is one of the most significant trends in the electric vehicle industry. Autonomous vehicles require advanced testing protocols to ensure that they are safe and reliable. Electric motor and electric vehicle testing will play a critical role in the development of autonomous vehicles.

Cybersecurity is another area of growing importance in electric vehicle testing. As electric vehicles become more connected and reliant on software, the risk of cyber threats increases. Electric motor and electric vehicle testing must include cybersecurity testing to ensure that vehicles are secure and reliable.

Artificial intelligence is also playing a larger role in electric vehicle testing. AI can be used to analyze data from testing, identify patterns and trends, and predict potential issues. Electric motor and electric vehicle testing will increasingly rely on AI to improve efficiency and accuracy.

Electric motor and electric vehicle testing are critical components of the EV development process. As the industry continues to evolve, the importance of rigorous testing will only continue to grow. By staying ahead of the curve and adopting the latest trends and technologies, manufacturers can ensure that their electric vehicles are safe, efficient, and reliable.

The future of electric vehicle testing is bright and full of opportunities. As the industry continues to grow and evolve, the importance of rigorous testing will only continue to increase. By embracing the latest trends and technologies, manufacturers can ensure that their electric vehicles are safe, efficient, and reliable, and can help to drive the widespread adoption of electric vehicles.