The Fundamentals of Electric Motor Design

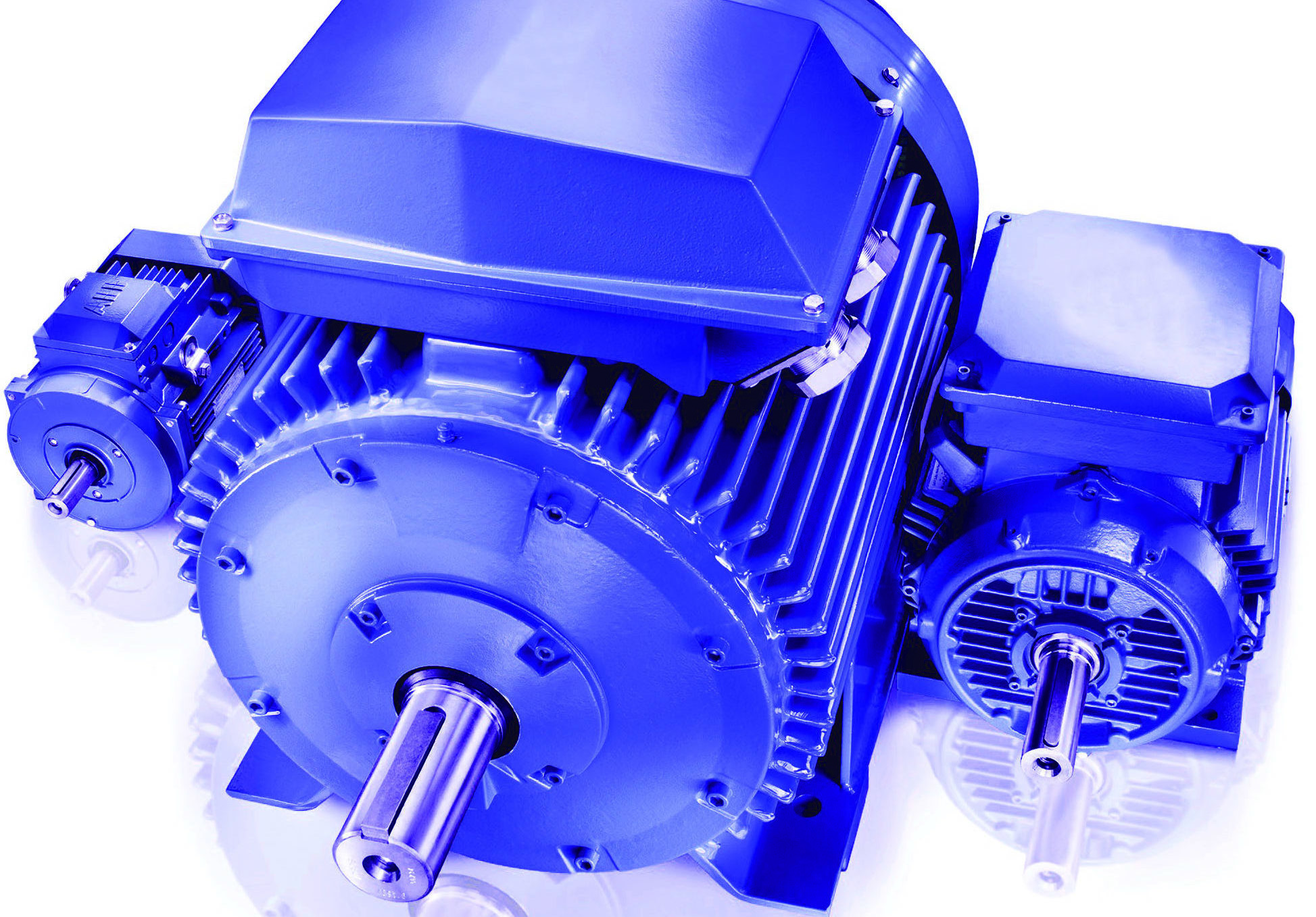

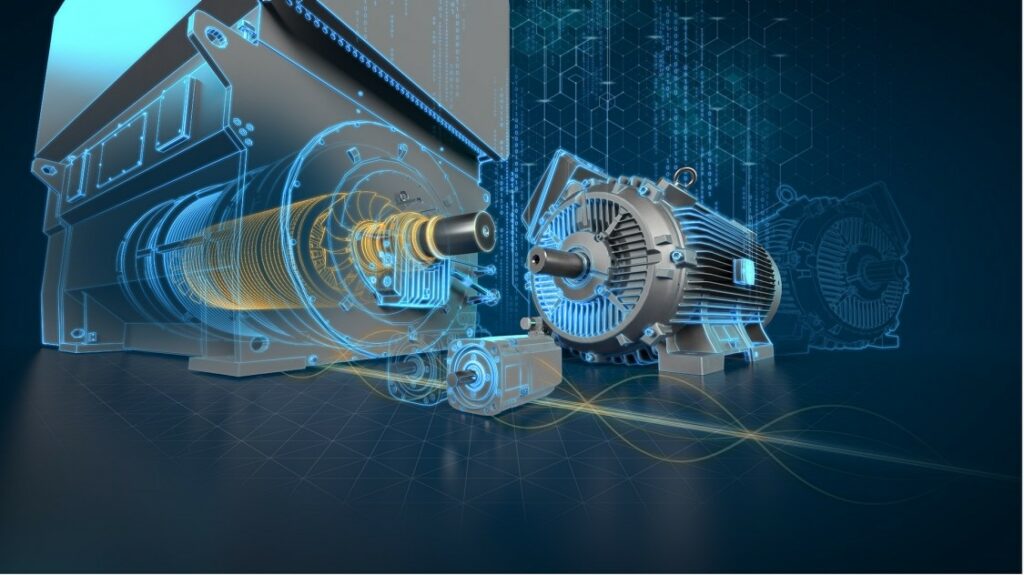

Electric motor design and development is a complex process that requires a deep understanding of the underlying principles of electromagnetism, motor types, and key components. At its core, an electric motor is a device that converts electrical energy into mechanical energy through the interaction of magnetic fields. The design of an electric motor involves the careful selection and arrangement of various components, including the stator, rotor, windings, and bearings, to achieve optimal performance, efficiency, and reliability.

The principles

The Fundamentals of Electric Motor Design

Electric motor design and development is a complex process that requires a deep understanding of the underlying principles of electromagnetism, motor types, and key components. At its core, an electric motor is a device that converts electrical energy into mechanical energy through the interaction of magnetic fields. The design of an electric motor involves the careful selection and arrangement of various components, including the stator, rotor, windings, and bearings, to achieve optimal performance, efficiency, and reliability.

The principles of electromagnetism play a crucial role in electric motor design, as they govern the behavior of magnetic fields and the interaction between the stator and rotor. The design of the motor’s magnetic circuit, including the selection of magnetic materials and the configuration of the windings, is critical to achieving optimal performance and efficiency. Additionally, the design of the motor’s mechanical components, such as the bearings and gearbox, must be carefully considered to ensure reliable operation and minimize maintenance requirements.

There are several types of electric motors, including DC, AC, and stepper motors, each with its own unique characteristics and applications. DC motors are commonly used in applications where high torque and low speed are required, such as in robotics and automotive systems. AC motors, on the other hand, are widely used in applications where high speed and low torque are required, such as in industrial pumps and fans. Stepper motors are used in applications where precise position control is required, such as in 3D printing and CNC machining.

Understanding the fundamentals of electric motor design is crucial for effective electric motor design and development. By carefully considering the principles of electromagnetism, motor types, and key components, designers and engineers can create electric motors that meet the specific requirements of their application, while also achieving optimal performance, efficiency, and reliability. Whether it’s for use in industrial, commercial, or consumer applications, a well-designed electric motor is essential for achieving success in today’s technology-driven world.

The Role of Materials Science in Electric Motor Development

Materials science plays a crucial role in electric motor design and development, as the selection of materials can significantly impact the performance, efficiency, and reliability of the motor. The choice of magnetic materials, conductors, and insulation materials can affect the motor’s ability to convert electrical energy into mechanical energy, and the use of advanced materials can provide significant benefits in terms of efficiency, power density, and thermal management.

Magnetic materials are a critical component of electric motors, as they provide the magnetic field necessary for motor operation. The choice of magnetic material can affect the motor’s efficiency, power density, and thermal management, and the use of advanced materials such as rare-earth magnets and high-temperature superconductors can provide significant benefits. Rare-earth magnets, for example, offer high magnetic strength and resistance to demagnetization, making them ideal for use in high-performance motors. High-temperature superconductors, on the other hand, offer zero electrical resistance, making them ideal for use in high-power motors.

Conductors are another critical component of electric motors, as they provide the path for electrical current to flow. The choice of conductor material can affect the motor’s efficiency, power density, and thermal management, and the use of advanced materials such as copper and aluminum can provide significant benefits. Copper, for example, offers high electrical conductivity and resistance to corrosion, making it ideal for use in high-performance motors. Aluminum, on the other hand, offers high electrical conductivity and low weight, making it ideal for use in high-power motors.

Insulation materials are also critical in electric motor design and development, as they provide the necessary electrical insulation between the motor’s windings and other components. The choice of insulation material can affect the motor’s efficiency, power density, and thermal management, and the use of advanced materials such

Electric Motor Design Software: A Review of Popular Tools

Electric motor design software is a crucial tool for engineers and designers involved in electric motor design and development. These software tools enable users to design, simulate, and optimize electric motor performance, reducing the need for physical prototypes and accelerating the development process. In this article, we will review some of the most popular electric motor design software tools, including ANSYS, COMSOL, and Autodesk.

ANSYS is a comprehensive software tool that offers a wide range of features and capabilities for electric motor design and development. ANSYS provides advanced simulation tools, including finite element analysis (FEA) and computational fluid dynamics (CFD), which enable users to optimize motor performance, efficiency, and reliability. ANSYS also offers a user-friendly interface and a wide range of customization options, making it a popular choice among engineers and designers.

COMSOL is another popular software tool for electric motor design and development. COMSOL offers a wide range of features and capabilities, including multiphysics simulation, which enables users to simulate the behavior of multiple physical phenomena, such as electromagnetism, heat transfer, and structural mechanics. COMSOL also offers a user-friendly interface and a wide range of customization options, making it a popular choice among engineers and designers.

Autodesk is a well-known software company that offers a range of tools for electric motor design and development. Autodesk’s software tools, including Autodesk Inventor and Autodesk Simulation, offer advanced features and capabilities, including 3D modeling, simulation, and optimization. Autodesk’s software tools are widely used in the industry and are known for their ease of use and customization options.

When choosing an electric motor design software tool, there are several factors to consider, including the type of motor being designed, the level of complexity, and the desired level of customization. It is also important to consider the user interface and the level of support offered by the software company. By choosing the right software tool, engineers and designers can accelerate the development process, reduce costs, and improve the overall performance and efficiency of electric motors.

In addition to the software tools mentioned above, there are several other popular electric motor design software tools available, including Motor-CAD, MotorSolve, and Infolytica. These software tools offer a range of features and capabilities, including simulation, optimization, and customization options. By choosing the right software tool, engineers and designers can improve the overall performance and efficiency of electric motors and accelerate the development process.

Case Study: Electric Motor Design for Electric Vehicles

Electric vehicles (EVs) are becoming increasingly popular, and the demand for efficient and reliable electric motors is on the rise. In this case study, we will explore the design requirements, challenges, and solutions for electric motor design in EV applications. We will also discuss the importance of optimizing motor design for EV applications, including efficiency, power density, and thermal management.

The design requirements for electric motors in EV applications are unique and challenging. EVs require high-performance motors that can deliver high torque and power density, while also providing high efficiency and reliability. The motor must also be designed to operate within a wide range of temperatures and environments, and must be able to withstand the rigors of high-speed operation.

One of the key challenges in designing electric motors for EV applications is optimizing the motor’s efficiency and power density. This requires careful consideration of the motor’s design parameters, including the number of poles, the winding configuration, and the magnetic material used. The motor’s thermal management system must also be carefully designed to ensure that the motor operates within a safe temperature range.

To address these challenges, engineers and designers can use advanced simulation tools and testing protocols to optimize the motor’s design. For example, finite element analysis (FEA) can be used to simulate the motor’s magnetic field and thermal behavior, while computational fluid dynamics (CFD) can be used to simulate the motor’s cooling system.

In addition to simulation tools, testing protocols can also be used to validate the motor’s performance and efficiency. For example, dynamometer testing can be used to measure the motor’s torque and power output, while thermal testing can be used to measure the motor’s temperature rise and thermal management system.

By using advanced simulation tools and testing protocols, engineers and designers can optimize the motor’s design for EV applications, resulting in improved efficiency, power density, and reliability. This can help to reduce the overall cost and weight of the EV, while also improving its performance and range.

In conclusion, the design of electric motors for EV applications is a complex and challenging task that requires careful consideration of the motor’s design parameters, thermal management system, and testing protocols. By using advanced simulation tools and testing protocols, engineers and designers can optimize the motor’s design, resulting in improved efficiency, power density, and reliability.

Emerging Trends in Electric Motor Technology

The electric motor industry is rapidly evolving, driven by advances in technology, changing market demands, and the need for more efficient and sustainable solutions. In this article, we will explore some of the emerging trends in electric motor technology, including the use of artificial intelligence, machine learning, and the Internet of Things (IoT).

Artificial intelligence (AI) is being increasingly used in electric motor design and development to optimize performance, efficiency, and reliability. AI algorithms can be used to simulate and analyze complex motor designs, predict performance, and identify potential faults. This can help to reduce the time and cost associated with motor development, while also improving overall performance.

Machine learning (ML) is another emerging trend in electric motor technology. ML algorithms can be used to analyze data from sensors and other sources to predict motor performance, detect anomalies, and optimize control systems. This can help to improve motor efficiency, reduce energy consumption, and extend motor lifespan.

The Internet of Things (IoT) is also having a significant impact on the electric motor industry. IoT sensors and devices can be used to monitor motor performance, detect faults, and optimize control systems. This can help to improve motor efficiency, reduce energy consumption, and extend motor lifespan.

Another emerging trend in electric motor technology is the use of advanced materials and manufacturing techniques. New materials such as graphene, nanomaterials, and advanced ceramics are being developed and used in electric motor design to improve performance, efficiency, and reliability. Advanced manufacturing techniques such as 3D printing and additive manufacturing are also being used to create complex motor designs and reduce production costs.

The use of electric motors in electric vehicles (EVs) is also driving innovation in the industry. EVs require high-performance motors that can deliver high torque and power density, while also providing high efficiency and reliability. This has led to the development of new motor designs, such as the use of permanent magnet motors and switched reluctance motors.

In conclusion, the electric motor industry is rapidly evolving, driven by advances in technology, changing market demands, and the need for more efficient and sustainable solutions. Emerging trends such as the use of artificial intelligence, machine learning, and the Internet of Things (IoT) are transforming the industry and creating new opportunities for innovation and growth.

Best Practices for Electric Motor Testing and Validation

Electric motor testing and validation are crucial steps in the design and development process, ensuring that the motor meets the required performance, efficiency, and reliability standards. A well-planned testing and validation protocol helps to identify potential issues early on, reducing the risk of costly redesigns and rework. In this section, we will discuss best practices for electric motor testing and validation, highlighting the importance of testing protocols, data acquisition systems, and simulation tools.

A comprehensive testing protocol should include a range of tests, such as no-load tests, full-load tests, and efficiency tests. These tests help to evaluate the motor’s performance under various operating conditions, including speed, torque, and temperature. It is essential to use standardized testing procedures, such as those outlined in IEEE and IEC standards, to ensure consistency and accuracy.

Data acquisition systems play a critical role in electric motor testing, enabling the collection and analysis of data on motor performance. These systems typically include sensors, data loggers, and software, which work together to capture and process data on parameters such as voltage, current, speed, and temperature. When selecting a data acquisition system, consider factors such as accuracy, resolution, and sampling rate to ensure that the system meets the testing requirements.

Simulation tools are also essential in electric motor testing and validation, allowing designers to model and analyze motor behavior under various operating conditions. These tools can help to identify potential issues early on, reducing the need for physical prototyping and testing. Popular simulation tools for electric motor design and development include finite element analysis (FEA) and computational fluid dynamics (CFD) software.

In addition to testing protocols, data acquisition systems, and simulation tools, it is essential to consider the testing environment and setup. This includes factors such as the test bench, instrumentation, and safety equipment. A well-designed testing environment helps to ensure accurate and reliable test results, while also minimizing the risk of injury or damage.

Electric motor design and development require a thorough understanding of testing and validation principles. By following best practices and using the right tools and techniques, designers can ensure that their motors meet the required performance, efficiency, and reliability standards. This, in turn, helps to reduce the risk of costly redesigns and rework, while also improving overall product quality and customer satisfaction.

The Future of Electric Motor Design and Development

The electric motor industry is on the cusp of a revolution, driven by emerging trends, technologies, and applications. As the world shifts towards more sustainable and efficient energy solutions, electric motor design and development are poised to play a critical role in shaping the future of industries such as automotive, aerospace, and renewable energy.

One of the key drivers of innovation in electric motor design and development is the increasing adoption of electric vehicles (EVs). As EVs become more mainstream, the demand for high-performance, efficient, and reliable electric motors is expected to grow exponentially. This, in turn, is driving the development of new motor technologies, such as axial flux motors and transverse flux motors, which offer improved efficiency and power density.

Another trend that is expected to shape the future of electric motor design and development is the integration of artificial intelligence (AI) and machine learning (ML) algorithms. These technologies have the potential to optimize motor performance, predict maintenance needs, and improve overall efficiency. For instance, AI-powered motor control systems can adjust motor parameters in real-time to optimize efficiency and reduce energy consumption.

The Internet of Things (IoT) is also expected to play a significant role in the future of electric motor design and development. IoT-enabled motors can communicate with other devices and systems, enabling real-time monitoring, predictive maintenance, and optimized performance. This, in turn, can lead to improved efficiency, reduced downtime, and increased productivity.

Advances in materials science are also expected to drive innovation in electric motor design and development. New materials, such as rare-earth magnets and high-temperature superconductors, offer improved performance, efficiency, and reliability. These materials are expected to play a critical role in the development of next-generation electric motors, which will be more efficient, compact, and powerful.

As the electric motor industry continues to evolve, it is essential for designers and developers to stay up-to-date with the latest trends, technologies, and applications. This requires a deep understanding of electric motor design and development principles, as well as the ability to adapt to new technologies and innovations. By embracing these changes, designers and developers can create electric motors that are more efficient, reliable, and sustainable, and that meet the needs of a rapidly changing world.

In conclusion, the future of electric motor design and development is exciting and full of possibilities. As the industry continues to evolve, it is essential to stay focused on innovation, sustainability, and efficiency. By doing so, we can create electric motors that are more efficient, reliable, and sustainable, and that meet the needs of a rapidly changing world.