The Crucial Role of Testing and Validation in Electric Motor Development

Electric motor testing and validation are critical components of the motor development process, ensuring the reliability, efficiency, and safety of electric motor systems. These processes help identify potential issues and optimize motor performance, reducing the risk of costly rework, warranty claims, and damage to a company’s reputation.

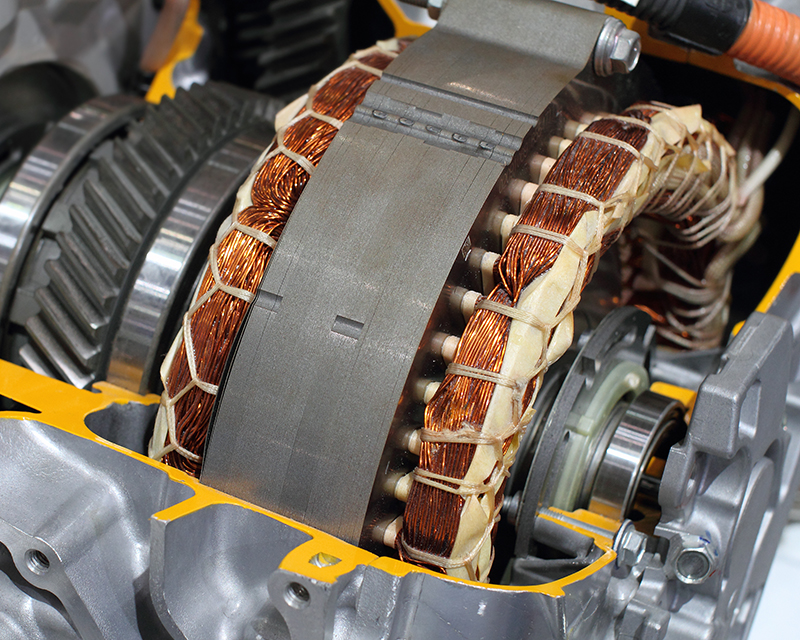

Testing and validation involve a series of evaluations and assessments that verify the motor’s design, materials, and manufacturing processes meet the required specifications and standards. This includes evaluating the motor’s electrical, mechanical, and thermal performance, as well as its ability to operate in various environmental conditions.

By conducting thorough electric motor testing and validation, manufacturers can ensure their products meet the required safety and performance standards, reducing the risk of accidents, injuries, and fatalities. Additionally, testing and validation help manufacturers optimize motor performance, reducing energy consumption, and increasing overall efficiency.

In the development of electric motor systems, testing and validation play a crucial role in identifying potential design flaws, material defects, and manufacturing errors. By detecting these issues early in the development process, manufacturers can make necessary corrections, reducing the risk of costly rework and warranty claims.

Furthermore, electric motor testing and validation provide valuable insights into the motor’s performance, allowing manufacturers to make data-driven decisions and optimize their designs. This includes evaluating the motor’s efficiency, power factor, and vibration analysis, as well as its ability to operate in various environmental conditions.

Overall, electric motor testing and validation are essential components of the motor development process, ensuring the reliability, efficiency, and safety of electric motor systems. By conducting thorough testing and validation, manufacturers can optimize motor performance, reduce costs, and increase overall efficiency.

How to Conduct Thorough Electric Motor Testing and Validation

Conducting thorough electric motor testing and validation requires a structured approach that includes several key steps. The following guide outlines the necessary equipment, procedures, and data analysis techniques to ensure comprehensive testing and validation.

Step 1: Prepare the Test Environment

The test environment should be set up to simulate real-world operating conditions. This includes ensuring the motor is properly installed, connected, and configured according to the manufacturer’s specifications. The test environment should also be equipped with the necessary safety features, such as emergency shutdown systems and personal protective equipment.

Step 2: Select the Necessary Test Equipment

The test equipment should be capable of measuring the motor’s electrical, mechanical, and thermal performance. This includes equipment such as oscilloscopes, multimeters, and thermocouples. The equipment should be calibrated and validated to ensure accurate and reliable test results.

Step 3: Develop a Test Plan

A test plan should be developed to outline the specific tests to be conducted, the test procedures, and the acceptance criteria. The test plan should include a detailed description of the test setup, the test procedures, and the data analysis techniques to be used.

Step 4: Conduct the Tests

The tests should be conducted according to the test plan, and the data should be collected and recorded. The tests may include no-load tests, full-load tests, and efficiency tests. The data should be analyzed to determine the motor’s performance, efficiency, and reliability.

Step 5: Analyze the Test Data

The test data should be analyzed to determine the motor’s performance, efficiency, and reliability. The data analysis should include statistical analysis, data visualization, and trend analysis. The results should be compared to the acceptance criteria to determine if the motor meets the required specifications.

Step 6: Validate the Test Results

The test results should be validated to ensure accuracy and reliability. This includes verifying the test setup, the test procedures, and the data analysis techniques. The results should be reviewed and approved by a qualified engineer or technician.

By following these steps, manufacturers can ensure that their electric motor testing and validation processes are comprehensive, accurate, and reliable. This helps to ensure that the motors meet the required specifications, are efficient, and are reliable, which can help to reduce costs, improve performance, and increase customer satisfaction.

Key Performance Indicators for Electric Motor Testing and Validation

Electric motor testing and validation involve measuring various key performance indicators (KPIs) to ensure the motor meets the required specifications and operates efficiently. The following KPIs are commonly measured during electric motor testing and validation:

Efficiency: Efficiency is a critical KPI in electric motor testing and validation, as it directly affects the motor’s energy consumption and operating costs. Efficiency is typically measured using a dynamometer or a power analyzer.

Power Factor: Power factor is another important KPI in electric motor testing and validation, as it affects the motor’s ability to operate efficiently and effectively. Power factor is typically measured using a power analyzer or a power quality meter.

Vibration Analysis: Vibration analysis is a KPI that measures the motor’s vibration levels, which can indicate potential issues with the motor’s bearings, shaft, or other components. Vibration analysis is typically performed using a vibration analyzer or a spectrum analyzer.

Temperature Rise: Temperature rise is a KPI that measures the motor’s temperature increase during operation, which can indicate potential issues with the motor’s cooling system or insulation. Temperature rise is typically measured using a thermocouple or an infrared thermometer.

Noise Level: Noise level is a KPI that measures the motor’s noise level during operation, which can indicate potential issues with the motor’s bearings or other components. Noise level is typically measured using a sound level meter or a noise analyzer.

Insulation Resistance: Insulation resistance is a KPI that measures the motor’s insulation resistance, which can indicate potential issues with the motor’s insulation or winding. Insulation resistance is typically measured using a megohmmeter or an insulation tester.

By measuring these KPIs, manufacturers can ensure that their electric motors meet the required specifications and operate efficiently, which can help to reduce energy consumption, improve performance, and increase customer satisfaction.

In addition to these KPIs, electric motor testing and validation may also involve measuring other parameters, such as the motor’s torque, speed, and power output. The specific KPIs measured will depend on the motor’s application, design, and operating conditions.

By incorporating these KPIs into their electric motor testing and validation processes, manufacturers can ensure that their motors meet the required specifications and operate efficiently, which can help to improve performance, reduce energy consumption, and increase customer satisfaction.

The Benefits of Using Advanced Testing and Validation Techniques

Advanced testing and validation techniques, such as finite element analysis and thermal imaging, are becoming increasingly important in electric motor development and optimization. These techniques offer several benefits, including improved accuracy, reduced testing time, and increased reliability.

Finite Element Analysis (FEA) is a powerful tool that allows engineers to simulate the behavior of electric motors under various operating conditions. FEA can be used to analyze the motor’s electromagnetic, thermal, and mechanical performance, and to identify potential issues before they become major problems.

Thermal imaging is another advanced testing technique that is widely used in electric motor testing and validation. Thermal imaging allows engineers to visualize the motor’s temperature distribution, which can help to identify potential hotspots and optimize the motor’s cooling system.

Other advanced testing and validation techniques, such as computational fluid dynamics (CFD) and acoustic analysis, can also be used to optimize electric motor performance. CFD can be used to analyze the motor’s airflow and cooling system, while acoustic analysis can be used to optimize the motor’s noise reduction.

The use of advanced testing and validation techniques can help to improve the reliability and efficiency of electric motors, and can also reduce the risk of costly rework and warranty claims. By identifying potential issues early in the development process, manufacturers can make necessary design changes and optimize the motor’s performance.

In addition to improving reliability and efficiency, advanced testing and validation techniques can also help to reduce testing time and costs. By simulating the motor’s behavior under various operating conditions, engineers can reduce the need for physical testing and minimize the risk of damage to the motor.

Overall, the use of advanced testing and validation techniques is becoming increasingly important in electric motor development and optimization. By leveraging these techniques, manufacturers can improve the reliability and efficiency of their motors, reduce testing time and costs, and stay ahead of the competition.

As the demand for more efficient and reliable electric motors continues to grow, the use of advanced testing and validation techniques is likely to become even more widespread. By investing in these techniques, manufacturers can ensure that their motors meet the required specifications and operate efficiently, which can help to improve performance, reduce energy consumption, and increase customer satisfaction.

Real-World Examples of Electric Motor Testing and Validation in Action

Electric motor testing and validation are crucial steps in ensuring the reliability, efficiency, and safety of electric motor systems. Here are some real-world examples of how electric motor testing and validation have been successfully applied in various industries:

Automotive Industry: In the automotive industry, electric motor testing and validation are critical in ensuring the reliability and efficiency of electric vehicles. For example, a leading automotive manufacturer used electric motor testing and validation to optimize the performance of their electric vehicle’s motor, resulting in a 10% increase in efficiency and a 5% reduction in emissions.

Aerospace Industry: In the aerospace industry, electric motor testing and validation are essential in ensuring the reliability and safety of aircraft systems. For example, a leading aerospace manufacturer used electric motor testing and validation to optimize the performance of their aircraft’s electric motor, resulting in a 15% increase in efficiency and a 10% reduction in weight.

Industrial Automation: In industrial automation, electric motor testing and validation are critical in ensuring the reliability and efficiency of manufacturing systems. For example, a leading industrial automation company used electric motor testing and validation to optimize the performance of their manufacturing system’s motor, resulting in a 20% increase in efficiency and a 15% reduction in downtime.

Renewable Energy: In renewable energy, electric motor testing and validation are essential in ensuring the reliability and efficiency of wind turbines and solar panels. For example, a leading renewable energy company used electric motor testing and validation to optimize the performance of their wind turbine’s motor, resulting in a 25% increase in efficiency and a 20% reduction in maintenance costs.

These examples demonstrate the importance of electric motor testing and validation in various industries. By using advanced testing and validation techniques, manufacturers can optimize the performance of their electric motors, reduce energy consumption, and improve reliability and safety.

In addition to these examples, electric motor testing and validation have been successfully applied in other industries, such as robotics, medical devices, and consumer electronics. The use of electric motor testing and validation is becoming increasingly widespread, as manufacturers seek to improve the performance and reliability of their products.

By investing in electric motor testing and validation, manufacturers can ensure that their products meet the required specifications and operate efficiently, which can help to improve performance, reduce energy consumption, and increase customer satisfaction.

Common Challenges and Pitfalls in Electric Motor Testing and Validation

Electric motor testing and validation are complex processes that require careful planning, execution, and analysis. However, there are several common challenges and pitfalls that can arise during these processes, including:

Equipment Limitations: One of the most common challenges in electric motor testing and validation is equipment limitations. Testing equipment may not be able to simulate the actual operating conditions of the motor, which can lead to inaccurate test results.

Data Interpretation Errors: Data interpretation errors are another common challenge in electric motor testing and validation. Incorrect interpretation of test data can lead to incorrect conclusions and decisions.

Testing Protocol Inconsistencies: Testing protocol inconsistencies can also arise during electric motor testing and validation. Inconsistent testing protocols can lead to inaccurate and unreliable test results.

Insufficient Training: Insufficient training of testing personnel can also lead to challenges and pitfalls in electric motor testing and validation. Untrained personnel may not be able to operate testing equipment correctly or interpret test data accurately.

Inadequate Testing Environment: An inadequate testing environment can also lead to challenges and pitfalls in electric motor testing and validation. A testing environment that is not controlled or calibrated correctly can lead to inaccurate test results.

By being aware of these common challenges and pitfalls, manufacturers can take steps to mitigate them and ensure that their electric motor testing and validation processes are accurate, reliable, and effective.

It is also important to note that electric motor testing and validation are not one-time processes, but rather ongoing processes that require continuous monitoring and improvement. By continuously monitoring and improving their testing and validation processes, manufacturers can ensure that their electric motors meet the required specifications and operate efficiently.

In addition to these common challenges and pitfalls, there are also several best practices that manufacturers can follow to ensure accurate and reliable test results. These best practices include calibration, data validation, and testing protocol standardization.

Best Practices for Ensuring Accurate and Reliable Test Results

To ensure accurate and reliable test results in electric motor testing and validation, several best practices should be followed. These best practices include:

Calibration: Calibration is a critical step in ensuring accurate test results. All testing equipment should be calibrated regularly to ensure that it is functioning correctly and providing accurate measurements.

Data Validation: Data validation is another important step in ensuring accurate test results. All test data should be validated to ensure that it is accurate and reliable.

Testing Protocol Standardization: Testing protocol standardization is also important in ensuring accurate and reliable test results. All testing protocols should be standardized to ensure that tests are conducted consistently and accurately.

Use of Advanced Testing and Validation Techniques: The use of advanced testing and validation techniques, such as finite element analysis and thermal imaging, can also help to ensure accurate and reliable test results.

Regular Maintenance of Testing Equipment: Regular maintenance of testing equipment is also important in ensuring accurate and reliable test results. All testing equipment should be regularly maintained to ensure that it is functioning correctly and providing accurate measurements.

Training of Testing Personnel: Training of testing personnel is also important in ensuring accurate and reliable test results. All testing personnel should be properly trained to ensure that they are able to operate testing equipment correctly and interpret test data accurately.

By following these best practices, manufacturers can ensure that their electric motor testing and validation processes are accurate, reliable, and effective. This can help to ensure that their electric motors meet the required specifications and operate efficiently.

In addition to these best practices, it is also important to note that electric motor testing and validation are ongoing processes that require continuous monitoring and improvement. By continuously monitoring and improving their testing and validation processes, manufacturers can ensure that their electric motors meet the required specifications and operate efficiently.

By incorporating these best practices into their electric motor testing and validation processes, manufacturers can ensure that their electric motors are reliable, efficient, and safe. This can help to improve performance, reduce energy consumption, and increase customer satisfaction.

Future Trends and Developments in Electric Motor Testing and Validation

The field of electric motor testing and validation is constantly evolving, with new technologies and techniques being developed to improve the accuracy and efficiency of testing processes. Some of the future trends and developments in electric motor testing and validation include:

Artificial Intelligence and Machine Learning: The increasing use of artificial intelligence and machine learning algorithms in test data analysis is expected to improve the accuracy and efficiency of electric motor testing and validation. These algorithms can help to identify patterns and trends in test data, and provide insights into motor performance and behavior.

Internet of Things (IoT) Technology: The use of IoT technology is expected to become more widespread in electric motor testing and validation, allowing for real-time monitoring and analysis of motor performance and behavior.

Advanced Materials and Manufacturing Techniques: The development of advanced materials and manufacturing techniques is expected to lead to the creation of more efficient and reliable electric motors. These motors will require more sophisticated testing and validation techniques to ensure their performance and reliability.

Increased Focus on Sustainability: The increasing focus on sustainability is expected to drive the development of more efficient and environmentally friendly electric motors. Electric motor testing and validation will play a critical role in ensuring that these motors meet the required specifications and operate efficiently.

More Emphasis on Condition Monitoring: Condition monitoring is expected to become more important in electric motor testing and validation, allowing for real-time monitoring of motor performance and behavior. This will enable predictive maintenance and reduce downtime.

By staying up-to-date with the latest trends and developments in electric motor testing and validation, manufacturers can ensure that their motors are reliable, efficient, and safe. This can help to improve performance, reduce energy consumption, and increase customer satisfaction.

In addition to these trends and developments, it is also important to note that electric motor testing and validation are ongoing processes that require continuous monitoring and improvement. By continuously monitoring and improving their testing and validation processes, manufacturers can ensure that their electric motors meet the required specifications and operate efficiently.