Unlocking the Power of Electric Vehicles: Understanding Certification and Compliance

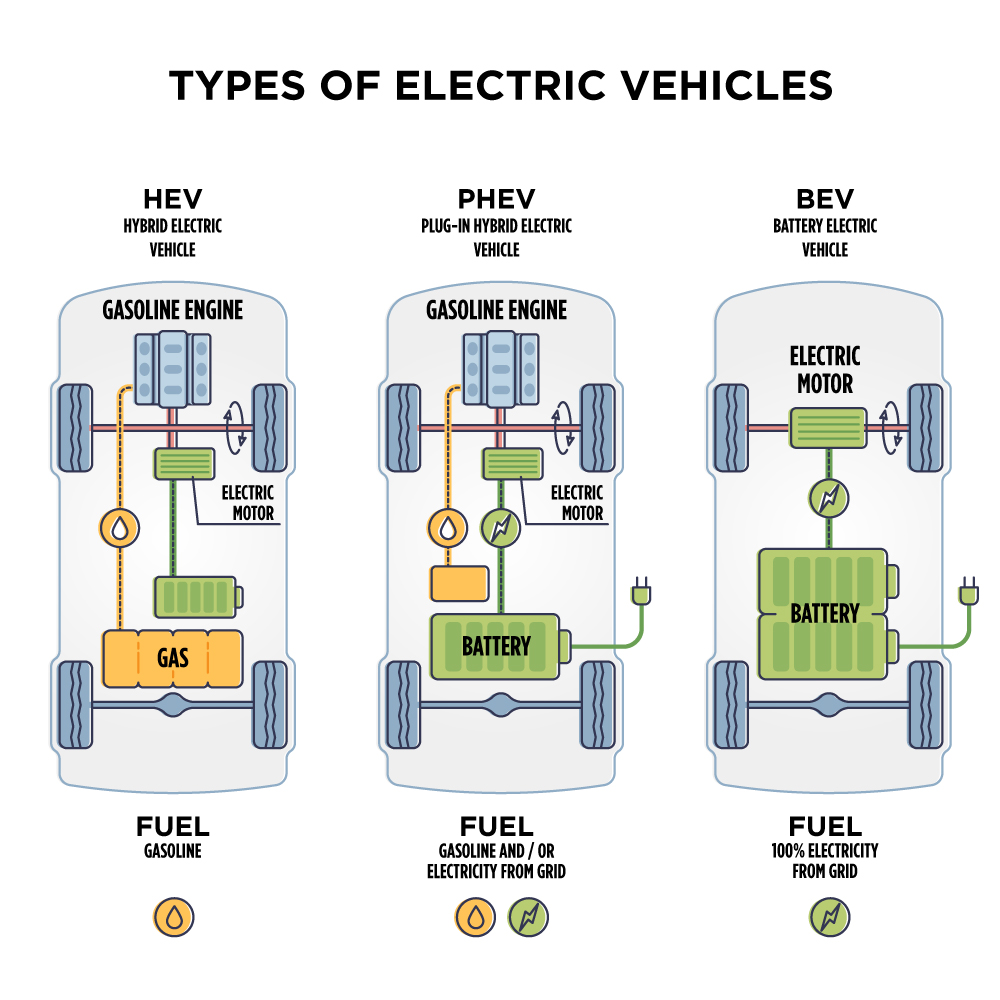

The electric vehicle (EV) industry is rapidly gaining momentum, driven by increasing concerns about climate change, air pollution, and energy sustainability. As governments and consumers alike turn to EVs as a cleaner alternative to traditional fossil fuel-powered vehicles, the need for standardized certification and compliance procedures has become more pressing than ever. Electric vehicle and electric motor certification and compliance standards play a crucial role in ensuring the safety, efficiency, and environmental sustainability of EVs, which is essential for widespread adoption and long-term success.

With the global EV market expected to reach 14 million units by 2025, the importance of certification and compliance cannot be overstated. Certification ensures that EVs and electric motors meet rigorous safety and performance standards, while compliance with regulations helps to prevent accidents, reduce emissions, and promote sustainable development. Moreover, certification and compliance provide a competitive edge for manufacturers, as consumers increasingly demand environmentally friendly and safe products.

However, the certification and compliance landscape for EVs and electric motors is complex and constantly evolving. Manufacturers must navigate a multitude of regulations, standards, and testing procedures, which can be time-consuming and costly. Furthermore, the lack of standardization across different regions and countries can create confusion and uncertainty, hindering the growth of the EV industry.

Despite these challenges, the benefits of certification and compliance far outweigh the costs. By ensuring that EVs and electric motors meet strict safety and performance standards, certification and compliance help to build consumer trust, reduce liability, and promote innovation. As the EV industry continues to grow and mature, the importance of certification and compliance will only continue to increase, making it essential for manufacturers to stay ahead of the curve.

How to Ensure Compliance with EV and Electric Motor Regulations

The electric vehicle (EV) and electric motor industry is rapidly evolving, with governments and regulatory bodies establishing standards to ensure safety, efficiency, and environmental sustainability. Compliance with these regulations is crucial for manufacturers, suppliers, and stakeholders to avoid penalties, reputational damage, and financial losses. In this section, we will provide an overview of the key regulations and standards governing EVs and electric motors, highlighting the importance of electric vehicle and electric motor certification and compliance standards.

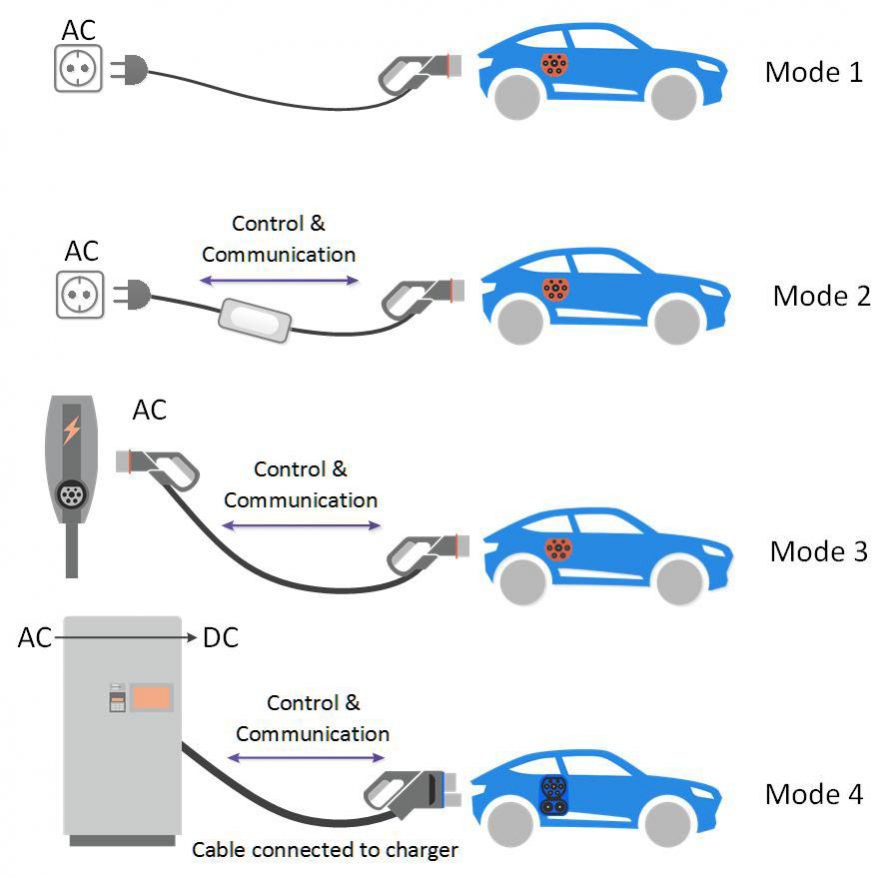

The International Electrotechnical Commission (IEC) plays a vital role in developing global standards for EVs and electric motors. The IEC 60034 series, for instance, provides guidelines for the design, testing, and performance of electric motors, while IEC 62196 outlines the requirements for EV charging systems. Similarly, the Society of Automotive Engineers (SAE) has established standards for electric motors, such as SAE J3016, which specifies test procedures for electric motor performance and efficiency.

In the United States, the National Highway Traffic Safety Administration (NHTSA) regulates EV safety through Federal Motor Vehicle Safety Standards (FMVSS). FMVSS 305, for example, sets safety standards for electric-powered vehicles, while FMVSS 305.5 addresses electric vehicle safety. Compliance with these regulations is mandatory for EV manufacturers, and certification is often required to demonstrate conformity.

Ensuring compliance with EV and electric motor regulations requires a comprehensive understanding of the relevant standards and regulations. Manufacturers must design and test their products to meet the specified requirements, and obtain certification from recognized testing laboratories or certification bodies. This involves a range of activities, including:

- Design and development: Ensuring that EVs and electric motors meet the requirements of relevant standards and regulations.

- Testing and validation: Conducting tests to demonstrate compliance with standards and regulations.

- Certification: Obtaining certification from recognized testing laboratories or certification bodies.

- Documentation: Maintaining records of design, testing, and certification to demonstrate compliance.

By understanding the key regulations and standards governing EVs and electric motors, manufacturers can ensure compliance and avoid potential risks. In the next section, we will delve into the specifics of IEC standards for EVs, exploring their significance and implementation in the industry.

IEC Standards for Electric Vehicles: A Comprehensive Guide

The International Electrotechnical Commission (IEC) plays a crucial role in developing global standards for electric vehicles (EVs). IEC standards provide a framework for ensuring the safety, efficiency, and environmental sustainability of EVs, and are widely adopted by manufacturers and regulatory bodies worldwide. In this section, we will delve into the specifics of IEC standards for EVs, including IEC 62196 (charging systems) and IEC 62660 (battery safety), and explore their significance and implementation in the industry.

IEC 62196, “Plugs, socket-outlets, vehicle connectors and vehicle inlets – Conductive charging of electric vehicles,” specifies the requirements for EV charging systems. This standard covers the design, testing, and performance of charging systems, including plugs, socket-outlets, vehicle connectors, and vehicle inlets. IEC 62196 ensures that EV charging systems are safe, efficient, and compatible with different types of EVs, and is widely adopted by manufacturers and regulatory bodies worldwide.

IEC 62660, “Secondary lithium-ion cells for the propulsion of electric road vehicles – Part 1: Performance testing,” specifies the requirements for lithium-ion battery cells used in EVs. This standard covers the performance testing of battery cells, including their electrical, thermal, and mechanical characteristics. IEC 62660 ensures that lithium-ion battery cells meet the required safety and performance standards, and is widely adopted by manufacturers and regulatory bodies worldwide.

Other notable IEC standards for EVs include IEC 60364 (electrical installations), IEC 60950 (safety of information technology equipment), and IEC 61558 (safety of power transformers). These standards provide a comprehensive framework for ensuring the safety, efficiency, and environmental sustainability of EVs, and are widely adopted by manufacturers and regulatory bodies worldwide.

The implementation of IEC standards for EVs has several benefits, including:

- Improved safety: IEC standards ensure that EVs meet the required safety standards, reducing the risk of accidents and injuries.

- Increased efficiency: IEC standards ensure that EVs are designed and tested to optimize their performance, reducing energy consumption and emissions.

- Environmental sustainability: IEC standards ensure that EVs meet the required environmental standards, reducing their impact on the environment.

- Global compatibility: IEC standards ensure that EVs are compatible with different types of charging systems and infrastructure, facilitating global adoption.

In the next section, we will examine the SAE standards for electric motors, including SAE J3016 (electric motor test procedures) and SAE J2954 (electric motor efficiency), and explore their role in ensuring performance, efficiency, and reliability.

SAE Standards for Electric Motors: Understanding the Requirements

The Society of Automotive Engineers (SAE) plays a crucial role in developing standards for electric motors used in electric vehicles (EVs). SAE standards provide a framework for ensuring the performance, efficiency, and reliability of electric motors, and are widely adopted by manufacturers and regulatory bodies worldwide. In this section, we will examine the SAE standards for electric motors, including SAE J3016 (electric motor test procedures) and SAE J2954 (electric motor efficiency), and explore their role in ensuring the quality and safety of EVs.

SAE J3016, “Electric Motor Test Procedures,” specifies the requirements for testing electric motors used in EVs. This standard covers the test procedures for evaluating the performance, efficiency, and reliability of electric motors, including their electrical, thermal, and mechanical characteristics. SAE J3016 ensures that electric motors meet the required standards for safety, efficiency, and performance, and is widely adopted by manufacturers and regulatory bodies worldwide.

SAE J2954, “Electric Motor Efficiency,” specifies the requirements for the efficiency of electric motors used in EVs. This standard covers the measurement and calculation of electric motor efficiency, including the effects of temperature, load, and speed. SAE J2954 ensures that electric motors meet the required standards for efficiency, reducing energy consumption and emissions, and is widely adopted by manufacturers and regulatory bodies worldwide.

Other notable SAE standards for electric motors include SAE J3048 (electric motor safety) and SAE J3050 (electric motor durability). These standards provide a comprehensive framework for ensuring the quality and safety of electric motors, and are widely adopted by manufacturers and regulatory bodies worldwide.

The implementation of SAE standards for electric motors has several benefits, including:

- Improved performance: SAE standards ensure that electric motors meet the required standards for performance, efficiency, and reliability.

- Increased efficiency: SAE standards ensure that electric motors meet the required standards for efficiency, reducing energy consumption and emissions.

- Enhanced safety: SAE standards ensure that electric motors meet the required standards for safety, reducing the risk of accidents and injuries.

- Global compatibility: SAE standards ensure that electric motors are compatible with different types of EVs and charging systems, facilitating global adoption.

In the next section, we will discuss the NHTSA regulations for EVs, including Federal Motor Vehicle Safety Standard (FMVSS) 305 (electric-powered vehicles) and FMVSS 305.5 (electric vehicle safety), and explore their impact on the industry.

NHTSA Regulations for Electric Vehicles: Safety and Performance Standards

The National Highway Traffic Safety Administration (NHTSA) plays a crucial role in regulating the safety and performance of electric vehicles (EVs) in the United States. NHTSA regulations provide a framework for ensuring the safety and performance of EVs, and are widely adopted by manufacturers and regulatory bodies worldwide. In this section, we will discuss the NHTSA regulations for EVs, including Federal Motor Vehicle Safety Standard (FMVSS) 305 (electric-powered vehicles) and FMVSS 305.5 (electric vehicle safety), and explore their impact on the industry.

FMVSS 305, “Electric-Powered Vehicles,” specifies the requirements for the safety and performance of electric-powered vehicles. This standard covers the requirements for the electrical system, battery, and charging system, as well as the requirements for the vehicle’s performance, including its acceleration, braking, and handling. FMVSS 305 ensures that electric-powered vehicles meet the required safety and performance standards, and is widely adopted by manufacturers and regulatory bodies worldwide.

FMVSS 305.5, “Electric Vehicle Safety,” specifies the requirements for the safety of electric vehicles. This standard covers the requirements for the electrical system, battery, and charging system, as well as the requirements for the vehicle’s safety features, including its crashworthiness and occupant protection. FMVSS 305.5 ensures that electric vehicles meet the required safety standards, and is widely adopted by manufacturers and regulatory bodies worldwide.

Other notable NHTSA regulations for EVs include FMVSS 401 (interior impact protection) and FMVSS 403 (platform lift systems). These regulations provide a comprehensive framework for ensuring the safety and performance of EVs, and are widely adopted by manufacturers and regulatory bodies worldwide.

The implementation of NHTSA regulations for EVs has several benefits, including:

- Improved safety: NHTSA regulations ensure that EVs meet the required safety standards, reducing the risk of accidents and injuries.

- Increased performance: NHTSA regulations ensure that EVs meet the required performance standards, improving their acceleration, braking, and handling.

- Enhanced environmental sustainability: NHTSA regulations ensure that EVs meet the required environmental standards, reducing their impact on the environment.

- Global compatibility: NHTSA regulations ensure that EVs are compatible with different types of charging systems and infrastructure, facilitating global adoption.

In the next section, we will provide real-world examples of EV and electric motor certification in practice, featuring companies like Tesla, General Motors, or Siemens, to illustrate the application of standards and regulations in the industry.

Real-World Examples: EV and Electric Motor Certification in Practice

The electric vehicle (EV) and electric motor industry is rapidly evolving, with companies like Tesla, General Motors, and Siemens leading the charge. In this section, we will provide real-world examples of EV and electric motor certification in practice, highlighting the application of standards and regulations in the industry.

Tesla, a pioneer in the EV industry, has been at the forefront of electric motor certification. Tesla’s electric motors are designed and tested to meet the requirements of SAE J3016 (electric motor test procedures) and SAE J2954 (electric motor efficiency). Tesla’s commitment to electric motor certification has enabled the company to produce high-performance, efficient, and reliable electric motors that meet the demands of the EV market.

General Motors, another leading player in the EV industry, has also invested heavily in electric motor certification. General Motors’ electric motors are designed and tested to meet the requirements of IEC 62196 (charging systems) and IEC 62660 (battery safety). General Motors’ commitment to electric motor certification has enabled the company to produce safe, efficient, and reliable electric motors that meet the demands of the EV market.

Siemens, a leading provider of electric motor solutions, has also been at the forefront of electric motor certification. Siemens’ electric motors are designed and tested to meet the requirements of NHTSA regulations, including FMVSS 305 (electric-powered vehicles) and FMVSS 305.5 (electric vehicle safety). Siemens’ commitment to electric motor certification has enabled the company to produce high-performance, efficient, and reliable electric motors that meet the demands of the EV market.

These real-world examples demonstrate the importance of electric vehicle and electric motor certification and compliance standards in the industry. By investing in electric motor certification, companies like Tesla, General Motors, and Siemens are able to produce high-quality, efficient, and reliable electric motors that meet the demands of the EV market.

In the next section, we will discuss the challenges and opportunities arising from the increasing demand for EV and electric motor certification, including the need for standardized testing procedures, training programs, and industry collaboration.

Challenges and Opportunities in EV and Electric Motor Certification

The increasing demand for electric vehicles (EVs) and electric motors has created new challenges and opportunities for the industry. One of the main challenges is the need for standardized testing procedures, training programs, and industry collaboration to ensure that EVs and electric motors meet the required safety, efficiency, and environmental sustainability standards.

Another challenge is the rapid evolution of technology, which requires continuous updates to certification and compliance standards. This can be a challenge for companies that need to stay ahead of the curve in terms of technology and innovation.

Despite these challenges, there are also opportunities for companies that are willing to invest in research and development, participate in industry forums, and monitor regulatory updates. By doing so, companies can stay ahead of the curve and position themselves for success in the EV and electric motor market.

One of the opportunities is the growing demand for EVs and electric motors, which is expected to continue in the coming years. This demand is driven by government regulations, consumer demand, and technological advancements.

Another opportunity is the potential for cost savings and increased efficiency through the use of EVs and electric motors. EVs and electric motors can reduce energy consumption and emissions, which can lead to cost savings and increased efficiency for companies and consumers.

In addition, the EV and electric motor industry is expected to create new job opportunities and stimulate economic growth. This can be a benefit for companies that are willing to invest in the industry and position themselves for success.

To take advantage of these opportunities, companies need to be aware of the challenges and opportunities in EV and electric motor certification and compliance standards. They need to stay up-to-date with the latest developments in technology and regulation, and be willing to invest in research and development and industry collaboration.

In the next section, we will offer guidance on how companies can stay ahead of the curve in EV and electric motor certification, including investing in research and development, participating in industry forums, and monitoring regulatory updates.

Future-Proofing Your EV and Electric Motor Business: Staying Ahead of the Curve

The electric vehicle (EV) and electric motor industry is rapidly evolving, with new technologies and innovations emerging every day. To stay ahead of the curve, companies need to be proactive in their approach to EV and electric motor certification and compliance standards.

One way to future-proof your EV and electric motor business is to invest in research and development. This can include investing in new technologies, such as advanced battery management systems or more efficient electric motors. It can also include investing in new manufacturing processes, such as 3D printing or advanced robotics.

Another way to stay ahead of the curve is to participate in industry forums and conferences. These events provide a platform for companies to share knowledge, best practices, and new developments in the industry. They also provide an opportunity for companies to network with other industry professionals and stay up-to-date with the latest trends and technologies.

Monitoring regulatory updates is also crucial for companies in the EV and electric motor industry. This can include staying up-to-date with changes to certification and compliance standards, as well as monitoring new regulations and laws that may impact the industry.

Finally, companies should consider investing in training programs for their employees. This can include training on new technologies, manufacturing processes, and certification and compliance standards. It can also include training on industry best practices and new developments in the industry.

By taking these steps, companies can future-proof their EV and electric motor business and stay ahead of the curve in the rapidly evolving industry. This can help companies to remain competitive, increase their market share, and achieve long-term success.

In conclusion, the EV and electric motor industry is rapidly evolving, and companies need to be proactive in their approach to certification and compliance standards to stay ahead of the curve. By investing in research and development, participating in industry forums, monitoring regulatory updates, and investing in training programs, companies can future-proof their business and achieve long-term success.