Unlocking the Potential of Electric Powertrains: A Competitive Landscape

The electric vehicle (EV) market is experiencing rapid growth, driven by increasing demand for sustainable and environmentally friendly transportation solutions. As governments worldwide implement stricter emissions regulations, manufacturers are under pressure to develop and produce EVs that meet these standards. A critical component of EVs is the electric motor, which plays a crucial role in determining the overall efficiency, performance, and range of the vehicle. In this article, we will delve into the competitive landscape of electric vehicles and motors, analyzing the strengths and weaknesses of different motor technologies and their impact on the market.

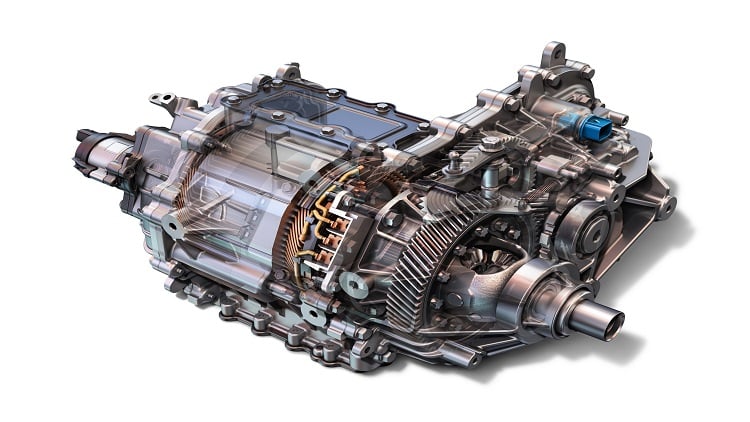

The electric motor is a key differentiator in the EV market, with various technologies vying for dominance. Permanent magnet motors, induction motors, and switched reluctance motors are among the most common types used in EVs. Each technology has its advantages and disadvantages, and manufacturers must carefully evaluate these factors when selecting a motor for their vehicles. For instance, permanent magnet motors offer high efficiency and reliability but are often more expensive than other options. Induction motors, on the other hand, are more affordable but may compromise on performance.

A thorough electric vehicle and electric motor competitive analysis is essential for manufacturers to understand the market dynamics and make informed decisions. This analysis involves evaluating the strengths and weaknesses of different motor technologies, as well as assessing the competitive landscape of the EV market. By doing so, manufacturers can identify opportunities to improve their products, reduce costs, and increase their market share.

The increasing competition in the EV market has led to a surge in innovation, with manufacturers investing heavily in research and development to improve their electric motor technologies. This has resulted in significant advancements in motor design, materials, and manufacturing processes, enabling the production of more efficient, reliable, and affordable EVs. As the market continues to evolve, it is essential for manufacturers to stay ahead of the curve and adapt to changing consumer demands and technological advancements.

In conclusion, the competitive landscape of electric vehicles and motors is complex and rapidly evolving. Manufacturers must carefully evaluate the strengths and weaknesses of different motor technologies and assess the market dynamics to make informed decisions. By doing so, they can unlock the potential of electric powertrains and stay ahead of the competition in the growing EV market.

How to Evaluate Electric Motor Efficiency: A Key Differentiator in the EV Market

Evaluating electric motor efficiency is crucial in the electric vehicle (EV) market, as it directly impacts the overall performance, range, and environmental sustainability of the vehicle. Electric motor efficiency is a key differentiator among EV manufacturers, and understanding how to evaluate it is essential for making informed decisions. In this section, we will provide a framework for evaluating different motor technologies, including permanent magnet motors, induction motors, and switched reluctance motors.

Permanent magnet motors are widely used in EVs due to their high efficiency, reliability, and power density. However, they can be more expensive than other options, and the sourcing of rare earth materials can be a challenge. Induction motors, on the other hand, are more affordable but may compromise on performance. Switched reluctance motors offer a balance between efficiency and cost but can be more complex to design and manufacture.

To evaluate electric motor efficiency, manufacturers must consider several factors, including the motor’s power output, torque, and efficiency at various speeds and loads. Additionally, the motor’s thermal management, noise, and vibration characteristics must be assessed. A comprehensive evaluation of these factors will enable manufacturers to select the most suitable motor technology for their EVs and stay competitive in the market.

In the context of electric vehicle and electric motor competitive analysis, evaluating motor efficiency is critical for understanding the strengths and weaknesses of different manufacturers. By analyzing the motor efficiency of various EV models, manufacturers can identify areas for improvement and optimize their motor designs to achieve better performance, range, and sustainability.

Furthermore, evaluating motor efficiency can also inform decisions on electric motor innovation and investment. By understanding the current state of motor technology and identifying areas for improvement, manufacturers can focus their research and development efforts on developing more efficient and sustainable motor technologies.

In conclusion, evaluating electric motor efficiency is a critical component of electric vehicle and electric motor competitive analysis. By understanding the strengths and weaknesses of different motor technologies and evaluating their efficiency, manufacturers can make informed decisions and stay competitive in the EV market.

Tesla’s Electric Motor Dominance: A Case Study

Tesla’s success in the electric vehicle (EV) market can be attributed to its innovative electric motor technology. The company’s use of permanent magnet motors has enabled it to achieve high efficiency, reliability, and performance in its vehicles. In this section, we will analyze Tesla’s electric motor technology and its impact on the company’s success in the EV market.

Tesla’s electric motor design is centered around the use of permanent magnet motors, which provide high efficiency and reliability. The company’s motors are designed to operate at high speeds and temperatures, enabling Tesla’s vehicles to achieve exceptional performance and range. Additionally, Tesla’s motor design is highly scalable, allowing the company to produce motors for a wide range of vehicles, from the Model 3 to the Model S.

One of the key advantages of Tesla’s electric motor technology is its ability to achieve high efficiency. Tesla’s motors have been shown to achieve efficiency rates of over 90%, which is significantly higher than many other EV manufacturers. This high efficiency enables Tesla’s vehicles to achieve longer ranges and better performance, making them highly competitive in the market.

However, Tesla’s electric motor technology is not without its challenges. The company’s use of permanent magnet motors requires the sourcing of rare earth materials, which can be expensive and difficult to obtain. Additionally, Tesla’s motor design is highly complex, requiring significant investment in research and development.

In the context of electric vehicle and electric motor competitive analysis, Tesla’s electric motor technology is a key differentiator in the market. The company’s ability to achieve high efficiency and performance has enabled it to establish a strong market presence and attract a loyal customer base. However, other manufacturers, such as Nissan and BYD, are also developing innovative electric motor technologies that could potentially challenge Tesla’s dominance in the market.

Overall, Tesla’s electric motor technology is a critical component of the company’s success in the EV market. Its ability to achieve high efficiency, reliability, and performance has enabled Tesla to establish a strong market presence and attract a loyal customer base. However, the company must continue to innovate and improve its motor technology to stay ahead of the competition and maintain its market leadership.

Nissan’s e-Power Technology: A Competitive Threat to Tesla?

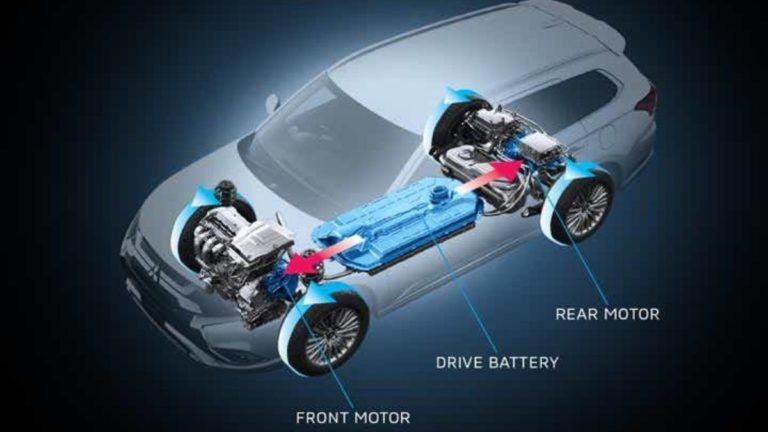

Nissan’s e-Power technology is a significant development in the electric vehicle (EV) market, and it has the potential to challenge Tesla’s dominance. e-Power is a series hybrid system that combines a gasoline engine with an electric motor, allowing for improved fuel efficiency and reduced emissions. In this section, we will examine Nissan’s e-Power technology and its potential to challenge Tesla’s dominance in the EV market.

Nissan’s e-Power technology is designed to provide a more efficient and cost-effective alternative to traditional hybrid systems. The system uses a gasoline engine to generate electricity, which is then used to power an electric motor. This approach allows for improved fuel efficiency and reduced emissions, making it an attractive option for consumers who are looking for a more environmentally friendly vehicle.

One of the key advantages of Nissan’s e-Power technology is its ability to provide a more affordable alternative to traditional EVs. The system is designed to be more cost-effective than traditional EVs, making it an attractive option for consumers who are looking for a more affordable option. Additionally, the system is designed to be more efficient than traditional hybrid systems, making it an attractive option for consumers who are looking for improved fuel efficiency.

However, Nissan’s e-Power technology also has some drawbacks. The system is designed to be more complex than traditional EVs, which can make it more difficult to maintain and repair. Additionally, the system is designed to be more dependent on the gasoline engine, which can make it less efficient than traditional EVs in certain driving conditions.

In the context of electric vehicle and electric motor competitive analysis, Nissan’s e-Power technology is a significant development that has the potential to challenge Tesla’s dominance in the EV market. The system’s ability to provide a more affordable and efficient alternative to traditional EVs makes it an attractive option for consumers who are looking for a more environmentally friendly vehicle. However, the system’s complexity and dependence on the gasoline engine may make it less attractive to some consumers.

Overall, Nissan’s e-Power technology is a significant development in the EV market that has the potential to challenge Tesla’s dominance. The system’s ability to provide a more affordable and efficient alternative to traditional EVs makes it an attractive option for consumers who are looking for a more environmentally friendly vehicle. However, the system’s complexity and dependence on the gasoline engine may make it less attractive to some consumers.

The Rise of Chinese EV Manufacturers: A New Era of Competition

The emergence of Chinese electric vehicle (EV) manufacturers has significantly impacted the global EV market. Companies such as BYD and NIO have made significant strides in recent years, and their influence is expected to continue growing in the coming years. In this section, we will discuss the strengths and weaknesses of these manufacturers and their electric motor technologies.

BYD is one of the largest EV manufacturers in China, and its electric motor technology is highly regarded in the industry. The company’s motors are designed to be highly efficient and reliable, and they have been used in a wide range of applications, from passenger vehicles to buses and trucks. BYD’s electric motor technology is also highly scalable, making it an attractive option for manufacturers who are looking to produce large quantities of EVs.

NIO is another Chinese EV manufacturer that has made significant strides in recent years. The company’s electric motor technology is highly advanced, and its motors are designed to be highly efficient and powerful. NIO’s electric motor technology is also highly customizable, making it an attractive option for manufacturers who are looking to produce EVs with unique performance characteristics.

Both BYD and NIO have made significant investments in research and development, and their electric motor technologies are highly regarded in the industry. However, the companies also face significant challenges, including intense competition from established manufacturers and the need to comply with increasingly stringent regulations.

In the context of electric vehicle and electric motor competitive analysis, the rise of Chinese EV manufacturers is a significant development that is expected to have a major impact on the global EV market. The companies’ electric motor technologies are highly advanced, and their influence is expected to continue growing in the coming years.

Overall, the emergence of Chinese EV manufacturers is a significant development that is expected to have a major impact on the global EV market. The companies’ electric motor technologies are highly advanced, and their influence is expected to continue growing in the coming years. As the global EV market continues to evolve, it will be important to monitor the progress of these companies and their electric motor technologies.

Electric Motor Innovation: The Key to Future Success

Innovation in electric motor technology is crucial for manufacturers to stay competitive in the electric vehicle (EV) market. As the demand for EVs continues to grow, manufacturers must develop more efficient, reliable, and cost-effective electric motors to meet the increasing demand. In this section, we will discuss recent advancements in motor design, materials, and manufacturing processes that are driving innovation in the EV market.

One of the most significant advancements in electric motor technology is the development of new materials and designs that improve efficiency and reduce weight. For example, the use of rare earth materials such as neodymium and dysprosium has enabled the development of more efficient and powerful electric motors. Additionally, the use of advanced materials such as carbon fiber and advanced ceramics has enabled the development of lighter and more efficient electric motors.

Another area of innovation in electric motor technology is the development of new manufacturing processes that improve efficiency and reduce costs. For example, the use of 3D printing and other advanced manufacturing techniques has enabled the development of complex motor designs that were previously impossible to produce. Additionally, the use of automation and robotics has enabled the development of more efficient and cost-effective manufacturing processes.

In the context of electric vehicle and electric motor competitive analysis, innovation in electric motor technology is a key differentiator for manufacturers. Companies that are able to develop more efficient, reliable, and cost-effective electric motors will be better positioned to succeed in the EV market. As the demand for EVs continues to grow, manufacturers must continue to innovate and improve their electric motor technologies to stay competitive.

Recent advancements in electric motor technology have also enabled the development of new types of electric motors that are more efficient and reliable than traditional motors. For example, the development of axial flux motors and transverse flux motors has enabled the development of more efficient and compact electric motors. Additionally, the development of new motor control systems has enabled the development of more efficient and reliable electric motors.

Overall, innovation in electric motor technology is driving the development of more efficient, reliable, and cost-effective electric motors that are enabling the growth of the EV market. As the demand for EVs continues to grow, manufacturers must continue to innovate and improve their electric motor technologies to stay competitive.

Challenges and Opportunities in the Electric Motor Supply Chain

The electric motor supply chain is a critical component of the electric vehicle (EV) industry, and it is facing several challenges and opportunities. In this section, we will examine the challenges and opportunities in the electric motor supply chain, including the sourcing of rare earth materials, manufacturing capacity, and logistics.

One of the major challenges facing the electric motor supply chain is the sourcing of rare earth materials. Rare earth materials, such as neodymium and dysprosium, are critical components of electric motors, and their availability is limited. The sourcing of these materials is a complex process, and it requires careful planning and management to ensure a stable supply.

Another challenge facing the electric motor supply chain is manufacturing capacity. As the demand for EVs continues to grow, the demand for electric motors is also increasing. However, the manufacturing capacity of electric motors is limited, and it is not keeping pace with the growing demand. This has resulted in a shortage of electric motors, which is affecting the production of EVs.

Logistics is another challenge facing the electric motor supply chain. The transportation of electric motors from the manufacturing plant to the assembly plant is a complex process, and it requires careful planning and management. The logistics of electric motor transportation are critical, and any disruptions can affect the production of EVs.

Despite these challenges, there are also opportunities in the electric motor supply chain. The growing demand for EVs is creating new opportunities for suppliers of electric motors, and it is driving innovation in the industry. The development of new technologies, such as 3D printing and advanced materials, is also creating new opportunities for suppliers of electric motors.

In the context of electric vehicle and electric motor competitive analysis, the electric motor supply chain is a critical component of the industry. The challenges and opportunities in the electric motor supply chain are affecting the production of EVs, and they are driving innovation in the industry. As the demand for EVs continues to grow, the electric motor supply chain will play an increasingly important role in the industry.

Overall, the electric motor supply chain is facing several challenges and opportunities. The sourcing of rare earth materials, manufacturing capacity, and logistics are critical components of the electric motor supply chain, and they are affecting the production of EVs. However, the growing demand for EVs is also creating new opportunities for suppliers of electric motors, and it is driving innovation in the industry.

Conclusion: The Future of Electric Vehicles and Motors

The electric vehicle (EV) market is rapidly evolving, and the competition is intensifying. As the demand for EVs continues to grow, manufacturers must stay ahead of the curve by innovating and improving their electric motor technologies. In this article, we have analyzed the competitive landscape of the EV market, highlighting the strengths and weaknesses of different electric motor technologies.

We have also examined the impact of innovation on the EV market, discussing recent advancements in motor design, materials, and manufacturing processes. Additionally, we have analyzed the challenges and opportunities in the electric motor supply chain, including the sourcing of rare earth materials, manufacturing capacity, and logistics.

Based on our analysis, we recommend that manufacturers focus on developing more efficient and cost-effective electric motor technologies. This can be achieved through innovation in motor design, materials, and manufacturing processes. Additionally, manufacturers should prioritize the development of sustainable and reliable supply chains to ensure a stable supply of rare earth materials and other critical