Unlocking the Power of Electric Motors: Understanding the Digital Shift

The automotive industry is undergoing a significant transformation, driven by the increasing adoption of electric vehicles (EVs) and the integration of digital technologies. At the heart of this transformation is the electric motor, a critical component that is being revolutionized by digital innovations. Electric vehicle and electric motor digital transformation is redefining the way EVs are designed, developed, and manufactured, enabling faster, more efficient, and more sustainable production processes.

One of the key drivers of this digital shift is the growing importance of electric motors in EVs. As the demand for EVs continues to rise, manufacturers are under pressure to produce high-quality, reliable, and efficient electric motors that can meet the performance and range expectations of consumers. Digital technologies, such as computer-aided design (CAD), computer-aided engineering (CAE), and simulation tools, are being used to optimize electric motor design, reduce development time, and improve manufacturing efficiency.

For instance, digital twin technology is being used to create virtual replicas of electric motors, allowing manufacturers to simulate real-world scenarios, test performance, and identify potential issues before physical prototypes are built. This approach enables faster and more accurate testing, reducing the need for physical prototypes and accelerating the development process.

Furthermore, digital technologies are also transforming the manufacturing process of electric motors. Advanced manufacturing techniques, such as 3D printing and robotics, are being used to improve production efficiency, reduce waste, and enhance product quality. These innovations are enabling manufacturers to produce high-quality electric motors at a lower cost, making EVs more competitive with traditional internal combustion engine vehicles.

In addition, electric vehicle and electric motor digital transformation is also driving innovation in the development of new electric motor technologies. For example, the use of advanced materials, such as rare-earth magnets and high-temperature superconductors, is enabling the development of more efficient and powerful electric motors. These advancements are critical to improving the performance and range of EVs, making them more appealing to consumers.

The integration of digital technologies in electric motor design, development, and manufacturing is a key aspect of electric vehicle and electric motor digital transformation. By leveraging these technologies, manufacturers can improve the efficiency, reliability, and sustainability of EVs, ultimately driving the adoption of electric vehicles and reducing our reliance on fossil fuels.

How to Leverage IoT and Data Analytics for Electric Motor Optimization

The increasing adoption of electric vehicles (EVs) has led to a growing demand for efficient and reliable electric motors. To meet this demand, manufacturers are turning to the Internet of Things (IoT) and data analytics to optimize electric motor performance, efficiency, and reliability. Electric vehicle and electric motor digital transformation is driving the use of IoT and data analytics in the automotive industry, enabling manufacturers to improve the overall quality and performance of their EV offerings.

IoT sensors and data analytics are being used to monitor and analyze electric motor performance in real-time, enabling manufacturers to identify areas for improvement and optimize motor design and development. For example, Tesla uses IoT sensors and data analytics to monitor the performance of its electric motors, enabling the company to optimize motor efficiency and reduce energy consumption.

Volkswagen is another company that is leveraging IoT and data analytics to optimize its electric motor performance. The company uses a data analytics platform to analyze data from its electric motors, enabling it to identify trends and patterns that can inform motor design and development. This approach has enabled Volkswagen to improve the efficiency and reliability of its electric motors, reducing energy consumption and improving overall vehicle performance.

The use of IoT and data analytics in electric motor optimization is a key aspect of electric vehicle and electric motor digital transformation. By leveraging these technologies, manufacturers can improve the performance, efficiency, and reliability of their electric motors, ultimately driving the adoption of EVs and reducing our reliance on fossil fuels.

In addition to optimizing electric motor performance, IoT and data analytics are also being used to improve the overall efficiency of EVs. For example, manufacturers are using data analytics to optimize battery management systems, enabling EVs to travel farther on a single charge. This approach has significant implications for the automotive industry, enabling manufacturers to improve the overall efficiency and performance of their EV offerings.

Furthermore, the use of IoT and data analytics in electric motor optimization is also driving innovation in the development of new electric motor technologies. For example, the use of advanced materials and designs is enabling the development

The Impact of Digital Twin Technology on Electric Vehicle Development

Digital twin technology is a rapidly emerging trend in the automotive industry, and its impact on electric vehicle (EV) development is significant. A digital twin is a virtual replica of a physical system, such as an electric motor or a battery, that can be used to simulate real-world scenarios, test performance, and identify potential issues before physical prototypes are built. Electric vehicle and electric motor digital transformation is driving the adoption of digital twin technology in the automotive industry, enabling manufacturers to accelerate the development process, reduce costs, and improve product quality.

The use of digital twin technology in EV development has several benefits. Firstly, it enables manufacturers to test and validate the performance of electric motors and batteries in a virtual environment, reducing the need for physical prototypes and accelerating the development process. This approach also enables manufacturers to identify and address potential issues early in the development process, reducing the risk of costly rework and improving overall product quality.

Secondly, digital twin technology enables manufacturers to optimize the performance of electric motors and batteries in real-time, using data analytics and machine learning algorithms to analyze performance data and identify areas for improvement. This approach enables manufacturers to improve the efficiency and reliability of their EV offerings, reducing energy consumption and improving overall vehicle performance.

Thirdly, digital twin technology enables manufacturers to create virtual models of entire EV systems, including the electric motor, battery, and power electronics. This approach enables manufacturers to simulate real-world scenarios, test performance, and identify potential issues before physical prototypes are built, reducing the risk of costly rework and improving overall product quality.

Companies like Siemens and Dassault Systèmes are already using digital twin technology to support EV development. For example, Siemens uses digital twin technology to create virtual models of electric motors and batteries, enabling manufacturers to test and validate performance in a virtual environment. Dassault Systèmes uses digital twin technology to create virtual models of entire EV systems, enabling manufacturers to simulate real-world scenarios and test performance.

In conclusion, the use of digital twin technology in EV development is a key aspect of electric vehicle and electric motor digital transformation. By leveraging digital twin technology, manufacturers can accelerate the development process, reduce costs, and improve product quality, ultimately driving the adoption of EVs and reducing our reliance on fossil fuels.

Electric Vehicle Charging Infrastructure: A Digital Transformation Imperative

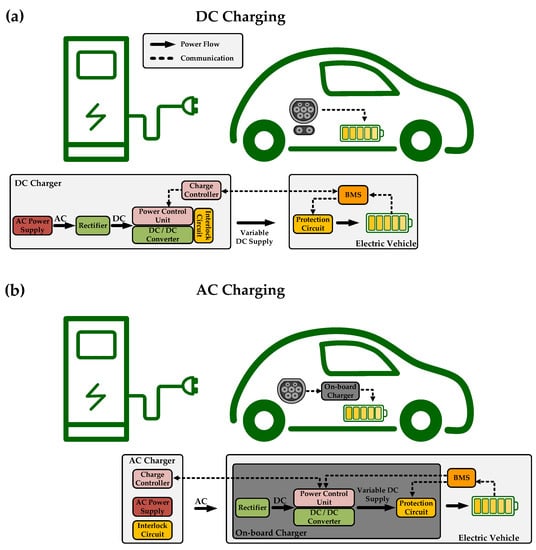

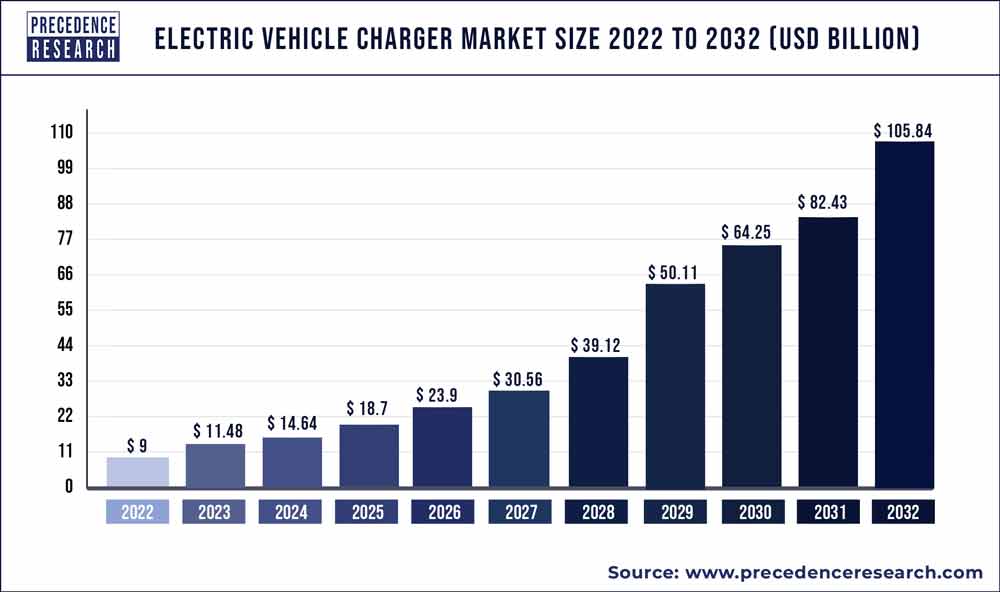

The widespread adoption of electric vehicles (EVs) is driving the need for a robust and efficient charging infrastructure. Electric vehicle and electric motor digital transformation is playing a critical role in the development of this infrastructure, enabling the creation of smart charging systems, grid management, and user-friendly payment systems. The integration of digital technologies in EV charging infrastructure is essential to support the growing demand for EVs and to ensure a seamless charging experience for drivers.

One of the key challenges in EV charging infrastructure is the need for smart charging systems that can manage the flow of energy between the grid and the vehicle. Digital technologies, such as IoT sensors and data analytics, are being used to create smart charging systems that can optimize energy flow, reduce peak demand, and improve overall efficiency. For example, companies like ChargePoint and EVgo are using IoT sensors and data analytics to create smart charging systems that can manage energy flow and optimize charging times.

Another critical aspect of EV charging infrastructure is grid management. Digital technologies, such as advanced grid management systems and energy storage systems, are being used to manage the flow of energy between the grid and the vehicle. These systems enable utilities to manage peak demand, reduce energy waste, and improve overall grid efficiency. For example, companies like Siemens and ABB are using advanced grid management systems to manage energy flow and optimize grid efficiency.

User-friendly payment systems are also essential to support the widespread adoption of EVs. Digital technologies, such as mobile payment systems and online payment platforms, are being used to create user-friendly payment systems that can simplify the charging experience for drivers. For example, companies like PayPal and Apple Pay are using mobile payment systems to enable drivers to pay for charging services using their smartphones.

In addition to these technologies, electric vehicle and electric motor digital transformation is also driving innovation in the development of new EV charging infrastructure. For example, companies like Tesla and Volkswagen are using digital technologies to create high-power charging systems that can charge EVs to 80% in just 15 minutes. These systems are essential to support the widespread adoption of EVs and to ensure a seamless charging experience for drivers.

In conclusion, the integration of digital technologies in EV charging infrastructure is essential to support the growing demand for EVs and to ensure a seamless charging experience for drivers. Electric vehicle and electric motor digital transformation is driving innovation in the development of smart charging systems, grid management, and user-friendly payment systems, and is playing a critical role in the creation of a robust and efficient charging infrastructure.

Real-World Examples: How Companies Like Nissan and BMW Are Embracing Electric Vehicle Digital Transformation

Nissan and BMW are two companies that are successfully embracing electric vehicle digital transformation. Nissan’s Leaf is one of the best-selling electric vehicles in the world, and the company has been at the forefront of electric vehicle digital transformation. BMW’s iSeries is another example of a successful electric vehicle that has been developed using digital technologies.

Nissan’s approach to electric vehicle digital transformation is centered around the use of digital technologies to improve the efficiency and performance of its electric vehicles. The company uses advanced computer simulations and modeling techniques to optimize the design and development of its electric motors and batteries. Nissan also uses data analytics and machine learning algorithms to analyze data from its electric vehicles and improve their performance and efficiency.

BMW’s approach to electric vehicle digital transformation is centered around the use of digital technologies to create a seamless and integrated driving experience. The company uses advanced computer simulations and modeling techniques to optimize the design and development of its electric vehicles, and it also uses data analytics and machine learning algorithms to analyze data from its electric vehicles and improve their performance and efficiency.

Both Nissan and BMW are using digital twin technology to simulate real-world scenarios and test the performance of their electric vehicles. This approach enables them to identify and address potential issues before physical prototypes are built, reducing the risk of costly rework and improving overall product quality.

In addition to these technologies, Nissan and BMW are also using digital technologies to create user-friendly and intuitive interfaces for their electric vehicles. For example, Nissan’s Leaf has a user-friendly interface that enables drivers to easily navigate and control the vehicle’s systems. BMW’s iSeries also has a user-friendly interface that enables drivers to easily navigate and control the vehicle’s systems.

Overall, Nissan and BMW are two companies that are successfully embracing electric vehicle digital transformation. Their approaches to electric vehicle digital transformation are centered around the use of digital technologies to improve the efficiency and performance of their electric vehicles, and to create a seamless and integrated driving experience.

Electric vehicle and electric motor digital transformation is a critical aspect of the automotive industry, and companies like Nissan and BMW are at the forefront of this transformation. By embracing digital technologies and using them to improve the efficiency and performance of their electric vehicles, these companies are able to stay competitive in the rapidly evolving automotive industry.

Overcoming the Challenges of Electric Vehicle Digital Transformation

Electric vehicle digital transformation is a complex and challenging process that requires companies to overcome several obstacles. One of the main challenges is data management, as companies need to collect, analyze, and interpret large amounts of data from various sources, including sensors, IoT devices, and customer feedback.

Another challenge is cybersecurity, as companies need to protect their data and systems from cyber threats and ensure the security of their electric vehicles. This requires implementing robust cybersecurity measures, such as encryption, firewalls, and intrusion detection systems.

Talent acquisition is also a significant challenge, as companies need to attract and retain skilled professionals with expertise in electric vehicle digital transformation. This includes data scientists, software engineers, and cybersecurity experts who can help companies navigate the complexities of electric vehicle digital transformation.

To overcome these challenges, companies can take several steps. First, they can invest in data management platforms that can help them collect, analyze, and interpret data from various sources. Second, they can implement robust cybersecurity measures to protect their data and systems from cyber threats. Third, they can develop training programs to upskill their existing workforce and attract new talent with expertise in electric vehicle digital transformation.

Additionally, companies can also consider partnering with startups and technology companies that specialize in electric vehicle digital transformation. This can help them access new technologies, expertise, and innovative solutions that can help them overcome the challenges of electric vehicle digital transformation.

Electric vehicle and electric motor digital transformation is a critical aspect of the automotive industry, and companies that can overcome the challenges of this transformation will be well-positioned to succeed in the future. By investing in data management, cybersecurity, and talent acquisition, companies can ensure a smooth transition to electric vehicle digital transformation and stay competitive in the rapidly evolving automotive industry.

In conclusion, overcoming the challenges of electric vehicle digital transformation requires a comprehensive approach that includes investing in data management, cybersecurity, and talent acquisition. By taking these steps, companies can ensure a successful transition to electric vehicle digital transformation and stay competitive in the automotive industry.

The Future of Electric Vehicle Digital Transformation: Trends and Predictions

The future of electric vehicle digital transformation is exciting and rapidly evolving. Emerging trends like autonomous vehicles, vehicle-to-grid technology, and advanced materials are expected to shape the industry in the coming years. Electric vehicle and electric motor digital transformation is expected to play a critical role in the development of these trends, enabling companies to create more efficient, sustainable, and connected electric vehicles.

Autonomous vehicles are one of the most significant trends in the automotive industry, and electric vehicle digital transformation is expected to play a critical role in their development. Autonomous vehicles require advanced sensors, software, and connectivity, which are all enabled by electric vehicle digital transformation. Companies like Tesla and Waymo are already using electric vehicle digital transformation to develop autonomous vehicles, and this trend is expected to continue in the coming years.

Vehicle-to-grid technology is another trend that is expected to shape the industry. This technology enables electric vehicles to act as energy storage devices, providing energy back to the grid when not in use. Electric vehicle digital transformation is critical to the development of vehicle-to-grid technology, as it enables companies to create advanced software and connectivity systems that can manage the flow of energy between the vehicle and the grid.

Advanced materials are also expected to play a critical role in the development of electric vehicles. Electric vehicle digital transformation is enabling companies to create advanced materials that are lighter, stronger, and more sustainable. These materials are expected to improve the efficiency and range of electric vehicles, making them more appealing to consumers.

In addition to these trends, electric vehicle digital transformation is also expected to enable the development of new business models and revenue streams. For example, companies like Tesla are using electric vehicle digital transformation to create new revenue streams through software updates and connectivity services. This trend is expected to continue in the coming years, as companies look for new ways to monetize their electric vehicle offerings.

Overall, the future of electric vehicle digital transformation is exciting and rapidly evolving. Emerging trends like autonomous vehicles, vehicle-to-grid technology, and advanced materials are expected to shape the industry in the coming years, and electric vehicle digital transformation is critical to their development. Companies that can successfully navigate these trends and create innovative electric vehicle offerings will be well-positioned to succeed in the rapidly evolving automotive industry.

Conclusion: Embracing the Electric Vehicle Digital Transformation Revolution

In conclusion, electric vehicle digital transformation is a critical aspect of the automotive industry, and companies that can successfully navigate this transformation will be well-positioned to succeed in the rapidly evolving market. The integration of digital technologies, such as IoT, data analytics, and digital twin technology, is transforming the design, development, and manufacturing of electric vehicles, enabling companies to create more efficient, sustainable, and connected electric vehicles.

As the automotive industry continues to evolve, it is essential for companies to stay ahead of the curve and embrace electric vehicle digital transformation. This requires a deep understanding of the latest digital technologies and their applications in electric vehicle development, as well as a willingness to invest in new technologies and talent.

By embracing electric vehicle digital transformation, companies can improve the efficiency and sustainability of their electric vehicles, reduce costs, and enhance the overall driving experience. Additionally, electric vehicle digital transformation can enable companies to create new business models and revenue streams, such as software updates and connectivity services.

In summary, electric vehicle digital transformation is a critical aspect of the automotive industry, and companies that can successfully navigate this transformation will be well-positioned to succeed in the rapidly evolving market. By embracing digital technologies and investing in new technologies and talent, companies can improve the efficiency and sustainability of their electric vehicles, reduce costs, and enhance the overall driving experience.

Electric vehicle and electric motor digital transformation is a rapidly evolving field, and companies that can stay ahead of the curve will be well-positioned to succeed in the future. By embracing digital technologies and investing in new technologies and talent, companies can create a sustainable and competitive advantage in the rapidly evolving automotive industry.