Unlocking the Power of Electrification: How Digital Transformation is Redefining the Industry

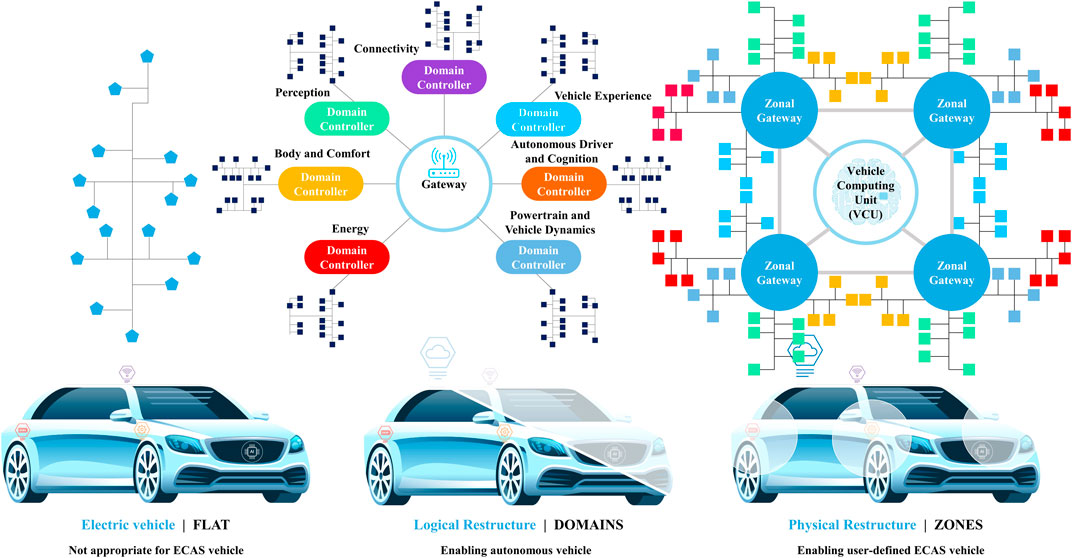

The electric vehicle (EV) and electric motor (EM) industry is undergoing a significant transformation, driven by the growing demand for sustainable and environmentally friendly transportation solutions. As governments and consumers increasingly prioritize eco-friendly options, the industry is shifting towards electrification, with digital transformation playing a crucial role in shaping its future. The integration of digital technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics, is revolutionizing the way EVs and EMs are designed, manufactured, and maintained.

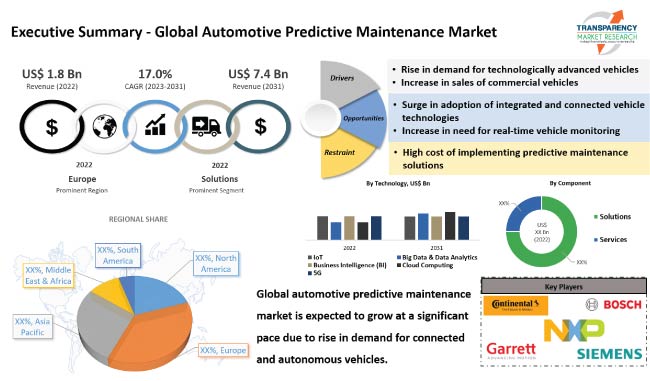

According to a recent report, the global EV market is expected to reach 14 million units by 2025, with digital transformation being a key driver of this growth. The adoption of digital technologies is enabling EV manufacturers to improve efficiency, reduce costs, and enhance customer experience. For instance, digital twin technology is being used to optimize EV design and performance, while AI-powered predictive maintenance is reducing downtime and improving overall efficiency.

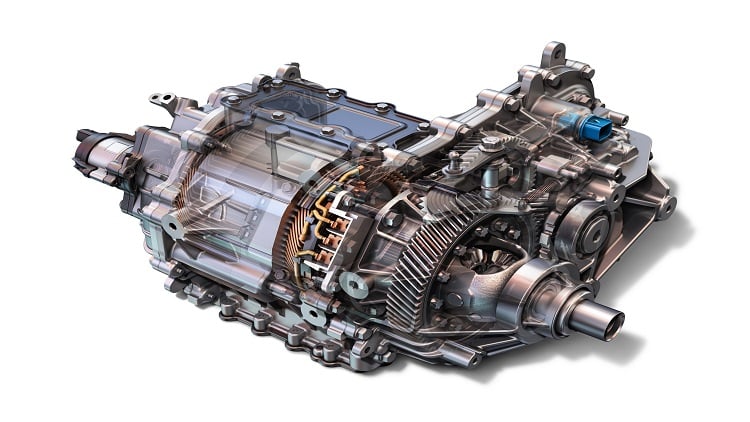

The electric motor industry is also undergoing a significant transformation, with digital transformation enabling the development of more efficient and sustainable motors. The use of advanced materials and digital technologies, such as 3D printing and simulation software, is enabling the creation of more efficient and compact motors. Additionally, the integration of IoT and AI is enabling real-time monitoring and optimization of motor performance, reducing energy consumption and improving overall efficiency.

As the EV and EM industry continues to evolve, it is clear that digital transformation will play a crucial role in shaping its future. The adoption of digital technologies is enabling the development of more sustainable, efficient, and customer-centric solutions, and it is essential that companies in the industry prioritize digital transformation to remain competitive. By leveraging digital transformation trends, such as IoT, AI, and data analytics, companies can unlock the power of electrification and drive innovation in the EV and EM industry.

In the next section, we will explore the key digital transformation trends in the EV and EM industry, including the adoption of IoT, AI, and data analytics. We will also examine the benefits and challenges of implementing these technologies and provide examples of companies that are already leveraging them to improve efficiency, reduce costs, and enhance customer experience.

Key Digital Transformation Trends in Electric Vehicles and Motors

The electric vehicle (EV) and electric motor (EM) industry is undergoing a significant transformation, driven by the adoption of digital technologies. Some of the most significant digital transformation trends in the EV and EM industry include the adoption of Internet of Things (IoT), Artificial Intelligence (AI), and data analytics. These technologies are enabling companies to improve efficiency, reduce costs, and enhance customer experience.

One of the key trends in the EV industry is the use of IoT to optimize vehicle performance and reduce energy consumption. For example, companies like Tesla are using IoT sensors to monitor vehicle performance and optimize energy consumption in real-time. Similarly, in the EM industry, companies like Siemens are using IoT to optimize motor performance and reduce energy consumption.

AI is another key trend in the EV and EM industry, enabling companies to predict and prevent maintenance issues. For example, companies like Volkswagen are using AI-powered predictive maintenance to reduce downtime and improve overall efficiency. Similarly, in the EM industry, companies like ABB are using AI to optimize motor performance and reduce energy consumption.

Data analytics is also playing a crucial role in the EV and EM industry, enabling companies to gain insights into vehicle and motor performance. For example, companies like General Motors are using data analytics to optimize vehicle performance and reduce energy consumption. Similarly, in the EM industry, companies like GE are using data analytics to optimize motor performance and reduce energy consumption.

Companies that are already leveraging these technologies to improve efficiency, reduce costs, and enhance customer experience include Tesla, Volkswagen, Siemens, ABB, General Motors, and GE. These companies are at the forefront of the electric vehicle and electric motor digital transformation trends, and are reaping the benefits of improved efficiency, reduced costs, and enhanced customer experience.

In the next section, we will explore the concept of digital twin technology and its applications in electric motor design and optimization. We will provide a step-by-step guide on how to implement digital twin technology to improve motor performance, reduce energy consumption, and increase overall efficiency.

How to Leverage Digital Twin Technology for Electric Motor Design and Optimization

Digital twin technology is a powerful tool that is revolutionizing the way electric motors are designed and optimized. A digital twin is a virtual replica of a physical motor, allowing engineers to simulate and test different design scenarios without the need for physical prototypes. This technology is particularly useful in the electric vehicle (EV) and electric motor (EM) industry, where the demand for high-performance and efficient motors is increasing.

To leverage digital twin technology for electric motor design and optimization, follow these steps:

Step 1: Create a digital twin of the motor by using computer-aided design (CAD) software to create a virtual model of the motor. This model should include all the physical components of the motor, including the windings, magnets, and bearings.

Step 2: Use simulation software to simulate the behavior of the motor under different operating conditions. This can include simulating the motor’s performance under different loads, speeds, and temperatures.

Step 3: Analyze the simulation results to identify areas for improvement. This can include optimizing the motor’s design to reduce energy consumption, improve efficiency, and increase overall performance.

Step 4: Use the insights gained from the simulation results to make design changes to the motor. This can include modifying the motor’s geometry, materials, or control algorithms.

Step 5: Repeat the simulation and analysis process to validate the design changes and ensure that the motor meets the required performance and efficiency standards.

By following these steps, engineers can use digital twin technology to design and optimize electric motors that meet the demanding requirements of the EV and EM industry. This technology has the potential to significantly improve the performance and efficiency of electric motors, and is an important part of the electric vehicle and electric motor digital transformation trends.

Companies such as Siemens and ABB are already using digital twin technology to design and optimize electric motors for the EV and EM industry. These companies are seeing significant improvements in motor performance and efficiency, and are able to reduce development time and costs.

In the next section, we will discuss the role of artificial intelligence in predictive maintenance for electric vehicles, and how this technology is being used to improve the overall efficiency and performance of EVs.

The Role of Artificial Intelligence in Predictive Maintenance for Electric Vehicles

Predictive maintenance is a critical aspect of the electric vehicle (EV) industry, as it enables companies to predict and prevent maintenance issues before they occur. Artificial intelligence (AI) is playing a key role in predictive maintenance, enabling companies to analyze vast amounts of data and identify potential issues before they become major problems.

AI-powered predictive maintenance solutions use machine learning algorithms to analyze data from various sources, including sensors, GPS, and other IoT devices. This data is used to identify patterns and anomalies, which can indicate potential maintenance issues. For example, an AI-powered predictive maintenance system might analyze data from a vehicle’s sensors to detect unusual vibrations or temperature fluctuations, which could indicate a problem with the motor or other components.

Companies such as Tesla and Volkswagen are already using AI-powered predictive maintenance solutions to improve the efficiency and reliability of their EVs. These solutions have been shown to reduce downtime and improve overall efficiency, resulting in cost savings and improved customer satisfaction.

One of the key benefits of AI-powered predictive maintenance is its ability to reduce the need for manual inspections and maintenance. By analyzing data from various sources, AI-powered systems can identify potential issues before they become major problems, reducing the need for manual inspections and maintenance. This can result in significant cost savings and improved efficiency.

Another benefit of AI-powered predictive maintenance is its ability to improve the overall reliability of EVs. By identifying potential issues before they become major problems, AI-powered systems can help to prevent breakdowns and other issues that can impact the reliability of EVs. This can result in improved customer satisfaction and reduced warranty claims.

In addition to its benefits for EV manufacturers, AI-powered predictive maintenance can also benefit EV owners. For example, AI-powered systems can provide EV owners with real-time information about the condition of their vehicle, enabling them to take proactive steps to prevent maintenance issues. This can result in improved safety and reduced maintenance costs.

In the next section, we will discuss the current state of electric vehicle charging infrastructure and how digital transformation is improving the charging experience. We will explore the role of smart charging systems, mobile payments, and real-time charging station information in enhancing the overall charging experience.

Electric Vehicle Charging Infrastructure: How Digital Transformation is Enhancing the Charging Experience

The electric vehicle (EV) charging infrastructure is a critical component of the EV ecosystem, and digital transformation is playing a key role in enhancing the charging experience. The current state of EV charging infrastructure is characterized by a lack of standardization, limited charging points, and a poor user experience. However, digital transformation is changing this landscape, enabling the development of smart charging systems, mobile payments, and real-time charging station information.

Smart charging systems are one of the key digital transformation trends in the EV charging infrastructure. These systems use advanced algorithms and machine learning to optimize the charging process, reducing energy consumption and costs. For example, smart charging systems can analyze the energy demand of a vehicle and adjust the charging rate accordingly, reducing peak demand and strain on the grid.

Mobile payments are another digital transformation trend that is enhancing the charging experience. Mobile payment systems enable EV owners to pay for charging sessions using their smartphones, eliminating the need for cash or credit cards. This not only improves the user experience but also reduces the administrative burden on charging station operators.

Real-time charging station information is also a key digital transformation trend in the EV charging infrastructure. This information enables EV owners to find available charging stations, check their status, and plan their routes accordingly. Real-time information can be accessed through mobile apps, websites, or in-car systems, making it easier for EV owners to charge their vehicles on the go.

Companies such as ChargePoint and EVgo are already leveraging digital transformation to enhance the charging experience. These companies are developing smart charging systems, mobile payment solutions, and real-time charging station information to improve the user experience and reduce costs.

The benefits of digital transformation in the EV charging infrastructure are numerous. It can improve the user experience, reduce costs, and increase the adoption of EVs. However, there are also challenges to be addressed, such as the need for standardization, interoperability, and cybersecurity.

In the next section, we will discuss real-world examples of electric vehicle and motor digital transformation success stories. We will highlight the benefits and results achieved by companies that have successfully implemented digital transformation strategies in the EV and EM industry.

Real-World Examples of Electric Vehicle and Motor Digital Transformation Success Stories

Several companies in the electric vehicle (EV) and electric motor (EM) industry have successfully implemented digital transformation strategies, achieving significant benefits and results. Here are a few examples:

Tesla, a leading EV manufacturer, has implemented a range of digital transformation strategies, including the use of artificial intelligence (AI) and machine learning (ML) to optimize its manufacturing processes. Tesla’s use of AI and ML has enabled the company to improve its production efficiency, reduce costs, and enhance the overall quality of its vehicles.

Siemens, a leading EM manufacturer, has implemented a digital twin strategy to optimize its motor design and production processes. Siemens’ use of digital twin technology has enabled the company to improve its motor performance, reduce energy consumption, and increase overall efficiency.

ChargePoint, a leading EV charging infrastructure company, has implemented a range of digital transformation strategies, including the use of smart charging systems and mobile payments. ChargePoint’s use of smart charging systems and mobile payments has enabled the company to improve the overall charging experience, reduce costs, and increase customer satisfaction.

These companies are just a few examples of the many organizations that are successfully implementing digital transformation strategies in the EV and EM industry. By leveraging digital technologies, these companies are able to improve efficiency, reduce costs, and enhance customer experience, ultimately driving business success and growth.

The benefits of digital transformation in the EV and EM industry are numerous. It can improve efficiency, reduce costs, and enhance customer experience, ultimately driving business success and growth. However, there are also challenges to be addressed, such as the need for standardization, interoperability, and cybersecurity.

In the next section, we will discuss the common challenges faced by companies in the EV and EM industry when implementing digital transformation strategies. We will provide tips and best practices on how to overcome these challenges, including change management, talent acquisition, and technology integration.

Overcoming the Challenges of Digital Transformation in the Electric Vehicle and Motor Industry

While digital transformation offers numerous benefits to the electric vehicle (EV) and electric motor (EM) industry, it also presents several challenges. Companies in this industry must navigate these challenges to successfully implement digital transformation strategies and achieve their goals.

One of the common challenges faced by companies in the EV and EM industry is change management. Digital transformation requires significant changes to business processes, organizational structures, and employee roles. Companies must manage these changes effectively to minimize disruption and ensure a smooth transition.

Talent acquisition is another challenge faced by companies in the EV and EM industry. Digital transformation requires specialized skills and expertise, such as data analytics, artificial intelligence, and cybersecurity. Companies must attract and retain top talent to support their digital transformation initiatives.

Technology integration is also a challenge faced by companies in the EV and EM industry. Digital transformation requires the integration of various technologies, such as IoT, AI, and data analytics. Companies must ensure that these technologies are integrated seamlessly to achieve their desired outcomes.

To overcome these challenges, companies in the EV and EM industry can follow several best practices. First, they must develop a clear digital transformation strategy that aligns with their business goals. Second, they must establish a strong change management program to manage the transition to digital transformation. Third, they must invest in talent acquisition and development to support their digital transformation initiatives. Finally, they must ensure that their technologies are integrated seamlessly to achieve their desired outcomes.

By following these best practices, companies in the EV and EM industry can overcome the challenges of digital transformation and achieve their goals. Digital transformation is a critical component of the EV and EM industry, and companies that successfully implement digital transformation strategies will be well-positioned for success in the future.

In the next section, we will discuss the importance of continuous innovation in the EV and EM industry, highlighting the need for companies to stay ahead of the curve in terms of technology adoption and digital transformation.

Preparing for the Future: The Importance of Continuous Innovation in Electric Vehicle and Motor Digital Transformation

The electric vehicle (EV) and electric motor (EM) industry is rapidly evolving, with new technologies and innovations emerging every day. To stay ahead of the curve, companies in this industry must prioritize continuous innovation and experimentation. This means fostering a culture of innovation within the organization, encouraging experimentation and risk-taking, and investing in research and development.

Continuous innovation is critical in the EV and EM industry because it enables companies to stay ahead of the competition and respond to changing market conditions. By investing in research and development, companies can identify new opportunities and develop new technologies that meet the evolving needs of their customers.

To foster a culture of innovation, companies in the EV and EM industry should encourage experimentation and risk-taking. This means providing employees with the freedom to try new things and learn from their mistakes. It also means investing in training and development programs that help employees build the skills they need to innovate.

Companies in the EV and EM industry should also prioritize collaboration and partnerships. By working with other companies, startups, and research institutions, companies can access new technologies and innovations that they might not have developed on their own.

Finally, companies in the EV and EM industry should prioritize sustainability and environmental responsibility. As the industry continues to evolve, companies must prioritize the development of sustainable and environmentally friendly technologies that meet the needs of their customers while minimizing their impact on the environment.

By prioritizing continuous innovation, companies in the EV and EM industry can stay ahead of the curve and achieve long-term success. The future of the industry will be shaped by companies that are willing to take risks, invest in research and development, and prioritize sustainability and environmental responsibility.