Unlocking the Potential of Electric Motors

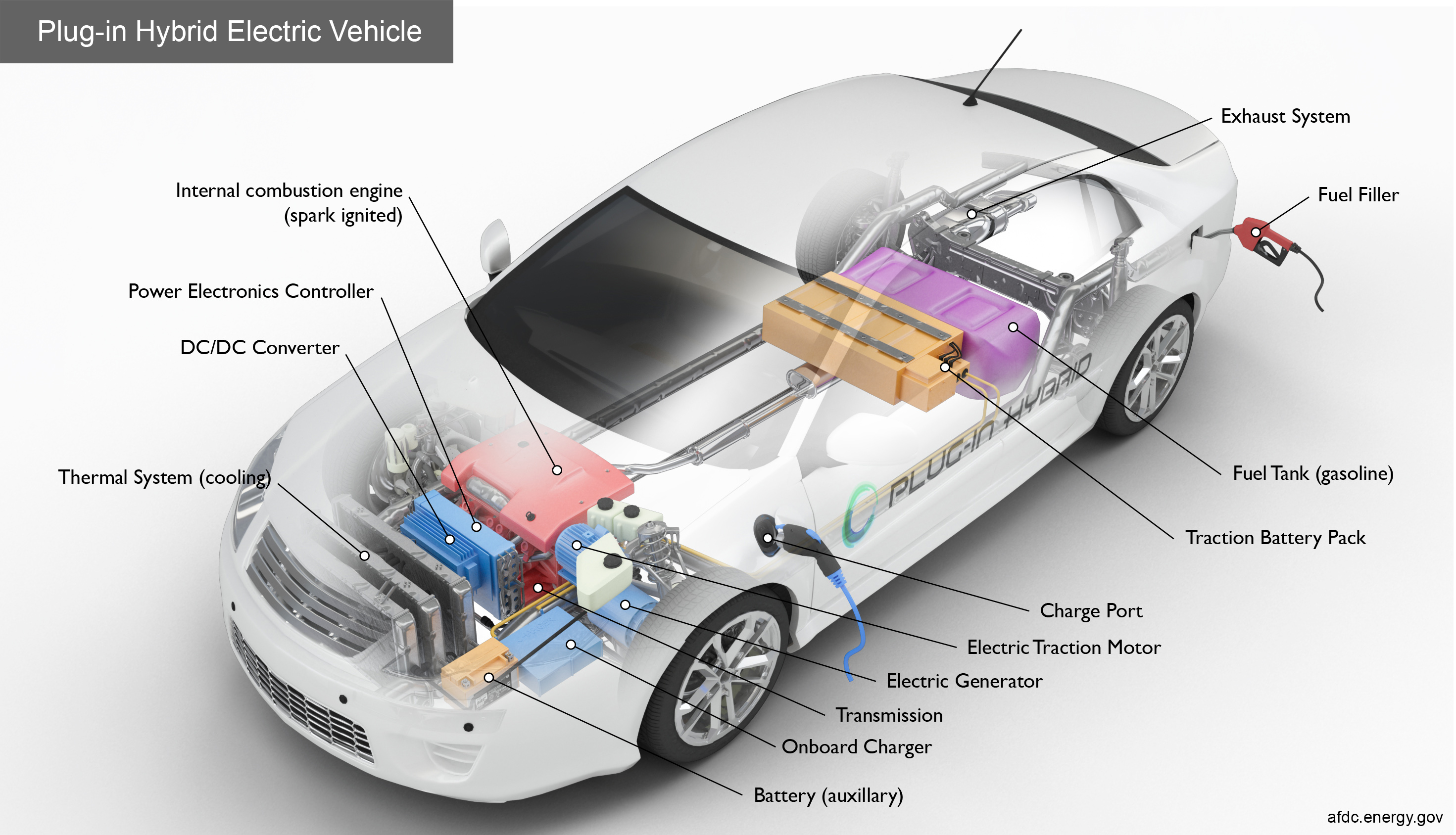

As the world shifts towards a more sustainable and environmentally conscious future, electric vehicles (EVs) have emerged as a vital component in reducing greenhouse gas emissions and mitigating climate change. At the heart of every EV lies the electric motor, a crucial component that plays a significant role in determining the vehicle’s overall performance, efficiency, and environmental sustainability. Electric motor energy efficiency standards have become a critical aspect of EV development, as manufacturers strive to create vehicles that not only minimize energy consumption but also provide exceptional driving experiences.

The importance of energy efficiency in electric vehicles cannot be overstated. Improved energy efficiency translates to increased driving ranges, reduced energy consumption, and lower operating costs. Moreover, energy-efficient EVs contribute significantly to reducing greenhouse gas emissions, making them an attractive option for environmentally conscious consumers. Electric motor efficiency is a critical factor in achieving these benefits, as it directly impacts the vehicle’s overall energy consumption and performance.

Electric motor energy efficiency standards, such as those set by the International Electrotechnical Commission (IEC) and the National Electric Manufacturers Association (NEMA), provide a framework for manufacturers to design and develop energy-efficient electric motors. These standards take into account various factors, including motor design, materials, and testing methods, to ensure that electric motors meet specific efficiency requirements. By adhering to these standards, manufacturers can create electric motors that not only meet but exceed energy efficiency expectations, resulting in better performing and more sustainable EVs.

As the demand for energy-efficient EVs continues to grow, manufacturers are under increasing pressure to develop vehicles that meet stringent energy efficiency standards. The integration of advanced technologies, such as regenerative braking and advanced power electronics, has enabled manufacturers to create EVs that not only minimize energy consumption but also provide exceptional driving experiences. Furthermore, the development of new materials and designs has led to the creation of more efficient electric motors, which in turn has improved the overall energy efficiency of EVs.

In conclusion, electric motor energy efficiency standards play a vital role in shaping the future of electric vehicles. As manufacturers continue to innovate and develop more efficient electric motors, EVs will become increasingly attractive to consumers seeking sustainable and environmentally conscious transportation options. By prioritizing energy efficiency, manufacturers can create EVs that not only minimize energy consumption but also provide exceptional driving experiences, making them an integral part of a sustainable transportation future.

Understanding Electric Motor Energy Efficiency Standards

Electric motor energy efficiency standards play a crucial role in ensuring that electric vehicles (EVs) meet specific energy efficiency requirements. These standards, set by organizations such as the International Electrotechnical Commission (IEC) and the National Electric Manufacturers Association (NEMA), provide a framework for manufacturers to design and develop energy-efficient electric motors. The IEC, for instance, has established the IEC 60034-30 standard, which defines the efficiency classes for electric motors, including IE1, IE2, IE3, and IE4.

The key factors that influence electric motor efficiency include design, materials, and testing methods. Electric motor design, for example, can significantly impact efficiency, with factors such as motor topology, winding configuration, and magnetic material selection all playing a role. The use of advanced materials, such as rare-earth magnets and high-temperature superconductors, can also improve efficiency. Additionally, testing methods, such as those outlined in the IEC 60034-2 standard, are used to verify the efficiency of electric motors.

Electric motor energy efficiency standards also take into account the specific requirements of electric vehicles. For instance, the SAE J2908 standard, developed by the Society of Automotive Engineers (SAE), provides guidelines for the testing and evaluation of electric motors for EVs. This standard addresses the unique challenges of EVs, such as the need for high power density and efficiency, as well as the importance of minimizing energy consumption.

By adhering to electric motor energy efficiency standards, manufacturers can create EVs that not only meet but exceed energy efficiency expectations. This, in turn, can lead to increased driving ranges, reduced energy consumption, and lower operating costs. Furthermore, the adoption of energy-efficient electric motors can contribute to a reduction in greenhouse gas emissions, making EVs an attractive option for environmentally conscious consumers.

In the context of electric vehicle and electric motor energy efficiency standards, it is essential to consider the interplay between motor efficiency, vehicle performance, and environmental sustainability. By prioritizing energy efficiency, manufacturers can create EVs that not only minimize energy consumption but also provide exceptional driving experiences, making them an integral part of a sustainable transportation future.

How to Choose an Energy-Efficient Electric Motor for Your Vehicle

Selecting an energy-efficient electric motor for your electric vehicle (EV) is crucial to achieving optimal performance, range, and sustainability. With the numerous options available, it’s essential to consider several factors to ensure you choose the right motor for your needs. Here’s a step-by-step guide to help you make an informed decision:

1. Determine your power output requirements: Consider the size and weight of your vehicle, as well as your desired acceleration and top speed. A higher power output motor may be necessary for larger or heavier vehicles, while smaller vehicles may require less power.

2. Evaluate torque and efficiency ratings: Torque is a measure of the motor’s rotational force, while efficiency ratings indicate how well the motor converts electrical energy into mechanical energy. Look for motors with high torque and efficiency ratings to ensure optimal performance and energy efficiency.

3. Consider the motor type: There are several types of electric motors, including induction motors, permanent magnet motors, and switched reluctance motors. Each type has its advantages and disadvantages, so it’s essential to research and compare the different options.

4. Check the motor’s compatibility: Ensure the motor is compatible with your vehicle’s electrical system, including the battery, inverter, and control systems.

5. Research real-world examples: Look at real-world examples of energy-efficient electric motors used in popular EVs, such as the Tesla Model 3 or the Nissan Leaf. These motors have been designed and optimized for specific applications, providing valuable insights into their performance and efficiency.

Some notable examples of energy-efficient electric motors include the Tesla Model 3’s permanent magnet motor, which achieves an impressive 90% efficiency rating, and the Nissan Leaf’s synchronous motor, which boasts a 95% efficiency rating. These motors demonstrate the potential for high efficiency and performance in EVs.

By following these steps and considering the factors mentioned above, you can choose an energy-efficient electric motor that meets your needs and helps you achieve optimal performance, range, and sustainability in your EV.

The Impact of Energy Efficiency on Electric Vehicle Range and Performance

Energy efficiency plays a crucial role in determining the range and performance of electric vehicles (EVs). Improvements in electric motor energy efficiency can lead to increased range, faster acceleration, and enhanced overall driving experience. In this section, we will examine the relationship between electric motor energy efficiency and EV range and performance.

Electric motor energy efficiency directly affects the range of an EV. A more efficient motor can extract more energy from the battery, resulting in a longer driving range. For example, the Tesla Model 3’s permanent magnet motor has an efficiency rating of 90%, which allows it to achieve a range of up to 325 miles on a single charge. In contrast, a less efficient motor may require more energy to achieve the same range, resulting in reduced driving range and increased energy consumption.

In addition to range, energy efficiency also impacts the performance of an EV. A more efficient motor can provide faster acceleration and a more responsive driving experience. This is because efficient motors can deliver more power to the wheels while consuming less energy. For instance, the Porsche Taycan’s electric motor has an efficiency rating of 93%, which enables it to accelerate from 0-60mph in just 2.4 seconds.

Furthermore, energy efficiency can also influence the overall driving experience of an EV. A more efficient motor can provide a smoother and quieter ride, as well as reduced vibrations and noise. This is because efficient motors tend to produce less heat and vibration, resulting in a more comfortable driving experience.

In conclusion, energy efficiency has a significant impact on the range and performance of electric vehicles. Improvements in electric motor energy efficiency can lead to increased range, faster acceleration, and enhanced overall driving experience. As the demand for EVs continues to grow, the importance of energy efficiency will only continue to increase, driving innovation and development in the field of electric motor technology.

Electric Vehicle Manufacturers’ Approaches to Energy Efficiency

Leading electric vehicle (EV) manufacturers are continually striving to improve energy efficiency in their vehicles. This is achieved through the development and implementation of innovative technologies and design approaches that minimize energy consumption while maximizing performance. In this section, we will explore the strategies employed by companies like Tesla, BMW, and Volkswagen to achieve energy efficiency in their EVs.

Tesla, a pioneer in the EV industry, has been at the forefront of energy efficiency innovation. The company’s electric motors, such as the one used in the Model 3, have achieved efficiency ratings of up to 90%. This is due in part to Tesla’s use of advanced materials, such as rare-earth magnets, and optimized motor design. Additionally, Tesla’s vehicles are equipped with advanced power electronics and battery management systems that optimize energy efficiency and minimize energy loss.

BMW, another leading EV manufacturer, has also made significant strides in energy efficiency. The company’s i-series vehicles, such as the i3 and iX3, feature advanced electric motors that achieve efficiency ratings of up to 92%. BMW’s approach to energy efficiency involves the use of lightweight materials, optimized aerodynamics, and advanced powertrain technologies. The company has also developed a range of energy-efficient driving modes that help to minimize energy consumption and maximize range.

Volkswagen, a company that has made a significant commitment to EV production, has also developed innovative approaches to energy efficiency. The company’s ID. series vehicles, such as the ID.3 and ID.4, feature advanced electric motors that achieve efficiency ratings of up to 90%. Volkswagen’s approach to energy efficiency involves the use of advanced materials, optimized motor design, and advanced power electronics. The company has also developed a range of energy-efficient driving modes and has implemented a range of measures to minimize energy consumption and maximize range.

In conclusion, leading EV manufacturers are continually striving to improve energy efficiency in their vehicles. Through the development and implementation of innovative technologies and design approaches, companies like Tesla, BMW, and Volkswagen are able to minimize energy consumption while maximizing performance. As the demand for EVs continues to grow, the importance of energy efficiency will only continue to increase, driving innovation and development in the field of electric motor technology.

Regulatory Frameworks and Incentives for Energy-Efficient Electric Vehicles

Governments and organizations around the world are implementing regulatory frameworks and incentives to encourage the adoption of energy-efficient electric vehicles (EVs). These initiatives aim to promote the development and use of EVs that meet energy efficiency standards, reducing greenhouse gas emissions and mitigating climate change.

In the United States, the Environmental Protection Agency (EPA) has established the Corporate Average Fuel Economy (CAFE) standards, which require automakers to meet specific fuel efficiency targets for their fleets. The EPA also offers tax credits and incentives for the production and purchase of energy-efficient EVs.

In the European Union, the EU has implemented the EU Emissions Trading System (EU ETS), which sets a cap on greenhouse gas emissions from power and industry sectors. The EU also offers incentives for the adoption of energy-efficient EVs, such as tax credits and subsidies for the installation of charging infrastructure.

In China, the government has implemented a range of policies to promote the adoption of energy-efficient EVs, including tax credits, subsidies, and incentives for the production and purchase of EVs. China has also established a national standard for EV energy efficiency, which requires EVs to meet specific energy efficiency targets.

These regulatory frameworks and incentives are driving innovation and investment in the EV industry, promoting the development of energy-efficient EVs that meet energy efficiency standards. As the demand for EVs continues to grow, governments and organizations will play a critical role in shaping the future of electric transportation.

In addition to regulatory frameworks and incentives, there are also various certification programs and labels that recognize energy-efficient EVs. For example, the ENERGY STAR program, run by the U.S. Environmental Protection Agency, certifies EVs that meet energy efficiency standards. Similarly, the EU’s Ecolabel program recognizes EVs that meet specific environmental standards, including energy efficiency.

These certification programs and labels provide consumers with valuable information about the energy efficiency of EVs, helping them make informed purchasing decisions. They also encourage manufacturers to design and produce energy-efficient EVs, driving innovation and investment in the industry.

Challenges and Opportunities in Achieving Higher Energy Efficiency Standards

As the electric vehicle (EV) industry continues to evolve, achieving higher energy efficiency standards remains a pressing challenge. Despite the progress made in recent years, there are still significant technical, economic, and social barriers to widespread adoption of energy-efficient electric motors. In this section, we will explore these challenges and opportunities, highlighting potential solutions and future directions for research and development.

One of the primary technical challenges is the trade-off between energy efficiency and cost. High-efficiency electric motors often require advanced materials and complex designs, which can increase production costs. Additionally, the development of new technologies, such as wide bandgap semiconductors, is still in its infancy, and their integration into electric motors is a complex task.

Another challenge is the lack of standardization in electric motor energy efficiency standards. Different countries and regions have their own standards, which can create confusion and make it difficult for manufacturers to design and produce energy-efficient electric motors that meet multiple standards. The International Electrotechnical Commission (IEC) and the National Electric Manufacturers Association (NEMA) are working to harmonize these standards, but more needs to be done to achieve global consistency.

From an economic perspective, the high upfront cost of energy-efficient electric motors can be a significant barrier to adoption. While these motors can provide long-term cost savings through reduced energy consumption, the initial investment can be prohibitively expensive for some manufacturers and consumers. Governments and organizations can play a crucial role in addressing this challenge by offering incentives, such as tax credits and subsidies, to encourage the adoption of energy-efficient electric motors.

Despite these challenges, there are also opportunities for innovation and growth. The development of new technologies, such as advanced magnetic materials and 3D printing, can help to improve energy efficiency while reducing costs. Additionally, the increasing demand for electric vehicles is driving investment in research and development, which can help to overcome the technical and economic barriers to widespread adoption.

In conclusion, achieving higher energy efficiency standards in electric vehicles requires a multifaceted approach that addresses technical, economic, and social challenges. By investing in research and development, promoting standardization, and offering incentives, we can overcome these challenges and create a more sustainable and efficient electric vehicle industry. As the industry continues to evolve, it is essential to prioritize energy efficiency and electric motor energy efficiency standards to ensure a cleaner, greener future for transportation.

Conclusion: The Future of Electric Vehicle Energy Efficiency

In conclusion, energy efficiency is a critical component of electric vehicle performance, and electric motor energy efficiency standards play a vital role in achieving improved performance, reduced energy consumption, and environmental sustainability. As the electric vehicle industry continues to evolve, it is essential to prioritize energy efficiency and electric motor energy efficiency standards to ensure a cleaner, greener future for transportation.

Throughout this article, we have explored the importance of energy efficiency in electric vehicles, the different types of electric motor energy efficiency standards, and the factors that influence electric motor efficiency. We have also discussed the impact of energy efficiency on electric vehicle range and performance, the strategies employed by leading electric vehicle manufacturers to improve energy efficiency, and the regulatory frameworks and incentives that encourage the adoption of energy-efficient electric vehicles.

As we look to the future, it is clear that electric vehicle and electric motor energy efficiency standards will continue to play a crucial role in shaping the electric vehicle industry. With ongoing research and development, innovative technologies and design approaches, and supportive regulatory frameworks, we can expect to see significant improvements in energy efficiency and electric vehicle performance in the years to come.

Ultimately, the widespread adoption of energy-efficient electric vehicles has the potential to transform the transportation sector, reducing greenhouse gas emissions, improving air quality, and enhancing energy security. As we move forward, it is essential to prioritize energy efficiency and electric motor energy efficiency standards to ensure a sustainable and efficient electric vehicle industry that benefits both people and the planet.

By understanding the importance of energy efficiency in electric vehicles and the role of electric motor energy efficiency standards, we can work together to create a cleaner, greener future for transportation. As the electric vehicle industry continues to evolve, one thing is clear: energy efficiency will remain a critical component of electric vehicle performance, and electric motor energy efficiency standards will play a vital role in shaping the future of electric transportation.