Unlocking the Potential of Electric Motors

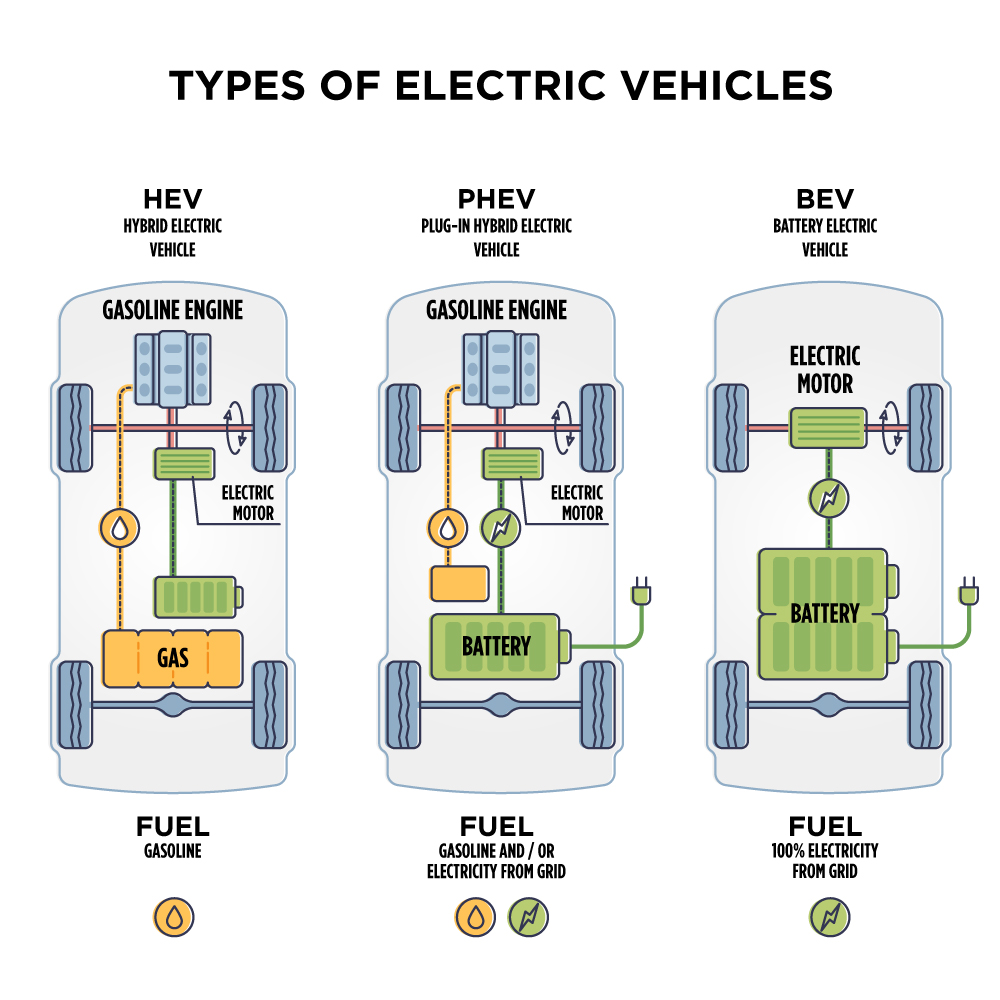

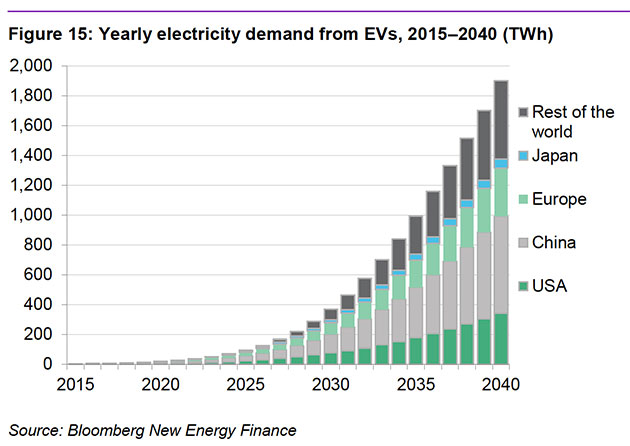

The growing importance of energy efficiency in electric vehicles cannot be overstated. As the world shifts towards more sustainable modes of transportation, electric vehicles (EVs) are becoming increasingly popular. However, their widespread adoption is hindered by concerns over driving range and energy consumption. This is where electric motors come into play. By improving the efficiency of electric motors, manufacturers can significantly reduce energy consumption and increase driving range, making EVs a more viable option for consumers.

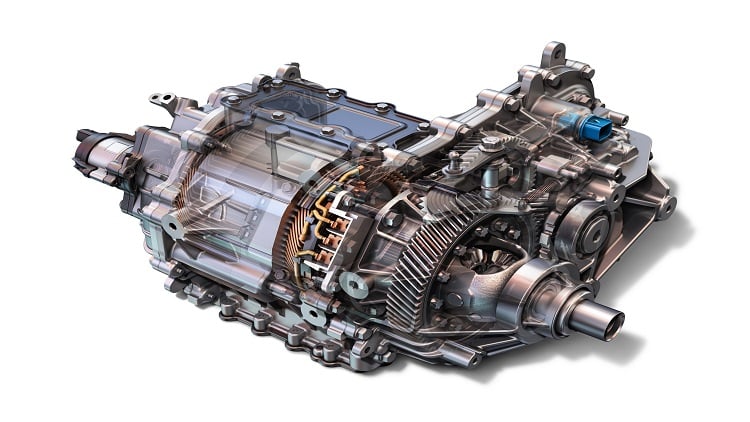

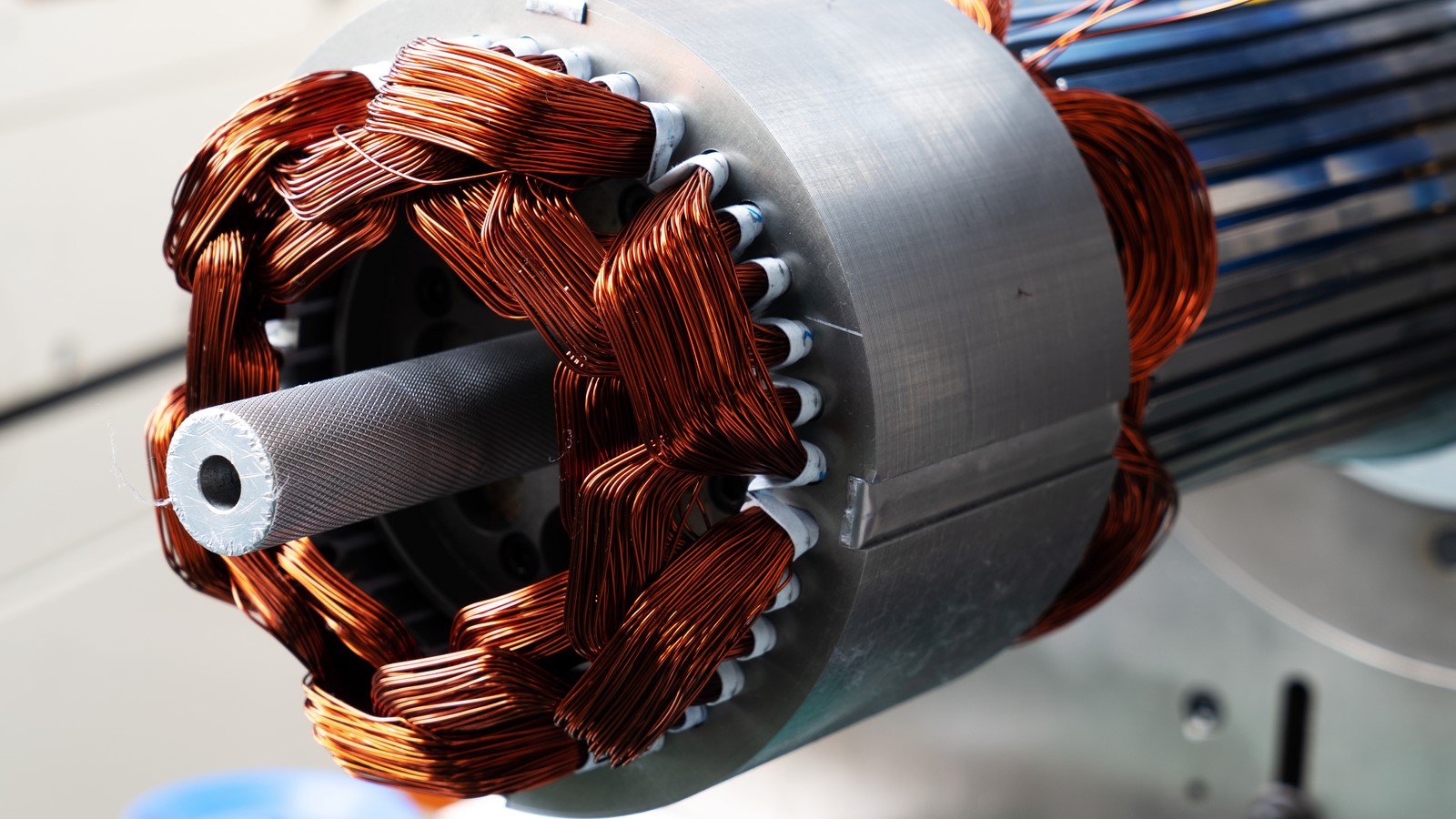

Electric motors are the heart of any electric vehicle, responsible for converting electrical energy into mechanical energy. However, they are also a significant source of energy loss, with some motors losing up to 20% of their energy as heat. To address this, manufacturers are turning to advanced materials and designs that can improve motor efficiency. For example, the use of permanent magnet motors and advanced winding techniques can reduce energy loss and increase overall efficiency.

The impact of electric motor efficiency on driving range cannot be overstated. A 10% improvement in motor efficiency can result in a 5-10% increase in driving range, making EVs more practical for daily use. Furthermore, improved motor efficiency can also reduce the strain on batteries, leading to longer lifetimes and reduced maintenance costs.

As the demand for energy-efficient electric vehicles continues to grow, manufacturers are under pressure to meet increasingly stringent energy efficiency standards. In the European Union, for example, electric vehicles are required to meet strict energy efficiency standards, with a minimum efficiency of 120 Wh/km. Similarly, in the United States, the National Highway Traffic Safety Administration (NHTSA) has established energy efficiency standards for electric vehicles, with a minimum efficiency of 140 Wh/km.

Despite these challenges, the trend towards energy-efficient electric vehicles is clear. As technology continues to advance, we can expect to see even more efficient electric motors and vehicles that meet the growing demand for sustainable transportation. By unlocking the potential of electric motors, manufacturers can play a critical role in shaping the future of transportation and reducing our reliance on fossil fuels.

How to Improve Electric Motor Efficiency: Latest Advances and Innovations

Improving electric motor efficiency is crucial for enhancing the overall performance of electric vehicles. Recent advances in technology have led to the development of innovative materials, designs, and cooling systems that can significantly boost motor efficiency. One of the most promising areas of research is the use of advanced materials, such as neodymium iron boron (NdFeB) magnets, which offer higher magnetic strength and reduced energy loss.

Optimized design is another key factor in improving electric motor efficiency. Techniques such as finite element analysis (FEA) and computational fluid dynamics (CFD) enable engineers to simulate and optimize motor performance, reducing energy loss and increasing efficiency. Additionally, innovative cooling systems, such as liquid-cooled motors, can help to reduce temperatures and increase motor lifespan.

Another area of innovation is the development of new motor designs, such as the axial flux motor, which offers higher efficiency and power density than traditional radial flux motors. Furthermore, the use of advanced manufacturing techniques, such as 3D printing, can enable the creation of complex motor geometries and reduce production costs.

The impact of these advances on electric vehicle performance cannot be overstated. Improved motor efficiency can lead to increased driving range, reduced energy consumption, and lower emissions. For example, a 10% improvement in motor efficiency can result in a 5-10% increase in driving range, making electric vehicles more practical for daily use.

As the demand for energy-efficient electric vehicles continues to grow, manufacturers are under pressure to adopt these innovative technologies and designs. By incorporating advanced materials, optimized design, and innovative cooling systems, manufacturers can create electric motors that meet the growing demand for sustainable transportation. The trend towards energy-efficient electric vehicles is clear, and the latest advances in electric motor technology are set to play a critical role in shaping the future of transportation.

The Impact of Energy Efficiency Standards on Electric Vehicle Design

Energy efficiency standards have a profound impact on electric vehicle design, driving innovation and optimization in various aspects of vehicle development. One of the primary effects of energy efficiency standards is the increased use of lightweight materials, such as aluminum and carbon fiber, which reduce vehicle weight and improve energy efficiency. Additionally, aerodynamic design plays a crucial role in minimizing energy consumption, with features like active grille shutters and air curtains becoming increasingly common.

Optimized battery management systems are also critical in meeting energy efficiency standards. Advanced battery management systems enable more efficient charging and discharging of batteries, reducing energy loss and increasing overall efficiency. Furthermore, the use of regenerative braking systems, which capture kinetic energy and convert it into electrical energy, is becoming more widespread, further improving energy efficiency.

The impact of energy efficiency standards on electric vehicle design is not limited to individual components, but also affects the overall vehicle architecture. For example, the use of electric motors and gearboxes with optimized efficiency enables the development of more efficient powertrains. Moreover, the integration of advanced thermal management systems, which optimize battery temperature and reduce energy loss, is becoming increasingly important.

As energy efficiency standards continue to evolve, electric vehicle manufacturers are responding by developing innovative designs and technologies. For instance, the use of advanced materials and manufacturing techniques, such as 3D printing, is enabling the creation of complex vehicle structures and components that optimize energy efficiency. Moreover, the development of new battery chemistries and cell designs is driving improvements in energy density and efficiency.

The trend towards energy-efficient electric vehicle design is clear, with manufacturers investing heavily in research and development to meet increasingly stringent energy efficiency standards. As the demand for sustainable transportation continues to grow, the importance of energy efficiency in electric vehicle design will only continue to increase, driving innovation and optimization in the industry.

Comparing Energy Efficiency in Popular Electric Vehicles: A Review

As the electric vehicle (EV) market continues to grow, energy efficiency has become a key differentiator among models. With varying levels of electric motor energy efficiency, popular EVs exhibit distinct strengths and weaknesses. This review compares the energy efficiency of the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf, highlighting their unique characteristics and features.

The Tesla Model 3, a best-seller in the EV market, boasts an impressive electric motor energy efficiency of 4.2 miles per kilowatt-hour (mi/kWh). Its advanced motor design, optimized for efficiency and performance, contributes to its exceptional range of up to 326 miles on a single charge. Additionally, Tesla’s sophisticated battery management system ensures optimal energy usage and minimizes waste.

In contrast, the Chevrolet Bolt, another popular EV, achieves an energy efficiency of 3.8 mi/kWh. While its range of up to 259 miles is respectable, it falls short of the Tesla Model 3’s benchmark. However, the Bolt’s more affordable price point and spacious interior make it an attractive option for those prioritizing practicality over range.

The Nissan Leaf, a pioneer in the EV market, has undergone significant improvements in recent years. Its latest model achieves an energy efficiency of 3.5 mi/kWh, with a range of up to 226 miles. Although it lags behind its competitors in terms of range, the Leaf’s advanced e-Powertrain and optimized battery management system make it a reliable choice for urban commuters.

A closer examination of these EVs reveals that energy efficiency is closely tied to electric motor design, battery management, and overall vehicle optimization. As electric vehicle and electric motor energy efficiency standards trends continue to evolve, manufacturers must prioritize innovation and investment in these areas to remain competitive. By comparing the energy efficiency of popular EVs, consumers can make informed decisions and drive the demand for more sustainable and efficient transportation solutions.

Trends in Electric Motor Energy Efficiency: What to Expect in the Future

The electric vehicle (EV) industry is on the cusp of a revolution, driven by advances in electric motor energy efficiency. As governments and manufacturers continue to prioritize sustainability, emerging trends in electric motor technology are poised to transform the EV landscape. This article explores the latest developments in electric motor energy efficiency, including the development of new materials, advanced manufacturing techniques, and innovative motor designs.

One of the most significant trends in electric motor energy efficiency is the use of advanced materials. Researchers are exploring the potential of new materials, such as graphene and nanomaterials, to improve motor efficiency and reduce weight. These materials offer exceptional strength-to-weight ratios, enabling the creation of more efficient and compact motors. Additionally, the use of advanced materials is expected to reduce production costs, making EVs more competitive in the market.

Another trend gaining traction is the adoption of advanced manufacturing techniques. Techniques like 3D printing and additive manufacturing enable the creation of complex motor geometries, which can improve efficiency and reduce energy consumption. Furthermore, these techniques allow for the rapid prototyping and testing of new motor designs, accelerating the development of more efficient motors.

Innovative motor designs are also playing a crucial role in improving electric motor energy efficiency. Manufacturers are exploring new motor architectures, such as axial flux motors and transverse flux motors, which offer improved efficiency and power density. These designs enable the creation of more compact and efficient motors, which can be integrated into a wider range of EV applications.

The integration of artificial intelligence (AI) and machine learning (ML) is also expected to play a significant role in improving electric motor energy efficiency. By analyzing data from various sources, including sensors and driver feedback, AI and ML algorithms can optimize motor performance in real-time, reducing energy consumption and improving overall efficiency.

As electric vehicle and electric motor energy efficiency standards trends continue to evolve, manufacturers must prioritize innovation and investment in these areas. By embracing emerging trends and technologies, the EV industry can unlock significant improvements in energy efficiency, driving range, and overall performance. As the world transitions to a more sustainable transportation system, the importance of electric motor energy efficiency will only continue to grow.

Regulatory Frameworks for Electric Vehicle Energy Efficiency: A Global Perspective

As the world transitions to a more sustainable transportation system, regulatory frameworks governing electric vehicle (EV) energy efficiency are becoming increasingly important. Governments around the globe are implementing policies and standards to promote the adoption of energy-efficient EVs, reduce greenhouse gas emissions, and mitigate climate change. This article provides a comprehensive overview of the regulatory frameworks governing EV energy efficiency, highlighting best practices and areas for improvement.

In the European Union, the EU’s Directive on the Promotion of Clean and Energy-Efficient Road Transport Vehicles sets a framework for the development of energy-efficient EVs. The directive establishes minimum energy efficiency standards for EVs, including a maximum energy consumption of 2.2 liters of fuel equivalent per 100 kilometers. Additionally, the EU’s Alternative Fuel Infrastructure Directive requires member states to develop a comprehensive network of charging infrastructure to support the widespread adoption of EVs.

In the United States, the Corporate Average Fuel Economy (CAFE) standards regulate the energy efficiency of EVs. The CAFE standards require automakers to achieve a minimum energy efficiency of 40 miles per gallon equivalent (mpg-e) for EVs by 2025. Furthermore, the US Department of Energy’s Electric Vehicle Everywhere Grand Challenge aims to make EVs more affordable and convenient, with a goal of achieving a 50% reduction in EV costs by 2025.

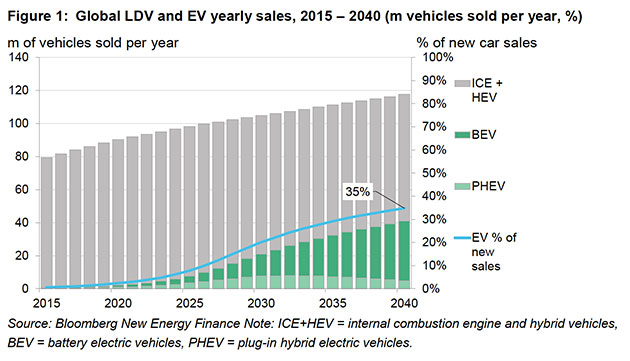

In China, the government has implemented a range of policies to promote the adoption of EVs, including tax incentives, subsidies, and investments in charging infrastructure. China’s New Energy Vehicle (NEV) policy sets a target of achieving 50% of new car sales being electric by 2025. Additionally, the Chinese government has established a comprehensive network of charging infrastructure, with over 200,000 public charging stations already in operation.

Other countries, such as Japan and South Korea, are also implementing regulatory frameworks to promote EV adoption and energy efficiency. Japan’s Next-Generation Vehicle Strategy aims to achieve a 50% reduction in greenhouse gas emissions from transportation by 2050, while South Korea’s Electric Vehicle Promotion Plan sets a target of achieving 30% of new car sales being electric by 2025.

As electric vehicle and electric motor energy efficiency standards trends continue to evolve, regulatory frameworks will play a critical role in promoting the adoption of energy-efficient EVs. By examining best practices and areas for improvement, governments and industry stakeholders can work together to create a more sustainable transportation system for the future.

Challenges and Opportunities in Implementing Energy Efficiency Standards

As the electric vehicle (EV) industry continues to evolve, implementing energy efficiency standards poses both challenges and opportunities. The transition to a more sustainable transportation system requires a concerted effort from industry stakeholders, governments, and consumers. This article discusses the challenges and opportunities associated with implementing energy efficiency standards for EVs, highlighting the need for industry-wide cooperation and investment in research and development.

One of the primary challenges in implementing energy efficiency standards is the need for industry-wide cooperation. EV manufacturers, suppliers, and regulatory bodies must work together to establish common standards and testing protocols. This requires a high degree of collaboration and communication, which can be time-consuming and resource-intensive. Additionally, the development of new technologies and materials can be costly, and manufacturers may be hesitant to invest in research and development without clear regulatory guidelines.

Another challenge is the need for investment in research and development. Improving energy efficiency in EVs requires significant investment in new technologies, materials, and manufacturing processes. This can be a barrier for smaller manufacturers or those with limited resources. Furthermore, the development of new energy-efficient technologies can be a complex and iterative process, requiring significant testing and validation.

Despite these challenges, there are also opportunities for growth and innovation. The implementation of energy efficiency standards can drive the development of new technologies and materials, creating new business opportunities and revenue streams. Additionally, the transition to a more sustainable transportation system can create new jobs and stimulate economic growth. Governments can also play a key role in supporting the development of energy-efficient EVs through incentives, tax credits, and investments in research and development.

As electric vehicle and electric motor energy efficiency standards trends continue to evolve, it is essential to address the challenges and opportunities associated with implementing these standards. By working together, industry stakeholders, governments, and consumers can create a more sustainable transportation system that benefits both the environment and the economy. The development of new technologies, materials, and manufacturing processes will be critical in achieving this goal, and investment in research and development will be essential.

Ultimately, the implementation of energy efficiency standards for EVs requires a long-term commitment to innovation and sustainability. By prioritizing energy efficiency and investing in research and development, the EV industry can create a more sustainable transportation system that benefits both the environment and the economy. As the world transitions to a more sustainable future, the importance of energy efficiency in EVs will only continue to grow.

Conclusion: The Future of Electric Vehicle Energy Efficiency

In conclusion, the importance of energy efficiency in electric vehicles cannot be overstated. As the world transitions to a more sustainable transportation system, electric vehicle and electric motor energy efficiency standards trends will play a critical role in reducing energy consumption and increasing driving range. The latest advances and innovations in electric motor efficiency, including the use of advanced materials, optimized design, and innovative cooling systems, will be essential in achieving this goal.

The impact of energy efficiency standards on electric vehicle design will also be significant, driving the use of lightweight materials, aerodynamic design, and optimized battery management systems. The comparison of energy efficiency in popular electric vehicles, such as the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf, highlights the strengths and weaknesses of each model and provides valuable insights for consumers and manufacturers.

Emerging trends in electric motor energy efficiency, including the development of new materials, advanced manufacturing techniques, and innovative motor designs, will also shape the future of electric vehicles. Regulatory frameworks governing electric vehicle energy efficiency around the world will play a critical role in promoting the adoption of energy-efficient EVs and reducing greenhouse gas emissions.

Finally, the challenges and opportunities associated with implementing energy efficiency standards for electric vehicles, including the need for industry-wide cooperation and investment in research and development, must be addressed. By working together, industry stakeholders, governments, and consumers can create a more sustainable transportation system that benefits both the environment and the economy.

In the future, we can expect to see continued innovation and investment in electric vehicle energy efficiency, driving the development of new technologies and materials that will further reduce energy consumption and increase driving range. As the world transitions to a more sustainable future, the importance of energy efficiency in electric vehicles will only continue to grow.