Understanding the Importance of Electric Motor Health

Electric vehicles (EVs) rely on electric motors to propel them forward, making motor health a critical aspect of overall vehicle performance, efficiency, and safety. Regular fault detection and diagnosis are essential to prevent costly repairs, ensure optimal vehicle operation, and maintain the longevity of the electric motor. Neglecting motor health can lead to reduced vehicle performance, decreased efficiency, and even safety hazards. For instance, a faulty electric motor can cause the vehicle to stall or lose power, posing a risk to the driver and other road users.

In addition to safety concerns, electric motor faults can also result in significant financial losses. Repairing or replacing a damaged electric motor can be expensive, with costs ranging from a few thousand to tens of thousands of dollars, depending on the vehicle model and extent of the damage. Furthermore, neglecting motor health can lead to increased energy consumption, reduced fuel efficiency, and higher emissions, ultimately affecting the environment and the vehicle’s overall carbon footprint.

Fortunately, advancements in technology have made it possible to detect electric motor faults early on, reducing the risk of costly repairs and ensuring optimal vehicle performance. By incorporating regular fault detection and diagnosis into maintenance routines, EV owners can identify potential issues before they become major problems. This proactive approach not only saves time and money but also helps to extend the lifespan of the electric motor, ensuring a safer and more efficient driving experience.

Effective fault detection and diagnosis require a combination of visual inspections, performance monitoring, and diagnostic testing. By leveraging these techniques, EV owners and maintenance professionals can identify potential faults, such as overheating, vibration, and noise, and take corrective action to prevent further damage. In the context of electric vehicle and electric motor fault detection and diagnosis, it is essential to prioritize motor health to ensure optimal vehicle performance and longevity.

Common Electric Motor Faults: Identifying the Warning Signs

Electric motor faults can manifest in various ways, and it is essential to identify the warning signs to prevent further damage. One of the most common electric motor faults in electric vehicles is overheating. This can occur due to a variety of reasons, including high ambient temperatures, excessive load, or poor cooling system performance. Overheating can cause the motor to degrade, leading to reduced efficiency and potentially catastrophic failure.

Another common electric motor fault is vibration. This can be caused by imbalance, misalignment, or worn-out bearings. Vibration can lead to noise, reduced motor performance, and increased energy consumption. In severe cases, vibration can cause the motor to fail, resulting in costly repairs.

Noise is also a common symptom of electric motor faults. This can be caused by worn-out bearings, misaligned motors, or loose connections. Noise can be a sign of impending failure, and it is essential to address the issue promptly to prevent further damage.

Other common electric motor faults in electric vehicles include electrical issues, such as short circuits, open circuits, or faulty sensors. These faults can cause the motor to malfunction, leading to reduced performance, increased energy consumption, and potentially safety hazards.

Ignoring these warning signs can have severe consequences, including costly repairs, reduced vehicle performance, and even safety hazards. Therefore, it is essential to prioritize electric motor health and address any issues promptly. By doing so, electric vehicle owners can ensure optimal vehicle performance, efficiency, and safety.

In the context of electric vehicle and electric motor fault detection and diagnosis, it is crucial to identify these common faults and address them promptly. By leveraging advanced diagnostic techniques and specialized tools, electric vehicle owners and maintenance professionals can detect these faults early on and take corrective action to prevent further damage.

How to Detect Electric Motor Faults: A Step-by-Step Guide

Detecting electric motor faults in electric vehicles requires a systematic approach that involves visual inspections, performance monitoring, and diagnostic testing. By following these steps, electric vehicle owners and maintenance professionals can identify potential faults and take corrective action to prevent further damage.

Step 1: Visual Inspection

Begin by visually inspecting the electric motor and its components, including the bearings, windings, and connections. Look for signs of wear, damage, or corrosion, and check for any unusual odors or noises.

Step 2: Performance Monitoring

Monitor the electric motor’s performance by checking its speed, torque, and efficiency. Use specialized tools, such as oscilloscopes or data loggers, to measure the motor’s electrical and mechanical parameters.

Step 3: Diagnostic Testing

Perform diagnostic tests, such as vibration analysis or thermal imaging, to identify potential faults that may not be apparent through visual inspections or performance monitoring. These tests can help detect issues such as imbalance, misalignment, or overheating.

Step 4: Data Analysis

Analyze the data collected during the diagnostic tests to identify potential faults and trends. Use specialized software or tools to interpret the data and determine the root cause of any issues.

Step 5: Repair and Maintenance

Once a fault has been identified, perform the necessary repairs or maintenance to correct the issue. Use genuine replacement parts and follow manufacturer guidelines to ensure that the repair is done correctly.

By following these steps, electric vehicle owners and maintenance professionals can detect electric motor faults and take corrective action to prevent further damage. Regular fault detection and diagnosis are essential to ensuring the optimal performance and longevity of electric vehicles.

In the context of electric vehicle and electric motor fault detection and diagnosis, it is crucial to use specialized tools and equipment to detect faults accurately. By leveraging advanced diagnostic techniques and technologies, electric vehicle owners and maintenance professionals can identify potential faults and take corrective action to prevent costly repairs and ensure safe operation.

The Role of Advanced Diagnostic Techniques in Electric Motor Fault Detection

Advanced diagnostic techniques play a crucial role in detecting electric motor faults in electric vehicles. These techniques can help identify faults that may not be apparent through visual inspections or performance monitoring. Two of the most effective advanced diagnostic techniques used in electric motor fault detection are vibration analysis and thermal imaging.

Vibration analysis involves measuring the vibrations of the electric motor and its components to identify potential faults. This technique can detect issues such as imbalance, misalignment, and bearing wear. By analyzing the vibration data, maintenance professionals can identify the root cause of the fault and take corrective action to prevent further damage.

Thermal imaging involves using specialized cameras to detect temperature anomalies in the electric motor and its components. This technique can detect issues such as overheating, electrical faults, and mechanical wear. By analyzing the thermal images, maintenance professionals can identify potential faults and take corrective action to prevent further damage.

Other advanced diagnostic techniques used in electric motor fault detection include acoustic emission testing, motor current signature analysis, and partial discharge testing. These techniques can provide valuable insights into the condition of the electric motor and its components, enabling maintenance professionals to detect faults early and prevent costly repairs.

The use of advanced diagnostic techniques in electric motor fault detection has several benefits. It can help reduce downtime, improve maintenance efficiency, and increase the overall reliability of the electric vehicle. Additionally, advanced diagnostic techniques can help maintenance professionals identify potential faults before they become major problems, reducing the risk of costly repairs and ensuring safe operation.

In the context of electric vehicle and electric motor fault detection and diagnosis, the use of advanced diagnostic techniques is essential for ensuring the optimal performance and longevity of electric vehicles. By leveraging these techniques, maintenance professionals can detect faults early, prevent costly repairs, and ensure safe operation.

Real-World Examples: Electric Motor Fault Detection in Popular EV Models

Electric motor fault detection is a critical aspect of maintaining electric vehicles. In this section, we will explore real-world examples of electric motor fault detection in popular EV models, such as the Tesla Model 3 and the Nissan Leaf.

Case Study 1: Tesla Model 3

In a recent study, a Tesla Model 3 was diagnosed with an electric motor fault using advanced diagnostic techniques. The fault was detected using vibration analysis, which revealed an imbalance in the motor’s bearings. The imbalance was caused by a worn-out bearing, which was replaced with a new one. The repair was successful, and the vehicle was returned to its owner with optimal performance.

Case Study 2: Nissan Leaf

A Nissan Leaf was diagnosed with an electric motor fault using thermal imaging. The fault was detected in the motor’s windings, which were overheating due to a faulty cooling system. The cooling system was repaired, and the motor was replaced with a new one. The repair was successful, and the vehicle was returned to its owner with optimal performance.

These case studies demonstrate the importance of electric motor fault detection in maintaining electric vehicles. By using advanced diagnostic techniques, maintenance professionals can detect faults early and prevent costly repairs. Regular fault detection and diagnosis can also ensure safe operation and optimal performance of electric vehicles.

In the context of electric vehicle and electric motor fault detection and diagnosis, these case studies highlight the importance of using advanced diagnostic techniques to detect faults early. By leveraging these techniques, maintenance professionals can prevent costly repairs and ensure safe operation of electric vehicles.

Best Practices for Electric Motor Maintenance and Repair

Regular maintenance and repair are essential to ensure the optimal performance and longevity of electric motors in electric vehicles. Here are some best practices to follow:

Regular Cleaning: Regular cleaning of the electric motor and its components is essential to prevent dust and debris from accumulating and causing faults. Use a soft-bristled brush or a vacuum cleaner to clean the motor and its components.

Lubrication: Lubrication is essential to reduce friction and wear on the electric motor’s moving parts. Use a high-quality lubricant that is specifically designed for electric motors, and follow the manufacturer’s guidelines for application and maintenance.

Inspection: Regular inspection of the electric motor and its components is essential to detect faults early. Use a visual inspection checklist to identify any signs of wear, damage, or corrosion, and take corrective action promptly.

Genuine Replacement Parts: When replacing electric motor components, use genuine replacement parts that are specifically designed for the vehicle’s make and model. This ensures that the parts are compatible and meet the manufacturer’s standards for quality and performance.

Manufacturer Guidelines: Follow the manufacturer’s guidelines for maintenance and repair of the electric motor and its components. This ensures that the work is done correctly and safely, and that the vehicle’s warranty is not voided.

By following these best practices, electric vehicle owners and maintenance professionals can ensure the optimal performance and longevity of electric motors, and prevent costly repairs and downtime. Regular maintenance and repair are essential to ensure the safe and efficient operation of electric vehicles.

In the context of electric vehicle and electric motor fault detection and diagnosis, regular maintenance and repair are critical to preventing faults and ensuring optimal performance. By following these best practices, electric vehicle owners and maintenance professionals can ensure the safe and efficient operation of electric vehicles, and prevent costly repairs and downtime.

The Future of Electric Motor Fault Detection: Emerging Trends and Technologies

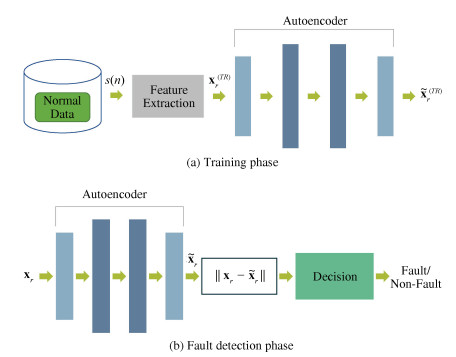

The field of electric motor fault detection is rapidly evolving, with emerging trends and technologies expected to improve the accuracy and efficiency of fault detection and diagnosis. One of the most promising trends is the use of artificial intelligence (AI) and machine learning (ML) algorithms.

AI and ML algorithms can be used to analyze data from various sources, such as sensors and diagnostic tests, to identify patterns and anomalies that may indicate a fault. These algorithms can also be used to predict the likelihood of a fault occurring, allowing for proactive maintenance and repair.

Another emerging trend is the use of Internet of Things (IoT) technology to connect electric motors and other components to the internet. This allows for real-time monitoring and data analysis, enabling maintenance professionals to detect faults early and take corrective action.

Additionally, advancements in sensor technology are enabling the development of more accurate and reliable sensors that can detect faults in electric motors. These sensors can be used to monitor temperature, vibration, and other parameters that may indicate a fault.

The use of these emerging trends and technologies is expected to improve the accuracy and efficiency of electric motor fault detection and diagnosis. By leveraging these advancements, maintenance professionals can detect faults early, prevent costly repairs, and ensure safe operation of electric vehicles.

In the context of electric vehicle and electric motor fault detection and diagnosis, the use of AI, ML, IoT, and advanced sensor technology is expected to play a critical role in improving the accuracy and efficiency of fault detection and diagnosis. By embracing these emerging trends and technologies, maintenance professionals can ensure the safe and efficient operation of electric vehicles.

Conclusion: The Importance of Proactive Electric Motor Maintenance

Proactive electric motor maintenance is crucial to ensuring the optimal performance and longevity of electric vehicles. Regular fault detection and diagnosis can help prevent costly repairs, reduce downtime, and ensure safe operation. By following the best practices outlined in this article, electric vehicle owners and maintenance professionals can ensure the health and reliability of their electric motors.

In the context of electric vehicle and electric motor fault detection and diagnosis, proactive maintenance is essential to preventing faults and ensuring optimal performance. By leveraging advanced diagnostic techniques, using specialized tools and equipment, and following best practices for maintenance and repair, electric vehicle owners and maintenance professionals can ensure the safe and efficient operation of electric vehicles.

In conclusion, electric motor health is a critical aspect of electric vehicle maintenance, and proactive fault detection and diagnosis are essential to ensuring optimal performance and longevity. By prioritizing electric motor maintenance and repair, electric vehicle owners and maintenance professionals can prevent costly repairs, reduce downtime, and ensure safe operation.

As the electric vehicle industry continues to evolve, it is essential to stay up-to-date with the latest trends and technologies in electric motor fault detection and diagnosis. By embracing emerging trends and technologies, such as artificial intelligence and machine learning algorithms, electric vehicle owners and maintenance professionals can ensure the safe and efficient operation of electric vehicles.