Setting the Standard for Electric Vehicle Excellence

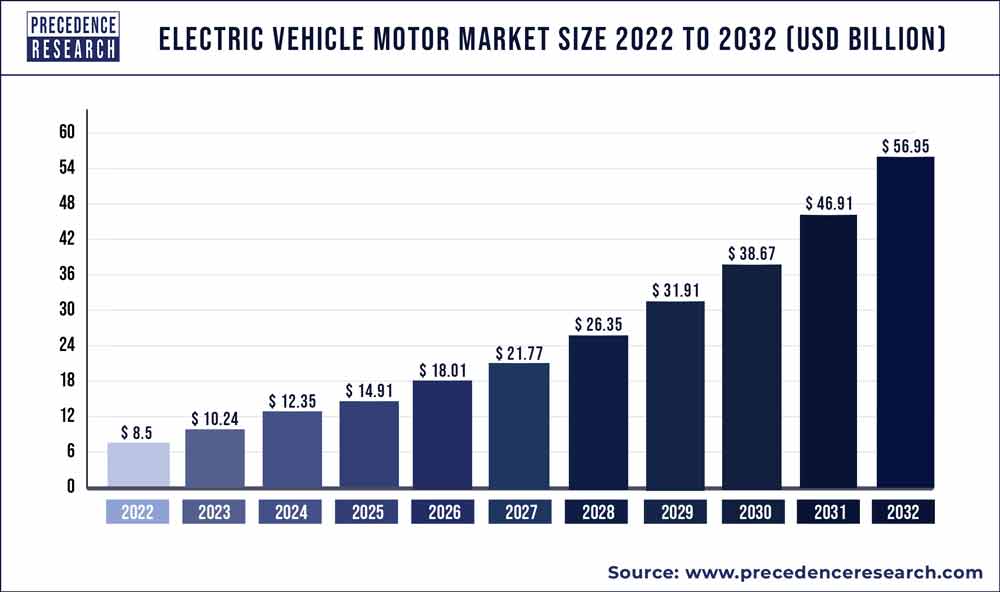

The electric vehicle (EV) and electric motor industries have experienced rapid growth in recent years, driven by increasing demand for sustainable and environmentally friendly transportation solutions. As the market continues to evolve, the importance of industry standards cannot be overstated. Electric vehicle and electric motor industry standards play a crucial role in ensuring consistency, safety, and performance across the sector. By establishing a common framework for manufacturers to follow, standards promote a level playing field, foster innovation, and enhance consumer confidence.

Industry standards for electric vehicles and electric motors address a wide range of critical aspects, including safety, performance, and environmental impact. For instance, standards for electric motor efficiency help manufacturers optimize their designs, reducing energy consumption and minimizing emissions. Similarly, standards for electric vehicle charging systems ensure seamless interoperability between different manufacturers’ products, making it easier for consumers to own and operate EVs.

The adoption of industry standards also facilitates the development of new technologies and business models. By providing a common language and set of requirements, standards enable manufacturers to focus on innovation and differentiation, rather than reinventing the wheel. This, in turn, drives competition, improves product quality, and reduces costs. Furthermore, standards help to mitigate risks associated with electric vehicle adoption, such as electrical shocks, fires, and other safety hazards.

As the electric vehicle and electric motor industries continue to mature, the importance of industry standards will only continue to grow. By embracing standards, manufacturers can ensure that their products meet the highest levels of quality, safety, and performance, while also promoting a more sustainable and environmentally friendly transportation sector. Ultimately, the widespread adoption of industry standards will be critical to realizing the full potential of electric vehicles and electric motors, and to creating a better future for generations to come.

How to Navigate the Complex World of Electric Motor Standards

The electric vehicle (EV) and electric motor industries are shaped by a complex array of standards organizations, each playing a critical role in developing and maintaining industry benchmarks. Two of the most prominent organizations in this space are the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). These organizations work tirelessly to create and update standards that ensure the safety, performance, and efficiency of electric vehicles and electric motors.

The IEC is a global organization that develops and publishes standards for electrical and electronic technologies, including electric vehicles and electric motors. The IEC’s standards for electric vehicles, such as the IEC 62196 standard for charging connectors, provide a common framework for manufacturers to follow, ensuring interoperability and safety. Similarly, the SAE is a US-based organization that develops standards for the automotive industry, including electric vehicles and electric motors. The SAE’s standards, such as the SAE J1772 standard for electric vehicle charging, provide guidance on critical aspects like charging speed, efficiency, and safety.

In addition to the IEC and SAE, other organizations like the National Electric Manufacturers Association (NEMA) and the Institute of Electrical and Electronics Engineers (IEEE) also play important roles in shaping the electric vehicle and electric motor industries. These organizations work together to create a comprehensive framework of standards that address every aspect of electric vehicle and electric motor design, development, and deployment.

Understanding the complex world of electric motor standards is crucial for manufacturers, policymakers, and consumers alike. By recognizing the importance of these standards, stakeholders can ensure that electric vehicles and electric motors meet the highest levels of quality, safety, and performance. Moreover, adherence to industry standards facilitates innovation, reduces costs, and promotes a more sustainable and environmentally friendly transportation sector.

As the electric vehicle and electric motor industries continue to evolve, the role of standards organizations will only continue to grow. By staying ahead of the curve and embracing industry standards, stakeholders can help shape the future of transportation and create a better world for generations to come.

Key Performance Indicators for Electric Vehicle Motors

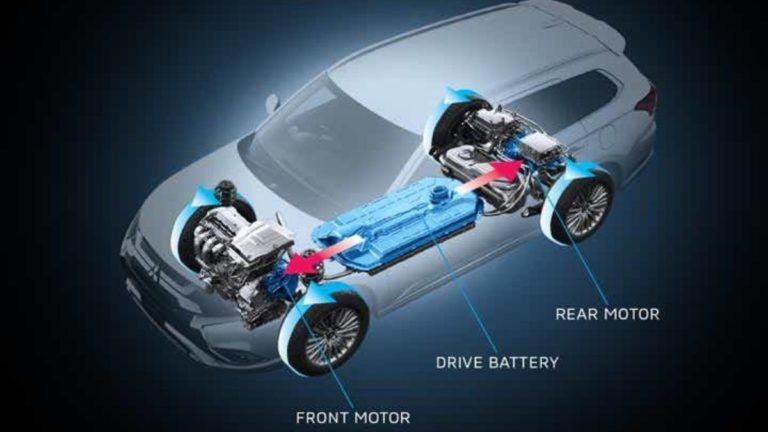

Electric vehicle (EV) motors are a critical component of the overall electric vehicle system, and their performance has a significant impact on the vehicle’s efficiency, range, and overall driving experience. To ensure that EV motors meet the required standards, manufacturers rely on a set of key performance indicators (KPIs) that measure their efficiency, power density, and thermal management.

Efficiency is a critical KPI for EV motors, as it directly affects the vehicle’s range and overall energy consumption. Electric motor efficiency is typically measured by its ability to convert electrical energy into mechanical energy, with higher efficiency motors resulting in longer ranges and reduced energy consumption. The International Electrotechnical Commission (IEC) has established standards for electric motor efficiency, including the IEC 60034-30 standard, which provides a framework for measuring and comparing motor efficiency.

Power density is another important KPI for EV motors, as it affects the vehicle’s acceleration and overall performance. Power density is typically measured in watts per kilogram (W/kg), with higher power density motors resulting in faster acceleration and improved overall performance. The Society of Automotive Engineers (SAE) has established standards for electric motor power density, including the SAE J3101 standard, which provides guidelines for measuring and comparing motor power density.

Thermal management is also a critical KPI for EV motors, as it affects the motor’s overall efficiency and lifespan. Electric motors generate heat during operation, and if not properly managed, this heat can reduce the motor’s efficiency and lifespan. The IEC has established standards for electric motor thermal management, including the IEC 60034-25 standard, which provides guidelines for measuring and managing motor temperature.

By understanding and measuring these KPIs, manufacturers can ensure that their EV motors meet the required standards and provide a high-quality driving experience for consumers. The adoption of industry standards for EV motors also facilitates innovation, reduces costs, and promotes a more sustainable and environmentally friendly transportation sector.

In the context of electric vehicle and electric motor industry standards, the measurement and management of these KPIs play a critical role in ensuring the overall performance and efficiency of EVs. By adopting industry standards, manufacturers can ensure that their EV motors meet the required standards, providing a high-quality driving experience for consumers and promoting a more sustainable and environmentally friendly transportation sector.

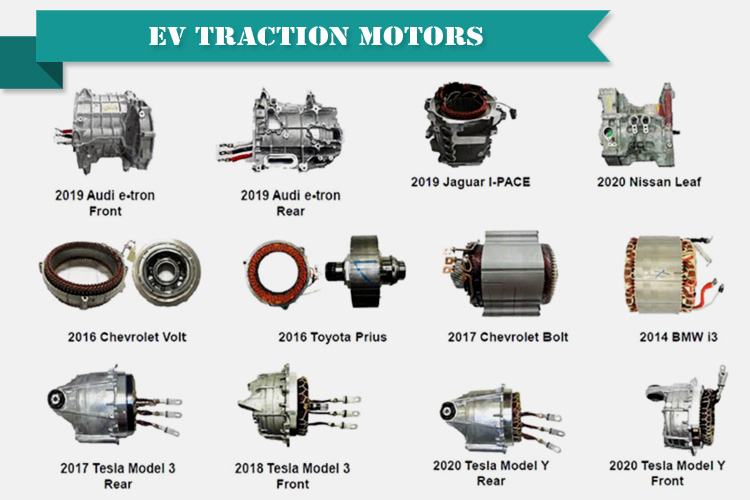

Industry-Leading Electric Vehicle Motor Technologies

The electric vehicle (EV) industry has witnessed significant advancements in motor technologies, leading to improved efficiency, performance, and range. Several innovative electric motor technologies have emerged, each with its advantages and disadvantages. In this section, we will explore some of the industry-leading electric vehicle motor technologies, including permanent magnet motors, induction motors, and switched reluctance motors.

Permanent magnet motors are widely used in EVs due to their high efficiency, reliability, and compact design. These motors use permanent magnets as the rotor, which eliminates the need for electrical excitation. Permanent magnet motors are known for their high power density, making them ideal for EV applications. However, they can be more expensive than other motor technologies and may require rare earth materials.

Induction motors are another popular choice for EVs, offering high efficiency and reliability. These motors use electromagnetic induction to produce torque, eliminating the need for permanent magnets. Induction motors are known for their simplicity, robustness, and low cost. However, they may have lower power density and efficiency compared to permanent magnet motors.

Switched reluctance motors are a newer technology that has gained significant attention in the EV industry. These motors use a unique design that eliminates the need for permanent magnets and electromagnetic induction. Switched reluctance motors offer high efficiency, reliability, and compact design, making them an attractive option for EV applications. However, they may require complex control systems and may have higher costs compared to other motor technologies.

The adoption of these innovative electric motor technologies has been driven by the need for improved efficiency, performance, and range in EVs. Industry standards, such as those developed by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), play a critical role in ensuring the safe and reliable operation of these motors. By understanding the advantages and disadvantages of each motor technology, manufacturers can make informed decisions about which technology to adopt, ultimately driving innovation and progress in the EV industry.

In the context of electric vehicle and electric motor industry standards, the development and adoption of innovative motor technologies are crucial for improving efficiency, performance, and range. By embracing industry standards, manufacturers can ensure that their EV motors meet the required standards, providing a high-quality driving experience for consumers and promoting a more sustainable and environmentally friendly transportation sector.

Ensuring Safety and Reliability in Electric Vehicle Systems

Safety and reliability are paramount in electric vehicle (EV) systems, as they directly impact the well-being of drivers, passengers, and pedestrians. The electric vehicle and electric motor industry standards play a critical role in ensuring the safe operation of EVs and preventing electrical shocks, fires, and other hazards. In this section, we will discuss the importance of safety and reliability in EV systems and the role of industry standards in ensuring their safe operation.

Robust testing and validation procedures are essential for ensuring the safety and reliability of EV systems. Industry standards, such as those developed by the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), provide guidelines for testing and validation procedures. These standards ensure that EV systems are designed and manufactured to meet strict safety and reliability requirements.

Electrical safety is a critical aspect of EV systems, as it directly impacts the risk of electrical shocks, fires, and other hazards. Industry standards, such as the IEC 60364 standard for electrical installations, provide guidelines for ensuring electrical safety in EV systems. These standards cover aspects such as electrical insulation, grounding, and protection against electrical shock.

Thermal management is another critical aspect of EV systems, as it directly impacts the safety and reliability of EV batteries and electric motors. Industry standards, such as the IEC 60034-25 standard for thermal management, provide guidelines for ensuring the safe operation of EV batteries and electric motors. These standards cover aspects such as thermal design, testing, and validation procedures.

The adoption of industry standards for safety and reliability in EV systems has numerous benefits, including improved safety, reduced risk of accidents, and increased consumer confidence. By embracing industry standards, manufacturers can ensure that their EV systems meet the required safety and reliability standards, providing a high-quality driving experience for consumers and promoting a more sustainable and environmentally friendly transportation sector.

In the context of electric vehicle and electric motor industry standards, the importance of safety and reliability cannot be overstated. By understanding the critical aspects of safety and reliability in EV systems and the role of industry standards in ensuring their safe operation, manufacturers can make informed decisions about designing and manufacturing safe and reliable EV systems.

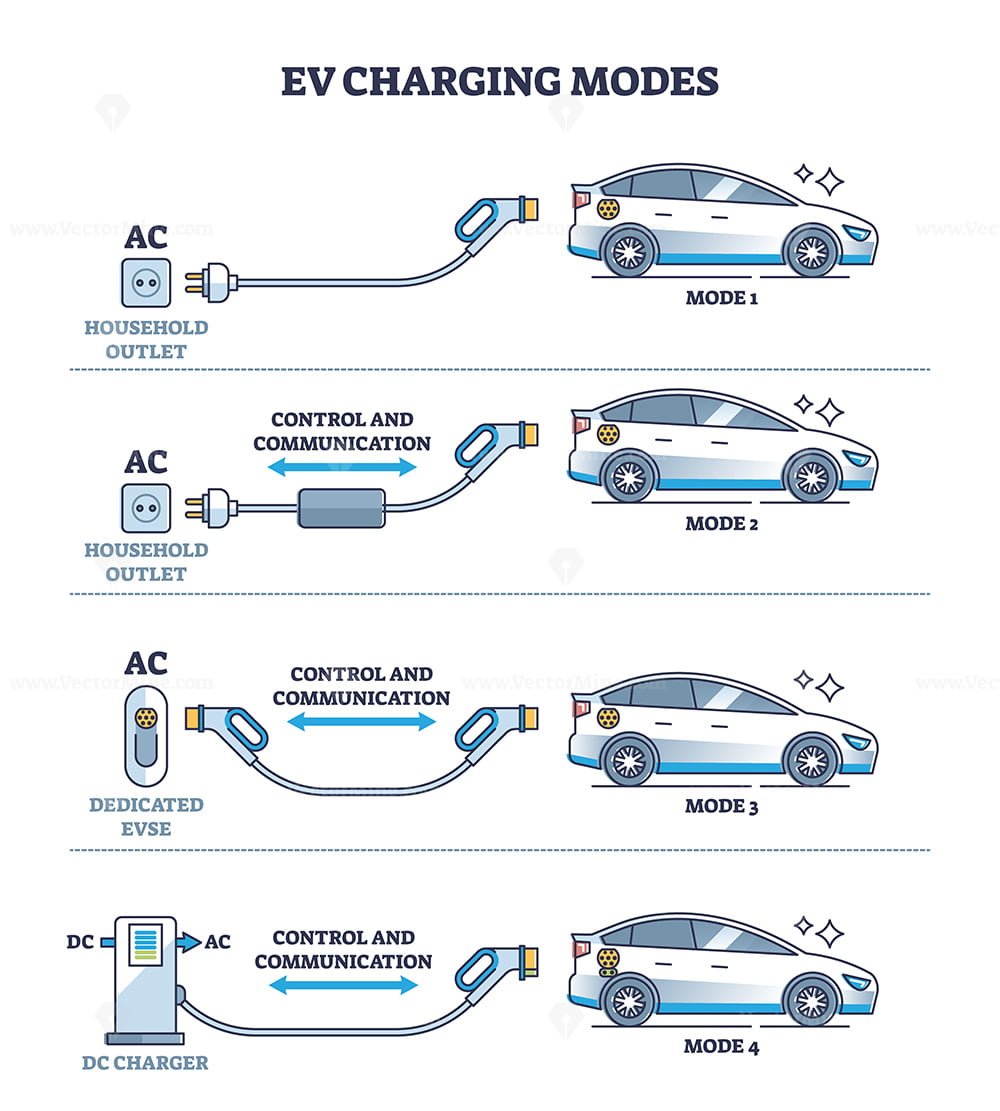

Charging Ahead: Standards for Electric Vehicle Charging Systems

Electric vehicle (EV) charging systems are a critical component of the EV ecosystem, enabling drivers to recharge their vehicles quickly and efficiently. Industry standards play a vital role in ensuring the safe and reliable operation of EV charging systems, and several organizations have developed standards to govern the development and deployment of these systems.

Level 1, Level 2, and DC Fast Charging are the three primary charging modes for EVs, each with its own set of standards and requirements. Level 1 charging uses a standard 120-volt AC outlet and is typically used for overnight charging at home. Level 2 charging uses a 240-volt AC outlet and is commonly used for public charging stations. DC Fast Charging uses a high-power DC connection and is typically used for rapid charging along highways and intercity routes.

The International Electrotechnical Commission (IEC) has developed several standards for EV charging systems, including the IEC 62196 standard for charging connectors and the IEC 60364 standard for electrical installations. The Society of Automotive Engineers (SAE) has also developed standards for EV charging systems, including the SAE J1772 standard for Level 1 and Level 2 charging and the SAE J1773 standard for DC Fast Charging.

Industry standards for EV charging systems ensure that charging equipment is safe, reliable, and compatible with a wide range of EVs. These standards also facilitate the development of new charging technologies and business models, such as pay-per-use charging and vehicle-to-grid (V2G) charging.

The adoption of industry standards for EV charging systems has numerous benefits, including improved safety, reduced costs, and increased convenience. By embracing industry standards, manufacturers can ensure that their charging equipment meets the required safety and performance standards, providing a high-quality charging experience for consumers and promoting a more sustainable and environmentally friendly transportation sector.

In the context of electric vehicle and electric motor industry standards, the development and adoption of standards for EV charging systems are critical for ensuring the safe and reliable operation of these systems. By understanding the different charging modes and standards, manufacturers can make informed decisions about designing and deploying EV charging systems that meet the required safety and performance standards.

Real-World Examples of Electric Vehicle Industry Standards in Action

The adoption of industry standards in the electric vehicle (EV) sector has numerous benefits, including improved interoperability, reduced development costs, and increased consumer confidence. Several EV manufacturers have successfully implemented industry standards, demonstrating the value of these standards in real-world applications.

Tesla, a leading EV manufacturer, has adopted the IEC 62196 standard for charging connectors. This standard ensures that Tesla’s charging connectors are compatible with a wide range of EVs, making it easier for consumers to charge their vehicles on the go. By adopting this standard, Tesla has improved interoperability and reduced development costs, allowing the company to focus on innovation and customer satisfaction.

Another example of industry standards in action is the adoption of the SAE J1772 standard for Level 1 and Level 2 charging by EV manufacturers such as General Motors and Ford. This standard ensures that EVs from these manufacturers can be charged using a wide range of charging equipment, making it easier for consumers to own and operate EVs.

The adoption of industry standards has also facilitated the development of new business models, such as pay-per-use charging and vehicle-to-grid (V2G) charging. These business models rely on the interoperability and compatibility ensured by industry standards, making it easier for consumers to access charging services and for manufacturers to develop new products and services.

In the context of electric vehicle and electric motor industry standards, the adoption of these standards has numerous benefits, including improved safety, reduced costs, and increased convenience. By understanding the value of industry standards, manufacturers can make informed decisions about adopting these standards, ultimately driving innovation and progress in the EV industry.

The real-world examples of industry standards in action demonstrate the importance of these standards in ensuring the safe and reliable operation of EVs. By adopting industry standards, manufacturers can improve interoperability, reduce development costs, and increase consumer confidence, ultimately driving the growth and adoption of EVs.

Future-Proofing the Electric Vehicle Industry: Emerging Trends and Standards

The electric vehicle (EV) industry is rapidly evolving, with emerging trends and standards shaping the future of the sector. As the industry continues to grow and mature, it is essential to stay ahead of the curve and understand the latest developments in EV technology and standards.

One of the most significant emerging trends in the EV industry is the development of new charging technologies. Wireless charging, for example, is becoming increasingly popular, offering a convenient and efficient way to charge EVs. The Society of Automotive Engineers (SAE) has developed a standard for wireless charging, SAE J2954, which ensures interoperability and safety.

Advanced battery management systems are another emerging trend in the EV industry. These systems enable EVs to optimize battery performance, range, and lifespan. The International Electrotechnical Commission (IEC) has developed a standard for battery management systems, IEC 62660, which provides guidelines for the design, testing, and validation of these systems.

Autonomous driving capabilities are also becoming increasingly important in the EV industry. Autonomous vehicles require advanced sensors, software, and communication systems, which must be integrated with EV systems. The IEC has developed a standard for autonomous vehicles, IEC 61508, which provides guidelines for the design, testing, and validation of these systems.

The adoption of these emerging trends and standards will shape the future of the EV industry, enabling the development of more efficient, safe, and convenient EVs. By staying ahead of the curve and understanding the latest developments in EV technology and standards, manufacturers can ensure that their products meet the required safety and performance standards, providing a high-quality driving experience for consumers and promoting a more sustainable and environmentally friendly transportation sector.

In the context of electric vehicle and electric motor industry standards, the development and adoption of emerging trends and standards are critical for ensuring the continued growth and innovation of the EV industry. By understanding the latest developments in EV technology and standards, manufacturers can make informed decisions about adopting these trends and standards, ultimately driving the future of the EV industry.