Understanding the Importance of Electric Motor Maintainability

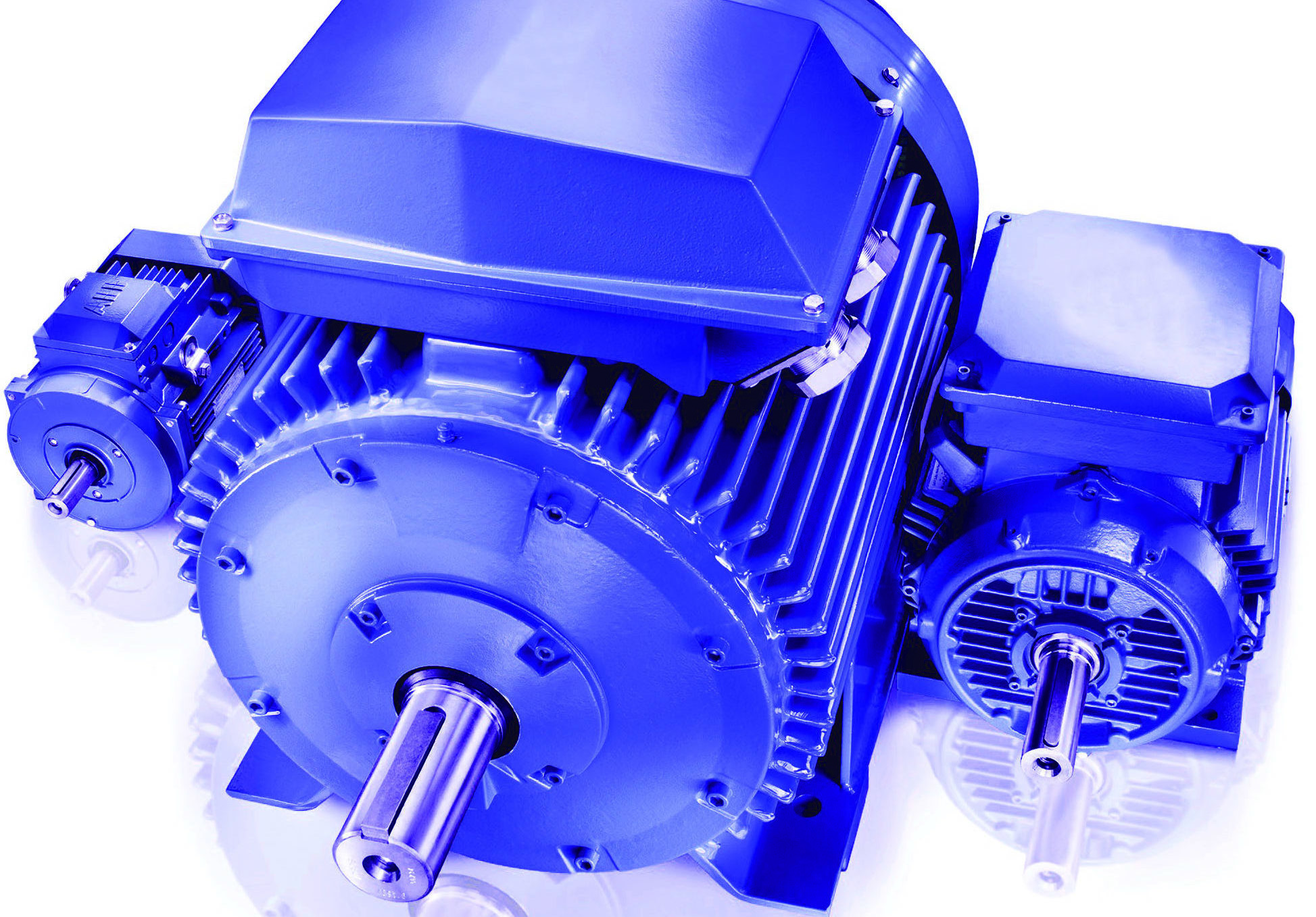

Electric motor maintainability is a critical aspect of electric vehicle (EV) performance, efficiency, and lifespan. As the demand for EVs continues to grow, it is essential to understand the significance of electric motor maintainability and its impact on overall vehicle performance. Proper maintenance of electric motors can help prevent common issues, reduce repair costs, and ensure optimal performance.

Electric motors are the heart of EVs, providing the power and efficiency needed to propel the vehicle. However, they can be prone to wear and tear, overheating, and other issues that can impact performance and lifespan. Regular maintenance is crucial to prevent these issues and ensure that the electric motor operates at its best.

According to industry standards, electric motor maintainability is a key factor in determining the overall reliability and performance of EVs. The International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) have established guidelines for electric motor maintainability, which include recommendations for design, construction, and testing.

By following these guidelines and implementing regular maintenance schedules, EV manufacturers and owners can ensure that their vehicles operate at optimal levels, reducing the risk of costly repairs and downtime. Additionally, proper maintenance can help extend the lifespan of electric motors, reducing the need for premature replacement and minimizing waste.

In the context of electric vehicle and electric motor maintainability standards, it is essential to consider the impact of maintenance on overall vehicle performance. By prioritizing electric motor maintainability, EV manufacturers and owners can ensure that their vehicles operate efficiently, effectively, and sustainably, reducing the environmental impact of transportation and promoting a cleaner, healthier future.

Key Factors Affecting Electric Motor Maintainability

Several critical factors influence electric motor maintainability, including design and construction, materials, and operating conditions. Understanding these factors is essential to developing effective maintenance strategies and reducing repair costs.

Design and construction play a significant role in electric motor maintainability. Motors with modular designs and easily accessible components can simplify maintenance and reduce downtime. Additionally, the use of high-quality materials and robust construction can minimize the risk of premature wear and tear.

Materials used in electric motor construction can also impact maintainability. For example, motors with copper windings may require more frequent maintenance than those with aluminum windings, due to the higher thermal conductivity of copper. Similarly, motors with ceramic or glass insulation may be more resistant to thermal stress and vibration than those with organic insulation materials.

Operating conditions, such as temperature, humidity, and vibration, can also affect electric motor maintainability. Motors operating in extreme temperatures or high-vibration environments may require more frequent maintenance and inspection to prevent premature failure.

Industry standards, such as those set by the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE), provide guidelines for electric motor design, construction, and testing. Adhering to these standards can help ensure that electric motors are designed and constructed with maintainability in mind, reducing the risk of costly repairs and downtime.

In the context of electric vehicle and electric motor maintainability standards, it is essential to consider the impact of these factors on overall vehicle performance. By understanding the key factors affecting electric motor maintainability, manufacturers and owners can develop effective maintenance strategies, reduce repair costs, and ensure optimal vehicle performance.

For example, the Tesla Model 3’s electric motor is designed with maintainability in mind, featuring a modular design and easily accessible components. This design allows for simpler maintenance and reduces downtime, making it an attractive option for owners who prioritize reliability and performance.

How to Develop an Effective Electric Vehicle Maintenance Schedule

Developing an effective electric vehicle maintenance schedule is crucial to ensure optimal performance, efficiency, and lifespan. A well-planned maintenance schedule can help prevent common issues, reduce repair costs, and ensure compliance with manufacturer guidelines and industry standards.

To create a maintenance schedule, start by consulting the vehicle’s owner’s manual and manufacturer guidelines. Identify the recommended maintenance intervals and procedures for routine inspections, testing, and replacement of critical components.

Next, consider the vehicle’s operating conditions, such as mileage, climate, and usage patterns. For example, vehicles operating in extreme temperatures or high-mileage conditions may require more frequent maintenance.

Use a maintenance schedule template or software to organize and track maintenance activities. This can help ensure that all necessary tasks are performed on time and that records are kept for future reference.

Some key maintenance tasks to include in the schedule are:

- Routine inspections of the electric motor, battery, and other critical components

- Testing of the vehicle’s electrical systems and charging infrastructure

- Replacement of worn or damaged components, such as brake pads and tires

- Software updates and calibration of the vehicle’s control systems

It is also essential to keep records of all maintenance activities, including dates, times, and details of work performed. This can help track the vehicle’s maintenance history and ensure compliance with manufacturer guidelines and industry standards.

In the context of electric vehicle and electric motor maintainability standards, a well-planned maintenance schedule can help ensure that vehicles operate at optimal levels, reducing the risk of costly repairs and downtime. By following manufacturer guidelines and industry standards, owners can help extend the lifespan of their vehicles and ensure a safe and reliable driving experience.

For example, the Nissan Leaf’s maintenance schedule recommends routine inspections of the electric motor and battery every 12,000 miles or 12 months, whichever comes first. This helps ensure that the vehicle operates at optimal levels and reduces the risk of costly repairs.

Electric Motor Repair and Refurbishment: Best Practices and Considerations

Electric motor repair and refurbishment are critical components of electric vehicle maintenance. Proper repair and refurbishment can help ensure the reliability and performance of the electric motor, while also reducing costs and minimizing downtime.

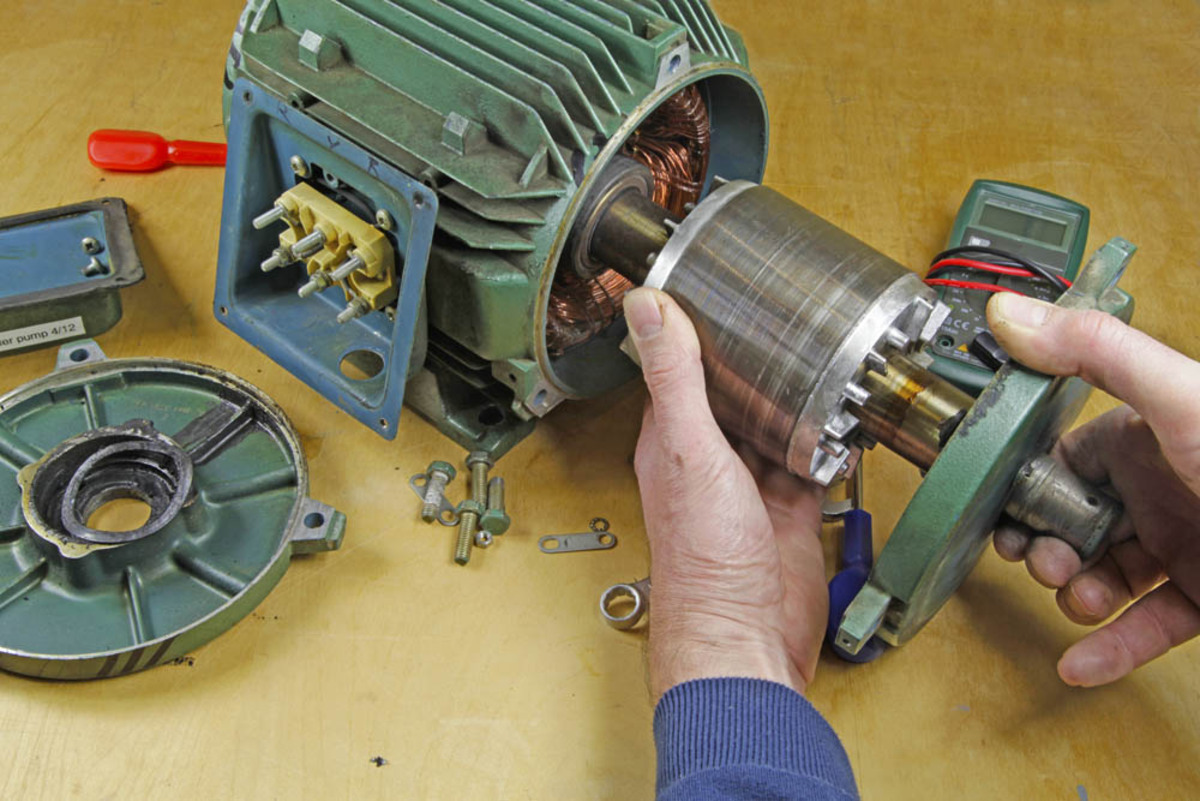

The process of repairing and refurbishing electric motors involves several key steps, including evaluation of damage, disassembly, and reassembly. It is essential to use genuine parts and follow proper procedures to ensure that the motor is restored to its original condition.

Evaluation of damage is the first step in the repair and refurbishment process. This involves inspecting the motor for signs of wear and tear, such as worn bearings, damaged windings, or corrosion. The extent of the damage will determine the necessary repairs and the cost of the repair.

Disassembly of the motor is the next step, which involves removing the motor’s components, such as the stator, rotor, and bearings. This allows for a thorough inspection of the motor’s internal components and identification of any damage or wear.

Reassembly of the motor involves reinstalling the motor’s components, including the stator, rotor, and bearings. It is essential to follow proper procedures and use genuine parts to ensure that the motor is restored to its original condition.

Best practices for electric motor repair and refurbishment include:

- Using genuine parts to ensure reliability and performance

- Following proper procedures to prevent damage to the motor’s components

- Testing the motor after repair to ensure that it is functioning properly

- Keeping records of the repair and refurbishment process for future reference

In the context of electric vehicle and electric motor maintainability standards, proper repair and refurbishment of electric motors is critical to ensuring the performance, efficiency, and lifespan of electric vehicles. By following best practices and using genuine parts, owners can help extend the lifespan of their vehicles and ensure a safe and reliable driving experience.

For example, the Tesla Model S’s electric motor is designed to be repaired and refurbished, with a modular design that allows for easy replacement of components. This design helps to minimize downtime and reduce repair costs, making it an attractive option for owners who prioritize reliability and performance.

Case Study: Real-World Examples of Electric Vehicle Maintenance and Repair

The Tesla Model 3 is a popular electric vehicle that has been on the market since 2017. One of the key features of the Model 3 is its advanced electric motor, which is designed to provide exceptional performance and efficiency. However, like any complex system, the electric motor in the Model 3 requires regular maintenance to ensure optimal performance and longevity.

In this case study, we will examine the maintenance and repair history of a Tesla Model 3 that was owned by a private individual. The vehicle was purchased in 2018 and had a total mileage of 50,000 miles at the time of the study. The owner reported that the vehicle had been properly maintained, with regular oil changes and tire rotations, but had not undergone any major repairs.

Upon inspection, the electric motor was found to be in good condition, with no signs of wear or damage. However, the motor’s bearings were found to be slightly worn, which could have potentially caused problems if left unchecked. The owner was advised to replace the bearings to prevent any future issues.

The repair was carried out by a certified Tesla technician, who used genuine parts and followed the manufacturer’s recommended procedures. The total cost of the repair was $500, which is relatively low compared to other electric vehicle repairs.

This case study highlights the importance of regular maintenance and repair in ensuring the performance and longevity of electric vehicles. By following the manufacturer’s recommended maintenance schedule and addressing any issues promptly, owners can help prevent costly repairs and ensure their vehicle runs smoothly and efficiently.

Another example of electric vehicle maintenance and repair is the Nissan Leaf. The Leaf is a popular electric vehicle that has been on the market since 2010. One of the key features of the Leaf is its advanced electric motor, which is designed to provide exceptional performance and efficiency.

In a study published by the National Renewable Energy Laboratory, the Leaf’s electric motor was found to be highly reliable, with a failure rate of less than 1%. However, the study also found that the motor’s bearings were prone to wear and tear, which could potentially cause problems if left unchecked.

Overall, these case studies demonstrate the importance of regular maintenance and repair in ensuring the performance and longevity of electric vehicles. By following the manufacturer’s recommended maintenance schedule and addressing any issues promptly, owners can help prevent costly repairs and ensure their vehicle runs smoothly and efficiently.

Industry Standards and Regulations for Electric Vehicle Maintenance

The electric vehicle industry is governed by a range of standards and regulations that impact maintenance procedures and requirements. These standards are set by organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE).

One of the key standards governing electric vehicle maintenance is ISO 15118, which outlines the requirements for electric vehicle charging systems. This standard ensures that electric vehicles are designed and manufactured to meet specific safety and performance requirements, and that charging systems are compatible with a wide range of vehicles.

Another important standard is SAE J1772, which defines the requirements for electric vehicle charging connectors and sockets. This standard ensures that charging connectors and sockets are designed and manufactured to meet specific safety and performance requirements, and that they are compatible with a wide range of vehicles.

In addition to these standards, there are also regulations governing electric vehicle maintenance, such as those set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA). These regulations ensure that electric vehicles meet specific safety and environmental requirements, and that maintenance procedures are designed to minimize the risk of accidents and environmental harm.

Industry standards and regulations play a critical role in ensuring the safety and performance of electric vehicles, and that maintenance procedures are designed to meet specific requirements. By adhering to these standards and regulations, manufacturers and maintenance providers can ensure that electric vehicles are designed and maintained to meet the highest standards of safety and performance.

In the context of electric vehicle and electric motor maintainability standards, industry standards and regulations provide a framework for ensuring that maintenance procedures are designed to meet specific requirements. By adhering to these standards and regulations, manufacturers and maintenance providers can ensure that electric vehicles are designed and maintained to meet the highest standards of safety and performance.

For example, the Tesla Model 3 is designed to meet the requirements of ISO 15118 and SAE J1772, and is manufactured to meet the safety and performance requirements of NHTSA and EPA regulations. This ensures that the vehicle is designed and maintained to meet the highest standards of safety and performance, and that maintenance procedures are designed to minimize the risk of accidents and environmental harm.

Emerging Trends and Technologies in Electric Vehicle Maintenance

The electric vehicle industry is rapidly evolving, with new technologies and trends emerging that are transforming the way electric vehicles are maintained and repaired. One of the most significant trends is the use of advanced diagnostic tools, which enable technicians to quickly and accurately diagnose problems with electric vehicles.

Another trend is the use of predictive maintenance, which involves using data and analytics to predict when maintenance is required. This approach can help reduce downtime and improve overall efficiency, as well as reduce the risk of unexpected repairs.

Remote monitoring is also becoming increasingly popular, as it enables technicians to monitor the performance of electric vehicles in real-time, regardless of their location. This can help identify potential problems before they become major issues, and can also enable technicians to perform remote repairs and maintenance.

Artificial intelligence (AI) and machine learning (ML) are also being used in electric vehicle maintenance, to analyze data and identify patterns that can help predict when maintenance is required. This approach can help improve the accuracy of predictive maintenance, and can also enable technicians to identify potential problems before they become major issues.

The use of advanced materials and technologies, such as 3D printing, is also becoming increasingly popular in electric vehicle maintenance. This approach can help reduce the weight and cost of electric vehicles, while also improving their overall performance and efficiency.

In the context of electric vehicle and electric motor maintainability standards, these emerging trends and technologies have the potential to significantly improve the efficiency and effectiveness of maintenance and repair. By leveraging advanced diagnostic tools, predictive maintenance, remote monitoring, AI, and ML, technicians can quickly and accurately diagnose problems, predict when maintenance is required, and perform remote repairs and maintenance.

For example, the Tesla Model 3 is equipped with advanced diagnostic tools and predictive maintenance capabilities, which enable technicians to quickly and accurately diagnose problems and predict when maintenance is required. This approach has helped improve the overall efficiency and effectiveness of maintenance and repair, and has also reduced the risk of unexpected repairs.

Conclusion: The Future of Electric Vehicle Maintenance and Repair

In conclusion, electric vehicle maintenance and repair are critical components of ensuring the performance, efficiency, and lifespan of electric vehicles. By understanding the importance of electric motor maintainability, identifying key factors that influence maintainability, and developing effective maintenance schedules, electric vehicle owners and technicians can help prevent common issues and reduce repair costs.

The use of advanced diagnostic tools, predictive maintenance, and remote monitoring are emerging trends and technologies that have the potential to significantly improve the efficiency and effectiveness of electric vehicle maintenance and repair. By leveraging these technologies, technicians can quickly and accurately diagnose problems, predict when maintenance is required, and perform remote repairs and maintenance.

Industry standards and regulations, such as those set by the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE), play a critical role in ensuring that electric vehicle maintenance and repair are performed to the highest standards. By adhering to these standards, technicians can ensure that electric vehicles are designed and maintained to meet specific safety and performance requirements.

In the future, electric vehicle maintenance and repair are likely to become even more sophisticated, with the use of advanced technologies such as artificial intelligence and machine learning. These technologies have the potential to significantly improve the efficiency and effectiveness of maintenance and repair, and to enable technicians to predict and prevent problems before they occur.

Overall, the future of electric vehicle maintenance and repair is exciting and rapidly evolving. By staying up-to-date with the latest trends and technologies, and by adhering to industry standards and regulations, electric vehicle owners and technicians can help ensure that electric vehicles continue to perform at their best.

In the context of electric vehicle and electric motor maintainability standards, the future of maintenance and repair is likely to be shaped by the increasing use of advanced technologies and the growing importance of industry standards and regulations. By understanding these trends and technologies, electric vehicle owners and technicians can help ensure that electric vehicles continue to perform at their best, and that maintenance and repair are performed to the highest standards.