The Evolving Landscape of Electric Vehicle Maintenance

The electric vehicle (EV) industry is experiencing rapid growth, with many countries investing heavily in EV infrastructure and incentivizing consumers to make the switch to electric. As the number of EVs on the road increases, the need for efficient maintenance management systems becomes more pressing. Electric vehicle and electric motor maintenance management trends are shifting towards more proactive and data-driven approaches, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles.

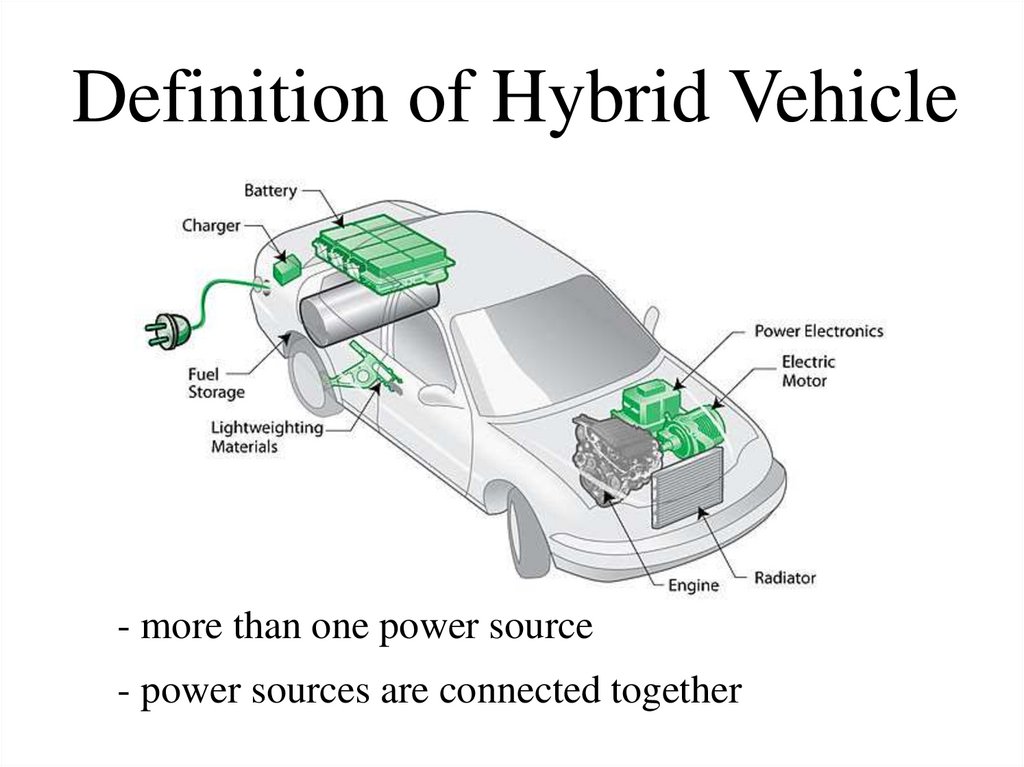

One of the primary challenges facing the EV industry is the lack of standardization in maintenance procedures. Unlike traditional internal combustion engine vehicles, EVs require specialized knowledge and equipment to repair and maintain. As a result, there is a growing need for trained technicians and standardized maintenance protocols to ensure that EVs are properly serviced and maintained.

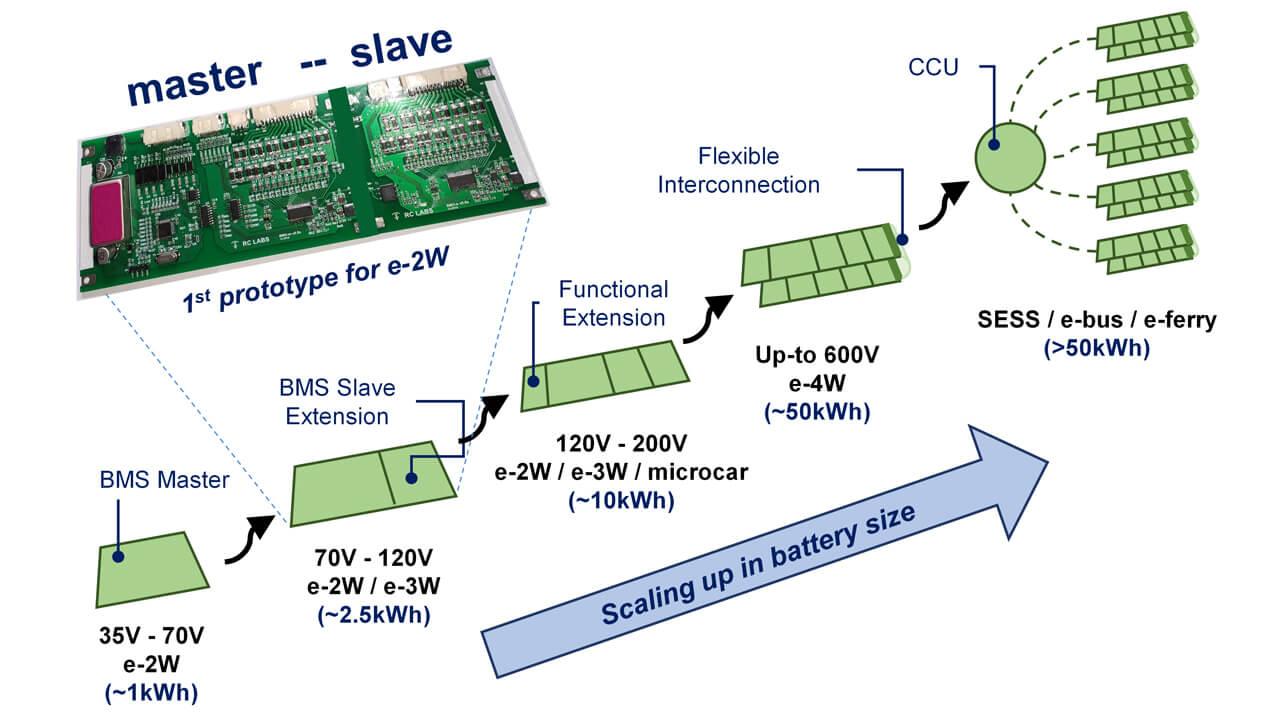

Moreover, the unique characteristics of EVs, such as their electric motors and battery systems, require new approaches to maintenance management. For instance, EV batteries require specific charging and discharging protocols to maintain their health and longevity. Similarly, electric motors require regular monitoring and maintenance to prevent overheating and reduce wear and tear.

As the EV industry continues to evolve, it is likely that we will see the development of more advanced maintenance management systems that leverage data analytics, artificial intelligence, and IoT sensors to predict maintenance needs and optimize performance. These systems will enable fleet managers and owners to make data-driven decisions, reduce costs, and improve the overall efficiency of their operations.

Ultimately, the key to success in EV maintenance management lies in adopting a proactive and data-driven approach. By investing in the latest technologies and training, fleet managers and owners can ensure that their EVs are running at optimal levels, reducing downtime and extending their lifespan. As the EV industry continues to grow and mature, it is likely that we will see significant advancements in maintenance management trends, enabling the widespread adoption of EVs and reducing our reliance on fossil fuels.

Proactive Maintenance Strategies for Electric Motors

Electric motors are a critical component of electric vehicles, and their maintenance is essential to ensure optimal performance and longevity. Proactive maintenance strategies can help reduce downtime, improve efficiency, and extend the lifespan of electric motors. One effective approach is condition monitoring, which involves tracking the motor’s temperature, vibration, and current to detect potential issues before they become major problems.

Predictive maintenance is another proactive strategy that uses data analytics and machine learning algorithms to forecast when maintenance is required. By analyzing data from sensors and other sources, predictive maintenance can identify patterns and anomalies that indicate potential issues, allowing for proactive maintenance to prevent unexpected failures.

Regular maintenance tasks, such as cleaning and inspecting the motor, can also help prevent issues and ensure optimal performance. Additionally, implementing a maintenance schedule that is tailored to the specific needs of the electric motor can help ensure that it is properly maintained and reduce the risk of unexpected failures.

Electric vehicle and electric motor maintenance management trends are shifting towards more proactive and data-driven approaches, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. By adopting proactive maintenance strategies, such as condition monitoring and predictive maintenance, electric vehicle owners can ensure that their vehicles are running at optimal levels and reduce the risk of unexpected failures.

Furthermore, proactive maintenance can also help improve the overall efficiency of electric vehicles. By ensuring that the electric motor is properly maintained, fleet managers and owners can optimize energy consumption, reduce emissions, and improve the overall performance of their vehicles.

In addition to condition monitoring and predictive maintenance, other proactive maintenance strategies for electric motors include thermal imaging, vibration analysis, and motor circuit analysis. These techniques can help identify potential issues before they become major problems, allowing for proactive maintenance to prevent unexpected failures.

How to Implement a Data-Driven Maintenance Approach for Electric Vehicles

Electric vehicle and electric motor maintenance management trends are shifting towards more data-driven approaches, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. One key aspect of a data-driven maintenance approach is the use of IoT sensors, which can provide real-time data on vehicle performance, battery health, and other critical systems.

Data analytics software can then be used to analyze this data and identify trends, patterns, and anomalies that may indicate potential issues. Machine learning algorithms can also be applied to predict maintenance needs and optimize performance. For example, predictive maintenance algorithms can analyze data from sensors and other sources to forecast when maintenance is required, allowing for proactive maintenance to prevent unexpected failures.

Another important aspect of a data-driven maintenance approach is the use of data visualization tools, which can provide a clear and concise view of vehicle performance and maintenance needs. This can help fleet managers and owners to quickly identify areas for improvement and make data-driven decisions about maintenance and repair.

In addition to IoT sensors, data analytics software, and machine learning algorithms, other key technologies for implementing a data-driven maintenance approach include cloud-based platforms, mobile apps, and telematics systems. These technologies can provide a comprehensive view of vehicle performance and maintenance needs, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles.

Electric vehicle manufacturers are also starting to provide data-driven maintenance solutions, such as remote monitoring and predictive maintenance, to help fleet managers and owners optimize performance and reduce downtime. These solutions can provide real-time data on vehicle performance, battery health, and other critical systems, enabling proactive maintenance to prevent unexpected failures.

Overall, a data-driven maintenance approach can help electric vehicle fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. By leveraging IoT sensors, data analytics software, machine learning algorithms, and other key technologies, fleet managers and owners can make data-driven decisions about maintenance and repair, and stay ahead of the curve in terms of electric vehicle and electric motor maintenance management trends.

The Role of Artificial Intelligence in Electric Vehicle Maintenance Management

Artificial intelligence (AI) is playing an increasingly important role in electric vehicle maintenance management, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. One of the key applications of AI in electric vehicle maintenance is predictive maintenance, which uses machine learning algorithms to analyze data from sensors and other sources to forecast when maintenance is required.

AI-powered predictive maintenance can help identify potential issues before they become major problems, allowing for proactive maintenance to prevent unexpected failures. For example, AI algorithms can analyze data from sensors to detect anomalies in battery performance, motor temperature, or other critical systems, enabling fleet managers and owners to take proactive measures to prevent failures.

Another important application of AI in electric vehicle maintenance is automated fault detection, which uses machine learning algorithms to analyze data from sensors and other sources to identify faults and diagnose issues. AI-powered automated fault detection can help reduce downtime and improve efficiency by enabling fleet managers and owners to quickly identify and address issues.

AI can also be used to optimize maintenance scheduling, enabling fleet managers and owners to schedule maintenance at the most convenient times and reduce downtime. For example, AI algorithms can analyze data from sensors and other sources to determine when maintenance is required, and schedule maintenance accordingly.

In addition to predictive maintenance, automated fault detection, and optimized maintenance scheduling, AI can also be used to improve the overall efficiency of electric vehicle maintenance. For example, AI-powered chatbots can be used to provide customer support and answer frequently asked questions, freeing up technicians to focus on more complex issues.

Electric vehicle manufacturers are also starting to integrate AI into their maintenance management systems, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. For example, some manufacturers are using AI-powered predictive maintenance to forecast when maintenance is required, and schedule maintenance accordingly.

Overall, AI is playing an increasingly important role in electric vehicle maintenance management, enabling fleet managers and owners to optimize performance, reduce downtime, and extend the lifespan of their vehicles. As electric vehicle and electric motor maintenance management trends continue to evolve, it is likely that AI will play an even more important role in the future.

Best Practices for Electric Vehicle Battery Maintenance

Electric vehicle batteries require special care to ensure optimal performance and longevity. Proper charging and discharging techniques, storage and handling procedures, and monitoring and testing protocols are essential to maintain the health and efficiency of electric vehicle batteries.

One of the most important best practices for electric vehicle battery maintenance is to follow the manufacturer’s recommended charging and discharging procedures. This includes avoiding extreme temperatures, keeping the battery away from physical stress, and avoiding deep discharging.

Regular monitoring and testing of the battery’s state of charge, voltage, and temperature are also crucial to ensure optimal performance and longevity. This can be done using specialized equipment, such as battery management systems, or by following the manufacturer’s recommended maintenance schedule.

Proper storage and handling procedures are also essential to maintain the health and efficiency of electric vehicle batteries. This includes storing the battery in a cool, dry place, away from physical stress, and avoiding exposure to extreme temperatures.

In addition to proper charging and discharging techniques, storage and handling procedures, and monitoring and testing protocols, regular maintenance and repair are also essential to maintain the health and efficiency of electric vehicle batteries. This includes replacing worn-out or damaged cells, updating software, and performing routine checks and inspections.

Electric vehicle manufacturers are also providing guidelines and recommendations for battery maintenance, including best practices for charging, discharging, and storing batteries. Following these guidelines can help ensure optimal performance and longevity of electric vehicle batteries.

Furthermore, advancements in battery technology are also leading to improved maintenance and repair procedures. For example, some electric vehicle manufacturers are using advanced battery management systems that can detect and prevent potential issues, such as overheating or overcharging.

Overall, proper maintenance and care of electric vehicle batteries are essential to ensure optimal performance and longevity. By following best practices for charging and discharging, storage and handling, monitoring and testing, and regular maintenance and repair, electric vehicle owners can help extend the life of their batteries and ensure optimal performance.

The Importance of Standardized Maintenance Procedures for Electric Vehicles

As the electric vehicle industry continues to grow and mature, the need for standardized maintenance procedures becomes increasingly important. Standardized maintenance procedures ensure that electric vehicles are properly maintained and repaired, which is critical for ensuring optimal performance, safety, and longevity.

Industry-wide standards and guidelines for maintenance and repair are essential for ensuring that electric vehicles are properly maintained and repaired. These standards and guidelines provide a framework for maintenance and repair procedures, ensuring that electric vehicles are maintained and repaired in a consistent and reliable manner.

Standardized maintenance procedures also help to reduce the risk of errors and misdiagnosis, which can lead to costly repairs and downtime. By following standardized procedures, technicians can ensure that electric vehicles are properly maintained and repaired, reducing the risk of errors and misdiagnosis.

In addition to reducing the risk of errors and misdiagnosis, standardized maintenance procedures also help to improve efficiency and productivity. By following standardized procedures, technicians can complete maintenance and repair tasks more quickly and efficiently, reducing downtime and improving overall productivity.

Electric vehicle manufacturers are also recognizing the importance of standardized maintenance procedures. Many manufacturers are developing their own maintenance and repair guidelines, which provide a framework for maintenance and repair procedures. These guidelines help to ensure that electric vehicles are properly maintained and repaired, reducing the risk of errors and misdiagnosis.

Furthermore, standardized maintenance procedures can also help to improve the overall safety of electric vehicles. By following standardized procedures, technicians can ensure that electric vehicles are properly maintained and repaired, reducing the risk of accidents and injuries.

Overall, standardized maintenance procedures are essential for ensuring that electric vehicles are properly maintained and repaired. By following industry-wide standards and guidelines, technicians can ensure that electric vehicles are maintained and repaired in a consistent and reliable manner, reducing the risk of errors and misdiagnosis and improving overall efficiency and productivity.