Mastering the Art of Electric Motor Simulation for Enhanced Performance

Electric vehicle and electric motor modeling and simulation play a vital role in the design and development of efficient, reliable, and sustainable electric vehicles. Accurate modeling and simulation of electric motors enable engineers to optimize motor performance, reduce energy consumption, and improve overall vehicle efficiency. This, in turn, leads to reduced emissions, increased reliability, and enhanced driver experience.

The importance of electric motor simulation in electric vehicle design cannot be overstated. By simulating different motor configurations, engineers can identify the most efficient design, reducing energy losses and improving overall system performance. Additionally, simulation enables the optimization of motor control systems, ensuring seamless interaction between the motor, power electronics, and battery management systems.

Electric motor simulation also facilitates the integration of advanced materials and technologies, such as permanent magnet motors, induction motors, and switched reluctance motors. By simulating the behavior of these motors under various operating conditions, engineers can optimize their performance, reduce material costs, and minimize environmental impact. Furthermore, electric motor simulation enables the development of more efficient battery management systems, reducing charging times and improving overall vehicle range.

The benefits of electric motor simulation in electric vehicle design are numerous. Improved efficiency, reduced emissions, and increased reliability are just a few of the advantages of using advanced modeling and simulation techniques. As the demand for sustainable transportation solutions continues to grow, the importance of electric vehicle and electric motor modeling and simulation will only continue to increase.

How to Choose the Right Simulation Tools for Your Electric Vehicle Project

Selecting the right simulation tools and software is crucial for successful electric vehicle and electric motor modeling and simulation. With a wide range of options available, engineers must carefully evaluate their needs and choose the tools that best fit their project requirements. Popular simulation tools and software used in electric vehicle design include ANSYS, OpenFOAM, and MATLAB.

ANSYS is a widely used simulation software that offers a comprehensive suite of tools for electric vehicle design, including electric motor simulation, thermal management, and structural analysis. OpenFOAM, on the other hand, is an open-source simulation software that provides a high degree of flexibility and customization. MATLAB is a high-level programming language that is widely used for electric vehicle modeling and simulation, particularly for control systems and battery management.

When choosing simulation tools and software, engineers should consider several factors, including the type of simulation required, the level of complexity, and the desired level of accuracy. They should also evaluate the software’s user interface, documentation, and support resources. Additionally, engineers should consider the software’s compatibility with other tools and systems, as well as its scalability and flexibility.

For example, if an engineer is working on a project that requires complex electric motor simulation, ANSYS may be the best choice. However, if the project requires a high degree of customization and flexibility, OpenFOAM may be a better option. MATLAB, on the other hand, may be the best choice for projects that require advanced control systems and battery management.

Ultimately, the choice of simulation tools and software will depend on the specific needs and requirements of the project. By carefully evaluating their options and choosing the right tools, engineers can ensure successful electric vehicle and electric motor modeling and simulation, and achieve their project goals.

Key Considerations for Electric Vehicle Modeling and Simulation

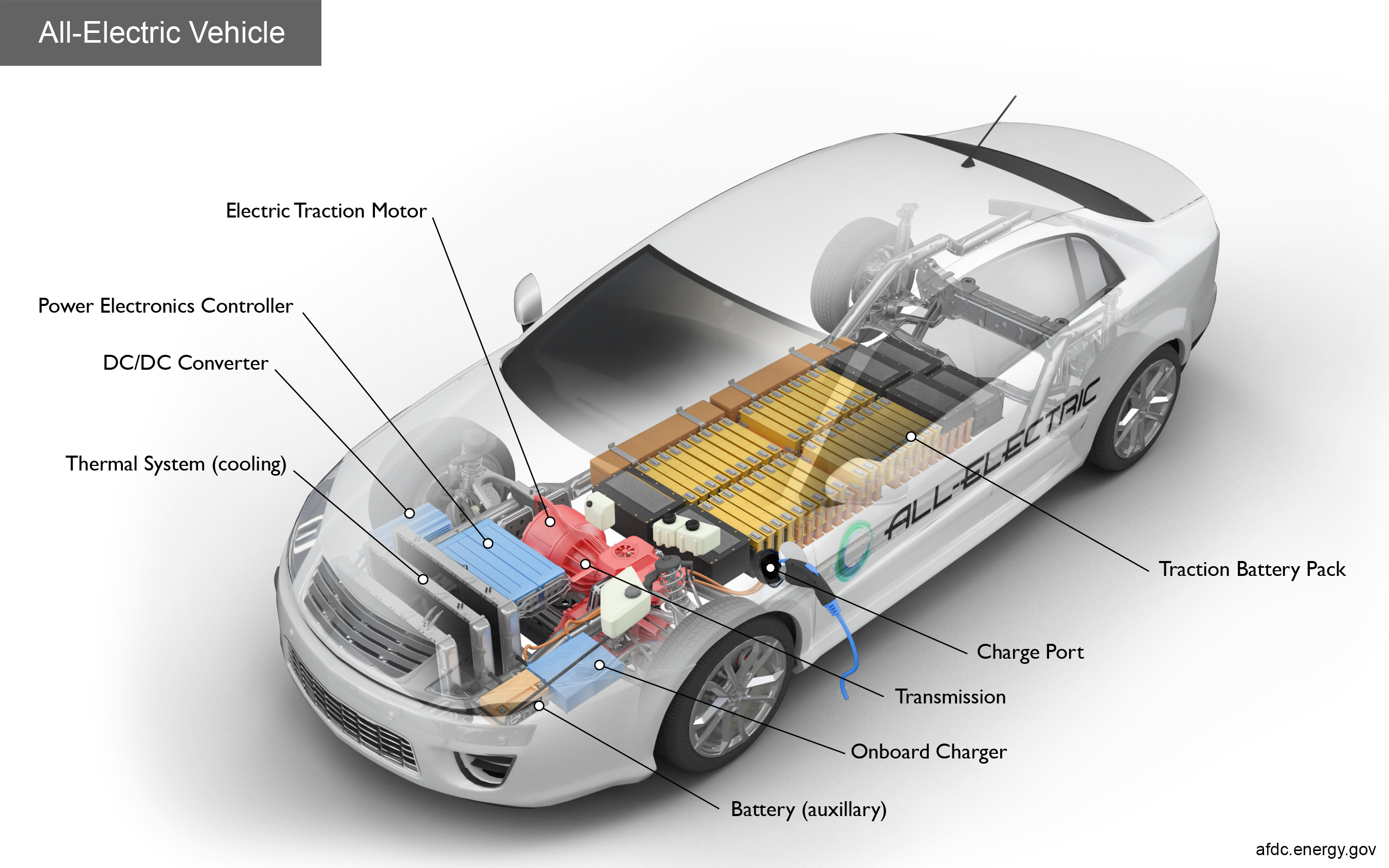

Electric vehicle (EV) modeling and simulation play a crucial role in the design and development of efficient and reliable EVs. To ensure accurate and effective modeling and simulation, several key considerations must be taken into account. These considerations include battery management, thermal management, and control systems, all of which are critical components of EV design.

Battery management is a critical aspect of EV modeling and simulation. The battery is the primary source of power for the vehicle, and its performance has a significant impact on the overall efficiency and range of the vehicle. When modeling and simulating EV batteries, it is essential to consider factors such as battery chemistry, state of charge, and depth of discharge. This information can be used to optimize battery performance, reduce energy consumption, and increase the overall efficiency of the vehicle.

Thermal management is another critical consideration in EV modeling and simulation. EVs generate a significant amount of heat, particularly in the battery and electric motor. If not properly managed, this heat can reduce the efficiency and lifespan of the vehicle’s components. When modeling and simulating EV thermal management systems, it is essential to consider factors such as heat transfer, cooling systems, and thermal interfaces. This information can be used to optimize thermal management system design, reduce energy consumption, and increase the overall efficiency of the vehicle.

Control systems are also a critical component of EV design, and must be carefully considered when modeling and simulating EVs. The control system is responsible for managing the flow of energy between the battery, electric motor, and other components. When modeling and simulating EV control systems, it is essential to consider factors such as control algorithms, sensor data, and actuator performance. This information can be used to optimize control system design, reduce energy consumption, and increase the overall efficiency of the vehicle.

In addition to these considerations, it is also essential to consider the integration of electric motor modeling and simulation into the overall EV design process. Electric motor modeling and simulation can be used to optimize motor performance, reduce energy consumption, and increase the overall efficiency of the vehicle. By integrating electric motor modeling and simulation into the EV design process, engineers can create more efficient, reliable, and sustainable vehicles.

By considering these key factors, engineers can create accurate and effective models and simulations of EVs, which can be used to optimize design, reduce energy consumption, and increase the overall efficiency of the vehicle. The use of advanced electric vehicle and electric motor modeling and simulation techniques can help to drive innovation in the EV industry, and play a critical role in achieving sustainable transportation goals.

Real-World Applications of Electric Motor Modeling and Simulation in Electric Vehicles

The use of electric motor modeling and simulation has become increasingly prevalent in the design and development of electric vehicles (EVs). Several successful EV projects have utilized advanced modeling and simulation techniques to optimize performance, reduce energy consumption, and increase overall efficiency. Two notable examples of such projects are the Tesla Model S and the Nissan Leaf.

The Tesla Model S is a luxury electric sedan that has been widely praised for its exceptional performance and range. Tesla’s engineers used advanced electric motor modeling and simulation techniques to optimize the design of the vehicle’s electric motor, resulting in a significant improvement in efficiency and range. The Model S’s electric motor is capable of producing 416 horsepower and 443 lb-ft of torque, making it one of the most powerful production electric vehicles on the market.

The Nissan Leaf is another successful EV that has utilized advanced modeling and simulation techniques. The Leaf’s electric motor is designed to provide exceptional efficiency and range, with a maximum output of 147 horsepower and 236 lb-ft of torque. Nissan’s engineers used simulation tools to optimize the design of the motor, resulting in a significant reduction in energy consumption and an increase in overall efficiency.

Other notable examples of successful EV projects that have utilized advanced modeling and simulation techniques include the Chevrolet Bolt, the BMW i3, and the Volkswagen e-Golf. These vehicles have all demonstrated exceptional performance and efficiency, thanks in part to the use of advanced electric motor modeling and simulation techniques.

The use of electric motor modeling and simulation in EV design has several benefits, including improved efficiency, reduced energy consumption, and increased overall performance. By optimizing the design of the electric motor, engineers can create vehicles that are more efficient, reliable, and sustainable. As the demand for EVs continues to grow, the use of advanced modeling and simulation techniques will become increasingly important in the design and development of these vehicles.

In addition to the benefits mentioned above, the use of electric motor modeling and simulation can also help to reduce the development time and cost of EVs. By using simulation tools to test and optimize the design of the electric motor, engineers can reduce the need for physical prototypes and minimize the risk of errors and rework. This can result in significant cost savings and a faster time-to-market for EV manufacturers.

Overall, the use of electric motor modeling and simulation has become a critical component of EV design and development. By leveraging advanced simulation tools and techniques, engineers can create vehicles that are more efficient, reliable, and sustainable, while also reducing development time and cost. As the EV industry continues to evolve, the importance of electric motor modeling and simulation will only continue to grow.

Overcoming Common Challenges in Electric Vehicle Modeling and Simulation

Electric vehicle (EV) modeling and simulation is a complex task that requires careful consideration of various factors, including battery management, thermal management, and control systems. However, despite the importance of EV modeling and simulation, engineers often face several challenges and limitations when working on EV projects. In this article, we will discuss some of the common challenges and limitations faced by engineers when modeling and simulating EVs, and provide tips on how to overcome them.

One of the biggest challenges faced by engineers when modeling and simulating EVs is complexity. EVs are complex systems that involve multiple components, including batteries, electric motors, and control systems. Modeling and simulating these components accurately can be a daunting task, especially for engineers who are new to EV design. To overcome this challenge, engineers can use simulation tools that are specifically designed for EV modeling and simulation, such as ANSYS and OpenFOAM. These tools provide a range of features and functionalities that can help engineers to model and simulate EV components accurately.

Scalability is another challenge faced by engineers when modeling and simulating EVs. As EVs become more complex and sophisticated, the need for scalable modeling and simulation tools becomes increasingly important. Engineers need to be able to model and simulate EV components at different scales, from individual components to entire systems. To overcome this challenge, engineers can use simulation tools that are designed to be scalable, such as MATLAB and Simulink. These tools provide a range of features and functionalities that can help engineers to model and simulate EV components at different scales.

Data accuracy is also a major challenge faced by engineers when modeling and simulating EVs. EVs generate a vast amount of data, including sensor data, battery data, and motor data. Engineers need to be able to collect, analyze, and interpret this data accurately in order to model and simulate EV components accurately. To overcome this challenge, engineers can use data analytics tools that are specifically designed for EV data analysis, such as Python and R. These tools provide a range of features and functionalities that can help engineers to collect, analyze, and interpret EV data accurately.

In addition to these challenges, engineers also face limitations when modeling and simulating EVs. One of the biggest limitations is the lack of standardization in EV modeling and simulation. There is currently no standardized approach to EV modeling and simulation, which can make it difficult for engineers to compare and validate their results. To overcome this limitation, engineers can use standardized modeling and simulation tools, such as the Society of Automotive Engineers (SAE) standards. These tools provide a range of features and functionalities that can help engineers to model and simulate EV components accurately and consistently.

Another limitation faced by engineers when modeling and simulating EVs is the lack of experimental validation. Experimental validation is critical to ensuring the accuracy and reliability of EV models and simulations. However, experimental validation can be time-consuming and expensive, especially for complex EV systems. To overcome this limitation, engineers can use experimental validation techniques that are specifically designed for EV systems, such as hardware-in-the-loop (HIL) testing. These techniques provide a range of features and functionalities that can help engineers to validate EV models and simulations accurately and efficiently.

In conclusion, EV modeling and simulation is a complex task that requires careful consideration of various factors, including battery management, thermal management, and control systems. Despite the importance of EV modeling and simulation, engineers often face several challenges and limitations when working on EV projects. By using simulation tools that are specifically designed for EV modeling and simulation, scalable modeling and simulation tools, data analytics tools, standardized modeling and simulation tools, and experimental validation techniques, engineers can overcome these challenges and limitations and create accurate and reliable EV models and simulations.

Best Practices for Validating Electric Vehicle Models and Simulation Results

Validating electric vehicle (EV) models and simulation results is crucial to ensure the accuracy and reliability of the design and development process. Validation involves comparing the simulation results with experimental data or real-world measurements to confirm that the model accurately represents the behavior of the EV. In this article, we will discuss the importance of validation and provide tips on how to ensure accuracy and reliability through experimental validation and data analysis.

Experimental validation is a critical step in the EV design and development process. It involves testing the EV under various operating conditions to collect data on its performance, efficiency, and reliability. This data is then compared with the simulation results to validate the accuracy of the model. Experimental validation can be performed using various techniques, including hardware-in-the-loop (HIL) testing, software-in-the-loop (SIL) testing, and vehicle testing.

Data analysis is also an essential step in the validation process. It involves analyzing the data collected during experimental validation to identify trends, patterns, and correlations. Data analysis can help to identify areas where the model needs to be improved or refined. Various data analysis techniques can be used, including statistical analysis, machine learning algorithms, and data visualization tools.

Best practices for validating EV models and simulation results include:

1. Use multiple validation methods: Use a combination of experimental validation and data analysis to validate the accuracy of the model.

2. Use high-quality data: Ensure that the data collected during experimental validation is accurate, reliable, and relevant to the EV design and development process.

3. Use advanced data analysis techniques: Use advanced data analysis techniques, such as machine learning algorithms and data visualization tools, to analyze the data and identify trends and patterns.

4. Validate the model at multiple levels: Validate the model at multiple levels, including component-level, system-level, and vehicle-level, to ensure that the model accurately represents the behavior of the EV.

5. Use standardized validation procedures: Use standardized validation procedures, such as those defined by the Society of Automotive Engineers (SAE), to ensure that the validation process is consistent and repeatable.

By following these best practices, engineers and researchers can ensure that their EV models and simulation results are accurate and reliable, which is critical for achieving sustainable transportation goals. The use of electric vehicle and electric motor modeling and simulation is becoming increasingly important in the EV industry, and validation is a critical step in ensuring the accuracy and reliability of these models.

In conclusion, validation is a critical step in the EV design and development process. By using experimental validation and data analysis, engineers and researchers can ensure that their EV models and simulation results are accurate and reliable. By following best practices for validation, engineers and researchers can ensure that their models are accurate, reliable, and relevant to the EV design and development process.

The Future of Electric Vehicle Modeling and Simulation: Trends and Opportunities

The field of electric vehicle (EV) modeling and simulation is rapidly evolving, driven by advances in technology, increasing demand for sustainable transportation, and the need for more efficient and reliable EV design and development processes. In this article, we will explore emerging trends and opportunities in EV modeling and simulation, including the integration of artificial intelligence (AI), machine learning (ML), and cloud computing.

One of the most significant trends in EV modeling and simulation is the increasing use of AI and ML algorithms. These algorithms can be used to optimize EV design and development processes, improve the accuracy of simulations, and reduce the time and cost associated with physical prototyping. For example, AI-powered simulation tools can be used to optimize EV battery design, predict battery life, and improve overall vehicle efficiency.

Cloud computing is another trend that is transforming the field of EV modeling and simulation. Cloud-based simulation platforms provide a scalable, flexible, and cost-effective way to perform complex simulations, collaborate with team members, and share results with stakeholders. Cloud computing also enables the use of high-performance computing (HPC) resources, which are essential for large-scale EV simulations.

The integration of AI, ML, and cloud computing is also enabling the development of more sophisticated EV modeling and simulation tools. For example, digital twin technology, which involves creating a virtual replica of a physical system, is being used to simulate EV behavior, predict maintenance needs, and optimize vehicle performance.

Other emerging trends in EV modeling and simulation include the use of advanced materials, such as graphene and nanomaterials, and the development of more efficient and sustainable EV battery technologies. These trends are driving innovation in the EV industry and enabling the creation of more efficient, reliable, and sustainable EVs.

The use of electric vehicle and electric motor modeling and simulation is becoming increasingly important in the EV industry, and the integration of AI, ML, and cloud computing is transforming the field. By leveraging these technologies, engineers and researchers can create more accurate and reliable EV models, optimize EV design and development processes, and drive innovation in the EV industry.

In addition to these trends, there are also several opportunities for innovation in EV modeling and simulation. For example, the development of more advanced EV battery technologies, such as solid-state batteries and lithium-air batteries, is driving the need for more sophisticated modeling and simulation tools. The integration of EVs with other systems, such as smart grids and renewable energy sources, is also creating new opportunities for innovation in EV modeling and simulation.

In conclusion, the field of EV modeling and simulation is rapidly evolving, driven by advances in technology, increasing demand for sustainable transportation, and the need for more efficient and reliable EV design and development processes. The integration of AI, ML, and cloud computing is transforming the field, and there are several opportunities for innovation in EV modeling and simulation. By leveraging these technologies and trends, engineers and researchers can drive innovation in the EV industry and create more efficient, reliable, and sustainable EVs.

Maximizing the Potential of Electric Vehicle Modeling and Simulation for Sustainable Transportation

The use of electric vehicle (EV) modeling and simulation is critical to achieving sustainable transportation goals. By leveraging advanced modeling and simulation techniques, engineers and researchers can design and develop more efficient, reliable, and sustainable EVs. In this article, we will emphasize the critical role of EV modeling and simulation in achieving sustainable transportation goals and encourage engineers and researchers to continue pushing the boundaries of innovation in this field.

Sustainable transportation is a critical component of a sustainable future. The transportation sector is one of the largest contributors to greenhouse gas emissions, and the widespread adoption of EVs is seen as a key strategy for reducing these emissions. However, the development of EVs is a complex task that requires careful consideration of multiple factors, including battery management, thermal management, and control systems.

EV modeling and simulation is a powerful tool for optimizing EV design and development processes. By using advanced modeling and simulation techniques, engineers and researchers can simulate the behavior of EVs under various operating conditions, optimize EV performance, and reduce the time and cost associated with physical prototyping. The use of EV modeling and simulation can also help to improve the accuracy of EV simulations, reduce the risk of errors and rework, and increase the overall efficiency of the EV design and development process.

The integration of artificial intelligence (AI), machine learning (ML), and cloud computing is also transforming the field of EV modeling and simulation. These technologies can be used to optimize EV design and development processes, improve the accuracy of simulations, and reduce the time and cost associated with physical prototyping. The use of AI, ML, and cloud computing can also help to improve the scalability and flexibility of EV modeling and simulation tools, enabling engineers and researchers to simulate complex EV systems and optimize EV performance.

In addition to the benefits mentioned above, the use of EV modeling and simulation can also help to reduce the environmental impact of EVs. By optimizing EV design and development processes, engineers and researchers can reduce the energy consumption and emissions associated with EV production and operation. The use of EV modeling and simulation can also help to improve the recyclability and reusability of EV components, reducing the waste and pollution associated with EV production and disposal.

In conclusion, the use of electric vehicle and electric motor modeling and simulation is critical to achieving sustainable transportation goals. By leveraging advanced modeling and simulation techniques, engineers and researchers can design and develop more efficient, reliable, and sustainable EVs. The integration of AI, ML, and cloud computing is also transforming the field of EV modeling and simulation, enabling engineers and researchers to simulate complex EV systems and optimize EV performance. As the demand for sustainable transportation continues to grow, the use of EV modeling and simulation will become increasingly important, and engineers and researchers must continue to push the boundaries of innovation in this field.

By emphasizing the critical role of EV modeling and simulation in achieving sustainable transportation goals, we hope to encourage engineers and researchers to continue pushing the boundaries of innovation in this field. The use of EV modeling and simulation has the potential to transform the transportation sector, enabling the widespread adoption of sustainable and efficient EVs. As the demand for sustainable transportation continues to grow, the use of EV modeling and simulation will become increasingly important, and engineers and researchers must be prepared to meet this challenge.