Understanding the Sources of Electric Vehicle Noise

Electric vehicles (EVs) are becoming increasingly popular due to their environmental benefits and lower operating costs. However, one of the challenges facing the widespread adoption of EVs is noise reduction. Electric vehicle and electric motor noise reduction are crucial for improving passenger comfort, reducing noise pollution, and enhancing the overall driving experience. To address this issue, it is essential to understand the main sources of noise in electric vehicles.

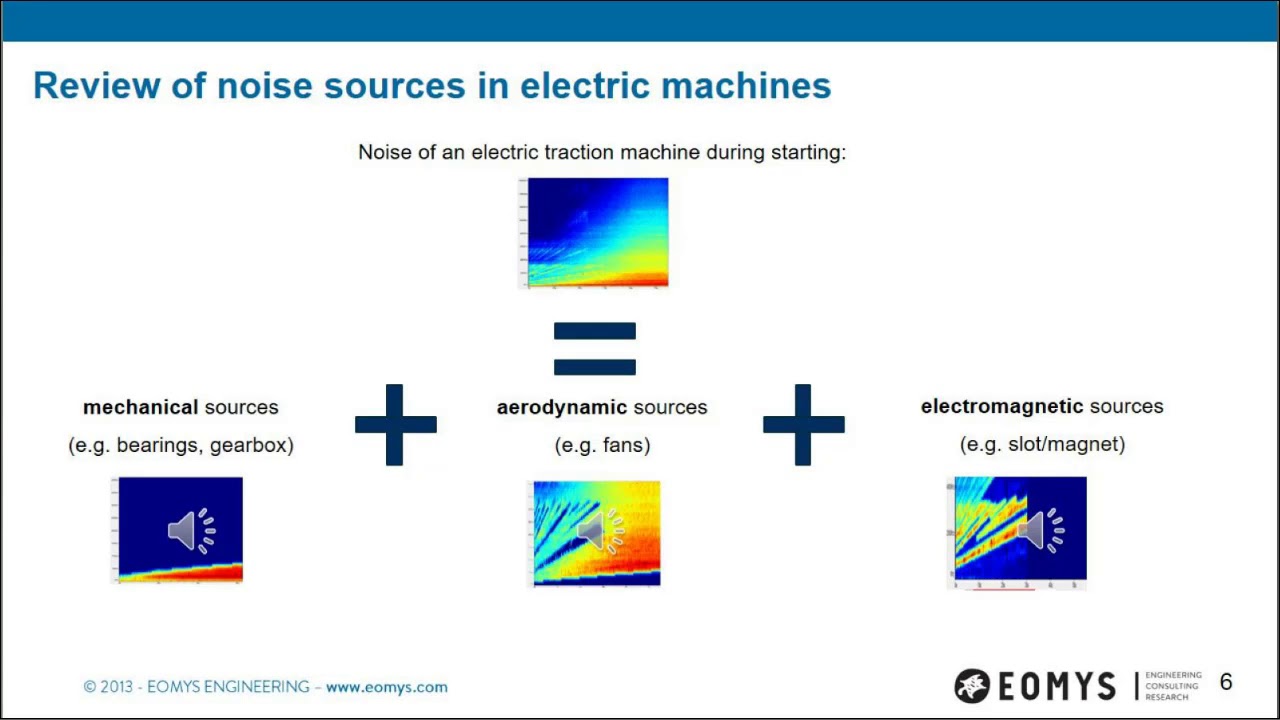

The primary sources of noise in EVs can be broadly categorized into three main areas: the electric motor, gearbox, and external factors. The electric motor is a significant contributor to noise levels, particularly at high speeds. The motor’s electromagnetic forces, magnetic field fluctuations, and mechanical vibrations all generate noise. Additionally, the gearbox and transmission system can produce noise due to gear meshing, bearing vibrations, and other mechanical interactions.

External factors, such as road surface and wind resistance, also play a significant role in determining the overall noise level of an electric vehicle. Road surface irregularities, such as potholes and bumps, can cause the vehicle’s suspension and tires to vibrate, generating noise. Similarly, wind resistance can create aerodynamic noise, particularly at high speeds. Understanding these sources of noise is critical for developing effective noise reduction strategies for electric vehicles.

Electric motor noise reduction is a key area of focus for EV manufacturers, as it can significantly impact the overall noise level of the vehicle. By optimizing motor design, materials, and control systems, manufacturers can reduce noise levels and improve the driving experience. Furthermore, advancements in gearbox and transmission technology can also contribute to reduced noise levels. By addressing these sources of noise, EV manufacturers can create a more comfortable and enjoyable driving experience for passengers.

The Importance of Noise Reduction in Electric Vehicles

Noise reduction is a critical aspect of electric vehicle (EV) design, as it directly impacts the overall driving experience, passenger comfort, and environmental sustainability. Electric vehicle and electric motor noise reduction are essential for minimizing the negative effects of noise pollution on both human health and the environment. By reducing noise levels, EV manufacturers can create a more comfortable and enjoyable driving experience for passengers, while also contributing to a quieter and more sustainable transportation ecosystem.

One of the primary reasons why noise reduction is crucial in EVs is the impact on passenger comfort. Excessive noise levels can cause fatigue, stress, and discomfort, ultimately affecting the overall driving experience. By reducing noise levels, EV manufacturers can create a more peaceful and relaxing environment for passengers, making long trips more enjoyable and reducing driver fatigue. Additionally, noise reduction can also improve the overall sound quality of the vehicle, enhancing the listening experience for passengers.

Noise reduction also plays a significant role in reducing noise pollution, which is a growing concern in urban areas. Electric vehicles are generally quieter than their internal combustion engine counterparts, but they can still generate significant noise levels, particularly at high speeds. By implementing effective noise reduction technologies, EV manufacturers can minimize the impact of noise pollution on the environment and contribute to a more sustainable transportation system.

Furthermore, noise reduction can also impact the performance and efficiency of electric vehicles. By reducing noise levels, EV manufacturers can minimize the energy lost due to noise generation, resulting in improved efficiency and range. Additionally, noise reduction can also enable the use of more efficient electric motor designs, which can further improve the overall performance and efficiency of the vehicle.

In conclusion, noise reduction is a critical aspect of electric vehicle design, with significant impacts on passenger comfort, environmental sustainability, and vehicle performance. By prioritizing electric vehicle and electric motor noise reduction, manufacturers can create a more comfortable, sustainable, and efficient transportation system for the future.

How to Reduce Electric Motor Noise: Advanced Materials and Designs

Electric motor noise reduction is a critical aspect of electric vehicle (EV) design, as it directly impacts the overall noise level of the vehicle. To address this challenge, researchers and manufacturers have been exploring advanced materials and designs that can help reduce electric motor noise. One of the most promising approaches is the use of magnetic bearings, which can significantly reduce the noise generated by the motor’s electromagnetic forces.

Another innovative technology is the use of advanced winding configurations, such as the hairpin winding or the wave winding. These configurations can help reduce the noise generated by the motor’s electrical currents, resulting in a quieter and more efficient motor. Additionally, optimized motor geometries, such as the use of skewed or angled magnets, can also help reduce noise levels by minimizing the motor’s electromagnetic forces.

Recent advancements in materials science have also led to the development of new materials that can help reduce electric motor noise. For example, the use of advanced magnetic materials, such as neodymium iron boron (NdFeB) or samarium cobalt (SmCo), can help reduce the motor’s electromagnetic forces and resulting noise levels. Similarly, the use of advanced insulation materials, such as ceramic or glass fiber, can help reduce the noise generated by the motor’s electrical currents.

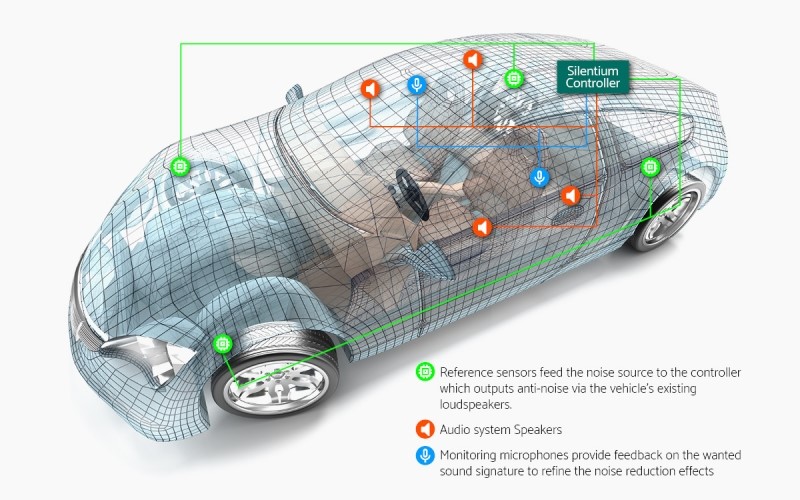

Furthermore, researchers have also been exploring the use of active noise control (ANC) systems to reduce electric motor noise. ANC systems use sensors and actuators to detect and cancel out noise waves, resulting in a quieter and more efficient motor. While ANC systems are still in the early stages of development, they hold great promise for reducing electric motor noise in EVs.

In addition to these advanced materials and designs, manufacturers are also exploring new manufacturing techniques to reduce electric motor noise. For example, the use of 3D printing or additive manufacturing can help create complex motor geometries that can reduce noise levels. Similarly, the use of advanced machining techniques, such as grinding or milling, can help create smooth and precise motor surfaces that can reduce noise levels.

Active Noise Cancellation Systems for Electric Vehicles

Active noise cancellation (ANC) systems are a promising technology for reducing noise levels in electric vehicles (EVs). ANC systems use sensors and actuators to detect and cancel out noise waves, resulting in a quieter and more efficient motor. This technology has been widely used in the aerospace and industrial sectors, but its application in EVs is still in its early stages.

The concept of ANC is based on the principle of destructive interference, where a secondary noise wave is generated to cancel out the primary noise wave. In the context of EVs, ANC systems can be used to reduce the noise generated by the electric motor, gearbox, and other components. By detecting the noise waves and generating a secondary wave to cancel them out, ANC systems can significantly reduce the overall noise level of the vehicle.

One of the benefits of ANC systems is their ability to adapt to changing noise conditions. Unlike passive noise reduction technologies, which rely on fixed designs and materials, ANC systems can adjust to different noise frequencies and levels in real-time. This makes them particularly effective in reducing noise levels in EVs, which can vary depending on factors such as speed, load, and road conditions.

However, ANC systems also have some limitations. One of the main challenges is the complexity of the system, which requires sophisticated sensors, actuators, and control algorithms to function effectively. Additionally, ANC systems can be energy-intensive, which can impact the overall efficiency of the vehicle. Nevertheless, the benefits of ANC systems in reducing noise levels and improving overall sound quality make them an attractive solution for EV manufacturers.

Several EV manufacturers have already started exploring the use of ANC systems in their vehicles. For example, the Tesla Model S uses an ANC system to reduce the noise generated by the electric motor, resulting in a quieter and more comfortable driving experience. Similarly, the BMW i3 uses an ANC system to reduce the noise generated by the gearbox and other components, resulting in a smoother and more efficient ride.

Real-World Examples: Electric Vehicles with Advanced Noise Reduction Features

Several electric vehicle (EV) manufacturers have already implemented advanced noise reduction features in their vehicles. One notable example is the Tesla Model S, which uses a combination of active noise cancellation (ANC) and passive noise reduction technologies to minimize noise levels. The Model S’s ANC system uses sensors and actuators to detect and cancel out noise waves, resulting in a quieter and more comfortable driving experience.

Another example is the BMW i3, which uses a unique sound-absorbing material in its interior to reduce noise levels. The i3’s sound-absorbing material is designed to absorb sound waves, rather than reflecting them, resulting in a quieter and more peaceful driving experience. Additionally, the i3’s electric motor is designed to be quieter than traditional internal combustion engines, resulting in a more comfortable and enjoyable driving experience.

The Nissan Leaf is another example of an EV that has implemented advanced noise reduction features. The Leaf uses a combination of ANC and passive noise reduction technologies to minimize noise levels. The Leaf’s ANC system uses sensors and actuators to detect and cancel out noise waves, resulting in a quieter and more comfortable driving experience. Additionally, the Leaf’s electric motor is designed to be quieter than traditional internal combustion engines, resulting in a more comfortable and enjoyable driving experience.

These examples demonstrate the effectiveness of advanced noise reduction technologies in reducing noise levels in EVs. By implementing these technologies, EV manufacturers can create a more comfortable and enjoyable driving experience for their customers, while also reducing noise pollution and improving overall sound quality.

In addition to these examples, other EV manufacturers are also exploring the use of advanced noise reduction technologies in their vehicles. For example, the Hyundai Kona Electric uses a combination of ANC and passive noise reduction technologies to minimize noise levels. The Kona Electric’s ANC system uses sensors and actuators to detect and cancel out noise waves, resulting in a quieter and more comfortable driving experience.

Challenges and Future Directions in Electric Vehicle Noise Reduction

Despite the advancements in electric vehicle (EV) noise reduction technologies, there are still several challenges and limitations that need to be addressed. One of the main challenges is the complexity of EV noise reduction, which requires a deep understanding of the various sources of noise and their interactions. Additionally, the development of effective noise reduction technologies requires significant investment in research and development, which can be a barrier for some manufacturers.

Another challenge is the trade-off between noise reduction and other performance metrics, such as efficiency and cost. For example, some noise reduction technologies may require additional components or materials, which can increase the weight and cost of the vehicle. Therefore, manufacturers must carefully balance the benefits of noise reduction with other performance metrics to ensure that their vehicles meet the needs of their customers.

Despite these challenges, there are several future directions that hold promise for EV noise reduction. One area of research is the development of new materials and technologies that can reduce noise levels while also improving other performance metrics. For example, researchers are exploring the use of advanced composites and nanomaterials to reduce noise levels while also improving the efficiency and durability of EVs.

Another area of research is the development of more sophisticated noise reduction algorithms and control systems. These systems can use advanced sensors and machine learning algorithms to detect and reduce noise levels in real-time, resulting in a more comfortable and enjoyable driving experience. Additionally, these systems can also be used to optimize other performance metrics, such as efficiency and cost.

Finally, there is a growing trend towards the use of electric vehicles in urban areas, where noise pollution is a significant concern. Therefore, there is a need for EV manufacturers to develop noise reduction technologies that are specifically designed for urban environments. This may include the use of advanced noise reduction materials and technologies, as well as the development of more sophisticated noise reduction algorithms and control systems.

Optimizing Electric Vehicle Noise Reduction through Simulation and Testing

Simulation and testing are crucial steps in optimizing electric vehicle (EV) noise reduction. By using computer-aided engineering (CAE) tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), engineers can simulate and predict noise levels in EVs. This allows them to identify areas of high noise levels and optimize the design of the vehicle to reduce noise.

FEA is a powerful tool for simulating the behavior of complex systems, such as EVs. By creating a detailed model of the vehicle, engineers can simulate the effects of different design changes on noise levels. For example, they can simulate the effect of changing the shape of the vehicle’s body or the design of the electric motor on noise levels.

CFD is another important tool for simulating EV noise levels. By simulating the flow of air around the vehicle, engineers can predict the noise levels generated by the vehicle’s aerodynamics. This allows them to optimize the design of the vehicle’s body and aerodynamics to reduce noise levels.

In addition to simulation, testing is also an important step in optimizing EV noise reduction. By testing the vehicle in a controlled environment, engineers can measure the actual noise levels generated by the vehicle and compare them to the simulated results. This allows them to refine the design of the vehicle and optimize noise reduction.

Several EV manufacturers have already adopted simulation and testing as part of their noise reduction strategies. For example, Tesla uses FEA and CFD to simulate and predict noise levels in their vehicles. They also conduct extensive testing to validate the results and refine the design of their vehicles.

By combining simulation and testing, EV manufacturers can optimize noise reduction and create a more comfortable and enjoyable driving experience for their customers. This approach also allows them to reduce the time and cost associated with traditional testing methods, making it a more efficient and effective way to develop noise reduction technologies.

Regulatory Frameworks and Standards for Electric Vehicle Noise Reduction

Regulatory frameworks and standards play a crucial role in governing electric vehicle (EV) noise reduction. In the European Union (EU), the European Commission has established regulations for EV noise reduction, including the EU’s Noise Directive (2002/49/EC). This directive sets limits for the maximum permissible noise levels for EVs, and manufacturers must comply with these limits to ensure that their vehicles meet EU regulations.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has established regulations for EV noise reduction, including the Federal Motor Vehicle Safety Standard (FMVSS) 141. This standard sets limits for the maximum permissible noise levels for EVs, and manufacturers must comply with these limits to ensure that their vehicles meet US regulations.

Additionally, the International Organization for Standardization (ISO) has established standards for EV noise reduction, including ISO 362-1:2015. This standard provides guidelines for measuring and evaluating the noise levels of EVs, and manufacturers can use this standard to ensure that their vehicles meet international noise reduction standards.

These regulatory frameworks and standards impact the development and implementation of noise reduction technologies in EVs. Manufacturers must ensure that their vehicles comply with these regulations, which can drive innovation and investment in noise reduction technologies. Additionally, these regulations can help to ensure that EVs are designed and manufactured with noise reduction in mind, which can improve the overall driving experience for consumers.

Furthermore, regulatory frameworks and standards can also influence consumer behavior and market trends. For example, consumers may be more likely to purchase EVs that meet or exceed noise reduction standards, which can drive demand for noise reduction technologies. Additionally, manufacturers may be more likely to invest in noise reduction technologies if they are required to meet regulatory standards.

In conclusion, regulatory frameworks and standards play a crucial role in governing EV noise reduction. By understanding these regulations and standards, manufacturers can ensure that their vehicles meet or exceed noise reduction requirements, which can improve the overall driving experience for consumers and drive innovation and investment in noise reduction technologies.