Mastering the Fundamentals of Electric Motor Management

Effective electric motor management is crucial for optimizing electric vehicle performance, efficiency, and overall driving experience. Electric motors are the heart of electric vehicles, converting electrical energy into mechanical energy to propel the vehicle forward. However, electric motor management is a complex task that requires a deep understanding of the underlying technology and its key factors.

Electric motor performance is influenced by several factors, including temperature, vibration, and power output. Temperature, in particular, plays a critical role in determining electric motor efficiency and lifespan. High temperatures can lead to reduced motor efficiency, increased energy consumption, and premature wear and tear. On the other hand, optimal temperature management can significantly improve motor performance, reduce energy consumption, and extend motor lifespan.

Electric vehicle manufacturers have developed various strategies to manage electric motor temperature, including the use of advanced cooling systems, thermal management materials, and sophisticated control algorithms. These strategies enable electric vehicles to maintain optimal motor temperatures, even in extreme driving conditions, ensuring optimal performance, efficiency, and reliability.

In addition to temperature management, electric motor management also involves monitoring and controlling other key factors, such as vibration, power output, and energy consumption. Advanced sensors and control systems are used to monitor these factors in real-time, enabling electric vehicles to optimize motor performance, reduce energy consumption, and minimize wear and tear.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By mastering the fundamentals of electric motor management, electric vehicle manufacturers can create vehicles that are not only efficient and reliable but also provide a superior driving experience. As the electric vehicle market continues to grow, the importance of effective electric motor management will only continue to increase, driving innovation and advancements in this critical area of electric vehicle technology.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance of electric motor health are crucial for ensuring optimal performance, efficiency, and reliability of electric vehicles. Neglecting motor health can lead to reduced performance, increased energy consumption, and premature wear and tear, ultimately affecting the overall driving experience.

To monitor electric motor health, it is essential to track key parameters such as temperature, vibration, and power output. Temperature monitoring is critical, as excessive heat can damage motor components and reduce efficiency. Vibration monitoring helps detect imbalances or misalignments that can cause motor damage or reduced performance. Power output monitoring ensures that the motor is operating within its designed specifications.

A step-by-step guide to monitoring electric motor health includes:

- Installing temperature sensors to track motor temperature in real-time

- Using vibration sensors to detect motor imbalances or misalignments

- Monitoring power output to ensure optimal motor performance

- Performing regular motor inspections to detect signs of wear and tear

- Updating motor software and firmware to ensure optimal performance and efficiency

In addition to monitoring, regular maintenance is essential for ensuring electric motor health. This includes:

- Performing routine motor cleaning to prevent dust and debris buildup

- Lubricating motor components to reduce friction and wear

- Replacing worn or damaged motor components to prevent further damage

- Updating motor control systems to ensure optimal performance and efficiency

By following these steps, electric vehicle owners and operators can ensure optimal electric motor health, reducing the risk of premature wear and tear, and maintaining optimal performance and efficiency. Effective electric vehicle and electric motor operations management is critical for ensuring a superior driving experience, and regular monitoring and maintenance are essential for achieving this goal.

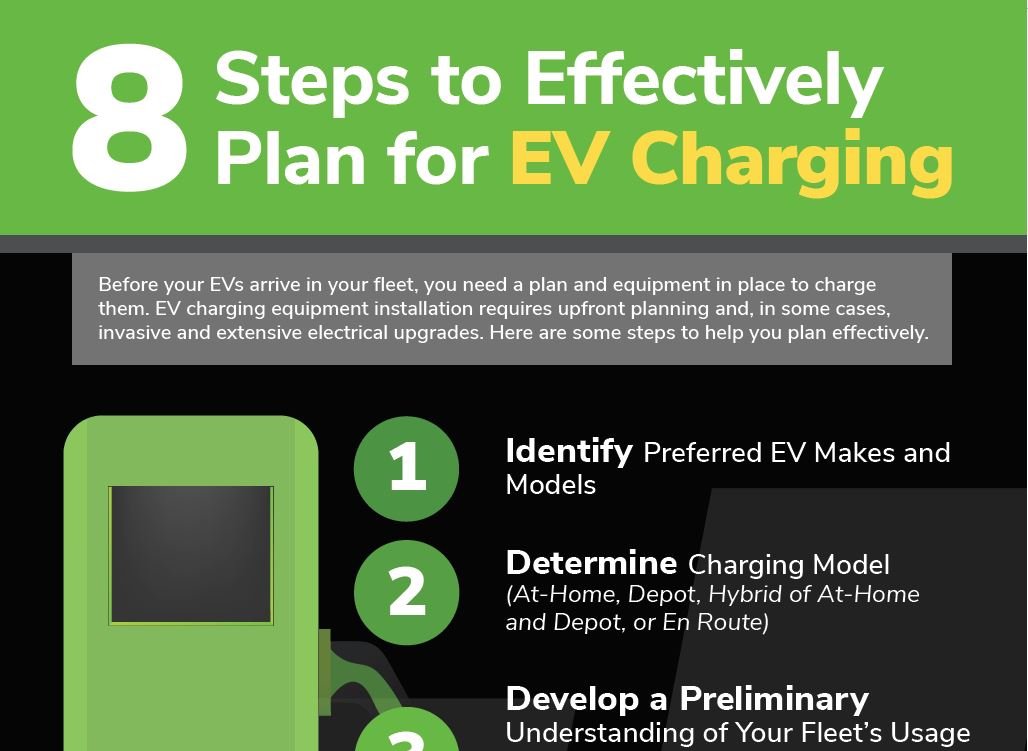

Electric Vehicle Charging Strategies for Optimal Motor Performance

Electric vehicle charging strategies play a crucial role in optimizing motor performance, efficiency, and overall driving experience. Different charging methods can significantly impact motor performance, and understanding the benefits and drawbacks of each method is essential for effective electric vehicle and electric motor operations management.

Level 1 charging is the slowest and most basic method, using a standard 120-volt household outlet to charge the vehicle. This method is suitable for overnight charging at home but is not ideal for frequent or long-distance driving. Level 2 charging, on the other hand, uses a 240-volt charging station and can charge the vehicle up to 5 times faster than Level 1. This method is more suitable for frequent or long-distance driving but requires a dedicated charging station.

DC Fast Charging is the fastest method, using a high-power charging station to charge the vehicle to 80% in under 30 minutes. This method is ideal for long-distance driving and is becoming increasingly popular along highways and intercity routes. However, DC Fast Charging can generate excessive heat, which can impact motor performance and efficiency if not properly managed.

Other charging strategies, such as regenerative braking and opportunistic charging, can also impact motor performance. Regenerative braking captures kinetic energy and converts it into electrical energy, which can be used to charge the vehicle’s battery. Opportunistic charging involves charging the vehicle during periods of low energy demand, such as during off-peak hours or when renewable energy sources are available.

When selecting a charging strategy, it is essential to consider factors such as driving habits, vehicle type, and charging infrastructure. Effective electric vehicle and electric motor operations management requires a deep understanding of the complex interactions between charging strategies, motor performance, and overall driving experience. By choosing the right charging strategy, electric vehicle owners and operators can optimize motor performance, reduce energy consumption, and enhance the overall driving experience.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric motor operations, as excessive heat can significantly impact motor efficiency, performance, and lifespan. Electric motors generate heat due to electrical resistance, friction, and other losses, which can lead to reduced efficiency, increased energy consumption, and premature wear and tear.

To mitigate these effects, various thermal management techniques are employed in electric vehicles. Air-cooling is a common method, using fans or blowers to circulate air through the motor and dissipate heat. However, air-cooling has limitations, particularly in high-performance applications or extreme environments.

Liquid-cooling is a more effective method, using a coolant to absorb heat from the motor and transfer it to a radiator or heat exchanger. This method is widely used in electric vehicles, offering improved thermal management and increased motor efficiency. However, liquid-cooling systems can be complex and require careful design and implementation.

Heat pipes are another thermal management technique, using a sealed tube filled with a working fluid to transfer heat from the motor to a radiator or heat exchanger. Heat pipes offer high thermal conductivity and can be used in a variety of applications, including electric vehicles.

In addition to these techniques, advanced materials and designs are being developed to improve thermal management in electric motors. These include the use of high-temperature superconductors, advanced composites, and optimized motor geometries.

Effective thermal management is essential for optimizing electric motor efficiency, performance, and lifespan. By employing advanced thermal management techniques, electric vehicle manufacturers can improve overall vehicle efficiency, reduce energy consumption, and enhance the driving experience. As electric vehicle technology continues to evolve, thermal management will play an increasingly important role in electric vehicle and electric motor operations management.

Electric Motor Control Systems: Understanding the Technology

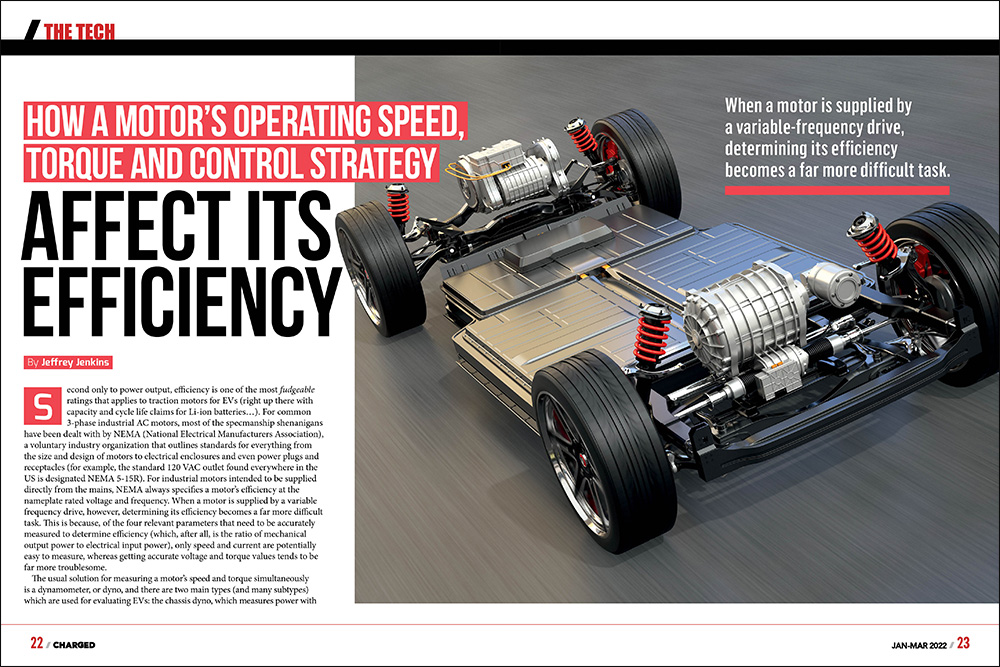

Electric motor control systems play a crucial role in optimizing electric vehicle performance, efficiency, and overall driving experience. These systems enable the efficient control of electric motors, ensuring optimal performance, reduced energy consumption, and extended motor lifespan.

Power electronics are a key component of electric motor control systems, responsible for converting DC power from the battery to AC power for the motor. Motor controllers, also known as inverters, use sophisticated algorithms to control the flow of electrical energy to the motor, optimizing performance and efficiency.

Software is also a critical component of electric motor control systems, enabling the implementation of advanced control strategies and optimization techniques. These systems can be programmed to optimize motor performance, reduce energy consumption, and extend motor lifespan.

There are several types of electric motor control systems, including scalar control, vector control, and field-oriented control. Scalar control is a basic control strategy that uses a fixed frequency and voltage to control the motor. Vector control, on the other hand, uses a more advanced algorithm to control the motor, optimizing performance and efficiency.

Field-oriented control is a more advanced control strategy that uses a combination of scalar and vector control to optimize motor performance and efficiency. This control strategy is widely used in electric vehicles, offering improved performance, efficiency, and reliability.

Electric motor control systems are a critical component of electric vehicle and electric motor operations management. By understanding the technology and principles behind these systems, electric vehicle manufacturers can optimize motor performance, reduce energy consumption, and enhance the overall driving experience.

Real-World Examples: Electric Vehicle Motor Operations in Practice

Electric vehicle motor operations are a critical component of electric vehicle performance, efficiency, and overall driving experience. Several manufacturers have successfully implemented electric vehicle motor operations management strategies, resulting in improved performance, efficiency, and reliability.

Tesla, for example, has developed a sophisticated electric motor control system that enables optimal performance, efficiency, and reliability. The company’s electric motor control system uses advanced algorithms and machine learning techniques to optimize motor performance, reduce energy consumption, and extend motor lifespan.

Nissan has also implemented a successful electric vehicle motor operations management strategy, focusing on the development of advanced electric motor control systems and thermal management techniques. The company’s electric motor control system uses a combination of scalar and vector control to optimize motor performance, efficiency, and reliability.

BMW has also made significant advancements in electric vehicle motor operations management, developing a sophisticated electric motor control system that enables optimal performance, efficiency, and reliability. The company’s electric motor control system uses advanced algorithms and machine learning techniques to optimize motor performance, reduce energy consumption, and extend motor lifespan.

These real-world examples demonstrate the importance of effective electric vehicle motor operations management in achieving optimal performance, efficiency, and reliability. By implementing advanced electric motor control systems, thermal management techniques, and other strategies, manufacturers can improve the overall driving experience, reduce energy consumption, and extend motor lifespan.

Electric vehicle and electric motor operations management is a critical component of electric vehicle performance, efficiency, and overall driving experience. By understanding the strategies and techniques used by successful manufacturers, electric vehicle owners and operators can optimize motor performance, reduce energy consumption, and enhance the overall driving experience.

Future Developments in Electric Motor Technology

The electric motor technology is rapidly evolving, with advancements in materials, design, and manufacturing. These developments have the potential to significantly impact electric vehicle performance, efficiency, and overall driving experience.

One of the most promising developments is the use of advanced materials, such as high-temperature superconductors and advanced composites. These materials can improve motor efficiency, reduce weight, and increase power density, leading to improved electric vehicle performance and efficiency.

Another area of development is the use of advanced design techniques, such as 3D printing and computer-aided design. These techniques can enable the creation of complex motor geometries and optimized motor designs, leading to improved performance and efficiency.

Manufacturing advancements, such as the use of robotics and automation, can also improve motor production efficiency and reduce costs. This can make electric vehicles more affordable and accessible to a wider range of consumers.

The integration of electric motors with other vehicle systems, such as the battery management system and the power electronics, is also an area of ongoing development. This integration can enable the creation of more efficient and optimized vehicle systems, leading to improved electric vehicle performance and efficiency.

Finally, the development of new motor technologies, such as the use of axial flux motors and transverse flux motors, is also underway. These motors have the potential to offer improved performance, efficiency, and reliability, and could play a key role in the future of electric vehicle technology.

Electric vehicle and electric motor operations management will continue to play a critical role in the development and implementation of these new technologies. By understanding the latest developments and advancements in electric motor technology, electric vehicle manufacturers and operators can optimize motor performance, reduce energy consumption, and enhance the overall driving experience.

Best Practices for Electric Vehicle Motor Operations Management

Effective electric vehicle motor operations management is critical for optimizing motor performance, reducing energy consumption, and enhancing the overall driving experience. By following best practices, electric vehicle manufacturers and operators can ensure efficient and effective motor operations.

Monitoring is a critical aspect of electric vehicle motor operations management. Regular monitoring of motor temperature, vibration, and power output can help identify potential issues before they become major problems. This can be achieved through the use of advanced sensors and data analytics.

Maintenance is also essential for electric vehicle motor operations management. Regular maintenance can help prevent motor damage, reduce energy consumption, and extend motor lifespan. This can include tasks such as cleaning, lubricating, and replacing motor components.

Optimization is also important for electric vehicle motor operations management. By optimizing motor performance, electric vehicle manufacturers and operators can reduce energy consumption, improve efficiency, and enhance the overall driving experience. This can be achieved through the use of advanced algorithms and machine learning techniques.

A comprehensive checklist for electric vehicle motor operations management should include:

- Regular monitoring of motor temperature, vibration, and power output

- Regular maintenance, including cleaning, lubricating, and replacing motor components

- Optimization of motor performance using advanced algorithms and machine learning techniques

- Use of advanced sensors and data analytics to identify potential issues

- Implementation of thermal management techniques to maintain optimal operating temperatures

By following these best practices, electric vehicle manufacturers and operators can ensure efficient and effective motor operations, optimizing motor performance, reducing energy consumption, and enhancing the overall driving experience.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle technology. By understanding the best practices for motor operations management, electric vehicle manufacturers and operators can optimize motor performance, reduce energy consumption, and enhance the overall driving experience.