Mastering the Fundamentals of Electric Motor Management

Electric motor management is a critical aspect of electric vehicle (EV) performance, efficiency, and lifespan. As the demand for EVs continues to grow, understanding the intricacies of electric motor operations has become increasingly important. Effective electric motor management can optimize EV performance, reduce energy consumption, and extend the lifespan of the motor. In this article, we will delve into the fundamentals of electric motor management and explore the key concepts that underpin efficient electric vehicle and electric motor operations management.

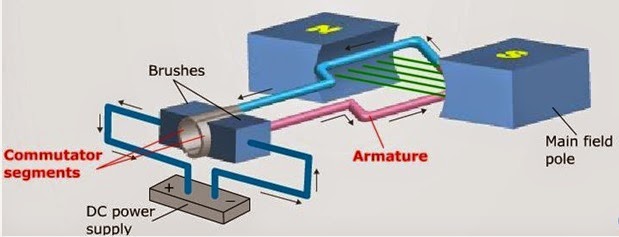

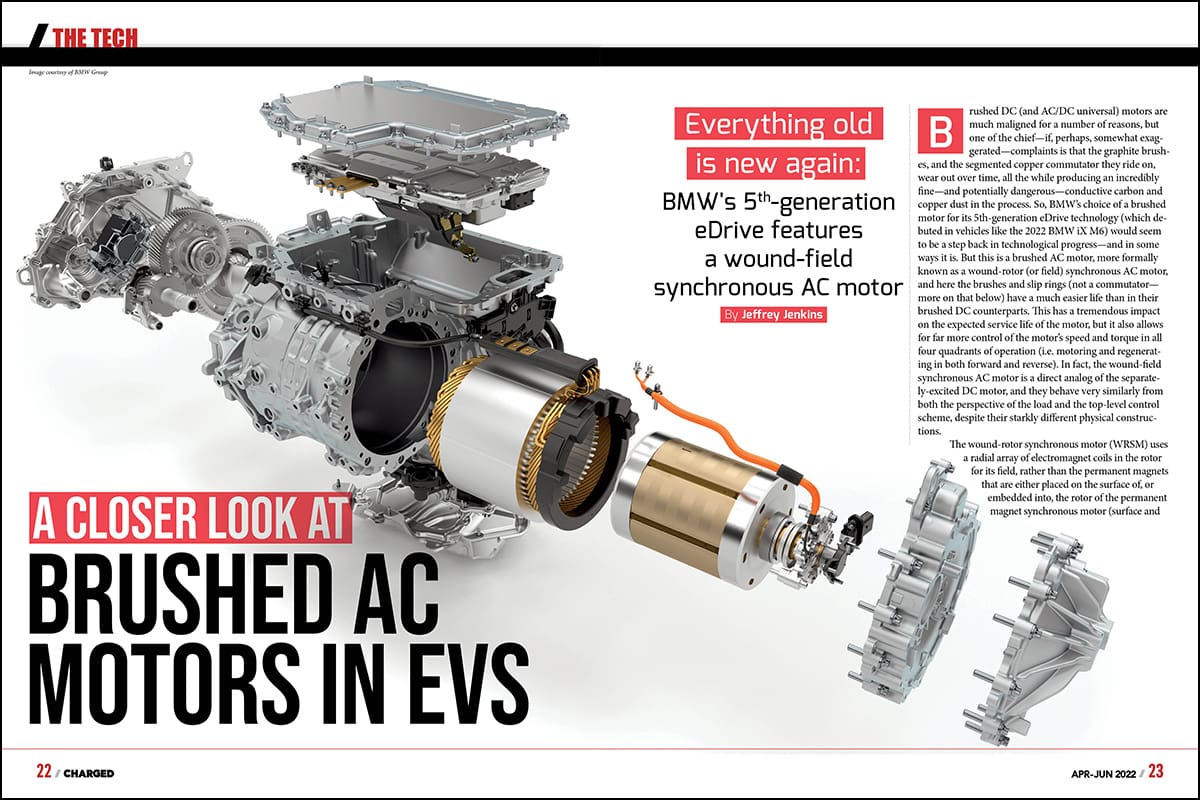

Electric motors are the heart of EVs, converting electrical energy into mechanical energy to propel the vehicle. There are several types of electric motors used in EVs, including induction motors, permanent magnet motors, and switched reluctance motors. Each type of motor has its unique characteristics, advantages, and disadvantages. Understanding the differences between these motor types is essential for optimizing EV performance and efficiency.

In addition to motor type, electric motor management also involves understanding motor configurations and control systems. Motor configurations refer to the arrangement of the motor, gearbox, and other components that work together to optimize EV performance. Control systems, on the other hand, refer to the electronic systems that regulate motor speed, torque, and direction. Advanced control systems, such as vector control and field-oriented control, can significantly improve EV performance and efficiency.

Electric vehicle and electric motor operations management is a complex field that requires a deep understanding of electric motor fundamentals, configurations, and control systems. By mastering these concepts, EV manufacturers and operators can optimize EV performance, reduce energy consumption, and extend the lifespan of the motor. In the next section, we will explore the importance of monitoring and maintaining electric motor health to prevent motor failures and reduce downtime.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance of electric motor health is crucial to prevent motor failures, reduce downtime, and optimize electric vehicle (EV) performance. Effective motor health monitoring involves tracking temperature, vibration, and other parameters that can indicate potential issues. In this section, we will discuss the best practices for monitoring and maintaining electric motor health, including temperature management, vibration analysis, and condition-based maintenance.

Temperature management is critical to maintaining electric motor health. High temperatures can reduce motor efficiency, lifespan, and performance. To manage temperature, EV manufacturers and operators can use thermal sensors, heat exchangers, and cooling systems. Thermal sensors can detect temperature changes, while heat exchangers and cooling systems can help to dissipate heat and maintain optimal motor temperatures.

Vibration analysis is another important aspect of motor health monitoring. Vibration can indicate potential issues with the motor, such as imbalance, misalignment, or bearing wear. Advanced vibration analysis techniques, such as spectral analysis and time-frequency analysis, can help to identify potential issues before they become major problems.

Condition-based maintenance is a proactive approach to maintaining electric motor health. This involves monitoring motor condition and performing maintenance only when necessary. Condition-based maintenance can help to reduce downtime, extend motor lifespan, and optimize EV performance. Advanced condition-based maintenance techniques, such as predictive maintenance and prescriptive maintenance, can help to optimize motor performance and reduce maintenance costs.

In addition to temperature management, vibration analysis, and condition-based maintenance, regular inspections and testing are also essential to maintaining electric motor health. Regular inspections can help to identify potential issues before they become major problems, while testing can help to validate motor performance and identify areas for improvement.

By implementing these best practices, EV manufacturers and operators can optimize electric motor health, reduce downtime, and improve overall EV performance. Effective motor health monitoring and maintenance are critical components of electric vehicle and electric motor operations management, and can help to ensure the long-term reliability and efficiency of EVs.

Electric Vehicle Charging Strategies for Efficient Motor Operations

Charging strategies play a crucial role in optimizing electric motor operations in electric vehicles (EVs). The way an EV is charged can significantly impact motor temperature, efficiency, and lifespan. In this section, we will discuss the effects of different charging strategies on electric motor operations and introduce charging management systems that can help optimize motor performance.

Fast charging, slow charging, and opportunity charging are three common charging strategies used in EVs. Fast charging involves charging the battery to 80% in under 30 minutes, while slow charging takes several hours to fully charge the battery. Opportunity charging, on the other hand, involves charging the battery during short periods of time, such as during a lunch break or while shopping.

The choice of charging strategy can significantly impact motor temperature, efficiency, and lifespan. Fast charging, for example, can cause motor temperatures to rise, reducing efficiency and lifespan. Slow charging, on the other hand, can help maintain optimal motor temperatures, improving efficiency and lifespan. Opportunity charging can also help reduce motor temperatures and improve efficiency, but it may not be suitable for all driving patterns.

Charging management systems can help optimize motor performance by regulating the flow of energy to the motor. These systems can monitor motor temperature, battery state of charge, and other parameters to determine the optimal charging strategy. Advanced charging management systems can also predict the driver’s behavior and adjust the charging strategy accordingly.

One example of a charging management system is the Tesla Model S’s Supercharger network. This system uses advanced algorithms to optimize charging times and reduce motor temperatures. Another example is the Chevrolet Bolt’s dual-level charging system, which allows drivers to choose between fast and slow charging.

In addition to charging management systems, EV manufacturers can also optimize motor performance by designing the motor and battery system to work together efficiently. This can involve using advanced materials, such as high-temperature superconductors, and designing the motor and battery system to minimize energy losses.

By understanding the effects of different charging strategies on electric motor operations and using charging management systems to optimize motor performance, EV manufacturers and operators can improve efficiency, reduce costs, and extend the lifespan of the motor. This is a critical aspect of electric vehicle and electric motor operations management, and can help ensure the long-term reliability and efficiency of EVs.

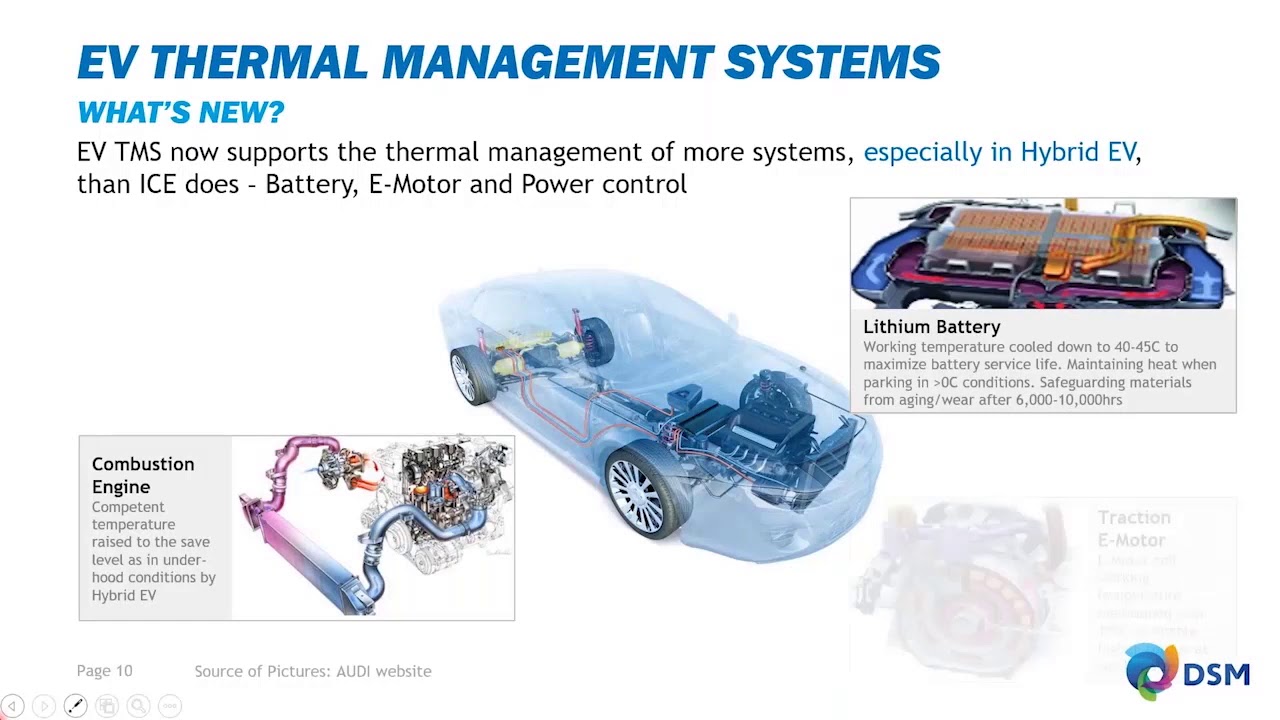

Thermal Management Systems for Electric Vehicles: A Key to Efficient Motor Operations

Thermal management systems play a crucial role in maintaining optimal motor temperatures in electric vehicles (EVs). High temperatures can reduce motor efficiency, lifespan, and performance, while low temperatures can reduce motor power and efficiency. In this section, we will discuss the importance of thermal management systems in EVs, including the role of cooling systems, heat exchangers, and thermal interfaces in maintaining optimal motor temperatures.

Cooling systems are a critical component of thermal management systems in EVs. These systems use air, water, or refrigerant to cool the motor, battery, and other components. Advanced cooling systems, such as liquid-cooled systems, can provide more efficient cooling and reduce motor temperatures. Heat exchangers, on the other hand, are used to transfer heat from the motor to a cooling fluid, which is then dissipated through a radiator or other heat exchanger.

Thermal interfaces are another important component of thermal management systems in EVs. These interfaces are used to connect the motor to a heat sink or other cooling system, and can significantly impact motor temperatures. Advanced thermal interfaces, such as those using graphene or other high-performance materials, can provide improved thermal conductivity and reduce motor temperatures.

The benefits of advanced thermal management systems in EVs are numerous. These systems can improve motor efficiency, reduce motor temperatures, and extend motor lifespan. Advanced thermal management systems can also provide improved performance, reduced energy consumption, and increased range. In addition, these systems can provide improved safety, reduced maintenance costs, and increased reliability.

Several EV manufacturers have implemented advanced thermal management systems in their vehicles. For example, the Tesla Model S uses a liquid-cooled system to cool the motor and battery, while the Chevrolet Bolt uses a air-cooled system. The Nissan Leaf, on the other hand, uses a combination of air-cooled and liquid-cooled systems to cool the motor and battery.

In addition to EV manufacturers, several companies are developing advanced thermal management systems for EVs. These companies are using innovative materials, designs, and technologies to improve thermal management and reduce motor temperatures. For example, some companies are using graphene or other high-performance materials to develop advanced thermal interfaces, while others are using advanced cooling systems, such as those using refrigerant or other fluids.

By understanding the importance of thermal management systems in EVs, including the role of cooling systems, heat exchangers, and thermal interfaces, EV manufacturers and operators can improve motor efficiency, reduce motor temperatures, and extend motor lifespan. This is a critical aspect of electric vehicle and electric motor operations management, and can help ensure the long-term reliability and efficiency of EVs.

Electric Motor Control Systems: A Deep Dive into Vector Control and Field-Oriented Control

Electric motor control systems are a critical component of electric vehicle (EV) performance, efficiency, and lifespan. These systems regulate the flow of energy to the motor, optimizing its performance and efficiency. In this section, we will delve into the details of electric motor control systems, including vector control and field-oriented control.

Vector control is a type of electric motor control system that uses a combination of speed and torque sensors to regulate the motor’s performance. This system uses a vector control algorithm to calculate the optimal speed and torque for the motor, based on the vehicle’s speed and load. Vector control systems are widely used in EVs due to their high efficiency and reliability.

Field-oriented control (FOC) is another type of electric motor control system that uses a combination of speed and torque sensors to regulate the motor’s performance. FOC systems use a complex algorithm to calculate the optimal speed and torque for the motor, based on the vehicle’s speed and load. FOC systems are widely used in EVs due to their high efficiency and reliability.

Both vector control and FOC systems have their advantages and limitations. Vector control systems are simpler and less expensive to implement, but they may not provide the same level of efficiency and reliability as FOC systems. FOC systems, on the other hand, are more complex and expensive to implement, but they provide higher efficiency and reliability.

The choice of electric motor control system depends on the specific requirements of the EV. For example, EVs that require high performance and efficiency may use FOC systems, while EVs that require simplicity and low cost may use vector control systems.

Several EV manufacturers have implemented advanced electric motor control systems in their vehicles. For example, the Tesla Model S uses a FOC system to regulate its motor performance, while the Chevrolet Bolt uses a vector control system. The Nissan Leaf, on the other hand, uses a combination of vector control and FOC systems to regulate its motor performance.

In addition to EV manufacturers, several companies are developing advanced electric motor control systems for EVs. These companies are using innovative technologies, such as artificial intelligence and machine learning, to improve the efficiency and reliability of electric motor control systems.

By understanding the principles and applications of electric motor control systems, including vector control and FOC, EV manufacturers and operators can optimize motor performance, efficiency, and lifespan. This is a critical aspect of electric vehicle and electric motor operations management, and can help ensure the long-term reliability and efficiency of EVs.

Real-World Examples of Efficient Electric Motor Operations in Electric Vehicles

Several electric vehicles (EVs) have achieved efficient motor operations through the implementation of advanced motor management strategies. In this section, we will showcase real-world examples of EVs that have optimized their motor performance, efficiency, and lifespan.

The Tesla Model S is a prime example of an EV that has achieved efficient motor operations. The Model S uses a combination of advanced motor control systems, thermal management systems, and charging management systems to optimize its motor performance. The vehicle’s motor is designed to operate at high efficiency, with a maximum efficiency of 90% at certain speeds. Additionally, the Model S’s thermal management system helps to maintain optimal motor temperatures, even in extreme weather conditions.

The Chevrolet Bolt is another example of an EV that has achieved efficient motor operations. The Bolt uses a combination of advanced motor control systems and thermal management systems to optimize its motor performance. The vehicle’s motor is designed to operate at high efficiency, with a maximum efficiency of 85% at certain speeds. Additionally, the Bolt’s thermal management system helps to maintain optimal motor temperatures, even in extreme weather conditions.

The Nissan Leaf is also an example of an EV that has achieved efficient motor operations. The Leaf uses a combination of advanced motor control systems and thermal management systems to optimize its motor performance. The vehicle’s motor is designed to operate at high efficiency, with a maximum efficiency of 80% at certain speeds. Additionally, the Leaf’s thermal management system helps to maintain optimal motor temperatures, even in extreme weather conditions.

These examples demonstrate the importance of advanced motor management strategies in achieving efficient motor operations in EVs. By implementing these strategies, EV manufacturers can optimize motor performance, efficiency, and lifespan, resulting in improved overall vehicle performance and reduced maintenance costs.

In addition to these examples, several other EV manufacturers have also achieved efficient motor operations through the implementation of advanced motor management strategies. For example, the BMW i3 uses a combination of advanced motor control systems and thermal management systems to optimize its motor performance, while the Volkswagen e-Golf uses a combination of advanced motor control systems and charging management systems to optimize its motor performance.

By analyzing these real-world examples, EV manufacturers and operators can gain valuable insights into the importance of advanced motor management strategies in achieving efficient motor operations. This knowledge can be used to optimize motor performance, efficiency, and lifespan, resulting in improved overall vehicle performance and reduced maintenance costs.

Future Trends in Electric Motor Operations Management: Advances in Materials, Design, and Control Systems

The electric vehicle (EV) industry is rapidly evolving, with advances in materials, design, and control systems driving improvements in electric motor operations management. In this section, we will discuss the future trends and advances in electric motor operations management, including the development of new materials, designs, and control systems.

One of the most significant trends in electric motor operations management is the development of new materials. Advances in materials science have led to the creation of new materials with improved properties, such as higher strength-to-weight ratios, improved thermal conductivity, and increased durability. These new materials are being used to develop more efficient and reliable electric motors, which are critical for EV performance and efficiency.

Another trend in electric motor operations management is the development of new designs. Advances in computer-aided design (CAD) and simulation tools have enabled engineers to design and optimize electric motors with unprecedented precision. This has led to the development of new motor designs, such as axial flux motors and transverse flux motors, which offer improved efficiency and performance.

Control systems are also a critical component of electric motor operations management. Advances in control systems have enabled the development of more sophisticated control algorithms, which can optimize motor performance and efficiency in real-time. This has led to the development of advanced control systems, such as model predictive control (MPC) and artificial intelligence (AI)-based control systems, which can optimize motor performance and efficiency in a wide range of operating conditions.

Emerging technologies, such as advanced power electronics and energy storage systems, are also playing a critical role in electric motor operations management. Advances in power electronics have enabled the development of more efficient and reliable power conversion systems, which are critical for EV performance and efficiency. Energy storage systems, such as batteries and supercapacitors, are also being developed to optimize motor performance and efficiency.

The development of new materials, designs, and control systems is driving improvements in electric motor operations management. These advances are enabling the development of more efficient and reliable electric motors, which are critical for EV performance and efficiency. By understanding these trends and advances, EV manufacturers and operators can optimize electric motor operations and improve overall vehicle performance and efficiency.

In addition to these trends and advances, several companies are also working on developing new technologies and solutions for electric motor operations management. For example, some companies are developing advanced motor control systems that can optimize motor performance and efficiency in real-time. Others are developing new materials and designs that can improve motor efficiency and reliability.

By staying up-to-date with the latest trends and advances in electric motor operations management, EV manufacturers and operators can optimize electric motor operations and improve overall vehicle performance and efficiency. This is a critical aspect of electric vehicle and electric motor operations management, and can help ensure the long-term reliability and efficiency of EVs.

Implementing Efficient Electric Motor Operations in Your Fleet: A Step-by-Step Guide

Implementing efficient electric motor operations in a fleet of electric vehicles requires a comprehensive approach that includes assessing current motor performance, selecting suitable charging strategies, and implementing thermal management systems. In this section, we will provide a step-by-step guide for implementing efficient electric motor operations in your fleet.

Step 1: Assess Current Motor Performance

The first step in implementing efficient electric motor operations is to assess the current performance of your fleet’s motors. This includes monitoring motor temperature, vibration, and efficiency, as well as analyzing motor performance data to identify areas for improvement.

Step 2: Select Suitable Charging Strategies

The next step is to select suitable charging strategies for your fleet. This includes choosing the right charging method, such as fast charging or slow charging, and selecting the optimal charging frequency and duration.

Step 3: Implement Thermal Management Systems

Thermal management systems are critical for maintaining optimal motor temperatures and preventing overheating. This includes implementing cooling systems, heat exchangers, and thermal interfaces to maintain optimal motor temperatures.

Step 4: Monitor and Maintain Motor Health

Regular monitoring and maintenance of motor health is essential for preventing motor failures and reducing downtime. This includes monitoring motor temperature, vibration, and efficiency, as well as performing regular maintenance tasks such as cleaning and lubricating the motor.

Step 5: Provide Ongoing Training and Support

Providing ongoing training and support is essential for ensuring that your fleet’s motors are operating efficiently and effectively. This includes providing training on motor maintenance and repair, as well as offering support and resources for troubleshooting and resolving motor-related issues.

By following these steps, you can implement efficient electric motor operations in your fleet and improve overall vehicle performance and efficiency. This is a critical aspect of electric vehicle and electric motor operations management, and can help ensure the long-term reliability and efficiency of your fleet.

In addition to these steps, it’s also important to consider the following best practices for implementing efficient electric motor operations:

Use advanced motor control systems to optimize motor performance and efficiency

Implement advanced thermal management systems to maintain optimal motor temperatures

Use high-efficiency motors and motor components to reduce energy consumption

Regularly monitor and maintain motor health to prevent motor failures and reduce downtime

Provide ongoing training and support to ensure that your fleet’s motors are operating efficiently and effectively