Mastering the Fundamentals of Electric Motor Operations

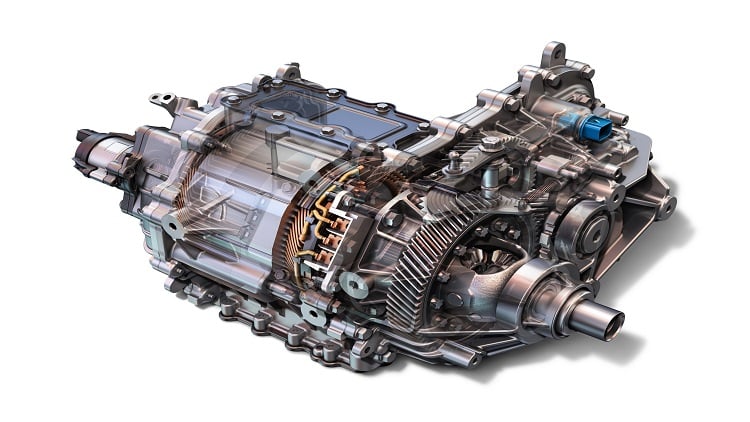

Electric motor operations are a crucial aspect of electric vehicle (EV) performance, and understanding the basics is essential for effective electric vehicle and electric motor operations management. At its core, an electric motor is a device that converts electrical energy into mechanical energy, utilizing the principles of electromagnetism. The interaction between a magnetic field and an electric current generates the torque required to propel an electric vehicle.

There are several types of electric motors used in EVs, including permanent magnet motors, induction motors, and switched reluctance motors. Each type has its unique characteristics, advantages, and disadvantages. For instance, permanent magnet motors are known for their high efficiency and reliability, while induction motors offer high torque density and low maintenance.

Efficiency considerations are also vital in electric motor operations. Electric motors can lose efficiency due to various factors, such as heat, friction, and electrical losses. To mitigate these losses, EV manufacturers employ various techniques, including advanced materials, optimized motor design, and sophisticated control systems. By minimizing energy losses, EVs can achieve better range, performance, and overall efficiency.

In the context of electric vehicle and electric motor operations management, understanding the basics of electric motor operations is crucial for optimizing performance, efficiency, and reliability. By grasping the fundamental principles of electromagnetism, motor types, and efficiency considerations, EV manufacturers and operators can make informed decisions to improve their electric motor operations and ultimately, the overall performance of their electric vehicles.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance of electric motors in electric vehicles are crucial for ensuring optimal performance, efficiency, and reliability. Neglecting motor health can lead to reduced vehicle range, decreased performance, and even motor failure. Effective electric vehicle and electric motor operations management requires a proactive approach to motor maintenance.

To identify potential issues, electric vehicle operators should perform routine checks on the motor, including monitoring temperature, vibration, and noise levels. Advanced diagnostic tools, such as motor condition monitoring systems, can also be employed to detect early signs of motor degradation. By catching potential problems early, operators can schedule maintenance and prevent downtime.

Preventive maintenance is essential for extending motor lifespan and optimizing performance. This includes tasks such as cleaning the motor, checking and replacing bearings, and lubricating moving parts. Regular maintenance can also help to identify and address issues related to motor control systems, power electronics, and thermal management.

In addition to routine checks and maintenance, electric vehicle operators should also keep accurate records of motor performance and maintenance activities. This data can be used to optimize motor operations, identify trends and patterns, and make informed decisions about maintenance and repair. By leveraging data analysis and insights, operators can optimize electric vehicle and electric motor operations management and achieve better overall performance.

Best practices for electric motor maintenance also include training drivers on proper vehicle operation and maintenance procedures. This includes educating drivers on how to monitor motor health, perform routine checks, and report any issues or concerns. By empowering drivers with the knowledge and skills to maintain motor health, operators can ensure that their electric vehicles are running at optimal levels.

Electric Vehicle Charging Strategies for Efficient Motor Operations

Electric vehicle charging strategies play a crucial role in optimizing motor operations and overall vehicle performance. The choice of charging method can significantly impact motor efficiency, lifespan, and reliability. Effective electric vehicle and electric motor operations management requires a deep understanding of the different charging strategies and their effects on motor operations.

Level 1 charging, also known as trickle charging, is the slowest method of charging an electric vehicle. This method uses a standard 120-volt outlet and is typically used for overnight charging. While Level 1 charging is convenient, it can be inefficient and may not be suitable for vehicles with high motor demands.

Level 2 charging, on the other hand, uses a 240-volt charging station and can charge an electric vehicle up to 5 times faster than Level 1 charging. This method is ideal for vehicles with high motor demands and is commonly used in commercial and industrial settings. However, Level 2 charging requires a dedicated charging station and may require additional infrastructure.

DC Fast Charging is the fastest method of charging an electric vehicle, capable of charging a vehicle to 80% in under 30 minutes. This method uses a high-power charging station and is typically used for long-distance driving. However, DC Fast Charging can be stressful on the motor and may require additional cooling systems to prevent overheating.

When choosing a charging strategy, it’s essential to consider the specific needs of the vehicle and its motor. Factors such as motor type, vehicle usage, and charging infrastructure should be taken into account to ensure optimal motor operations. By selecting the right charging strategy, electric vehicle operators can optimize motor performance, efficiency, and reliability, ultimately leading to a better overall driving experience.

In addition to choosing the right charging strategy, electric vehicle operators should also consider the impact of charging on motor health. Regular monitoring of motor temperature, vibration, and noise levels can help identify potential issues and prevent motor damage. By combining the right charging strategy with regular maintenance and monitoring, electric vehicle operators can ensure optimal motor operations and extend the lifespan of their vehicle.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric motor operations, as excessive heat can significantly impact motor efficiency, lifespan, and reliability. Effective electric vehicle and electric motor operations management requires a deep understanding of thermal management techniques to optimize motor performance.

Heat is generated in electric motors due to electrical losses, such as copper losses, iron losses, and friction losses. These losses can cause the motor temperature to rise, leading to reduced efficiency, increased wear and tear, and potentially even motor failure. To mitigate these effects, thermal management techniques are employed to manage motor temperature and maintain optimal operating conditions.

Cooling systems are a common thermal management technique used in electric motors. These systems can be liquid-based or air-based and are designed to absorb heat from the motor and dissipate it to the surroundings. Liquid-based cooling systems, such as oil or water cooling, are often used in high-performance electric motors, while air-based cooling systems, such as fans or heat sinks, are commonly used in lower-power applications.

Thermal monitoring is another essential aspect of thermal management in electric motors. This involves monitoring motor temperature in real-time to detect any anomalies or potential issues. Thermal monitoring systems can be used to trigger alarms or alerts when motor temperature exceeds a certain threshold, allowing for prompt action to be taken to prevent motor damage.

In addition to cooling systems and thermal monitoring, other thermal management techniques can be employed to optimize electric motor efficiency. These include the use of thermal interface materials, heat sinks, and thermal insulation. By combining these techniques, electric vehicle operators can ensure optimal motor temperature and maintain peak performance.

Effective thermal management is critical for electric vehicle and electric motor operations management, as it can significantly impact motor efficiency, lifespan, and reliability. By understanding the principles of thermal management and employing the right techniques, electric vehicle operators can optimize motor performance, reduce downtime, and extend the lifespan of their vehicles.

Electric Motor Control Systems for Optimized Performance

Electric motor control systems play a crucial role in optimizing the performance, efficiency, and reliability of electric vehicles. These systems, which include power electronics and control algorithms, are designed to manage the flow of electrical energy to the motor, ensuring that it operates within optimal parameters.

Power electronics are a key component of electric motor control systems, as they enable the efficient conversion of electrical energy from the battery to the motor. This is achieved through the use of power electronic devices such as insulated gate bipolar transistors (IGBTs) and power MOSFETs, which are capable of handling high currents and voltages.

Control algorithms are another critical aspect of electric motor control systems, as they enable the optimization of motor performance and efficiency. These algorithms, which are typically implemented in software, use data from sensors and other sources to adjust the flow of electrical energy to the motor, ensuring that it operates within optimal parameters.

One of the key benefits of electric motor control systems is their ability to optimize motor performance and efficiency. By adjusting the flow of electrical energy to the motor, these systems can ensure that it operates within optimal parameters, resulting in improved efficiency, reduced energy consumption, and increased reliability.

In addition to optimizing motor performance and efficiency, electric motor control systems can also provide a range of other benefits, including improved safety, reduced maintenance, and increased flexibility. For example, these systems can be designed to provide advanced safety features, such as overcurrent protection and thermal monitoring, which can help to prevent motor damage and ensure safe operation.

Effective electric vehicle and electric motor operations management requires a deep understanding of electric motor control systems and their role in optimizing motor performance and efficiency. By leveraging the latest advancements in power electronics and control algorithms, electric vehicle operators can ensure that their vehicles operate at optimal levels, resulting in improved efficiency, reduced energy consumption, and increased reliability.

Real-World Examples of Electric Vehicle Motor Operations Management

Effective electric vehicle and electric motor operations management is crucial for optimizing performance, efficiency, and reliability in various industries. Here are some real-world examples of successful electric vehicle motor operations management in different sectors:

In the automotive industry, companies like Tesla and General Motors have implemented advanced motor operations management systems to optimize performance and efficiency. For instance, Tesla’s electric vehicles are equipped with advanced motor control systems that enable real-time monitoring and optimization of motor performance.

In the aerospace industry, companies like Boeing and Airbus are using electric motors in their aircraft, and implementing advanced motor operations management systems to optimize performance and efficiency. For example, Boeing’s 787 Dreamliner uses electric motors to power its auxiliary power unit, and the company has implemented a advanced motor operations management system to optimize performance and efficiency.

In the renewable energy sector, companies like Vestas and Siemens Gamesa are using electric motors in their wind turbines, and implementing advanced motor operations management systems to optimize performance and efficiency. For example, Vestas’ wind turbines use electric motors to power their yaw and pitch systems, and the company has implemented a advanced motor operations management system to optimize performance and efficiency.

These examples demonstrate the importance of effective electric vehicle and electric motor operations management in various industries. By implementing advanced motor operations management systems, companies can optimize performance, efficiency, and reliability, and reduce downtime and maintenance costs.

In addition to these examples, there are many other industries that can benefit from effective electric vehicle and electric motor operations management, such as public transportation, logistics, and construction. By implementing advanced motor operations management systems, companies in these industries can optimize performance, efficiency, and reliability, and reduce downtime and maintenance costs.

Best Practices for Electric Vehicle Motor Operations in Fleet Management

Effective electric vehicle and electric motor operations management is crucial for optimizing performance, efficiency, and reliability in fleet management scenarios. Here are some best practices for implementing effective motor operations management in fleet management:

Data analysis is a critical component of effective motor operations management in fleet management. By analyzing data on motor performance, efficiency, and reliability, fleet managers can identify trends and patterns that can inform maintenance scheduling, driver training, and other operational decisions.

Driver training is another important aspect of effective motor operations management in fleet management. By providing drivers with training on proper vehicle operation, maintenance, and troubleshooting, fleet managers can ensure that drivers are equipped to optimize motor performance and efficiency.

Maintenance scheduling is also essential for effective motor operations management in fleet management. By scheduling regular maintenance and repairs, fleet managers can prevent downtime, reduce maintenance costs, and optimize motor performance and efficiency.

In addition to these best practices, fleet managers should also consider implementing advanced motor operations management systems, such as telematics and predictive maintenance software. These systems can provide real-time data on motor performance, efficiency, and reliability, and enable fleet managers to make data-driven decisions about maintenance, repairs, and other operational activities.

By implementing these best practices and leveraging advanced motor operations management systems, fleet managers can optimize motor performance, efficiency, and reliability, and reduce downtime and maintenance costs. This can help to improve overall fleet performance, reduce costs, and enhance customer satisfaction.

Furthermore, effective motor operations management in fleet management can also help to reduce the environmental impact of fleet operations. By optimizing motor performance and efficiency, fleet managers can reduce energy consumption, lower emissions, and minimize waste. This can help to improve the sustainability of fleet operations and reduce the environmental footprint of the organization.

Future Trends in Electric Vehicle Motor Operations Management

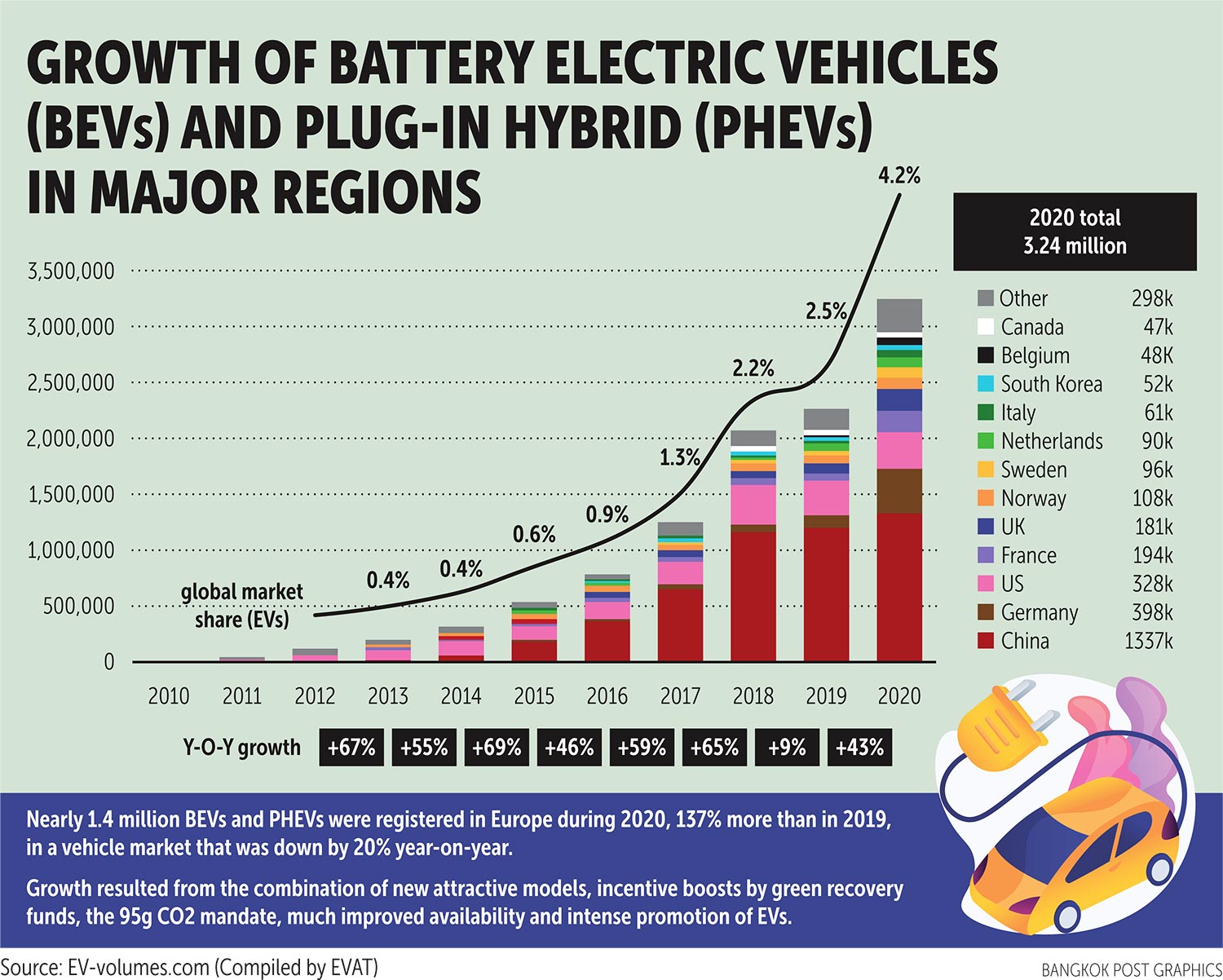

The future of electric vehicle motor operations management is exciting and rapidly evolving. Advancements in motor technology, charging infrastructure, and autonomous vehicles are transforming the way electric vehicles are designed, manufactured, and operated.

One of the most significant trends in electric vehicle motor operations management is the development of more efficient and powerful electric motors. New motor technologies, such as permanent magnet motors and switched reluctance motors, are being developed to improve efficiency, reduce weight, and increase power density.

Another trend is the expansion of charging infrastructure, including the development of high-power charging systems and wireless charging technology. This will enable faster and more convenient charging, making electric vehicles more appealing to consumers and fleets.

Autonomous vehicles are also expected to play a significant role in the future of electric vehicle motor operations management. Autonomous vehicles will require advanced motor control systems and sophisticated sensor systems to ensure safe and efficient operation.

In addition to these trends, there are also advancements in motor control systems, including the development of more advanced power electronics and control algorithms. These advancements will enable more efficient and reliable motor operation, and will also enable the integration of multiple motors and other components into a single system.

As the electric vehicle market continues to grow and evolve, it is essential for manufacturers, fleets, and operators to stay up-to-date with the latest trends and advancements in electric vehicle motor operations management. By doing so, they can ensure that their vehicles are optimized for performance, efficiency, and reliability, and that they are well-positioned to take advantage of the opportunities and challenges that the future will bring.

Overall, the future of electric vehicle motor operations management is bright and exciting, with many opportunities for innovation and growth. As the industry continues to evolve, it is essential to stay focused on the key trends and advancements that will shape the future of electric vehicle motor operations management.