Unlocking the Potential of Electric Motor Management

Efficient electric motor management is crucial for the optimal performance of electric vehicles. By optimizing electric motor operations, electric vehicle owners and operators can enjoy improved performance, reduced energy consumption, and extended lifespan. Electric motor management is a critical aspect of electric vehicle and electric motor operations management, as it directly impacts the overall efficiency and effectiveness of the vehicle.

The importance of efficient electric motor management cannot be overstated. Electric motors are the heart of electric vehicles, and their performance has a direct impact on the vehicle’s overall performance. By optimizing electric motor operations, electric vehicle owners and operators can reduce energy consumption, lower emissions, and improve overall efficiency. This, in turn, can lead to cost savings, reduced maintenance, and extended lifespan.

Electric vehicle and electric motor operations management involves a range of activities, including monitoring and controlling electric motor performance, optimizing energy consumption, and performing routine maintenance. By implementing effective electric motor management strategies, electric vehicle owners and operators can unlock the full potential of their vehicles and achieve optimal performance.

One of the key benefits of efficient electric motor management is improved performance. By optimizing electric motor operations, electric vehicle owners and operators can enjoy faster acceleration, improved torque, and enhanced overall performance. This can be particularly beneficial for commercial fleets, where improved performance can lead to increased productivity and reduced downtime.

In addition to improved performance, efficient electric motor management can also lead to reduced energy consumption. By optimizing electric motor operations, electric vehicle owners and operators can reduce energy consumption, lower emissions, and improve overall efficiency. This can be particularly beneficial for environmentally conscious consumers, who are increasingly seeking out sustainable and eco-friendly transportation options.

Finally, efficient electric motor management can also lead to extended lifespan. By performing routine maintenance and optimizing electric motor operations, electric vehicle owners and operators can extend the lifespan of their vehicles and reduce the need for costly repairs. This can be particularly beneficial for commercial fleets, where extended lifespan can lead to reduced maintenance costs and improved overall efficiency.

Understanding Electric Motor Fundamentals: A Primer

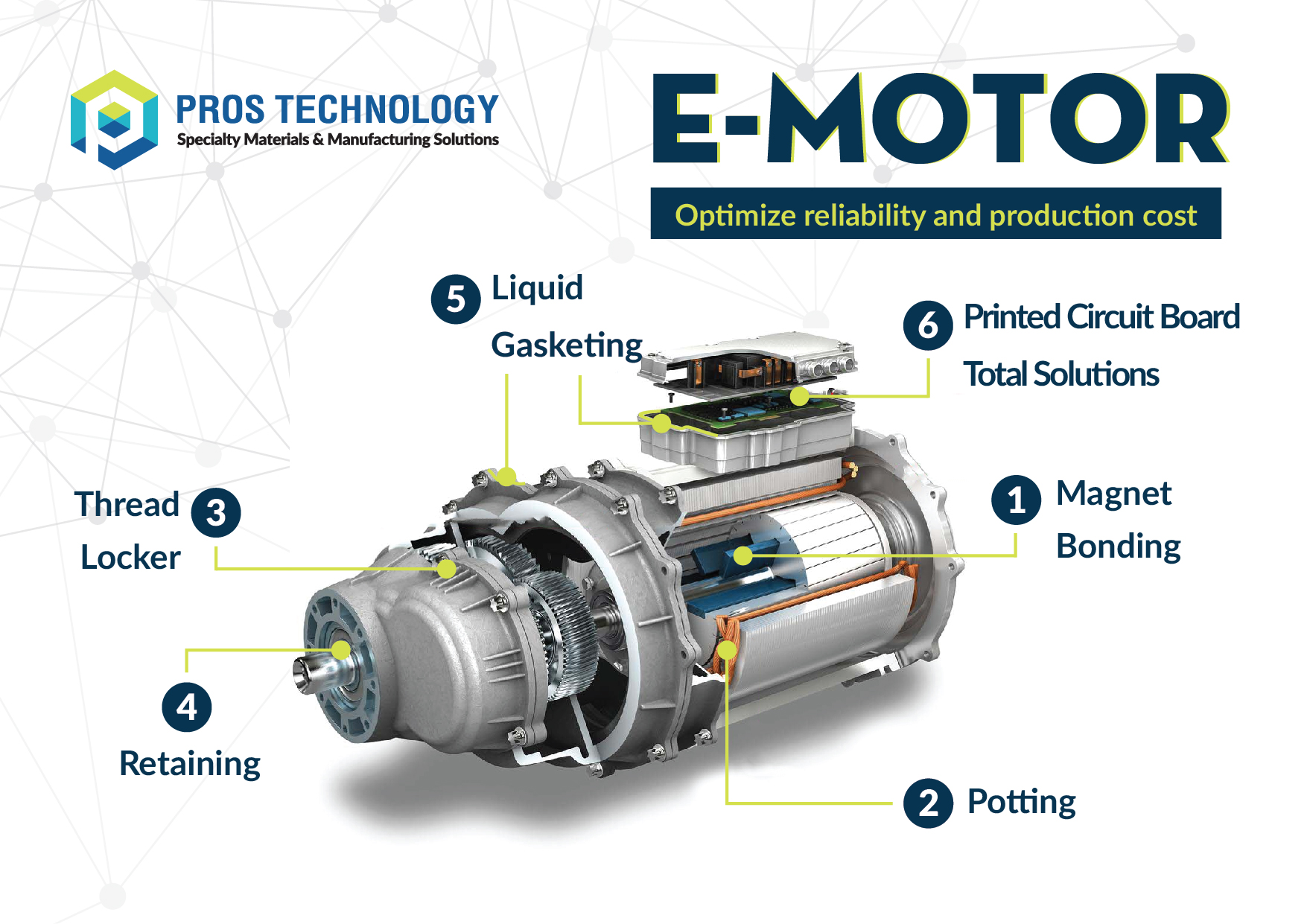

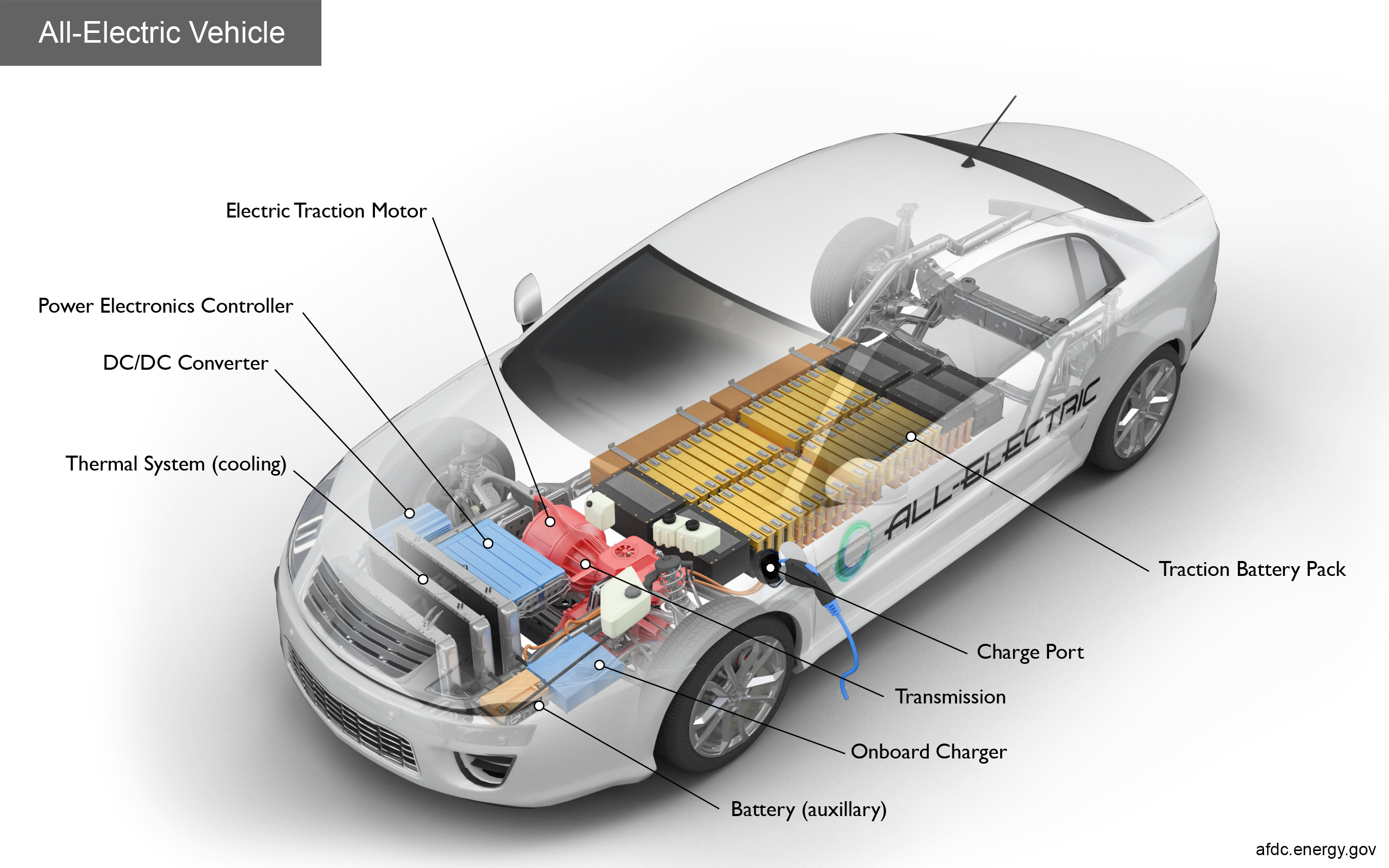

Electric motors are the heart of electric vehicles, and understanding their fundamentals is crucial for effective electric vehicle and electric motor operations management. There are several types of electric motors used in electric vehicles, including permanent magnet motors, induction motors, and switched reluctance motors. Each type of motor has its own unique characteristics, advantages, and disadvantages.

Permanent magnet motors, for example, are widely used in electric vehicles due to their high efficiency, reliability, and durability. They use a permanent magnet as the rotor and a coil as the stator, which provides a high power-to-weight ratio and excellent thermal management. The Tesla Model S, for instance, uses a permanent magnet motor to achieve exceptional performance and efficiency.

Induction motors, on the other hand, are commonly used in electric vehicles due to their simplicity, reliability, and low cost. They use a coil as the rotor and a magnet as the stator, which provides a high starting torque and excellent speed control. The Nissan Leaf, for example, uses an induction motor to achieve excellent performance and efficiency.

Switched reluctance motors are another type of electric motor used in electric vehicles, which offer high efficiency, reliability, and durability. They use a coil as the rotor and a magnet as the stator, which provides a high power-to-weight ratio and excellent thermal management. The BMW i3, for instance, uses a switched reluctance motor to achieve exceptional performance and efficiency.

In addition to understanding the types of electric motors, it’s also essential to consider torque and power output, as well as efficiency considerations. Electric motors produce torque, which is the rotational force that propels the vehicle forward. The power output of an electric motor is measured in kilowatts (kW), and it’s essential to consider the power output required for the vehicle’s intended application.

Efficiency considerations are also critical in electric motor operations management. Electric motors convert electrical energy into mechanical energy, and efficiency is measured by the amount of energy converted. High-efficiency electric motors can significantly reduce energy consumption, lower emissions, and improve overall efficiency.

By understanding the fundamentals of electric motors, electric vehicle owners and operators can optimize their performance, reduce energy consumption, and improve overall efficiency. This knowledge is essential for effective electric vehicle and electric motor operations management, and it can help to unlock the full potential of electric vehicles.

Electric Vehicle Operations Management: Key Challenges and Opportunities

Managing electric vehicle operations is a complex task that requires careful consideration of several key factors. One of the primary challenges is battery management, as electric vehicles rely on batteries to store energy and propel the vehicle forward. Effective battery management is critical to ensuring optimal performance, range, and lifespan of the battery.

Another challenge is charging infrastructure, as electric vehicles require access to charging stations to recharge their batteries. The availability and accessibility of charging infrastructure can significantly impact the adoption and usage of electric vehicles. Electric vehicle operations management must consider factors such as charging speed, capacity, and location to ensure seamless and efficient charging.

Route optimization is also a critical aspect of electric vehicle operations management. Electric vehicles have limited range and require careful planning to ensure that they can complete their routes without running out of charge. Route optimization software can help to identify the most efficient routes and reduce energy consumption.

Despite these challenges, there are also opportunities for improvement in electric vehicle operations management. One of the key opportunities is the use of data-driven insights to optimize electric vehicle performance. By analyzing data on energy consumption, battery health, and route optimization, electric vehicle operations managers can identify areas for improvement and make data-driven decisions to optimize performance.

Predictive maintenance is another opportunity for improvement in electric vehicle operations management. By using advanced analytics and machine learning algorithms, electric vehicle operations managers can predict when maintenance is required and schedule it accordingly. This can help to reduce downtime, improve efficiency, and extend the lifespan of the vehicle.

Electric vehicle operations management software can also help to optimize electric vehicle performance and reduce energy consumption. These software solutions can provide real-time data on energy consumption, battery health, and route optimization, and offer insights and recommendations for improvement.

By understanding the key challenges and opportunities in electric vehicle operations management, electric vehicle owners and operators can optimize their performance, reduce energy consumption, and improve overall efficiency. This requires a comprehensive approach that considers all aspects of electric vehicle operations, from battery management to route optimization.

Effective electric vehicle operations management is critical to ensuring the success of electric vehicle adoption and usage. By leveraging data-driven insights, predictive maintenance, and electric vehicle operations management software, electric vehicle owners and operators can unlock the full potential of their vehicles and achieve optimal performance.

How to Optimize Electric Motor Performance: Best Practices and Strategies

Optimizing electric motor performance is crucial for efficient electric vehicle operations. Proper maintenance, thermal management, and energy-efficient driving techniques can significantly improve electric motor performance and reduce energy consumption. In this section, we will discuss best practices and strategies for optimizing electric motor performance.

Regular maintenance is essential for optimal electric motor performance. This includes checking and replacing worn-out parts, lubricating moving parts, and ensuring proper alignment. Regular maintenance can help prevent overheating, reduce energy consumption, and extend the lifespan of the electric motor.

Thermal management is also critical for electric motor performance. Electric motors can overheat during operation, which can reduce their efficiency and lifespan. Proper thermal management techniques, such as using heat sinks or cooling systems, can help maintain optimal operating temperatures and improve electric motor performance.

Energy-efficient driving techniques can also optimize electric motor performance. Techniques such as accelerating smoothly, maintaining a consistent speed, and avoiding hard braking can help reduce energy consumption and improve electric motor performance.

Case studies have shown that optimizing electric motor performance can have significant benefits. For example, a study by the National Renewable Energy Laboratory found that optimizing electric motor performance in electric vehicles can improve efficiency by up to 20%. Another study by the Electric Power Research Institute found that optimizing electric motor performance can reduce energy consumption by up to 15%.

Industries such as manufacturing, logistics, and transportation can also benefit from optimizing electric motor performance. For example, a manufacturing plant can optimize electric motor performance in its machinery to reduce energy consumption and improve productivity. A logistics company can optimize electric motor performance in its electric vehicles to reduce energy consumption and improve delivery times.

In addition to these strategies, electric vehicle operations management software can also help optimize electric motor performance. These software solutions can provide real-time data on energy consumption, battery health, and route optimization, and offer insights and recommendations for improvement.

By implementing these best practices and strategies, electric vehicle owners and operators can optimize electric motor performance, reduce energy consumption, and improve overall efficiency. This requires a comprehensive approach that considers all aspects of electric vehicle operations, from maintenance to driving techniques.

Effective electric motor performance optimization is critical to ensuring the success of electric vehicle adoption and usage. By leveraging these best practices and strategies, electric vehicle owners and operators can unlock the full potential of their vehicles and achieve optimal performance.

Electric Vehicle Charging Infrastructure: Planning and Management Considerations

Electric vehicle charging infrastructure is a critical component of electric vehicle operations management. The availability and accessibility of charging infrastructure can significantly impact the adoption and usage of electric vehicles. In this section, we will discuss the importance of charging infrastructure planning and management for electric vehicle operations.

Charging speed is a key consideration in charging infrastructure planning. Faster charging speeds can reduce downtime and improve the overall efficiency of electric vehicle operations. However, faster charging speeds also require more powerful charging equipment, which can increase costs.

Charging capacity is another important consideration. The capacity of the charging infrastructure should be sufficient to meet the demands of the electric vehicle fleet. This requires careful planning and management to ensure that the charging infrastructure can handle the required load.

Location is also a critical factor in charging infrastructure planning. Charging stations should be located in convenient and accessible locations, such as near highways, shopping centers, and workplaces. This can help to reduce range anxiety and improve the overall user experience.

Strategies for optimizing charging infrastructure include implementing smart charging systems, which can optimize charging speeds and reduce energy consumption. Another strategy is to use renewable energy sources, such as solar or wind power, to generate electricity for charging.

Case studies have shown that effective charging infrastructure planning and management can have significant benefits. For example, a study by the International Council on Clean Transportation found that optimized charging infrastructure can reduce energy consumption by up to 20%. Another study by the National Renewable Energy Laboratory found that optimized charging infrastructure can improve the overall efficiency of electric vehicle operations by up to 15%.

Industries such as transportation, logistics, and government can benefit from effective charging infrastructure planning and management. For example, a transportation company can optimize its charging infrastructure to reduce downtime and improve the overall efficiency of its electric vehicle fleet. A logistics company can optimize its charging infrastructure to reduce energy consumption and improve delivery times.

In addition to these strategies, electric vehicle operations management software can also help optimize charging infrastructure. These software solutions can provide real-time data on energy consumption, charging speeds, and charging capacity, and offer insights and recommendations for improvement.

By implementing these strategies and best practices, electric vehicle owners and operators can optimize their charging infrastructure, reduce energy consumption, and improve overall efficiency. This requires a comprehensive approach that considers all aspects of electric vehicle operations, from charging infrastructure to route optimization.

Electric Motor Maintenance and Repair: A Proactive Approach

Proactive maintenance and repair are essential for ensuring the optimal performance and longevity of electric motors in electric vehicles. Regular inspections, condition monitoring, and predictive maintenance can help identify potential issues before they become major problems, reducing downtime and improving overall efficiency.

Regular inspections are critical for identifying potential issues with electric motors. These inspections should include checks on the motor’s electrical and mechanical systems, as well as its cooling and lubrication systems. By identifying potential issues early, maintenance personnel can take proactive steps to prevent them from becoming major problems.

Condition monitoring is another important aspect of proactive maintenance. This involves using sensors and other technologies to monitor the condition of the electric motor in real-time, allowing maintenance personnel to identify potential issues before they become major problems.

Predictive maintenance is a proactive approach to maintenance that uses data and analytics to predict when maintenance is required. This approach can help reduce downtime and improve overall efficiency by allowing maintenance personnel to schedule maintenance during periods of low usage.

Troubleshooting common issues is also an important aspect of electric motor maintenance and repair. This includes identifying and resolving issues such as overheating, vibration, and electrical faults. By troubleshooting these issues quickly and effectively, maintenance personnel can minimize downtime and improve overall efficiency.

Performing repairs is also an important aspect of electric motor maintenance and repair. This includes replacing worn or damaged components, as well as performing more complex repairs such as rewinding or rebuilding the motor. By performing repairs quickly and effectively, maintenance personnel can minimize downtime and improve overall efficiency.

Case studies have shown that proactive maintenance and repair can have significant benefits for electric vehicle operations. For example, a study by the International Council on Clean Transportation found that proactive maintenance and repair can reduce downtime by up to 20%. Another study by the National Renewable Energy Laboratory found that proactive maintenance and repair can improve overall efficiency by up to 15%.

Industries such as transportation, logistics, and government can benefit from proactive maintenance and repair of electric motors. For example, a transportation company can use proactive maintenance and repair to reduce downtime and improve the overall efficiency of its electric vehicle fleet. A logistics company can use proactive maintenance and repair to reduce energy consumption and improve delivery times.

In addition to these strategies, electric vehicle operations management software can also help with proactive maintenance and repair. These software solutions can provide real-time data on the condition of the electric motor, as well as insights and recommendations for maintenance and repair.

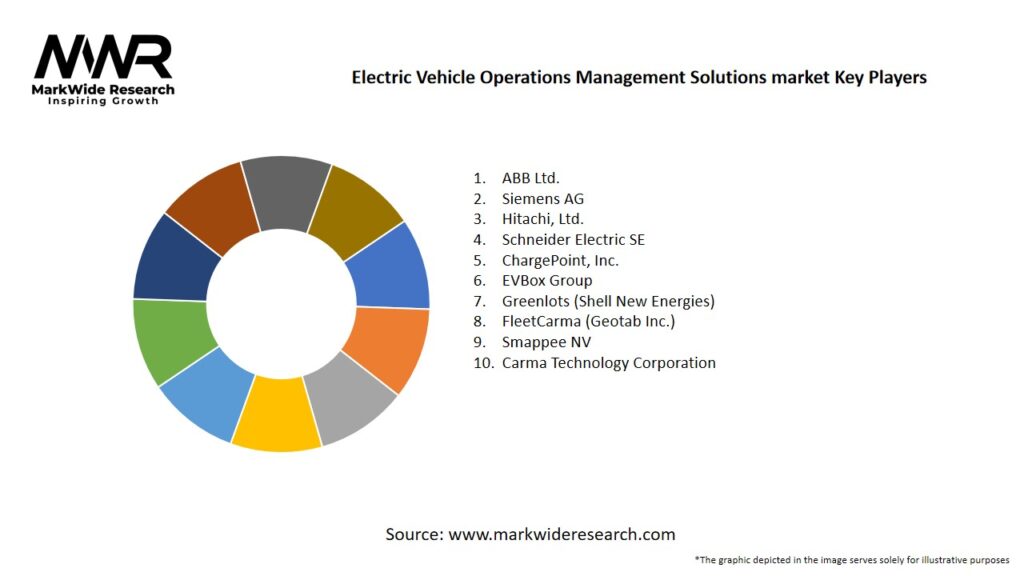

Electric Vehicle Operations Management Software: A Review of Leading Solutions

Electric vehicle operations management software is a critical tool for optimizing the performance and efficiency of electric vehicles. These software solutions provide a range of features and functionalities that enable fleet managers to monitor and manage their electric vehicle fleets in real-time.

One of the leading electric vehicle operations management software solutions is Fleet Complete. This software provides a range of features, including real-time vehicle tracking, route optimization, and driver behavior monitoring. Fleet Complete also offers a range of integrations with other software solutions, including telematics and fleet management systems.

Another leading electric vehicle operations management software solution is Geotab. This software provides a range of features, including real-time vehicle tracking, route optimization, and driver behavior monitoring. Geotab also offers a range of integrations with other software solutions, including telematics and fleet management systems.

Verizon Connect is another popular electric vehicle operations management software solution. This software provides a range of features, including real-time vehicle tracking, route optimization, and driver behavior monitoring. Verizon Connect also offers a range of integrations with other software solutions, including telematics and fleet management systems.

When selecting an electric vehicle operations management software solution, it’s essential to consider a range of factors, including the software’s features and functionalities, its ease of use, and its scalability. It’s also important to consider the software’s integrations with other software solutions and its compatibility with different types of electric vehicles.

Electric vehicle operations management software can provide a range of benefits, including improved efficiency, reduced energy consumption, and extended vehicle lifespan. By optimizing the performance and efficiency of electric vehicles, fleet managers can reduce their operating costs and improve their bottom line.

Case studies have shown that electric vehicle operations management software can have a significant impact on the efficiency and performance of electric vehicle fleets. For example, a study by the International Council on Clean Transportation found that electric vehicle operations management software can improve the efficiency of electric vehicle fleets by up to 20%.

Industries such as transportation, logistics, and government can benefit from electric vehicle operations management software. For example, a transportation company can use electric vehicle operations management software to optimize the performance and efficiency of its electric vehicle fleet, reducing energy consumption and improving overall efficiency.

In addition to these benefits, electric vehicle operations management software can also provide a range of insights and analytics that can help fleet managers to optimize their electric vehicle fleets. By analyzing data on energy consumption, vehicle performance, and driver behavior, fleet managers can identify areas for improvement and make data-driven decisions to optimize their electric vehicle fleets.

Future-Proofing Electric Vehicle Operations: Emerging Trends and Technologies

The electric vehicle industry is rapidly evolving, with new trends and technologies emerging that are set to transform the way electric vehicles are operated and managed. In this section, we will explore some of the key emerging trends and technologies in electric vehicle operations management, including advancements in battery technology, autonomous vehicles, and smart charging infrastructure.

Advances in battery technology are set to play a major role in the future of electric vehicle operations management. New battery technologies, such as solid-state batteries and lithium-air batteries, are being developed that offer improved range, efficiency, and charging times. These advancements will enable electric vehicles to travel further and faster, making them more viable for long-distance transportation.

Autonomous vehicles are another emerging trend in electric vehicle operations management. Autonomous vehicles use a combination of sensors, GPS, and artificial intelligence to navigate roads and traffic patterns without human intervention. This technology has the potential to revolutionize the way electric vehicles are operated and managed, enabling greater efficiency, safety, and productivity.

Smart charging infrastructure is also an emerging trend in electric vehicle operations management. Smart charging infrastructure uses advanced technologies, such as IoT sensors and AI algorithms, to optimize charging times and reduce energy consumption. This technology has the potential to enable greater efficiency and productivity in electric vehicle operations, while also reducing costs and environmental impact.

Other emerging trends and technologies in electric vehicle operations management include vehicle-to-grid (V2G) technology, which enables electric vehicles to supply energy back to the grid, and advanced driver-assistance systems (ADAS), which use sensors and AI algorithms to enhance safety and efficiency.

These emerging trends and technologies have the potential to transform the way electric vehicles are operated and managed, enabling greater efficiency, productivity, and sustainability. By embracing these innovations, electric vehicle operators and managers can future-proof their operations and stay ahead of the curve in the rapidly evolving electric vehicle industry.

Case studies have shown that embracing emerging trends and technologies in electric vehicle operations management can have significant benefits. For example, a study by the International Council on Clean Transportation found that the adoption of autonomous vehicles could reduce energy consumption by up to 20% and improve safety by up to 30%.

Industries such as transportation, logistics, and government can benefit from embracing emerging trends and technologies in electric vehicle operations management. For example, a transportation company can use autonomous vehicles to improve safety and efficiency, while a logistics company can use smart charging infrastructure to reduce energy consumption and costs.

In addition to these benefits, embracing emerging trends and technologies in electric vehicle operations management can also provide a range of insights and analytics that can help operators and managers to optimize their electric vehicle fleets. By analyzing data on energy consumption, vehicle performance, and driver behavior, operators and managers can identify areas for improvement and make data-driven decisions to optimize their electric vehicle operations.