Mastering the Fundamentals of Electric Motor Management

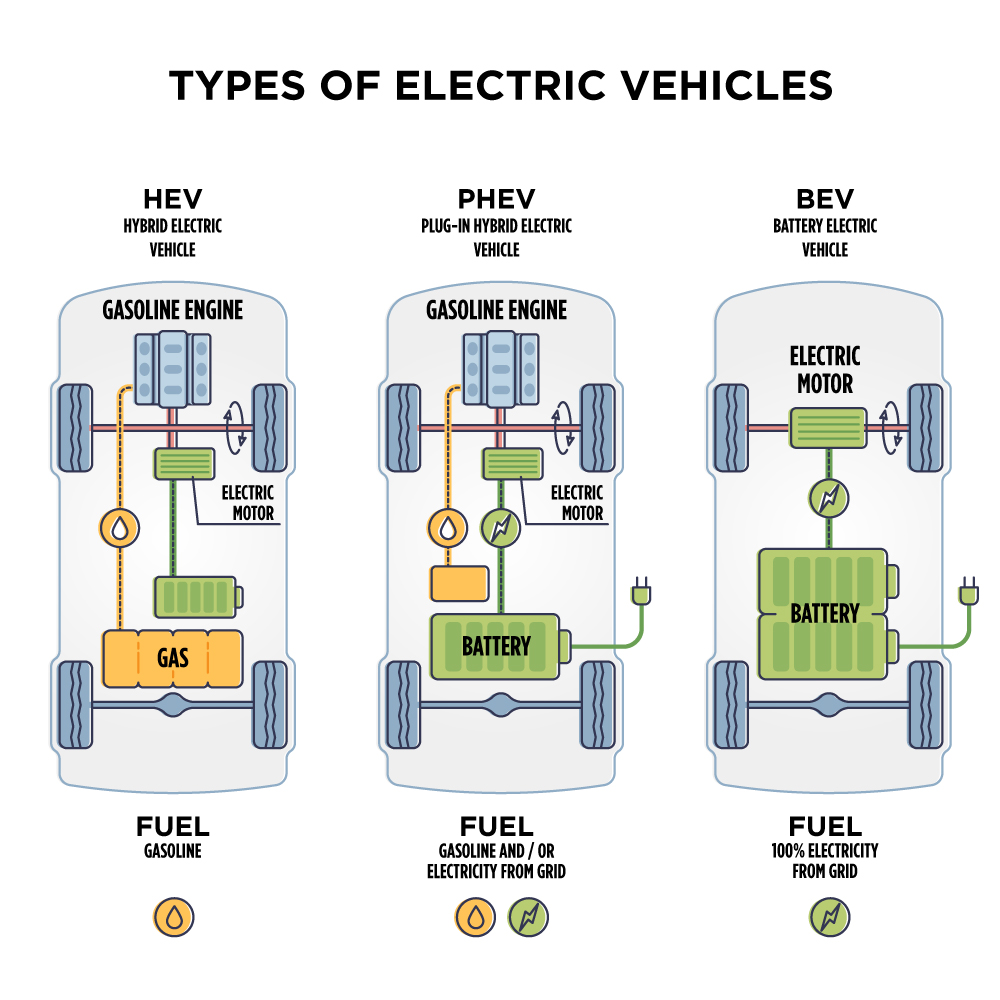

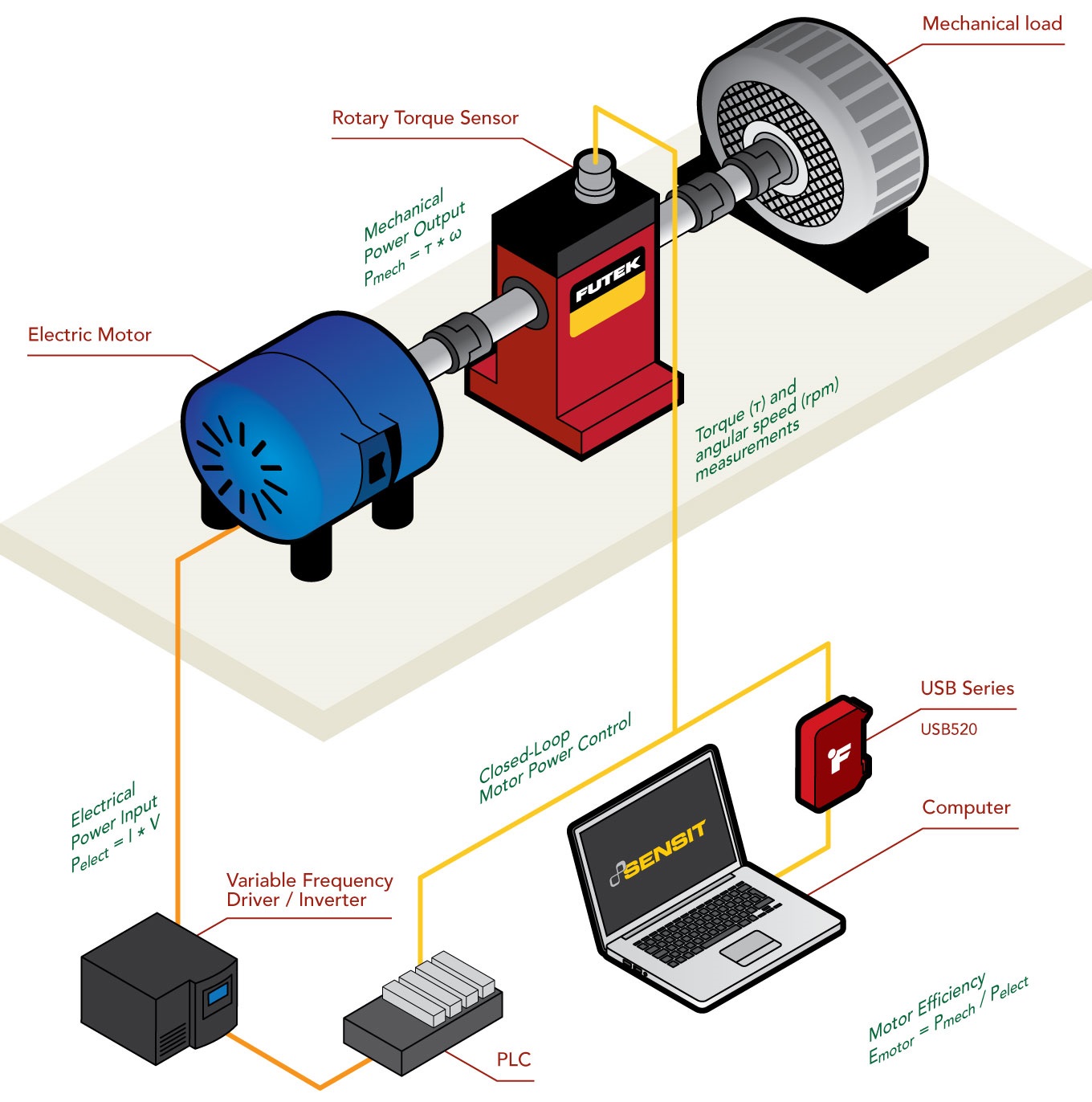

Electric vehicle and electric motor operations management is a critical aspect of ensuring the optimal performance and longevity of electric vehicles. At the heart of electric vehicle operations is the electric motor, which plays a crucial role in converting electrical energy into mechanical energy. Understanding the fundamentals of electric motor management is essential for optimizing electric vehicle performance, reducing energy consumption, and minimizing downtime.

One of the key aspects of electric motor management is efficient energy use. Electric motors consume a significant amount of energy, and optimizing their performance can lead to substantial cost savings and reduced environmental impact. This can be achieved by implementing energy-efficient driving techniques, such as regenerative braking and optimizing motor speed. Additionally, monitoring motor temperature and battery health is critical to preventing overheating and degradation, which can lead to reduced performance and increased maintenance costs.

Effective electric motor management also involves regular maintenance and monitoring. This includes performing routine inspections, updating software, and troubleshooting common issues. By identifying and addressing potential problems early, fleet managers and owners can prevent downtime, reduce maintenance costs, and ensure optimal vehicle performance. Furthermore, implementing a proactive maintenance schedule can help extend the lifespan of electric motors, reducing the need for costly repairs and replacements.

In the context of electric vehicle and electric motor operations management, understanding the fundamentals of electric motor management is crucial for optimizing performance, reducing energy consumption, and minimizing downtime. By implementing efficient energy use strategies, monitoring motor temperature and battery health, and performing regular maintenance, fleet managers and owners can ensure the optimal performance and longevity of their electric vehicles.

How to Implement a Proactive Maintenance Schedule for Electric Motors

Implementing a proactive maintenance schedule is crucial for optimizing electric vehicle performance and reducing downtime. A well-planned maintenance schedule can help identify potential issues before they become major problems, reducing the need for costly repairs and minimizing the risk of vehicle breakdowns. In the context of electric vehicle and electric motor operations management, a proactive maintenance schedule is essential for ensuring the optimal performance and longevity of electric motors.

To create a proactive maintenance schedule, fleet managers and owners should start by identifying the specific maintenance needs of their electric vehicles. This includes regular inspections of the electric motor, battery, and other critical components. Software updates should also be performed regularly to ensure that the vehicle’s systems are running with the latest software and firmware.

Regular inspections should include checks on the electric motor’s temperature, battery state of charge, and other critical parameters. This can help identify potential issues before they become major problems, allowing for proactive maintenance and reducing the risk of downtime. Additionally, troubleshooting common issues such as electrical faults, software glitches, and mechanical problems can help minimize the risk of vehicle breakdowns.

Another key aspect of a proactive maintenance schedule is data analysis. By analyzing data from the vehicle’s systems, fleet managers and owners can identify trends and patterns that can help optimize maintenance and reduce downtime. This can include analyzing data on energy consumption, motor temperature, and other critical parameters to identify areas for improvement.

By implementing a proactive maintenance schedule, fleet managers and owners can optimize electric vehicle performance, reduce downtime, and minimize costs. This is particularly important in the context of electric vehicle and electric motor operations management, where proactive maintenance can help ensure the optimal performance and longevity of electric motors.

The Role of Telematics in Electric Vehicle Operations Management

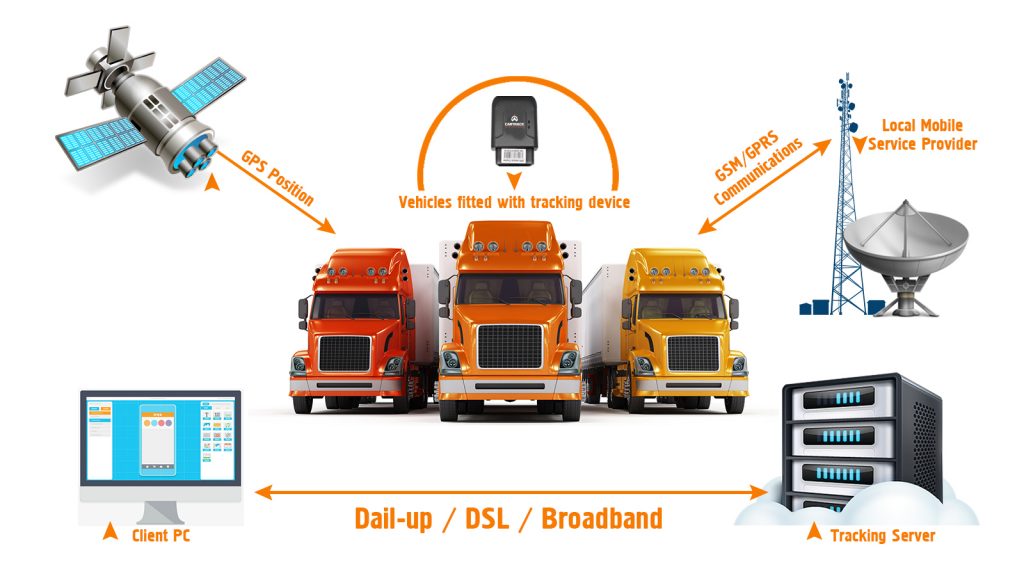

Telematics plays a vital role in electric vehicle operations management, enabling fleet managers and owners to optimize energy efficiency, reduce maintenance costs, and improve overall vehicle performance. By leveraging real-time data and analytics, telematics systems can help identify areas for improvement, predict potential issues, and provide insights into driver behavior and vehicle performance.

In the context of electric vehicle and electric motor operations management, telematics can help optimize energy efficiency by monitoring and analyzing data on energy consumption, motor temperature, and other critical parameters. This can help identify opportunities to reduce energy consumption, such as optimizing motor speed, using regenerative braking, and implementing energy-efficient driving techniques.

Telematics can also help reduce maintenance costs by enabling real-time monitoring and predictive maintenance. By analyzing data on vehicle performance and condition, telematics systems can help identify potential issues before they become major problems, reducing the need for costly repairs and minimizing downtime.

Furthermore, telematics can help improve overall vehicle performance by providing insights into driver behavior and vehicle performance. By analyzing data on driving habits, vehicle speed, and other parameters, telematics systems can help identify areas for improvement, such as optimizing route planning, reducing idling time, and improving driver training.

Some of the key benefits of telematics in electric vehicle operations management include improved energy efficiency, reduced maintenance costs, and enhanced vehicle performance. By leveraging real-time data and analytics, telematics systems can help fleet managers and owners optimize their electric vehicle operations, reducing costs and improving overall performance.

In addition, telematics can also help electric vehicle owners and fleet managers to comply with regulatory requirements, such as tracking and reporting on energy consumption and emissions. By providing a comprehensive view of vehicle performance and energy consumption, telematics systems can help owners and managers to make data-driven decisions and optimize their operations.

Electric Motor Efficiency: Strategies for Reducing Energy Consumption

Electric motor efficiency is a critical aspect of electric vehicle operations management, as it directly impacts the overall performance and range of the vehicle. By optimizing motor efficiency, fleet managers and owners can reduce energy consumption, lower operating costs, and minimize environmental impact.

One of the most effective strategies for reducing energy consumption in electric motors is optimizing motor speed. By adjusting the motor speed to match the specific requirements of the vehicle, energy consumption can be significantly reduced. This can be achieved through the use of advanced motor control systems, which can optimize motor speed in real-time based on factors such as vehicle speed, load, and terrain.

Another strategy for reducing energy consumption is the use of regenerative braking. Regenerative braking captures kinetic energy and converts it into electrical energy, which can be stored in the vehicle’s battery and used to power the motor. This can significantly reduce energy consumption, particularly in urban driving scenarios where frequent braking is common.

Implementing energy-efficient driving techniques is also an effective way to reduce energy consumption in electric motors. This can include techniques such as smooth acceleration, gentle braking, and maintaining a consistent speed. By promoting energy-efficient driving practices, fleet managers and owners can reduce energy consumption and lower operating costs.

In addition to these strategies, advancements in electric motor technology are also playing a critical role in reducing energy consumption. For example, the development of more efficient motor designs, such as permanent magnet motors and induction motors, is helping to reduce energy consumption and improve overall motor efficiency.

By implementing these strategies and leveraging advancements in electric motor technology, fleet managers and owners can significantly reduce energy consumption and improve the overall efficiency of their electric vehicle operations. This can lead to cost savings, reduced environmental impact, and improved vehicle performance.

Case Study: Real-World Examples of Electric Vehicle Operations Management in Action

Several companies have successfully implemented efficient motor operations and telematics systems to optimize their electric vehicle operations. One such example is a leading logistics company that operates a fleet of electric vehicles for last-mile delivery. By implementing a proactive maintenance schedule, telematics system, and energy-efficient driving techniques, the company was able to reduce energy consumption by 15% and lower operating costs by 10%.

Another example is a public transportation agency that operates a fleet of electric buses. By implementing a telematics system and real-time monitoring, the agency was able to optimize energy efficiency, reduce maintenance costs, and improve overall vehicle performance. The agency reported a 20% reduction in energy consumption and a 15% reduction in maintenance costs.

A third example is a ride-sharing company that operates a fleet of electric vehicles. By implementing a proactive maintenance schedule, telematics system, and energy-efficient driving techniques, the company was able to reduce energy consumption by 12% and lower operating costs by 8%. The company also reported a significant improvement in vehicle performance and a reduction in downtime.

These case studies demonstrate the benefits of implementing efficient motor operations and telematics systems in electric vehicle operations management. By optimizing energy efficiency, reducing maintenance costs, and improving overall vehicle performance, companies can achieve significant cost savings and improve their bottom line.

In addition to these case studies, there are many other examples of companies that have successfully implemented efficient motor operations and telematics systems to optimize their electric vehicle operations. These examples demonstrate the potential of electric vehicle operations management to improve efficiency, reduce costs, and enhance overall performance.

Overcoming Common Challenges in Electric Vehicle Operations Management

Despite the many benefits of electric vehicles, there are several common challenges that fleet managers and owners may face in electric vehicle operations management. One of the most significant challenges is range anxiety, which refers to the fear of running out of charge before reaching a charging station. To overcome this challenge, fleet managers and owners can implement route planning and optimization strategies, such as identifying charging stations along routes and scheduling charging sessions in advance.

Another common challenge is charging infrastructure limitations. While charging infrastructure is expanding rapidly, there are still many areas where charging stations are scarce. To overcome this challenge, fleet managers and owners can consider installing their own charging stations or partnering with charging station providers to ensure that their vehicles have access to reliable and convenient charging.

Battery degradation is another common challenge in electric vehicle operations management. To overcome this challenge, fleet managers and owners can implement battery health monitoring and maintenance strategies, such as regular battery checks and software updates. They can also consider implementing battery replacement programs to ensure that their vehicles are always equipped with healthy and efficient batteries.

In addition to these challenges, fleet managers and owners may also face challenges related to vehicle performance and maintenance. To overcome these challenges, they can implement proactive maintenance schedules, including regular inspections and software updates. They can also consider implementing vehicle monitoring and diagnostic systems to identify and address potential issues before they become major problems.

By understanding and addressing these common challenges, fleet managers and owners can optimize their electric vehicle operations and achieve significant cost savings and performance improvements. By implementing strategies such as route planning and optimization, charging infrastructure development, battery health monitoring, and proactive maintenance, they can ensure that their electric vehicles are running efficiently and effectively, and that they are achieving their full potential.

The Future of Electric Vehicle Operations Management: Emerging Trends and Technologies

The electric vehicle industry is rapidly evolving, with emerging trends and technologies that are transforming the way electric vehicles are operated and managed. One of the most significant trends is the development of advanced battery technologies, such as solid-state batteries and lithium-air batteries. These technologies have the potential to significantly improve the range and efficiency of electric vehicles, making them more viable for widespread adoption.

Another emerging trend is the development of autonomous driving technologies. Autonomous vehicles have the potential to revolutionize the way electric vehicles are operated, enabling them to drive themselves and reducing the need for human intervention. This could lead to significant improvements in safety, efficiency, and productivity.

Vehicle-to-grid (V2G) systems are another emerging technology that is transforming the way electric vehicles are operated and managed. V2G systems enable electric vehicles to act as energy storage devices, providing energy back to the grid when not in use. This could lead to significant improvements in energy efficiency and grid stability.

In addition to these emerging trends and technologies, there are also several other developments that are transforming the electric vehicle industry. For example, the development of advanced telematics systems is enabling fleet managers and owners to optimize their electric vehicle operations, reducing energy consumption and improving overall performance.

The integration of electric vehicles with renewable energy sources is also becoming increasingly popular. This enables electric vehicles to be powered by renewable energy sources, such as solar and wind power, reducing greenhouse gas emissions and improving energy efficiency.

Overall, the future of electric vehicle operations management is exciting and rapidly evolving. Emerging trends and technologies are transforming the way electric vehicles are operated and managed, enabling significant improvements in efficiency, productivity, and sustainability.

Best Practices for Electric Vehicle Operations Management: A Summary

Electric vehicle operations management is a complex and multifaceted field that requires a comprehensive approach to optimize performance and reduce costs. By implementing best practices such as proactive maintenance, telematics, energy efficiency, and overcoming common challenges, fleet managers and owners can ensure that their electric vehicles are running efficiently and effectively.

Proactive maintenance is a critical component of electric vehicle operations management. By implementing a proactive maintenance schedule, fleet managers and owners can prevent downtime, reduce maintenance costs, and improve overall vehicle performance. This includes regular inspections, software updates, and troubleshooting common issues.

Telematics is another important aspect of electric vehicle operations management. By leveraging real-time monitoring, data analytics, and performance optimization, fleet managers and owners can optimize energy efficiency, reduce maintenance costs, and improve overall vehicle performance. Telematics can also help identify potential issues before they become major problems, reducing downtime and improving overall efficiency.

Energy efficiency is also a key consideration in electric vehicle operations management. By implementing energy-efficient driving techniques, optimizing motor speed, and using regenerative braking, fleet managers and owners can reduce energy consumption and lower operating costs. This can also help reduce greenhouse gas emissions and improve environmental sustainability.

Finally, overcoming common challenges such as range anxiety, charging infrastructure limitations, and battery degradation is critical to optimizing electric vehicle performance. By implementing strategies such as route planning and optimization, charging infrastructure development, and battery health monitoring, fleet managers and owners can overcome these challenges and ensure that their electric vehicles are running efficiently and effectively.

By implementing these best practices, fleet managers and owners can optimize their electric vehicle operations and achieve significant cost savings and performance improvements. By taking a comprehensive approach to electric vehicle operations management, they can ensure that their electric vehicles are running efficiently and effectively, and that they are achieving their full potential.