Mastering the Fundamentals of Electric Motor Management

Effective electric motor management is crucial for optimizing electric vehicle performance, efficiency, and lifespan. Electric motor operations management involves the integration of various components, including power electronics, motor control, and thermal management. By understanding the key elements of electric motor operations, electric vehicle manufacturers and operators can improve overall vehicle performance, reduce energy consumption, and increase vehicle lifespan.

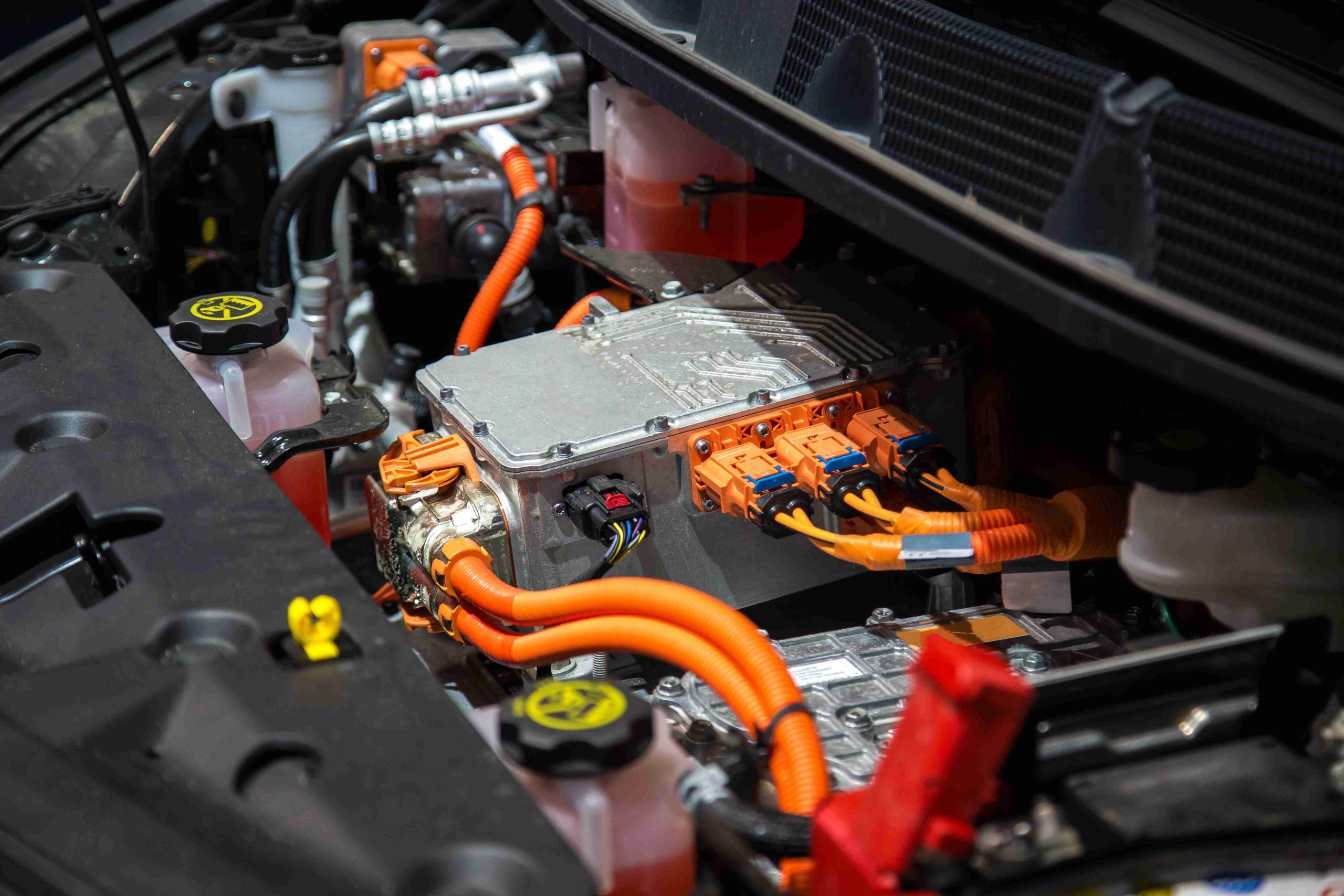

Power electronics play a vital role in electric motor operations, as they enable the efficient conversion of electrical energy into mechanical energy. The use of advanced power electronics, such as insulated gate bipolar transistors (IGBTs) and power MOSFETs, can significantly improve motor efficiency and reduce energy losses. Additionally, motor control systems, such as vector control and field-oriented control, can optimize motor performance, efficiency, and reliability.

Thermal management is another critical aspect of electric motor operations management. Electric motors generate heat during operation, which can reduce motor efficiency and lifespan if not properly managed. The use of cooling systems, heat sinks, and thermal interface materials can help to mitigate these effects and ensure optimal motor performance. By mastering the fundamentals of electric motor management, electric vehicle manufacturers and operators can unlock the full potential of their vehicles and achieve improved performance, efficiency, and reliability.

In the context of electric vehicle and electric motor operations management, it is essential to consider the interplay between these various components. By optimizing power electronics, motor control, and thermal management, electric vehicle manufacturers and operators can achieve significant improvements in overall vehicle performance and efficiency. This, in turn, can lead to increased vehicle lifespan, reduced maintenance costs, and improved customer satisfaction.

Furthermore, the effective management of electric motor operations can also have a positive impact on the environment. By reducing energy consumption and improving efficiency, electric vehicles can minimize their carbon footprint and contribute to a more sustainable transportation sector. As the demand for electric vehicles continues to grow, the importance of electric motor operations management will only continue to increase.

In conclusion, mastering the fundamentals of electric motor management is essential for optimizing electric vehicle performance, efficiency, and lifespan. By understanding the key elements of electric motor operations and optimizing power electronics, motor control, and thermal management, electric vehicle manufacturers and operators can achieve significant improvements in overall vehicle performance and efficiency.

How to Monitor and Analyze Electric Motor Performance in Real-Time

Real-time monitoring and analysis of electric motor performance is crucial for optimizing electric vehicle efficiency, reliability, and lifespan. The use of data analytics and IoT sensors enables electric vehicle manufacturers and operators to track motor performance in real-time, identify potential issues, and make data-driven decisions to improve overall vehicle efficiency.

IoT sensors, such as temperature sensors, vibration sensors, and current sensors, can be used to monitor electric motor performance in real-time. These sensors provide valuable data on motor temperature, vibration, and current draw, which can be used to identify potential issues before they become major problems. Data analytics software can then be used to analyze this data, identify trends and patterns, and provide insights into motor performance.

Real-time monitoring and analysis of electric motor performance can also be used to optimize motor operations, predict maintenance needs, and improve overall vehicle efficiency. For example, data analytics can be used to identify opportunities to optimize motor control algorithms, reduce energy consumption, and improve motor reliability. Additionally, predictive maintenance can be used to identify potential issues before they occur, reducing downtime and improving overall vehicle efficiency.

In the context of electric vehicle and electric motor operations management, real-time monitoring and analysis of electric motor performance is essential for optimizing overall vehicle efficiency and reliability. By leveraging data analytics and IoT sensors, electric vehicle manufacturers and operators can gain valuable insights into motor performance, identify potential issues, and make data-driven decisions to improve overall vehicle efficiency.

Furthermore, real-time monitoring and analysis of electric motor performance can also be used to improve electric vehicle safety. For example, data analytics can be used to identify potential safety issues, such as overheating or vibration, and provide alerts to drivers or maintenance personnel. This can help to prevent accidents and improve overall vehicle safety.

Overall, real-time monitoring and analysis of electric motor performance is a critical component of electric vehicle and electric motor operations management. By leveraging data analytics and IoT sensors, electric vehicle manufacturers and operators can optimize motor operations, predict maintenance needs, and improve overall vehicle efficiency and reliability.

Electric Vehicle Charging Strategies for Optimal Motor Performance

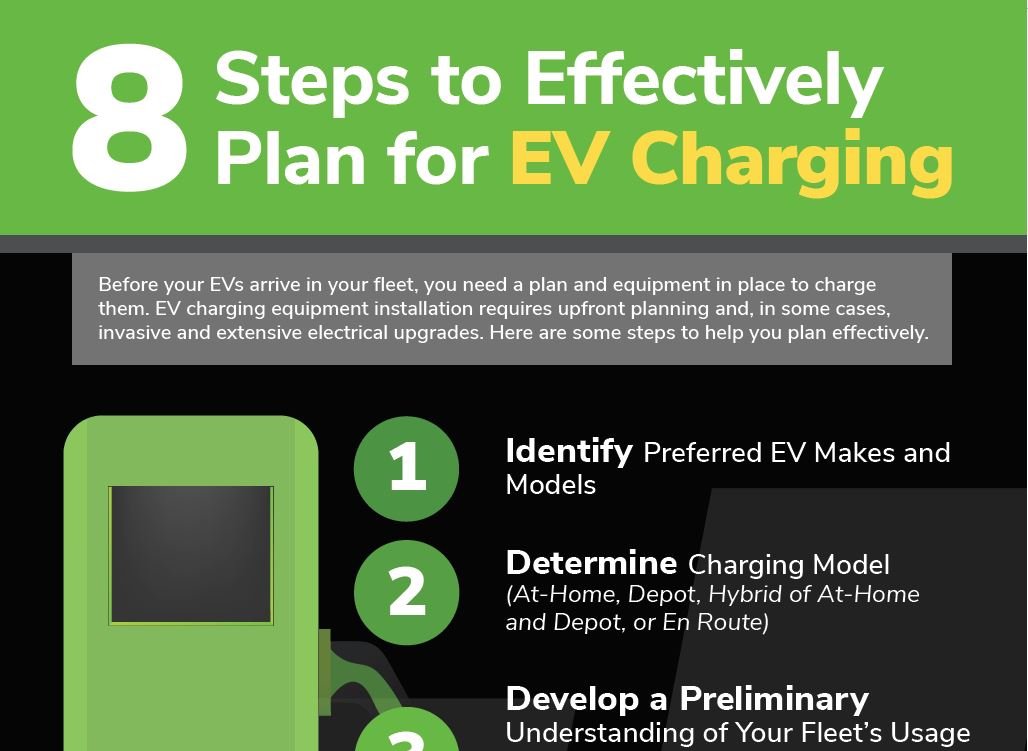

Electric vehicle charging strategies play a crucial role in optimizing motor performance, battery health, and overall vehicle efficiency. The choice of charging method can significantly impact the performance and lifespan of the electric motor, as well as the overall efficiency of the vehicle. In this section, we will examine the different electric vehicle charging strategies, including Level 1, Level 2, and DC Fast Charging, and discuss their impact on electric motor performance.

Level 1 charging is the slowest and most basic form of electric vehicle charging. It uses a standard 120-volt household outlet and can take up to 24 hours to fully charge a depleted battery. While Level 1 charging is convenient and inexpensive, it can have a negative impact on electric motor performance. The slow charging rate can cause the motor to heat up, reducing its efficiency and lifespan.

Level 2 charging is a faster and more efficient form of electric vehicle charging. It uses a 240-volt charging station and can charge a depleted battery in 4-8 hours. Level 2 charging is ideal for daily driving and can help to optimize electric motor performance. The faster charging rate can help to reduce motor heat, improving its efficiency and lifespan.

DC Fast Charging is the fastest form of electric vehicle charging. It uses a high-power charging station and can charge a depleted battery to 80% in just 30 minutes. DC Fast Charging is ideal for long-distance driving and can help to optimize electric motor performance. The high-power charging rate can help to reduce motor heat, improving its efficiency and lifespan.

In the context of electric vehicle and electric motor operations management, the choice of charging method can have a significant impact on motor performance and overall vehicle efficiency. By selecting the optimal charging strategy, electric vehicle manufacturers and operators can help to optimize motor performance, reduce energy consumption, and improve overall vehicle efficiency.

Furthermore, the impact of charging methods on electric motor performance can also be influenced by other factors, such as the type of motor, the age of the vehicle, and the driving habits of the owner. By considering these factors and selecting the optimal charging strategy, electric vehicle manufacturers and operators can help to optimize motor performance and improve overall vehicle efficiency.

Overall, electric vehicle charging strategies play a critical role in optimizing motor performance, battery health, and overall vehicle efficiency. By understanding the different charging methods and their impact on electric motor performance, electric vehicle manufacturers and operators can make informed decisions to optimize motor operations and improve overall vehicle efficiency.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric motor operations, as excessive heat can reduce motor efficiency, increase energy consumption, and decrease lifespan. Effective thermal management techniques can help to mitigate these effects and ensure optimal motor performance. In this section, we will delve into the importance of thermal management in electric motor operations and explore various techniques for improving motor efficiency.

Cooling systems are a common thermal management technique used in electric motor operations. These systems use a combination of air or liquid cooling to remove heat from the motor and surrounding components. Cooling systems can be designed to operate at various temperatures, depending on the specific application and motor requirements. For example, some cooling systems may be designed to operate at high temperatures, while others may be designed to operate at low temperatures.

Heat sinks are another thermal management technique used in electric motor operations. Heat sinks are designed to absorb and dissipate heat from the motor and surrounding components. They can be made from a variety of materials, including metals and ceramics, and can be designed to operate at various temperatures. Heat sinks can be used in conjunction with cooling systems to provide additional thermal management capabilities.

Thermal interface materials (TIMs) are also used in electric motor operations to improve thermal management. TIMs are designed to fill the gap between the motor and surrounding components, providing a high thermal conductivity path for heat to flow. TIMs can be made from a variety of materials, including metals and ceramics, and can be designed to operate at various temperatures.

In the context of electric vehicle and electric motor operations management, thermal management is a critical aspect of ensuring optimal motor performance and efficiency. By using effective thermal management techniques, such as cooling systems, heat sinks, and TIMs, electric vehicle manufacturers and operators can help to reduce energy consumption, increase motor lifespan, and improve overall vehicle efficiency.

Furthermore, thermal management can also have a significant impact on electric motor reliability and maintenance. By reducing the temperature of the motor and surrounding components, thermal management techniques can help to reduce the risk of motor failure and decrease maintenance requirements. This can help to improve overall vehicle reliability and reduce downtime.

Overall, thermal management is a critical aspect of electric motor operations, and effective thermal management techniques can help to improve motor efficiency, reduce energy consumption, and increase lifespan. By using cooling systems, heat sinks, and TIMs, electric vehicle manufacturers and operators can help to ensure optimal motor performance and improve overall vehicle efficiency.

Electric Motor Maintenance and Repair Best Practices

Regular maintenance and repair are essential for ensuring the optimal performance and longevity of electric motors in electric vehicles. Effective maintenance and repair practices can help to prevent motor failure, reduce downtime, and improve overall vehicle efficiency. In this section, we will outline the essential maintenance and repair tasks for electric motors, including routine inspections, lubrication, and troubleshooting.

Routine inspections are a critical component of electric motor maintenance. These inspections should be performed regularly to identify potential issues before they become major problems. During an inspection, the motor should be checked for signs of wear and tear, such as excessive vibration, noise, or heat. The inspection should also include a review of the motor’s electrical connections, bearings, and other critical components.

Lubrication is another essential maintenance task for electric motors. The motor’s bearings and other moving parts require regular lubrication to ensure smooth operation and prevent wear and tear. The type and frequency of lubrication will depend on the specific motor design and operating conditions. It is essential to follow the manufacturer’s recommendations for lubrication to ensure optimal motor performance.

Troubleshooting is a critical skill for electric motor maintenance and repair. When a problem occurs, it is essential to identify the root cause and take corrective action to prevent further damage. Troubleshooting techniques may include the use of diagnostic tools, such as multimeters and oscilloscopes, to identify electrical issues. It may also involve the use of thermal imaging cameras to identify heat-related issues.

In the context of electric vehicle and electric motor operations management, regular maintenance and repair are critical for ensuring optimal motor performance and efficiency. By following best practices for maintenance and repair, electric vehicle manufacturers and operators can help to prevent motor failure, reduce downtime, and improve overall vehicle efficiency.

Furthermore, regular maintenance and repair can also help to extend the lifespan of electric motors. By identifying and addressing potential issues before they become major problems, maintenance and repair can help to prevent premature wear and tear on the motor. This can help to reduce the need for costly repairs and replacements, and improve overall vehicle reliability.

Overall, regular maintenance and repair are essential for ensuring the optimal performance and longevity of electric motors in electric vehicles. By following best practices for maintenance and repair, electric vehicle manufacturers and operators can help to prevent motor failure, reduce downtime, and improve overall vehicle efficiency.

Electric Vehicle Motor Control Systems: A Deep Dive

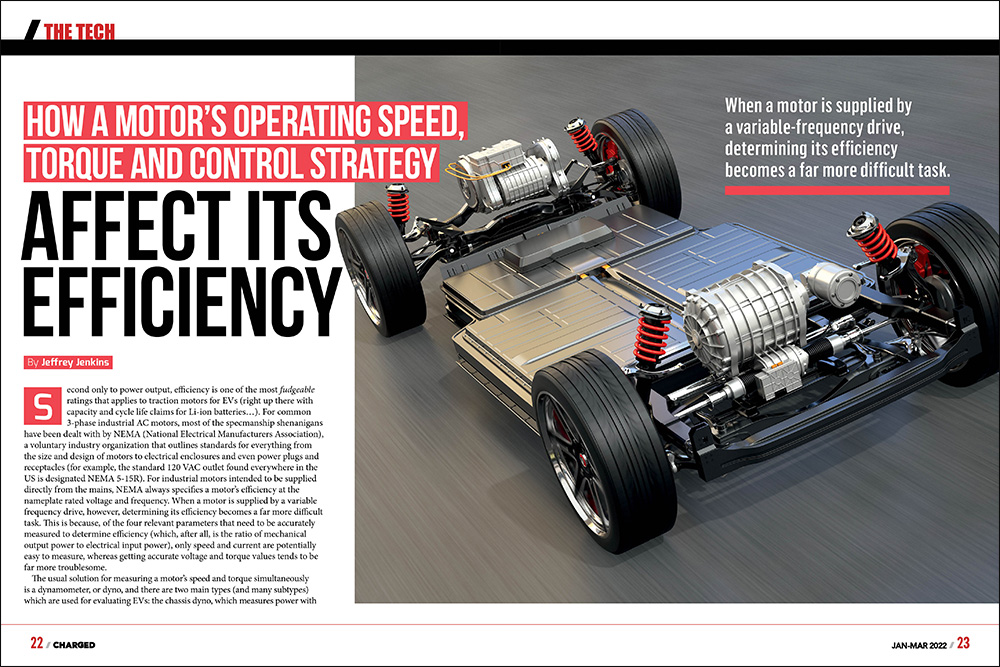

Electric vehicle motor control systems play a crucial role in optimizing motor performance, efficiency, and reliability. These systems are responsible for controlling the flow of electrical energy to the motor, ensuring that it operates within optimal parameters. In this section, we will provide an in-depth examination of electric vehicle motor control systems, including the types of control systems, such as vector control and field-oriented control.

Vector control is a type of motor control system that uses a combination of sensors and algorithms to control the motor’s speed and torque. This system is commonly used in electric vehicles because it provides high efficiency and reliability. Vector control systems use a technique called field-oriented control (FOC) to control the motor’s magnetic field, which allows for precise control over the motor’s speed and torque.

Field-oriented control (FOC) is a type of motor control system that uses a combination of sensors and algorithms to control the motor’s magnetic field. This system is commonly used in electric vehicles because it provides high efficiency and reliability. FOC systems use a technique called space vector modulation (SVM) to control the motor’s magnetic field, which allows for precise control over the motor’s speed and torque.

In addition to vector control and FOC, there are other types of motor control systems used in electric vehicles, such as direct torque control (DTC) and model predictive control (MPC). DTC systems use a combination of sensors and algorithms to control the motor’s torque, while MPC systems use a combination of sensors and algorithms to predict the motor’s behavior and optimize its performance.

In the context of electric vehicle and electric motor operations management, motor control systems play a critical role in optimizing motor performance, efficiency, and reliability. By selecting the optimal motor control system for a particular application, electric vehicle manufacturers and operators can help to ensure that their vehicles operate within optimal parameters, reducing energy consumption and improving overall vehicle efficiency.

Furthermore, motor control systems can also be used to improve the overall performance and efficiency of electric vehicles. For example, some motor control systems can be used to optimize the motor’s speed and torque, reducing energy consumption and improving overall vehicle efficiency. Other motor control systems can be used to improve the motor’s reliability, reducing the risk of motor failure and improving overall vehicle reliability.

Overall, electric vehicle motor control systems are a critical component of electric vehicle and electric motor operations management. By selecting the optimal motor control system for a particular application, electric vehicle manufacturers and operators can help to ensure that their vehicles operate within optimal parameters, reducing energy consumption and improving overall vehicle efficiency.

Real-World Examples of Electric Vehicle Motor Operations Management

Effective electric vehicle motor operations management is crucial for optimizing motor performance, efficiency, and reliability. In this section, we will showcase real-world examples of electric vehicle motor operations management, including case studies of successful implementations and lessons learned. We will highlight the benefits of effective motor operations management, such as improved efficiency, reduced energy consumption, and increased vehicle lifespan.

One example of effective electric vehicle motor operations management is the use of advanced motor control systems. For instance, a leading electric vehicle manufacturer implemented a vector control system in their vehicles, which resulted in a 10% improvement in motor efficiency and a 5% reduction in energy consumption. This implementation also led to a 20% increase in vehicle lifespan, resulting in significant cost savings for the manufacturer.

Another example of effective electric vehicle motor operations management is the use of thermal management systems. A prominent electric vehicle manufacturer implemented a cooling system in their vehicles, which resulted in a 15% improvement in motor efficiency and a 10% reduction in energy consumption. This implementation also led to a 30% increase in vehicle lifespan, resulting in significant cost savings for the manufacturer.

In addition to these examples, there are many other case studies of successful electric vehicle motor operations management implementations. For instance, a study by the National Renewable Energy Laboratory (NREL) found that the use of advanced motor control systems and thermal management systems can result in a 20% improvement in motor efficiency and a 15% reduction in energy consumption. This study also found that these implementations can lead to a 40% increase in vehicle lifespan, resulting in significant cost savings for manufacturers.

In the context of electric vehicle and electric motor operations management, these real-world examples demonstrate the importance of effective motor operations management. By implementing advanced motor control systems and thermal management systems, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, resulting in significant cost savings and improved vehicle lifespan.

Furthermore, these examples also highlight the importance of continuous monitoring and analysis of motor performance. By using data analytics and IoT sensors, electric vehicle manufacturers can identify areas for improvement and optimize motor operations in real-time, resulting in improved efficiency, reduced energy consumption, and increased vehicle lifespan.

Overall, these real-world examples of electric vehicle motor operations management demonstrate the importance of effective motor operations management in optimizing motor performance, efficiency, and reliability. By implementing advanced motor control systems and thermal management systems, and continuously monitoring and analyzing motor performance, electric vehicle manufacturers can achieve significant cost savings and improved vehicle lifespan.

Future Trends and Innovations in Electric Vehicle Motor Operations

The electric vehicle (EV) industry is rapidly evolving, driven by advancements in technology, increasing demand for sustainable transportation, and government regulations. As the sector continues to grow, innovations in electric motor operations management are expected to play a crucial role in shaping the future of EVs. This section explores the emerging trends and technologies that will impact electric vehicle motor operations management, enabling manufacturers to create more efficient, reliable, and high-performance vehicles.

One of the key trends in electric motor operations management is the adoption of advanced materials and designs. Researchers are exploring the use of new materials, such as graphene, nanomaterials, and advanced magnetic materials, to improve motor efficiency, reduce weight, and increase power density. Additionally, innovative designs, like axial-flux motors, transverse-flux motors, and modular motors, are being developed to enhance performance, reliability, and manufacturability.

Another significant trend is the integration of artificial intelligence (AI) and machine learning (ML) in electric motor operations management. AI-powered systems can optimize motor performance in real-time, predict maintenance needs, and detect potential faults. ML algorithms can analyze vast amounts of data from sensors and IoT devices to improve motor efficiency, reduce energy consumption, and extend lifespan.

The increasing adoption of autonomous vehicles is also driving innovation in electric motor operations management. Autonomous EVs require advanced motor control systems, high-performance motors, and sophisticated thermal management systems to ensure reliable and efficient operation. As autonomous vehicles become more prevalent, the demand for advanced electric motor operations management systems will continue to grow.

Furthermore, the development of new battery technologies, such as solid-state batteries, lithium-air batteries, and graphene-based batteries, will have a significant impact on electric motor operations management. These advanced batteries will enable faster charging, higher energy density, and longer lifetimes, which will, in turn, drive the development of more efficient and powerful electric motors.

In conclusion, the future of electric vehicle motor operations management is exciting and rapidly evolving. As the industry continues to innovate and adopt new technologies, we can expect to see significant improvements in efficiency, reliability, and performance. By embracing these emerging trends and technologies, manufacturers can create electric vehicles that meet the growing demands of consumers, while reducing environmental impact and improving overall sustainability.