Mastering the Fundamentals of Electric Motor Management

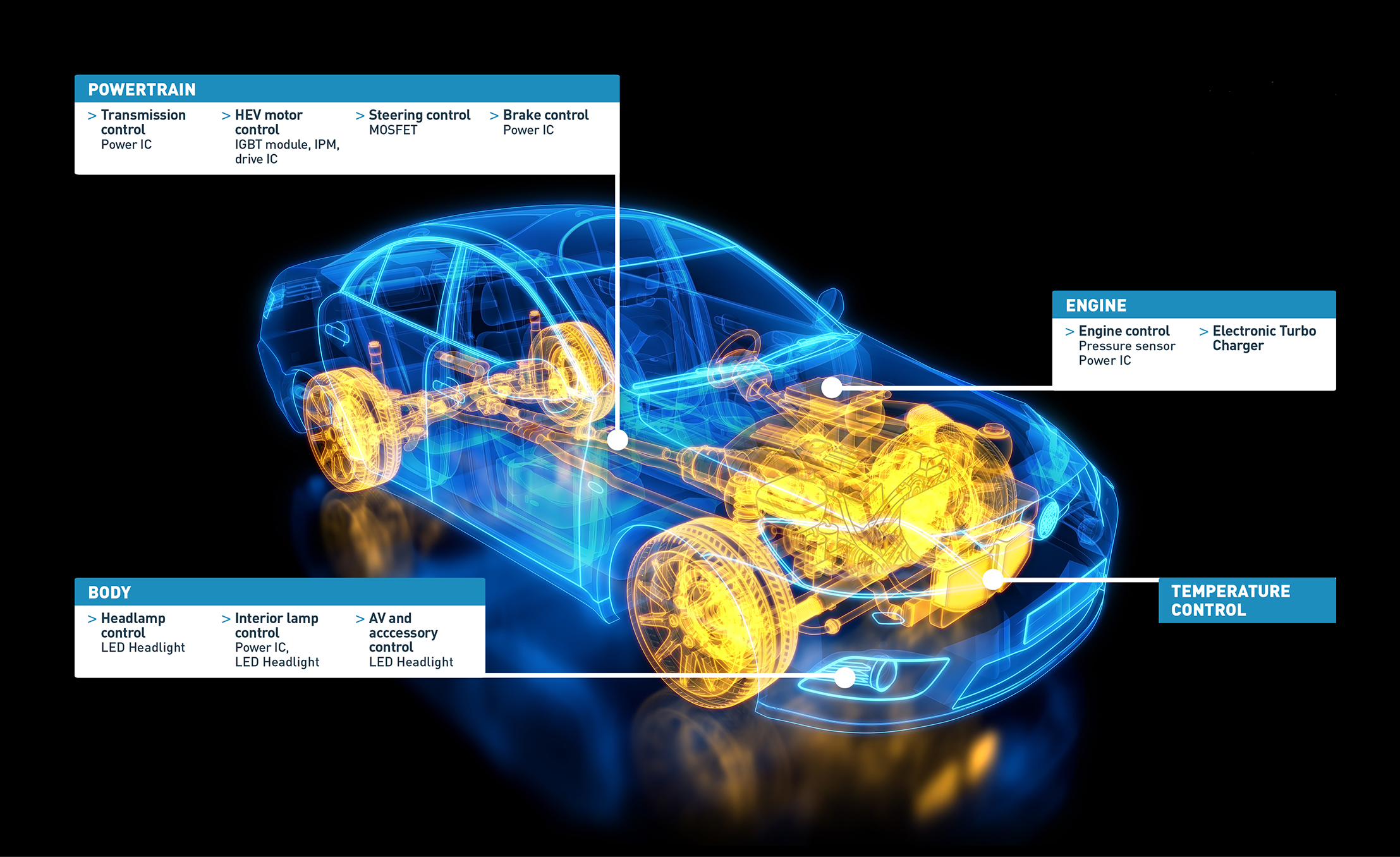

Efficient electric motor operations are crucial for optimal electric vehicle (EV) performance, range, and overall driving experience. Electric motor management plays a vital role in ensuring that EVs operate at their best, and it is essential to understand the basics of this complex system. Electric vehicle and electric motor operations management involve the coordination of various components, including the electric motor, power electronics, and control systems, to achieve efficient and reliable operation.

The electric motor is the heart of an EV, responsible for converting electrical energy into mechanical energy. It is essential to manage the motor’s performance, efficiency, and lifespan to ensure optimal EV operation. This involves monitoring and controlling the motor’s temperature, speed, and torque, as well as managing the flow of electrical energy to the motor. By mastering the fundamentals of electric motor management, EV owners and operators can optimize their vehicle’s performance, reduce energy consumption, and extend the lifespan of the motor.

Electric motor management involves a range of techniques and strategies, including thermal management, power electronics management, and control systems management. Thermal management is critical to prevent overheating, which can reduce the motor’s efficiency and lifespan. Power electronics management involves the use of power converters, such as DC-DC converters and inverters, to control the flow of electrical energy to the motor. Control systems management involves the use of software algorithms and sensors to monitor and control the motor’s performance.

By understanding the basics of electric motor management, EV owners and operators can take the first step towards optimizing their vehicle’s performance and efficiency. This involves recognizing the importance of electric vehicle and electric motor operations management and taking steps to implement effective management strategies. By doing so, EV owners and operators can enjoy a better driving experience, reduce energy consumption, and extend the lifespan of their vehicle’s motor.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance of electric motor health are crucial for ensuring optimal electric vehicle (EV) performance and efficiency. A well-maintained motor can provide a longer lifespan, reduced energy consumption, and improved overall driving experience. In the context of electric vehicle and electric motor operations management, motor health monitoring and maintenance are essential for achieving efficient motor operations.

One of the most critical aspects of motor health monitoring is regular checks. EV owners and operators should perform routine checks on the motor’s temperature, speed, and torque to identify any potential issues. This can be done using onboard diagnostic systems or external monitoring tools. Additionally, troubleshooting common issues such as overheating, vibration, or unusual noises can help prevent more severe problems from developing.

Performing routine maintenance tasks is also vital for maintaining motor health. This includes tasks such as cleaning the motor, checking and replacing worn-out components, and updating software and firmware. Regular maintenance can help prevent motor failure, reduce downtime, and ensure optimal performance.

Another essential aspect of motor health monitoring is the use of data analytics and condition monitoring. Advanced data analytics and condition monitoring systems can provide real-time insights into motor performance, allowing EV owners and operators to identify potential issues before they become major problems. This can help reduce maintenance costs, improve motor lifespan, and optimize overall EV performance.

In addition to regular checks and maintenance, EV owners and operators should also be aware of common motor health issues and their causes. For example, overheating can be caused by high ambient temperatures, inadequate cooling systems, or excessive load. By understanding the causes of common motor health issues, EV owners and operators can take proactive steps to prevent them and ensure optimal motor performance.

By following these best practices for monitoring and maintaining electric motor health, EV owners and operators can ensure optimal motor performance, reduce energy consumption, and extend the lifespan of their vehicle’s motor. This is particularly important in the context of electric vehicle and electric motor operations management, where efficient motor operations are critical for achieving optimal EV performance and efficiency.

Electric Vehicle Charging Strategies for Efficient Motor Operations

Charging strategies play a crucial role in electric vehicle (EV) motor operations, as they can significantly impact the efficiency, performance, and lifespan of the motor. In the context of electric vehicle and electric motor operations management, choosing the right charging strategy is essential for optimizing motor performance and efficiency.

Rapid charging, slow charging, and optimal charging schedules are three common charging strategies used in EVs. Rapid charging involves charging the battery to 80% capacity in under 30 minutes, while slow charging involves charging the battery over a longer period, typically several hours. Optimal charging schedules, on the other hand, involve charging the battery during off-peak hours when electricity rates are lower.

The choice of charging strategy depends on various factors, including the type of EV, motor type, and driving habits. For example, rapid charging may be suitable for EVs with high-power motors, while slow charging may be more suitable for EVs with lower-power motors. Additionally, optimal charging schedules can help reduce energy costs and minimize the impact on the grid.

It’s also important to consider the impact of charging strategies on motor health. For example, rapid charging can cause increased heat generation, which can reduce motor lifespan. On the other hand, slow charging can help reduce heat generation and prolong motor lifespan.

To choose the right charging strategy for your EV and motor type, it’s essential to consider the following factors: motor type, battery type, driving habits, and charging infrastructure. By understanding these factors and choosing the right charging strategy, EV owners and operators can optimize motor performance, reduce energy consumption, and extend the lifespan of their vehicle’s motor.

In addition to choosing the right charging strategy, EV owners and operators can also optimize motor performance by using advanced charging technologies, such as smart charging systems and vehicle-to-grid (V2G) technology. These technologies can help optimize charging schedules, reduce energy costs, and minimize the impact on the grid.

By optimizing charging strategies and using advanced charging technologies, EV owners and operators can ensure efficient motor operations, reduce energy consumption, and prolong the lifespan of their vehicle’s motor. This is particularly important in the context of electric vehicle and electric motor operations management, where efficient motor operations are critical for achieving optimal EV performance and efficiency.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric vehicle (EV) motor operations, as it directly impacts motor efficiency, performance, and lifespan. In the context of electric vehicle and electric motor operations management, thermal management is essential for optimizing motor performance and efficiency.

Temperature plays a significant role in motor efficiency and lifespan. High temperatures can reduce motor efficiency, increase energy consumption, and shorten motor lifespan. On the other hand, low temperatures can improve motor efficiency, reduce energy consumption, and prolong motor lifespan.

There are several thermal management techniques used in EV motor operations, including cooling systems and thermal shielding. Cooling systems, such as air-cooled or liquid-cooled systems, are designed to remove heat from the motor and maintain a stable temperature. Thermal shielding, on the other hand, involves using materials with high thermal resistance to reduce heat transfer between the motor and surrounding components.

Advanced thermal management techniques, such as advanced cooling systems and thermal energy harvesting, are also being developed to improve motor efficiency and performance. These techniques involve using advanced materials and technologies to optimize heat transfer and reduce energy consumption.

In addition to thermal management techniques, EV manufacturers are also using advanced motor designs and materials to improve motor efficiency and performance. For example, some EV manufacturers are using permanent magnet motors, which are more efficient and have a longer lifespan than traditional induction motors.

By using thermal management techniques and advanced motor designs, EV manufacturers can improve motor efficiency, reduce energy consumption, and prolong motor lifespan. This is particularly important in the context of electric vehicle and electric motor operations management, where efficient motor operations are critical for achieving optimal EV performance and efficiency.

Furthermore, thermal management techniques can also be used to improve the overall driving experience of EVs. For example, advanced cooling systems can be used to improve the performance of EVs in hot weather conditions, while thermal shielding can be used to reduce noise and vibration.

In conclusion, thermal management is a critical aspect of EV motor operations, and using advanced thermal management techniques and motor designs can improve motor efficiency, reduce energy consumption, and prolong motor lifespan. By optimizing thermal management, EV manufacturers can improve the overall performance and efficiency of their vehicles, and provide a better driving experience for their customers.

Electric Motor Control Systems: Understanding the Technology

Electric motor control systems play a crucial role in optimizing the performance and efficiency of electric vehicles (EVs). In the context of electric vehicle and electric motor operations management, understanding the technology behind these systems is essential for achieving optimal EV performance.

Electric motor control systems consist of three main components: power electronics, motor controllers, and software algorithms. Power electronics are responsible for converting DC power from the battery to AC power for the motor. Motor controllers regulate the flow of electrical energy to the motor, while software algorithms optimize motor performance and efficiency.

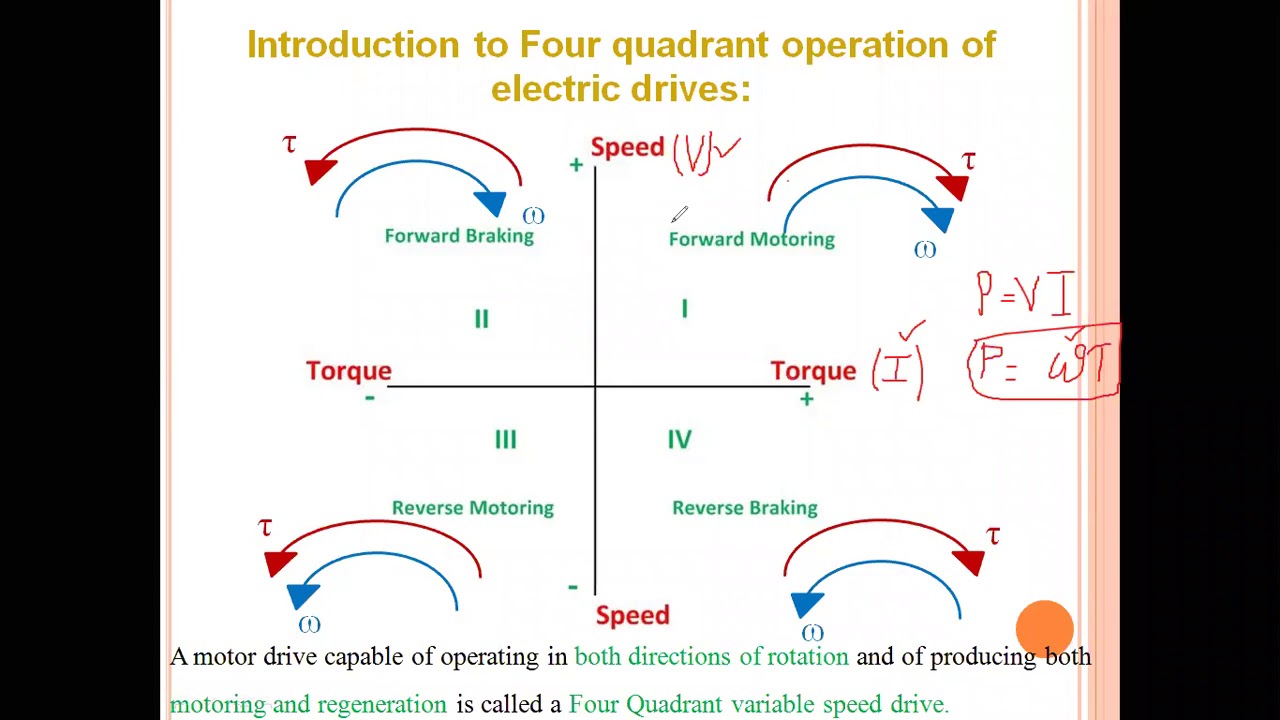

Advanced motor control systems use sophisticated software algorithms to optimize motor performance and efficiency. These algorithms can adjust the motor’s speed, torque, and power output in real-time to achieve optimal performance and efficiency. Additionally, some motor control systems use artificial intelligence (AI) and machine learning (ML) to predict and adapt to changing driving conditions.

One of the key benefits of advanced motor control systems is improved efficiency. By optimizing motor performance and efficiency, EVs can achieve longer ranges and reduced energy consumption. Additionally, advanced motor control systems can improve the overall driving experience by providing smoother acceleration and quieter operation.

Another important aspect of electric motor control systems is the use of power electronics. Power electronics are responsible for converting DC power from the battery to AC power for the motor. Advanced power electronics can improve the efficiency and reliability of the motor control system, while also reducing the overall cost and weight of the system.

In addition to power electronics and software algorithms, motor controllers are also a critical component of electric motor control systems. Motor controllers regulate the flow of electrical energy to the motor, and can adjust the motor’s speed, torque, and power output in real-time to achieve optimal performance and efficiency.

By understanding the technology behind electric motor control systems, EV manufacturers and operators can optimize motor performance and efficiency, achieving longer ranges and reduced energy consumption. This is particularly important in the context of electric vehicle and electric motor operations management, where efficient motor operations are critical for achieving optimal EV performance and efficiency.

Furthermore, advanced motor control systems can also provide real-time monitoring and diagnostics, allowing EV manufacturers and operators to identify and address potential issues before they become major problems. This can help improve the overall reliability and efficiency of the motor control system, while also reducing maintenance costs and downtime.

Real-World Examples: Electric Vehicle Motor Operations in Practice

Electric vehicle (EV) motor operations are a critical aspect of EV performance and efficiency. In the context of electric vehicle and electric motor operations management, understanding how EV motor operations work in practice is essential for optimizing EV performance and efficiency.

One example of successful EV motor operations is the Tesla Model S. The Tesla Model S uses a high-performance electric motor that is capable of producing up to 762 horsepower. The motor is controlled by a sophisticated motor control system that optimizes motor performance and efficiency in real-time.

Another example of successful EV motor operations is the Nissan Leaf. The Nissan Leaf uses a high-efficiency electric motor that is capable of producing up to 147 horsepower. The motor is controlled by a advanced motor control system that optimizes motor performance and efficiency in real-time.

In addition to these examples, there are many other successful EV motor operations in practice. For example, the BMW i3 uses a high-performance electric motor that is capable of producing up to 170 horsepower. The motor is controlled by a sophisticated motor control system that optimizes motor performance and efficiency in real-time.

These examples demonstrate the importance of efficient motor operations in EVs. By optimizing motor performance and efficiency, EV manufacturers can improve the overall driving experience, reduce energy consumption, and increase the range of their vehicles.

In addition to these examples, there are also many lessons learned from industry experts. For example, a study by the National Renewable Energy Laboratory (NREL) found that optimizing motor performance and efficiency can improve the overall efficiency of EVs by up to 20%.

Another study by the International Council on Clean Transportation (ICCT) found that advanced motor control systems can improve the overall efficiency of EVs by up to 15%.

These studies demonstrate the importance of efficient motor operations in EVs. By optimizing motor performance and efficiency, EV manufacturers can improve the overall driving experience, reduce energy consumption, and increase the range of their vehicles.

In conclusion, efficient motor operations are critical to the performance and efficiency of EVs. By understanding how EV motor operations work in practice, EV manufacturers can optimize motor performance and efficiency, improving the overall driving experience, reducing energy consumption, and increasing the range of their vehicles.

Future Developments in Electric Motor Operations Management

The field of electric vehicle (EV) motor operations management is rapidly evolving, with emerging trends and technologies poised to transform the industry. In the context of electric vehicle and electric motor operations management, understanding these developments is crucial for optimizing EV performance and efficiency.

One of the most significant emerging trends in EV motor operations management is the use of advanced materials. New materials such as graphene, nanomaterials, and advanced ceramics are being developed to improve the efficiency and performance of EV motors. These materials have the potential to increase the power density and efficiency of EV motors, leading to improved range and performance.

Another emerging trend in EV motor operations management is the use of artificial intelligence (AI) and machine learning (ML). AI and ML can be used to optimize motor performance and efficiency in real-time, by analyzing data from sensors and adjusting motor parameters accordingly. This can lead to improved range, performance, and efficiency, as well as reduced maintenance costs.

Advances in power electronics are also expected to play a major role in the future of EV motor operations management. New power electronic devices such as wide bandgap semiconductors and advanced power modules are being developed to improve the efficiency and performance of EV motors. These devices have the potential to increase the power density and efficiency of EV motors, leading to improved range and performance.

In addition to these emerging trends, there are also several new technologies being developed to improve EV motor operations management. For example, advanced motor control systems that use model predictive control (MPC) and other advanced algorithms are being developed to optimize motor performance and efficiency. These systems have the potential to improve range, performance, and efficiency, as well as reduce maintenance costs.

Another new technology being developed is the use of thermal energy harvesting (TEH) to improve EV motor efficiency. TEH involves using advanced materials and technologies to capture and convert waste heat into electrical energy, which can then be used to improve motor efficiency. This technology has the potential to improve range and performance, as well as reduce maintenance costs.

In conclusion, the future of electric vehicle motor operations management is exciting and rapidly evolving. Emerging trends and technologies such as advanced materials, AI and ML, and new power electronic devices are poised to transform the industry. By understanding these developments, EV manufacturers and operators can optimize EV performance and efficiency, leading to improved range, performance, and efficiency.

Best Practices for Electric Vehicle Motor Operations Management

To ensure optimal performance, efficiency, and lifespan of electric vehicle (EV) motors, it is essential to follow best practices in electric motor operations management. By implementing these strategies, EV owners and operators can maximize their vehicle’s potential, reduce energy consumption, and minimize maintenance costs. Here is a comprehensive checklist for efficient electric motor operations management:

Regular Maintenance: Regularly inspect and maintain the electric motor, including checking for signs of wear, tear, and overheating. Perform routine tasks such as cleaning, lubricating, and replacing worn-out components to prevent damage and ensure optimal performance.

Optimal Charging Strategies: Choose the right charging strategy for your EV and motor type. Avoid rapid charging when possible, and opt for slow charging or optimal charging schedules to minimize heat generation and reduce stress on the motor.

Thermal Management: Implement effective thermal management techniques, such as cooling systems and thermal shielding, to maintain optimal motor temperatures. This will help prevent overheating, reduce energy consumption, and prolong the motor’s lifespan.

Efficient Driving Habits: Encourage efficient driving habits, such as smooth acceleration, gentle braking, and maintaining a consistent speed. This will help reduce energy consumption, minimize wear and tear on the motor, and optimize overall EV performance.

Monitoring and Troubleshooting: Regularly monitor the electric motor’s performance and troubleshoot common issues, such as unusual noises, vibrations, or overheating. Addressing these issues promptly will help prevent damage, reduce downtime, and ensure optimal EV performance.

Software Updates and Calibration: Regularly update the electric motor control system’s software and calibrate the motor to ensure optimal performance and efficiency. This will help improve the motor’s responsiveness, reduce energy consumption, and prolong its lifespan.

Training and Education: Provide training and education to EV owners and operators on electric motor operations management best practices. This will help ensure that they understand the importance of efficient motor operations and can implement strategies to optimize performance, efficiency, and lifespan.

By following these best practices in electric vehicle and electric motor operations management, EV owners and operators can optimize their vehicle’s performance, reduce energy consumption, and minimize maintenance costs. Implementing these strategies will help ensure a longer lifespan for the electric motor, reduce downtime, and provide a better overall driving experience.