Understanding the Fundamentals of Electric Motor Operations

Electric motor operations are a crucial aspect of electric vehicle (EV) performance, efficiency, and reliability. At its core, an electric motor is a device that converts electrical energy into mechanical energy, utilizing the principles of electromagnetism. The interaction between magnetic fields and electric currents generates torque, which propels the vehicle forward. In the context of EVs, electric motor operations management is essential for optimizing performance, minimizing energy consumption, and ensuring a smooth driving experience.

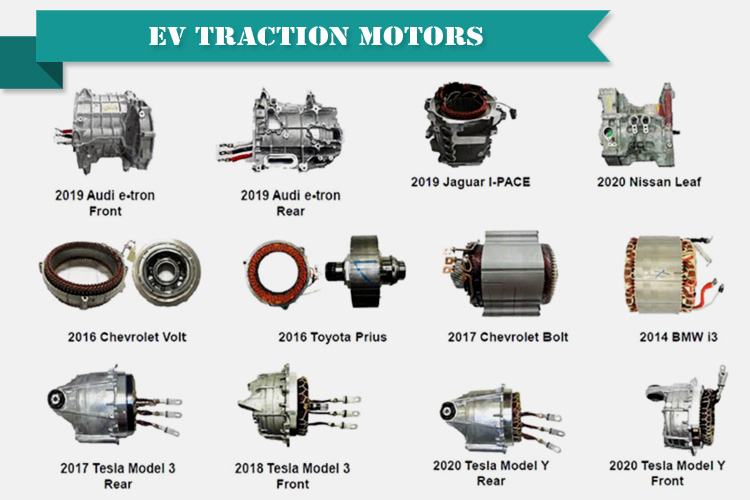

There are several types of electric motors used in EVs, including permanent magnet motors, induction motors, and switched reluctance motors. Each type has its unique characteristics, advantages, and disadvantages. For instance, permanent magnet motors are known for their high efficiency and reliability, while induction motors offer high torque density and low maintenance. Understanding the strengths and weaknesses of each motor type is vital for effective electric motor operations management.

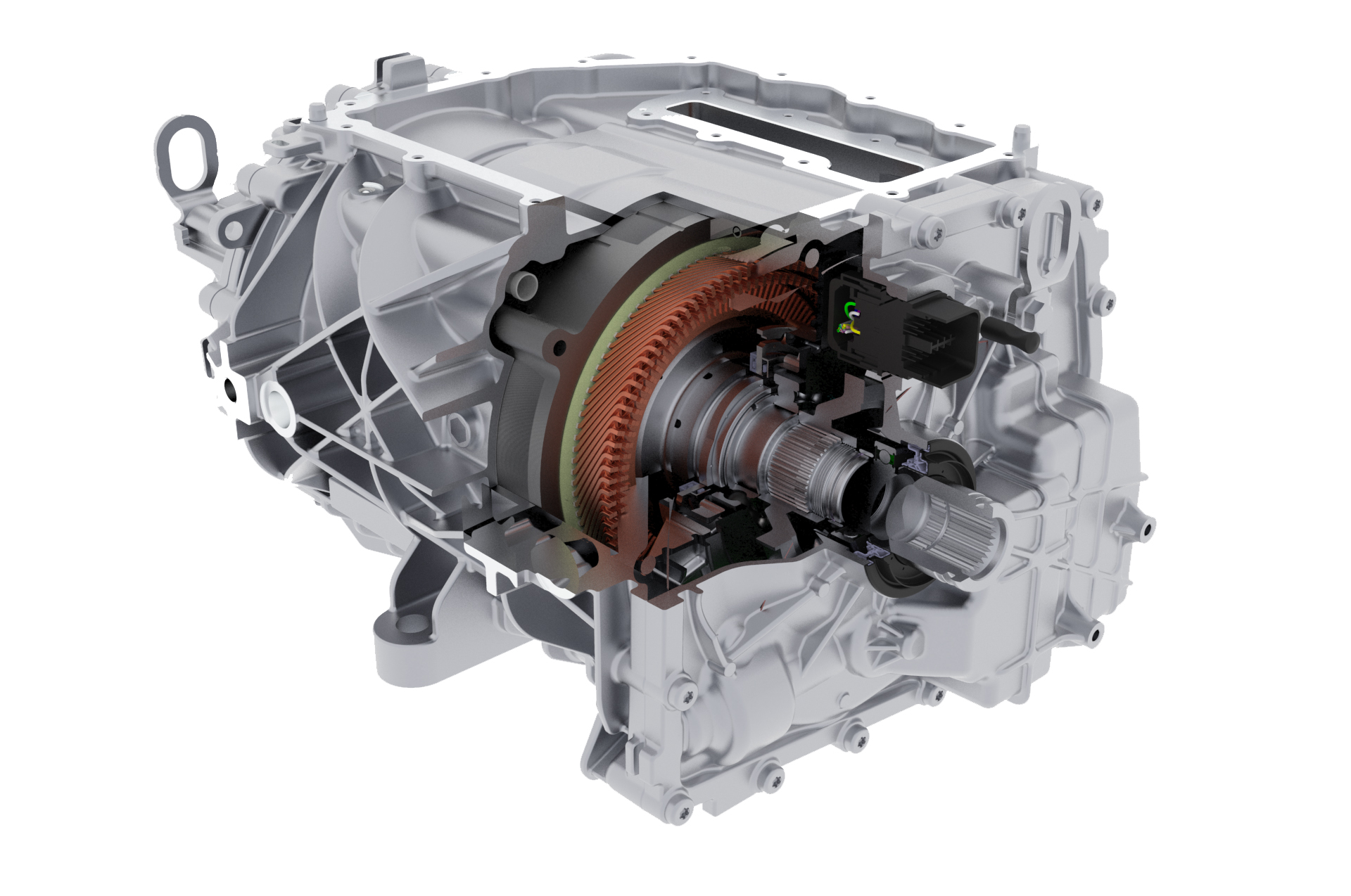

In EVs, electric motor operations management involves the coordination of various components, including the motor, gearbox, battery, and power electronics. The motor control unit (MCU) plays a critical role in regulating the flow of electrical energy to the motor, ensuring optimal performance and efficiency. Advanced motor control strategies, such as field-oriented control and direct torque control, can significantly improve EV performance and reduce energy consumption.

The importance of efficient electric motor operations in EVs cannot be overstated. Inefficient motor operations can lead to reduced vehicle range, decreased performance, and increased energy consumption. Moreover, poor motor operations management can result in premature wear and tear on motor components, leading to increased maintenance costs and reduced vehicle lifespan. By optimizing electric motor operations, EV manufacturers can improve vehicle performance, reduce energy consumption, and enhance the overall driving experience.

Effective electric motor operations management is also crucial for ensuring the reliability and sustainability of EVs. As the demand for EVs continues to grow, the need for efficient and reliable motor operations management systems will become increasingly important. By understanding the fundamentals of electric motor operations and implementing advanced motor control strategies, EV manufacturers can create vehicles that are not only environmentally friendly but also efficient, reliable, and sustainable.

Key Challenges in Electric Vehicle Motor Operations Management

Electric vehicle motor operations management is a complex task that involves overcoming several challenges to ensure efficient, reliable, and sustainable performance. One of the primary challenges is thermal management, which refers to the ability to regulate the temperature of the motor and its components. Excessive heat can lead to reduced motor efficiency, decreased lifespan, and increased energy consumption. Effective thermal management strategies, such as the use of advanced cooling systems and thermal interface materials, are essential for maintaining optimal motor performance.

Another significant challenge in electric vehicle motor operations management is vibration and noise reduction. Electric motors can generate significant vibrations and noise, which can impact the overall driving experience and vehicle reliability. Advanced motor control strategies, such as active vibration control and noise reduction algorithms, can help mitigate these issues and provide a smoother and quieter ride.

In addition to thermal management and vibration reduction, electric vehicle motor operations management must also address the challenge of electromagnetic interference (EMI). EMI can occur when the motor’s electromagnetic fields interact with other vehicle systems, causing malfunctions and reduced performance. Effective EMI mitigation strategies, such as the use of shielding materials and filtering techniques, are essential for ensuring reliable motor operations.

The impact of these challenges on electric vehicle performance, efficiency, and reliability cannot be overstated. Inefficient motor operations can lead to reduced vehicle range, decreased performance, and increased energy consumption. Moreover, poor motor operations management can result in premature wear and tear on motor components, leading to increased maintenance costs and reduced vehicle lifespan. By addressing these challenges, electric vehicle manufacturers can create vehicles that are not only environmentally friendly but also efficient, reliable, and sustainable.

Effective electric vehicle motor operations management requires a comprehensive approach that incorporates advanced technologies, innovative strategies, and best practices. By understanding the key challenges in electric vehicle motor operations management, manufacturers can develop and implement solutions that optimize motor performance, efficiency, and reliability. This, in turn, can help drive the widespread adoption of electric vehicles and reduce our reliance on fossil fuels.

How to Implement a Robust Electric Motor Operations Management System

Implementing a robust electric motor operations management system is crucial for optimizing electric vehicle performance, efficiency, and reliability. A well-designed system can help electric vehicle manufacturers improve motor efficiency, reduce energy consumption, and enhance the overall driving experience. Here is a step-by-step guide on how to implement a robust electric motor operations management system:

Step 1: Select Suitable Motor Control Strategies

The first step in implementing a robust electric motor operations management system is to select suitable motor control strategies. This involves choosing the right motor control algorithm, such as field-oriented control or direct torque control, that can optimize motor performance and efficiency. The selected algorithm should be able to handle various operating conditions, including start-up, acceleration, and braking.

Step 2: Choose Monitoring and Diagnostic Tools

The next step is to choose monitoring and diagnostic tools that can provide real-time data on motor performance and efficiency. This includes selecting suitable sensors, such as temperature sensors, vibration sensors, and current sensors, that can provide accurate data on motor conditions. The data collected from these sensors can be used to optimize motor performance, detect potential faults, and schedule maintenance.

Step 3: Select Data Analytics Platforms

The third step is to select data analytics platforms

Real-World Examples of Electric Vehicle Motor Operations Management in Action

Several electric vehicle manufacturers have successfully implemented effective motor operations management systems, resulting in improved performance, efficiency, and reliability. Here are a few examples:

Tesla’s Motor Control System

Tesla’s motor control system is a prime example of effective electric vehicle motor operations management. The system uses advanced algorithms and machine learning techniques to optimize motor performance and efficiency. Tesla’s motor control system has been instrumental in achieving exceptional acceleration and range in their electric vehicles.

BMW’s eDrive Technology

BMW’s eDrive technology is another example of effective electric vehicle motor operations management. The eDrive system uses a combination of electric motors and gearboxes to optimize performance and efficiency. BMW’s eDrive technology has been used in several of their electric and hybrid vehicles, resulting in improved performance and reduced emissions.

Nissan’s Motor Control System

Nissan’s motor control system is another example of effective electric vehicle motor operations management. The system uses advanced algorithms and sensors to optimize motor performance and efficiency. Nissan’s motor control system has been used in several of their electric vehicles, resulting in improved performance and reduced emissions.

Benefits and Results

The benefits of effective electric vehicle motor operations management are numerous. Improved performance, efficiency, and reliability are just a few of the advantages of implementing a well-designed motor operations management system. Additionally, effective motor operations management can result in reduced emissions, improved safety, and increased customer satisfaction.

In conclusion, effective electric vehicle motor operations management is crucial for achieving efficient performance, reliability, and sustainability. By implementing advanced motor control strategies, monitoring and diagnostic tools, and data analytics platforms, electric vehicle manufacturers can optimize motor performance and efficiency, resulting in improved performance, reduced emissions, and increased customer satisfaction.

The Role of Advanced Technologies in Electric Vehicle Motor Operations Management

Advanced technologies, such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), are transforming the electric vehicle (EV) industry. These technologies have the potential to optimize electric vehicle motor operations management, leading to improved performance, efficiency, and reliability.

Artificial Intelligence (AI) in Electric Vehicle Motor Operations Management

AI can play a significant role in optimizing electric vehicle motor operations management. AI algorithms can analyze data from various sources, such as sensors and IoT devices, to predict and prevent potential faults. AI can also optimize motor performance in real-time, leading to improved efficiency and reduced energy consumption.

Machine Learning (ML) in Electric Vehicle Motor Operations Management

ML is another advanced technology that can optimize electric vehicle motor operations management. ML algorithms can learn from data and improve motor performance over time. ML can also detect anomalies and predict potential faults, leading to improved reliability and reduced maintenance costs.

Internet of Things (IoT) in Electric Vehicle Motor Operations Management

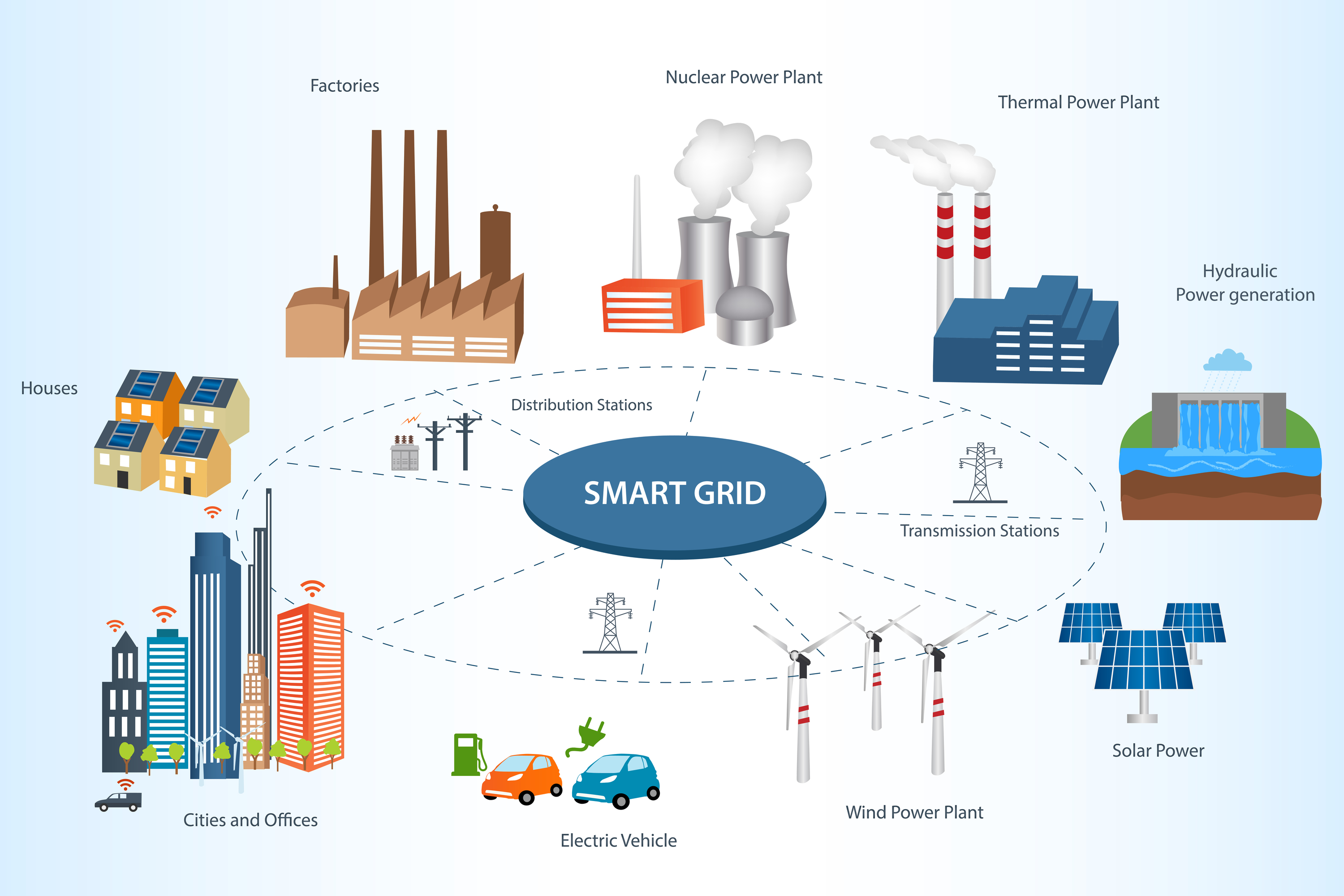

IoT is a network of physical devices, vehicles, and other items that are embedded with sensors, software, and connectivity. IoT can play a significant role in optimizing electric vehicle motor operations management by providing real-time data on motor performance and efficiency. IoT can also enable remote monitoring and maintenance, leading to improved reliability and reduced maintenance costs.

Potential Benefits and Challenges of Integrating Advanced Technologies

The integration of advanced technologies, such as AI, ML, and IoT, can bring numerous benefits to electric vehicle motor operations management. These benefits include improved performance, efficiency, and reliability, as well as reduced energy consumption and maintenance costs. However, there are also challenges associated with integrating these technologies, such as data security and privacy concerns, as well as the need for significant investment in infrastructure and training.

In conclusion, advanced technologies, such as AI, ML, and IoT, have the potential to optimize electric vehicle motor operations management, leading to improved performance, efficiency, and reliability. However, there are also challenges associated with integrating these technologies, and electric vehicle manufacturers must carefully consider these challenges when implementing these technologies.

Best Practices for Electric Vehicle Motor Operations Management Maintenance

Regular maintenance is crucial for ensuring the optimal performance and reliability of electric vehicle motor operations management systems. Here are some best practices for maintaining these systems:

Regular Software Updates

Regular software updates are essential for ensuring that the motor operations management system is running with the latest features and security patches. This can help prevent potential faults and ensure that the system is operating at optimal levels.

Hardware Inspections

Regular hardware inspections are necessary for identifying potential faults and ensuring that the motor operations management system is running smoothly. This can include inspecting the motor, gearbox, and other components for signs of wear and tear.

Troubleshooting Techniques

Effective troubleshooting techniques are essential for quickly identifying and resolving potential faults in the motor operations management system. This can include using diagnostic tools and software to identify the root cause of the problem and implementing corrective actions.

Preventative Maintenance

Preventative maintenance is a proactive approach to maintaining the motor operations management system. This can include scheduling regular maintenance tasks, such as software updates and hardware inspections, to prevent potential faults and ensure optimal performance.

Training and Support

Training and support are essential for ensuring that personnel are equipped to maintain and troubleshoot the motor operations management system. This can include providing training on the system’s operation and maintenance, as well as offering technical support and resources.

By following these best practices, electric vehicle manufacturers can ensure that their motor operations management systems are running at optimal levels, providing efficient performance, reliability, and sustainability.

Future Trends and Developments in Electric Vehicle Motor Operations Management

The electric vehicle (EV) industry is rapidly evolving, with new technologies and innovations emerging regularly. In the field of electric vehicle motor operations management, several trends and developments are expected to shape the future of the industry.

Adoption of New Motor Technologies

New motor technologies, such as axial flux motors and transverse flux motors, are being developed to improve the efficiency and performance of EVs. These motors offer several advantages over traditional radial flux motors, including higher power density, improved efficiency, and reduced weight.

Advancements in Battery Management

Battery management systems (BMS) play a critical role in EVs, as they ensure the safe and efficient operation of the battery pack. Advancements in BMS technology are expected to improve the range and performance of EVs, while also reducing costs and increasing safety.

Impact of Autonomous Vehicles

Autonomous vehicles (AVs) are expected to have a significant impact on the EV industry, as they will require advanced motor operations management systems to ensure safe and efficient operation. AVs will also require advanced sensor systems and sophisticated software to enable autonomous driving.

Increased Focus on Sustainability

The EV industry is expected to place an increased focus on sustainability in the coming years, with a greater emphasis on reducing waste and minimizing environmental impact. This may involve the development of new motor technologies and materials that are more sustainable and environmentally friendly.

Greater Use of Advanced Materials

Advanced materials, such as graphene and nanomaterials, are being developed to improve the performance and efficiency of EV motors. These materials offer several advantages over traditional materials, including higher strength, improved conductivity, and reduced weight.

In conclusion, the future of electric vehicle motor operations management is expected to be shaped by several trends and developments, including the adoption of new motor technologies, advancements in battery management, and the impact of autonomous vehicles. As the industry continues to evolve, it is likely that we will see significant improvements in the performance, efficiency, and sustainability of EVs.

Conclusion: Unlocking Efficient Electric Vehicle Performance through Effective Motor Operations Management

In conclusion, effective electric vehicle motor operations management is crucial for achieving efficient performance, reliability, and sustainability in electric vehicles. By understanding the fundamentals of electric motor operations, addressing common challenges, and implementing robust management systems, electric vehicle manufacturers can unlock the full potential of their vehicles. The integration of advanced technologies, such as artificial intelligence and IoT, will continue to play a vital role in optimizing electric vehicle motor operations management. As the electric vehicle market continues to grow, it is essential for manufacturers to prioritize innovation and improvement in this field to stay ahead of the competition.

The benefits of effective electric vehicle motor operations management are numerous, including improved energy efficiency, increased reliability, and reduced maintenance costs. Moreover, it enables electric vehicles to achieve better performance, range, and overall driving experience. As the world shifts towards a more sustainable and environmentally friendly transportation system, the importance of efficient electric vehicle motor operations management will only continue to grow.

By adopting best practices for electric vehicle motor operations management maintenance, manufacturers can ensure that their vehicles remain in optimal condition, providing a better experience for drivers and passengers. Furthermore, the development of new motor technologies, advancements in battery management, and the impact of autonomous vehicles will continue to shape the future of electric vehicle motor operations management.

Ultimately, the key to unlocking efficient electric vehicle performance lies in the effective management of electric motor operations. By prioritizing innovation, improvement, and sustainability in this field, electric vehicle manufacturers can create a better future for transportation and contribute to a more environmentally friendly world.