Mastering the Fundamentals of Electric Motor Management

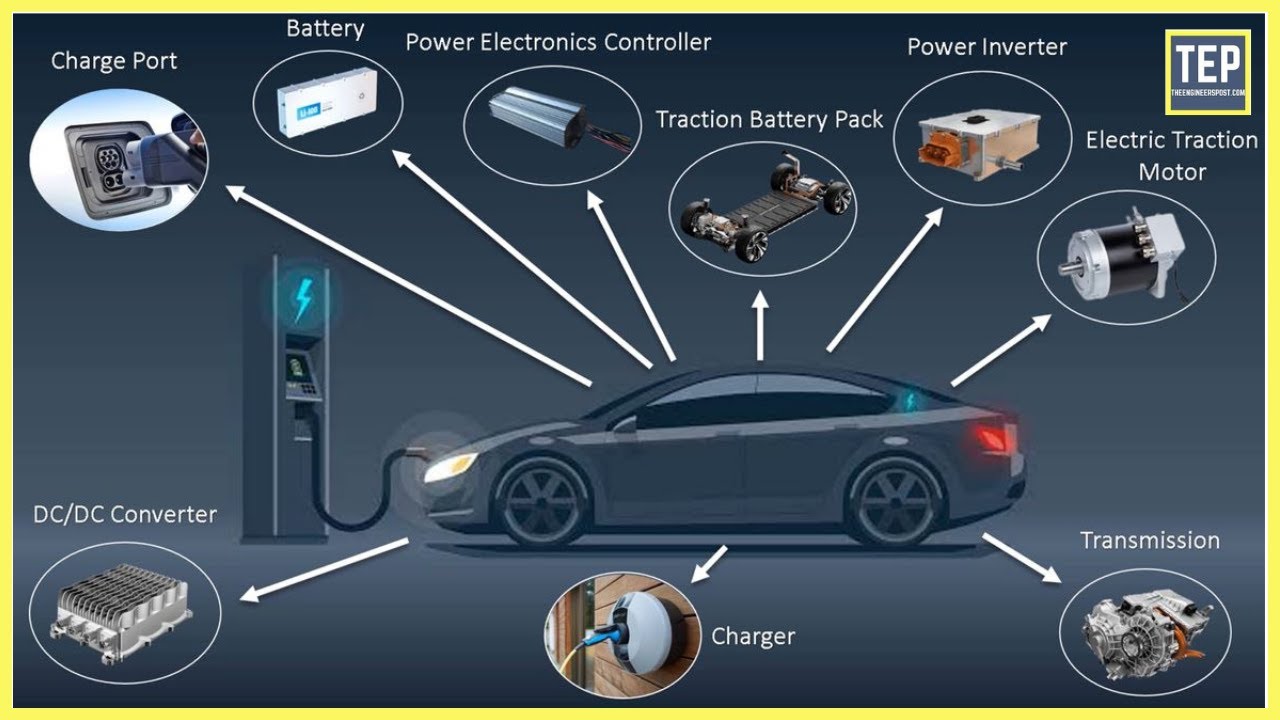

Effective electric motor management is crucial for optimizing the performance, efficiency, and overall driving experience of electric vehicles. The electric motor is the heart of an electric vehicle, responsible for converting electrical energy into mechanical energy to propel the vehicle forward. As such, it is essential to understand the key components of electric motor operations and their role in optimizing vehicle performance.

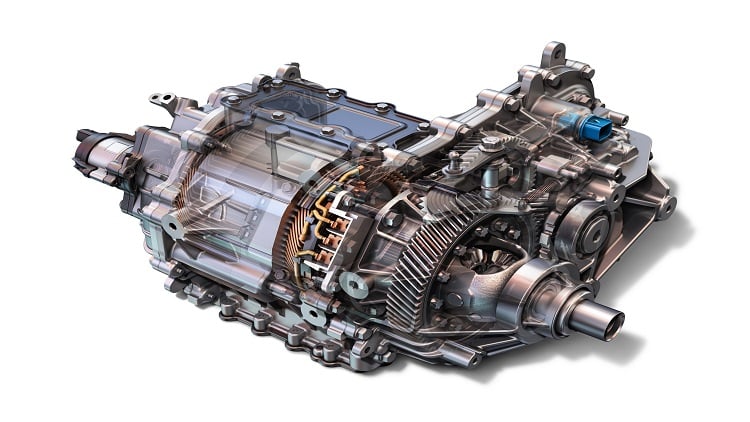

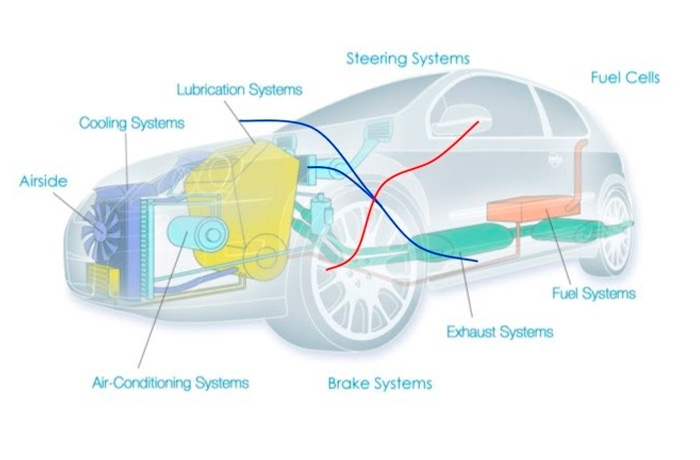

The electric motor consists of several critical components, including the motor itself, the power electronics, and the control systems. The motor is responsible for generating torque, while the power electronics manage the flow of electrical energy to the motor. The control systems, including the motor controller and software algorithms, work together to optimize motor performance, efficiency, and reliability.

Proper electric motor management involves monitoring and controlling various parameters, such as temperature, voltage, and current, to ensure optimal performance and prevent damage to the motor. This requires a deep understanding of the complex interactions between the motor, power electronics, and control systems. By mastering the fundamentals of electric motor management, electric vehicle manufacturers and owners can unlock the full potential of their vehicles, achieving improved efficiency, performance, and reliability.

In the context of electric vehicle and electric motor operations management, it is essential to consider the impact of motor management on the overall driving experience. A well-managed electric motor can provide a smooth, quiet, and responsive driving experience, while a poorly managed motor can lead to reduced performance, efficiency, and reliability. By prioritizing electric motor management, electric vehicle manufacturers and owners can create a more enjoyable and sustainable driving experience.

Furthermore, effective electric motor management can also have a significant impact on the environment. By optimizing motor performance and efficiency, electric vehicles can reduce their energy consumption and greenhouse gas emissions, making them a more sustainable transportation option. As the demand for electric vehicles continues to grow, the importance of electric motor management will only continue to increase.

In conclusion, mastering the fundamentals of electric motor management is critical for optimizing the performance, efficiency, and overall driving experience of electric vehicles. By understanding the key components of electric motor operations and their role in optimizing vehicle performance, electric vehicle manufacturers and owners can unlock the full potential of their vehicles and create a more sustainable transportation option.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance are crucial for ensuring the optimal performance and longevity of electric vehicle motors. By performing routine checks and troubleshooting common issues, electric vehicle owners can prevent costly repairs and maintain their vehicle’s efficiency and reliability.

One of the most important aspects of electric motor maintenance is monitoring the motor’s temperature. High temperatures can reduce the motor’s efficiency and lifespan, so it’s essential to ensure that the motor is operating within a safe temperature range. This can be achieved by installing a temperature monitoring system or by regularly checking the motor’s temperature using a thermometer.

Another critical aspect of electric motor maintenance is checking the motor’s electrical connections. Loose or corroded connections can cause the motor to malfunction or reduce its efficiency, so it’s essential to regularly inspect and clean the connections. Additionally, electric vehicle owners should ensure that the motor’s power electronics are functioning correctly, as faulty power electronics can cause the motor to overheat or malfunction.

In addition to regular checks, electric vehicle owners should also perform routine maintenance tasks, such as updating the motor’s software and replacing worn-out components. This can help to ensure that the motor is operating at its optimal level and reduce the risk of costly repairs.

Proactive maintenance is also essential for preventing common issues, such as motor overheating or electrical faults. By identifying and addressing these issues early, electric vehicle owners can prevent costly repairs and maintain their vehicle’s efficiency and reliability.

In the context of electric vehicle and electric motor operations management, regular monitoring and maintenance are critical for ensuring the optimal performance and longevity of electric vehicle motors. By performing routine checks and troubleshooting common issues, electric vehicle owners can prevent costly repairs and maintain their vehicle’s efficiency and reliability.

Furthermore, regular monitoring and maintenance can also help to improve the overall driving experience. By ensuring that the motor is operating at its optimal level, electric vehicle owners can enjoy a smoother, quieter, and more responsive driving experience.

In conclusion, regular monitoring and maintenance are essential for ensuring the optimal performance and longevity of electric vehicle motors. By performing routine checks and troubleshooting common issues, electric vehicle owners can prevent costly repairs and maintain their vehicle’s efficiency and reliability.

Electric Vehicle Charging Strategies for Efficient Motor Operations

Electric vehicle charging strategies play a crucial role in optimizing motor operations and achieving maximum efficiency. The choice of charging method can significantly impact the performance, range, and overall driving experience of an electric vehicle. In this section, we will discuss the different electric vehicle charging strategies and their impact on motor operations.

Level 1 charging is the most basic form of electric vehicle charging, using a standard 120-volt household outlet to charge the vehicle. This method is convenient and widely available, but it is also the slowest, taking up to 24 hours to fully charge a depleted battery. Level 1 charging is best suited for vehicles with small batteries or for drivers who only need to charge their vehicle occasionally.

Level 2 charging is a faster and more efficient method, using a 240-volt charging station to charge the vehicle. This method can charge a depleted battery in 4-8 hours, making it a popular choice for drivers who need to charge their vehicle regularly. Level 2 charging is also more efficient than Level 1 charging, with a higher power output and faster charging times.

DC Fast Charging is the fastest method of electric vehicle charging, using a high-power charging station to charge the vehicle to 80% in under 30 minutes. This method is ideal for long-distance driving, as it allows drivers to quickly recharge their vehicle and get back on the road. However, DC Fast Charging is also the most expensive method, requiring a high-power charging station and specialized equipment.

In the context of electric vehicle and electric motor operations management, the choice of charging method can have a significant impact on motor performance and efficiency. By selecting the most efficient charging strategy for their specific driving needs, electric vehicle owners can optimize their motor operations and achieve maximum efficiency.

For example, drivers who only need to charge their vehicle occasionally may prefer Level 1 charging, while drivers who need to charge their vehicle regularly may prefer Level 2 charging. DC Fast Charging is best suited for long-distance driving, where quick recharging is essential.

Ultimately, the choice of charging method will depend on the specific needs and preferences of the driver. By understanding the different electric vehicle charging strategies and their impact on motor operations, electric vehicle owners can make informed decisions and optimize their motor operations for maximum efficiency.

Thermal Management Techniques for Electric Motor Efficiency

Thermal management is a critical aspect of electric motor operations, as excessive heat can reduce motor efficiency, lifespan, and overall performance. In electric vehicles, thermal management is particularly important, as the motor and other components are often subjected to high temperatures during operation.

One of the most effective thermal management techniques for electric motors is the use of cooling systems. These systems typically involve a combination of air or liquid cooling, and are designed to remove heat from the motor and other components. Cooling systems can be particularly effective in high-performance electric vehicles, where the motor is subjected to high temperatures during rapid acceleration or sustained high-speed driving.

Another thermal management technique is the use of thermal shielding. This involves the use of materials with high thermal resistance to shield the motor and other components from heat sources. Thermal shielding can be particularly effective in electric vehicles, where the motor and other components are often located in close proximity to heat sources such as the battery or power electronics.

In addition to cooling systems and thermal shielding, there are several other thermal management techniques that can be used to optimize electric motor efficiency. These include the use of thermal interface materials, which can help to improve heat transfer between the motor and other components, and the use of advanced materials with high thermal conductivity, such as graphene or carbon nanotubes.

In the context of electric vehicle and electric motor operations management, thermal management is a critical aspect of optimizing motor efficiency and performance. By using effective thermal management techniques, electric vehicle manufacturers and owners can help to ensure that their vehicles operate at optimal levels, even in extreme temperatures or during high-performance driving.

For example, the Tesla Model S uses a advanced cooling system to manage the temperature of its electric motor, which helps to optimize its performance and efficiency. Similarly, the Nissan Leaf uses a combination of cooling systems and thermal shielding to manage the temperature of its electric motor, which helps to ensure optimal performance and efficiency.

Ultimately, the choice of thermal management technique will depend on the specific needs and requirements of the electric vehicle and its motor. By understanding the different thermal management techniques available, electric vehicle manufacturers and owners can make informed decisions and optimize their motor operations for maximum efficiency.

Electric Motor Control Systems: Understanding the Technology

Electric motor control systems are a critical component of electric vehicle operations, playing a crucial role in optimizing motor performance, efficiency, and reliability. These systems consist of power electronics, motor controllers, and software algorithms that work together to control the flow of electrical energy to the motor.

Power electronics are responsible for converting the DC power from the battery to AC power, which is then used to drive the motor. Motor controllers, on the other hand, regulate the flow of electrical energy to the motor, ensuring that it operates within its optimal range. Software algorithms, such as those used in model predictive control, optimize the performance of the motor by predicting and adjusting to changes in the vehicle’s operating conditions.

The integration of these components enables electric motor control systems to optimize motor performance, efficiency, and reliability. For example, advanced motor control algorithms can optimize the motor’s torque output, reducing energy consumption and improving overall efficiency. Additionally, real-time monitoring and diagnostic capabilities enable the early detection of potential issues, reducing downtime and improving overall reliability.

In the context of electric vehicle and electric motor operations management, understanding the technology behind electric motor control systems is essential for optimizing motor performance and efficiency. By leveraging advanced technologies, such as model predictive control and real-time monitoring, electric vehicle manufacturers and owners can improve the overall efficiency and reliability of their vehicles.

For instance, the Tesla Model S uses advanced motor control algorithms to optimize its motor performance, resulting in improved efficiency and range. Similarly, the Nissan Leaf uses real-time monitoring and diagnostic capabilities to detect potential issues, reducing downtime and improving overall reliability.

Furthermore, the integration of emerging technologies, such as artificial intelligence and machine learning, is expected to further improve the performance and efficiency of electric motor control systems. By leveraging these technologies, electric vehicle manufacturers and owners can optimize motor operations, reduce energy consumption, and improve overall efficiency.

Ultimately, the effective management of electric motor control systems is critical for optimizing electric vehicle performance and efficiency. By understanding the technology behind these systems and leveraging advanced technologies, electric vehicle manufacturers and owners can improve the overall efficiency and reliability of their vehicles.

Real-World Examples of Efficient Electric Motor Operations in Electric Vehicles

The Tesla Model 3 and the Nissan Leaf are two examples of electric vehicles that have achieved exceptional efficiency and performance through optimized electric motor operations. These vehicles have implemented various strategies and technologies to optimize their motor operations, resulting in improved efficiency, range, and overall driving experience.

The Tesla Model 3, for instance, uses a advanced electric motor control system that optimizes the motor’s performance and efficiency. The system uses advanced algorithms and real-time monitoring to adjust the motor’s torque output, resulting in improved efficiency and range. Additionally, the Model 3’s motor is designed to operate at optimal temperatures, reducing energy consumption and improving overall efficiency.

The Nissan Leaf, on the other hand, uses a combination of advanced motor control algorithms and thermal management techniques to optimize its motor operations. The Leaf’s motor control system uses advanced algorithms to optimize the motor’s performance and efficiency, while its thermal management system uses advanced cooling techniques to reduce the motor’s temperature and improve its efficiency.

Both the Tesla Model 3 and the Nissan Leaf have achieved exceptional efficiency and performance through their optimized electric motor operations. The Model 3 has a range of up to 325 miles on a single charge, while the Leaf has a range of up to 226 miles. These vehicles demonstrate the potential of optimized electric motor operations to improve efficiency, range, and overall driving experience.

In the context of electric vehicle and electric motor operations management, these real-world examples demonstrate the importance of optimizing motor operations to achieve exceptional efficiency and performance. By implementing advanced strategies and technologies, electric vehicle manufacturers can improve the efficiency, range, and overall driving experience of their vehicles.

Furthermore, these examples highlight the potential of optimized electric motor operations to reduce energy consumption and improve overall efficiency. By reducing energy consumption, electric vehicles can reduce their environmental impact and improve their overall sustainability.

Ultimately, the optimization of electric motor operations is critical for achieving exceptional efficiency and performance in electric vehicles. By implementing advanced strategies and technologies, electric vehicle manufacturers can improve the efficiency, range, and overall driving experience of their vehicles, while reducing energy consumption and improving overall sustainability.

Future Developments in Electric Motor Operations Management

The electric vehicle industry is rapidly evolving, with advancements in technology and innovations in electric motor operations management. One of the most significant trends in the industry is the integration of artificial intelligence (AI) and machine learning (ML) technologies into electric motor control systems.

AI and ML technologies have the potential to revolutionize electric motor operations management by enabling real-time monitoring and optimization of motor performance. These technologies can analyze vast amounts of data from various sources, including sensors and IoT devices, to predict and prevent potential issues, such as motor overheating or reduced efficiency.

Another emerging trend in electric motor operations management is the use of IoT technologies to enable remote monitoring and control of electric motors. IoT devices can be integrated into electric motor control systems to provide real-time data on motor performance, enabling remote monitoring and optimization of motor operations.

In addition to AI, ML, and IoT technologies, there are several other future developments in electric motor operations management that are worth noting. These include the use of advanced materials and manufacturing techniques to improve motor efficiency and reduce weight, as well as the development of new motor designs and architectures that can improve performance and efficiency.

In the context of electric vehicle and electric motor operations management, these emerging trends and technologies have the potential to significantly improve the efficiency, performance, and reliability of electric motors. By leveraging these advancements, electric vehicle manufacturers can improve the overall efficiency and performance of their vehicles, while reducing energy consumption and improving overall sustainability.

For example, the use of AI and ML technologies can enable real-time optimization of motor performance, reducing energy consumption and improving overall efficiency. Similarly, the use of IoT technologies can enable remote monitoring and control of electric motors, reducing downtime and improving overall reliability.

Ultimately, the future of electric motor operations management is exciting and rapidly evolving. By staying ahead of the curve and leveraging the latest advancements in technology, electric vehicle manufacturers can improve the efficiency, performance, and reliability of their vehicles, while reducing energy consumption and improving overall sustainability.

Best Practices for Electric Vehicle Owners: Optimizing Motor Operations for Maximum Efficiency

As an electric vehicle owner, optimizing motor operations is crucial for achieving maximum efficiency and performance. By following best practices and implementing effective driving techniques, maintenance schedules, and charging strategies, owners can ensure their vehicle operates at its best.

One of the most important best practices for electric vehicle owners is to maintain a consistent driving style. Aggressive driving, such as rapid acceleration and braking, can reduce motor efficiency and increase energy consumption. By driving smoothly and consistently, owners can optimize motor performance and reduce energy consumption.

Regular maintenance is also essential for optimizing motor operations. Owners should follow the recommended maintenance schedule for their vehicle, including regular checks of the motor, battery, and other components. By performing routine maintenance tasks, owners can identify and address potential issues before they become major problems.

Charging strategies are also critical for optimizing motor operations. Owners should choose the most efficient charging method for their vehicle, taking into account factors such as driving habits, climate, and charging infrastructure. By optimizing charging strategies, owners can reduce energy consumption and improve overall efficiency.

In addition to driving techniques, maintenance schedules, and charging strategies, there are several other best practices that electric vehicle owners can follow to optimize motor operations. These include monitoring motor performance, adjusting driving habits to suit climate and terrain, and using regenerative braking to recover energy.

By following these best practices and implementing effective driving techniques, maintenance schedules, and charging strategies, electric vehicle owners can optimize motor operations and achieve maximum efficiency. By taking an active role in optimizing motor performance, owners can improve the overall efficiency and performance of their vehicle, while reducing energy consumption and improving overall sustainability.

Ultimately, optimizing motor operations is a critical aspect of electric vehicle ownership. By following best practices and implementing effective driving techniques, maintenance schedules, and charging strategies, owners can ensure their vehicle operates at its best and achieves maximum efficiency.