Mastering the Fundamentals of Electric Motor Management

Efficient electric motor operations are crucial for the performance, range, and overall driving experience of electric vehicles. As the demand for electric vehicles continues to grow, the importance of optimizing electric motor management has become increasingly evident. Electric motor management involves the control and regulation of electric motor performance, including torque, speed, and power output. By understanding the fundamentals of electric motor management, electric vehicle manufacturers and owners can improve the efficiency, reliability, and sustainability of their vehicles.

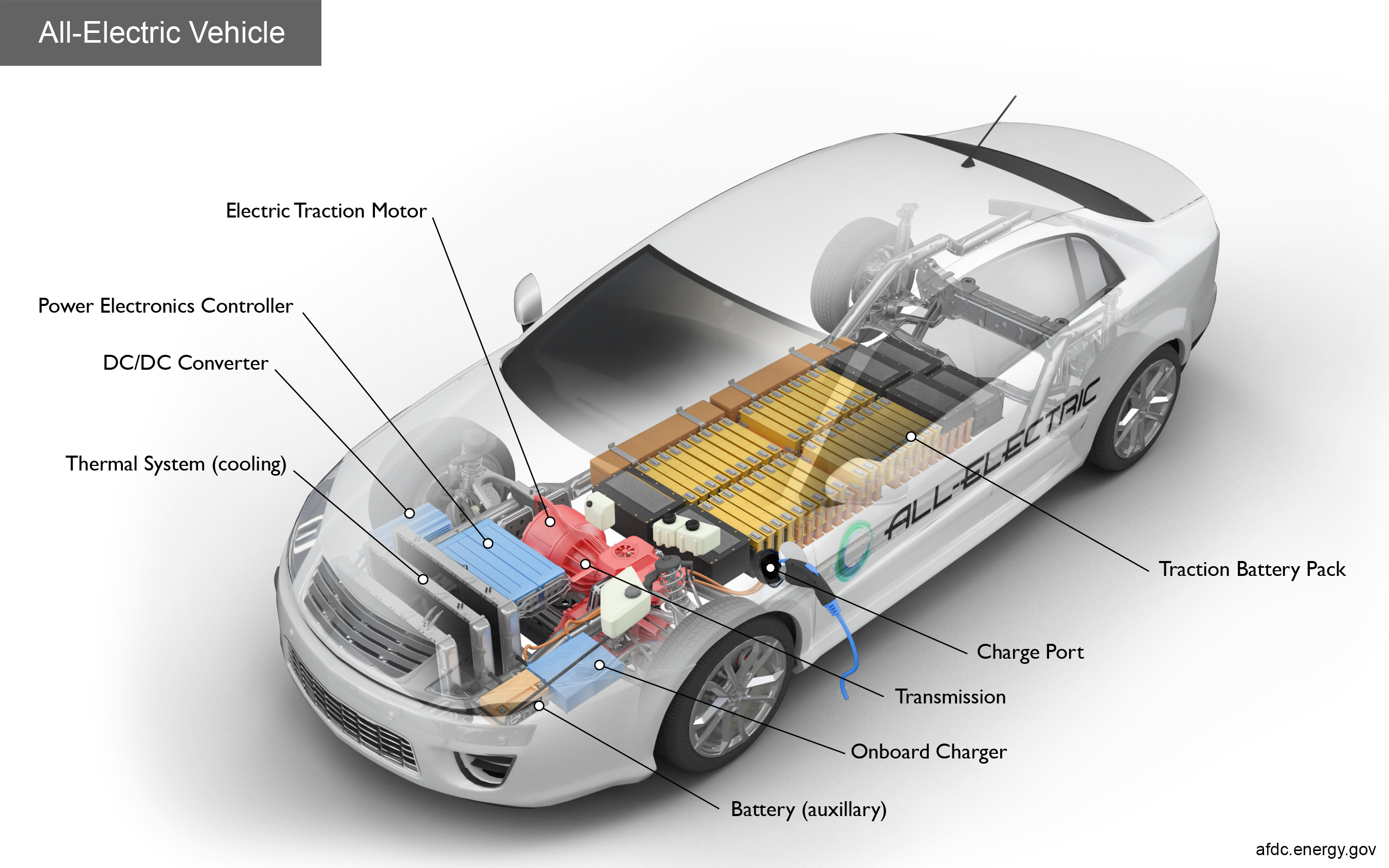

At its core, electric motor management involves the interaction between the electric motor, power electronics, and control systems. The electric motor converts electrical energy into mechanical energy, while the power electronics manage the flow of electrical energy to the motor. The control systems, including software algorithms and motor controllers, regulate the performance of the electric motor and optimize its efficiency. By optimizing the performance of the electric motor, electric vehicle manufacturers can improve the overall efficiency of their vehicles, reducing energy consumption and emissions.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By mastering the fundamentals of electric motor management, electric vehicle manufacturers can create vehicles that are not only efficient and reliable but also sustainable and environmentally friendly. As the electric vehicle market continues to evolve, the importance of electric motor management will only continue to grow, making it essential for manufacturers and owners to stay up-to-date with the latest developments and technologies in this field.

In addition to improving efficiency and reliability, electric motor management also plays a critical role in extending the lifespan of electric vehicle components. By regulating the performance of the electric motor, manufacturers can reduce wear and tear on components, minimizing the need for maintenance and repairs. This not only reduces costs but also improves the overall driving experience, making electric vehicles a more attractive option for consumers.

As the demand for electric vehicles continues to grow, the importance of electric motor management will only continue to increase. By understanding the fundamentals of electric motor management, electric vehicle manufacturers and owners can improve the efficiency, reliability, and sustainability of their vehicles, making them a more attractive option for consumers. Whether you’re an electric vehicle manufacturer or owner, mastering the fundamentals of electric motor management is essential for optimizing the performance of your vehicle and reducing your environmental impact.

How to Monitor and Maintain Electric Motor Health

Regular monitoring and maintenance of electric motor health are crucial for ensuring optimal performance, efficiency, and reliability of electric vehicles

Electric Vehicle Charging Strategies for Optimal Motor Performance

Charging strategies play a crucial role in optimizing electric motor performance in electric vehicles. The way an electric vehicle is charged can significantly impact the motor’s efficiency, reliability, and overall lifespan. In this section, we will discuss the impact of different charging strategies on electric motor performance and provide tips on how to optimize charging habits for improved motor efficiency and reduced wear.

Fast charging is a popular choice for electric vehicle owners, as it allows for quick and convenient charging. However, fast charging can also have a negative impact on electric motor performance. High-power charging can cause increased heat generation, which can reduce motor efficiency and lifespan. To mitigate this, electric vehicle manufacturers can implement thermal management systems to regulate motor temperature during fast charging.

Slow charging, on the other hand, is a more gentle approach to charging electric vehicles. Slow charging can help reduce heat generation and minimize motor wear, resulting in improved efficiency and reliability. However, slow charging can also take longer, which may not be suitable for drivers who need to charge their vehicles quickly.

Opportunistic charging is a charging strategy that takes advantage of available charging opportunities, such as charging during off-peak hours or when the vehicle is not in use. Opportunistic charging can help reduce strain on the motor and improve overall efficiency. Electric vehicle manufacturers can implement smart charging systems that optimize charging based on the vehicle’s usage patterns and available charging opportunities.

To optimize charging habits for improved motor efficiency and reduced wear, electric vehicle owners can follow a few simple tips. First, it’s essential to charge the vehicle regularly, rather than letting the battery drain to zero. This can help reduce strain on the motor and improve overall efficiency. Second, electric vehicle owners can use a combination of fast and slow charging to balance convenience and motor health. Finally, electric vehicle owners can take advantage of opportunistic charging to optimize charging based on their usage patterns and available charging opportunities.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By optimizing charging strategies, electric vehicle manufacturers can improve motor efficiency, reliability, and overall lifespan. By following simple tips and best practices, electric vehicle owners can also play a crucial role in optimizing motor performance and reducing wear.

In conclusion, charging strategies play a significant role in optimizing electric motor performance in electric vehicles. By understanding the impact of different charging strategies and following simple tips and best practices, electric vehicle manufacturers and owners can work together to improve motor efficiency, reliability, and overall lifespan.

Thermal Management Systems for Electric Vehicles: A Deep Dive

Thermal management systems play a crucial role in electric vehicle performance, efficiency, and reliability. Electric motors, batteries, and power electronics generate heat during operation, which can impact motor performance, lifespan, and overall vehicle efficiency. In this section, we will delve into the world of thermal management systems for electric vehicles, explaining the importance of temperature control and discussing various thermal management strategies.

Temperature control is essential for electric motor performance and longevity. High temperatures can reduce motor efficiency, increase wear and tear, and even cause motor failure. Electric vehicle manufacturers use various thermal management strategies to regulate motor temperature, including air cooling, liquid cooling, and heat exchangers. Air cooling is a simple and cost-effective method, but it may not be sufficient for high-performance electric vehicles. Liquid cooling, on the other hand, is more effective but also more complex and expensive.

Heat exchangers are another thermal management strategy used in electric vehicles. Heat exchangers transfer heat from the motor to a coolant, which is then dissipated through a radiator or other cooling system. Heat exchangers can be used in conjunction with air cooling or liquid cooling to provide optimal temperature control. Electric vehicle manufacturers can also use advanced materials and designs to improve thermal management, such as using high-temperature-resistant materials or designing motors with built-in cooling systems.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By optimizing thermal management systems, electric vehicle manufacturers can improve motor efficiency, reliability, and overall lifespan. Thermal management systems can also impact battery performance and lifespan, as high temperatures can reduce battery efficiency and increase degradation.

In addition to motor temperature control, thermal management systems can also be used to regulate battery temperature. Battery temperature control is essential for optimal battery performance and lifespan. Electric vehicle manufacturers can use various thermal management strategies to regulate battery temperature, including air cooling, liquid cooling, and heat exchangers.

Thermal management systems can also be integrated with other electric vehicle systems, such as the power electronics and motor control systems. This can provide optimal temperature control and improve overall vehicle efficiency. Electric vehicle manufacturers can use advanced software and algorithms to optimize thermal management systems and improve overall vehicle performance.

In conclusion, thermal management systems play a critical role in electric vehicle performance, efficiency, and reliability. By understanding the importance of temperature control and using various thermal management strategies, electric vehicle manufacturers can improve motor efficiency, reliability, and overall lifespan.

Electric Motor Control Systems: Understanding the Technology

Electric motor control systems are a critical component of electric vehicle performance, efficiency, and reliability. These systems work together to optimize motor performance, efficiency, and reliability, and are essential for achieving optimal electric vehicle performance. In this section, we will explore the technology behind electric motor control systems, including power electronics, motor controllers, and software algorithms.

Power electronics are a key component of electric motor control systems, and are responsible for converting DC power from the battery to AC power for the motor. Power electronics include devices such as inverters, converters, and controllers, which work together to optimize motor performance and efficiency. Motor controllers, on the other hand, are responsible for controlling the flow of electrical energy to the motor, and are typically used in conjunction with power electronics.

Software algorithms play a critical role in electric motor control systems, and are used to optimize motor performance, efficiency, and reliability. These algorithms can be used to control the flow of electrical energy to the motor, and can also be used to monitor and diagnose motor performance. Electric vehicle manufacturers can use advanced software algorithms to optimize motor performance and efficiency, and to improve overall vehicle reliability.

Electric motor control systems can also be integrated with other electric vehicle systems, such as the battery management system and the thermal management system. This can provide optimal motor performance and efficiency, and can also improve overall vehicle reliability. Electric vehicle manufacturers can use advanced software algorithms to optimize the integration of these systems, and to improve overall vehicle performance.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By understanding the technology behind electric motor control systems, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and can improve overall vehicle performance. Electric motor control systems can also be used to improve the efficiency and reliability of other electric vehicle systems, such as the battery management system and the thermal management system.

In addition to optimizing motor performance and efficiency, electric motor control systems can also be used to improve the safety and reliability of electric vehicles. Electric vehicle manufacturers can use advanced software algorithms to monitor and diagnose motor performance, and can use this information to improve overall vehicle safety and reliability.

Electric motor control systems are a rapidly evolving field, and new technologies and innovations are continually being developed. Electric vehicle manufacturers can stay up-to-date with the latest developments in electric motor control systems by attending industry conferences and trade shows, and by participating in online forums and discussion groups.

Real-World Examples: Electric Vehicle Motor Operations in Practice

Electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. In this section, we will showcase real-world examples of electric vehicle motor operations in practice, highlighting successful implementations and lessons learned. We will also discuss the experiences of manufacturers, such as Tesla, and their approaches to electric motor management.

Tesla is a leading manufacturer of electric vehicles, and their approach to electric motor management is a prime example of successful implementation. Tesla’s electric motor control systems are designed to optimize motor performance, efficiency, and reliability, and are integrated with other vehicle systems to provide optimal performance. Tesla’s approach to electric motor management includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

Another example of successful electric vehicle motor operations is the Nissan Leaf. The Nissan Leaf is a popular electric vehicle that has been on the market for several years, and its electric motor control system is designed to optimize motor performance, efficiency, and reliability. The Nissan Leaf’s electric motor control system includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

In addition to these examples, there are many other manufacturers that are successfully implementing electric vehicle motor operations. For example, BMW’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers. Similarly, Volkswagen’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.

In conclusion, electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.

Real-World Examples: Electric Vehicle Motor Operations in Practice

Electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. In this section, we will showcase real-world examples of electric vehicle motor operations in practice, highlighting successful implementations and lessons learned. We will also discuss the experiences of manufacturers, such as Tesla, and their approaches to electric motor management.

Tesla is a leading manufacturer of electric vehicles, and their approach to electric motor management is a prime example of successful implementation. Tesla’s electric motor control systems are designed to optimize motor performance, efficiency, and reliability, and are integrated with other vehicle systems to provide optimal performance. Tesla’s approach to electric motor management includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

Another example of successful electric vehicle motor operations is the Nissan Leaf. The Nissan Leaf is a popular electric vehicle that has been on the market for several years, and its electric motor control system is designed to optimize motor performance, efficiency, and reliability. The Nissan Leaf’s electric motor control system includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

In addition to these examples, there are many other manufacturers that are successfully implementing electric vehicle motor operations. For example, BMW’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers. Similarly, Volkswagen’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.

In conclusion, electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.

Real-World Examples: Electric Vehicle Motor Operations in Practice

Electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. In this section, we will showcase real-world examples of electric vehicle motor operations in practice, highlighting successful implementations and lessons learned. We will also discuss the experiences of manufacturers, such as Tesla, and their approaches to electric motor management.

Tesla is a leading manufacturer of electric vehicles, and their approach to electric motor management is a prime example of successful implementation. Tesla’s electric motor control systems are designed to optimize motor performance, efficiency, and reliability, and are integrated with other vehicle systems to provide optimal performance. Tesla’s approach to electric motor management includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

Another example of successful electric vehicle motor operations is the Nissan Leaf. The Nissan Leaf is a popular electric vehicle that has been on the market for several years, and its electric motor control system is designed to optimize motor performance, efficiency, and reliability. The Nissan Leaf’s electric motor control system includes the use of advanced software algorithms, power electronics, and motor controllers to optimize motor performance and efficiency.

In addition to these examples, there are many other manufacturers that are successfully implementing electric vehicle motor operations. For example, BMW’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers. Similarly, Volkswagen’s electric vehicle motor control system is designed to optimize motor performance, efficiency, and reliability, and includes the use of advanced software algorithms, power electronics, and motor controllers.

Electric vehicle and electric motor operations management is a critical aspect of electric vehicle design and development. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.

In conclusion, electric vehicle motor operations are a critical aspect of electric vehicle performance, efficiency, and reliability. By understanding the experiences of manufacturers and their approaches to electric motor management, electric vehicle manufacturers can optimize motor performance, efficiency, and reliability, and improve overall vehicle performance. Electric vehicle motor operations are a rapidly evolving field, and new technologies and innovations are continually being developed.