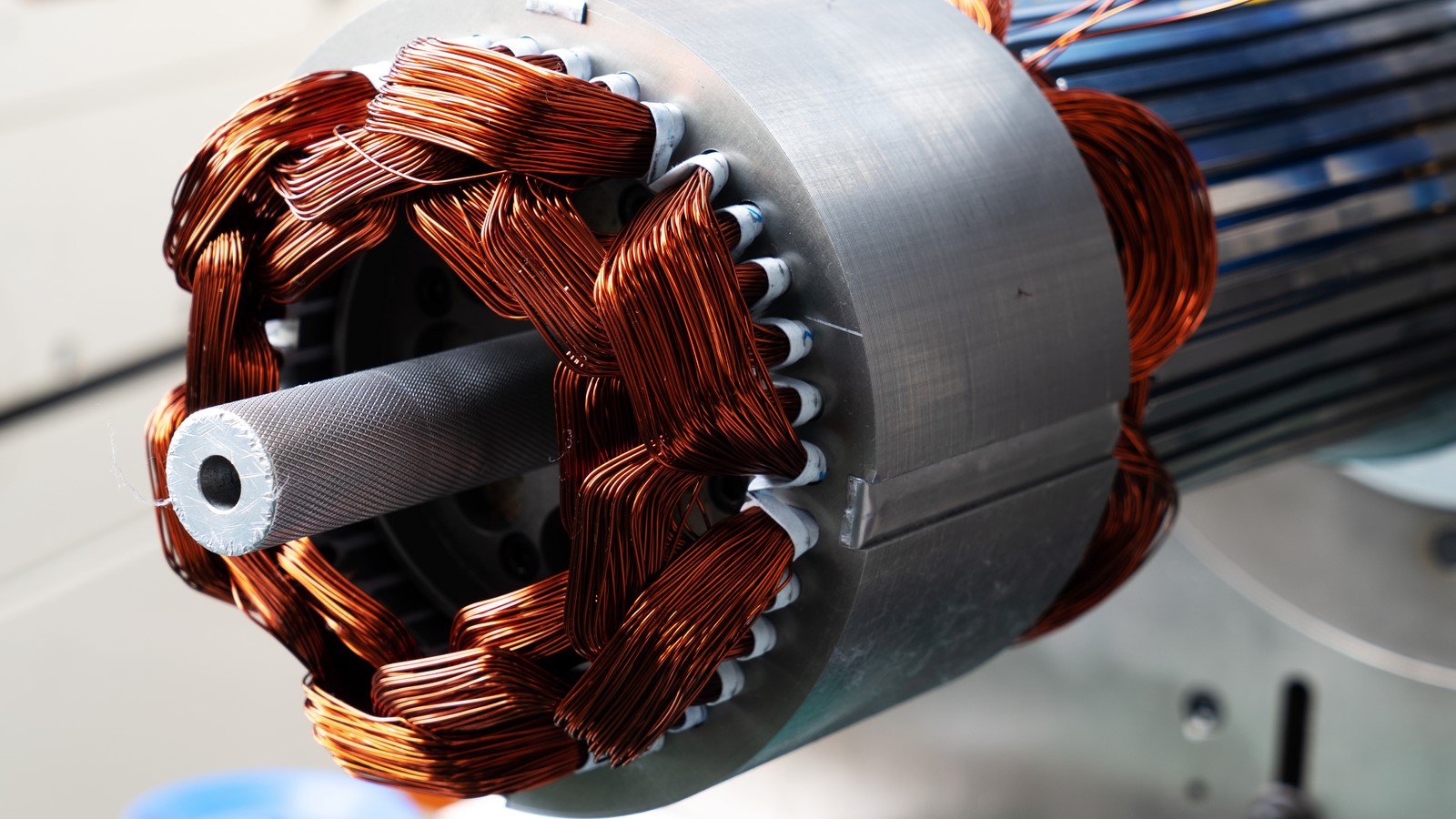

What Drives Electric Motor Efficiency: Understanding the Basics

Electric motor efficiency is a critical factor in determining the overall performance of electric vehicles (EVs). As the world shifts towards more sustainable and environmentally friendly transportation options, understanding the basics of electric motor design and operation is essential to appreciate the performance standards that follow. Electric motor efficiency refers to the ability of the motor to convert electrical energy into mechanical energy, with minimal energy loss as heat. This efficiency is typically measured in terms of the motor’s power output, torque,

How to Evaluate Electric Motor Performance: Key Metrics and Benchmarks

Evaluating electric motor performance is crucial to understanding the overall efficiency and effectiveness of electric vehicles (EVs). To assess electric motor performance, several key metrics and benchmarks are used, including power density, efficiency, and torque output. These metrics provide a comprehensive understanding of an electric motor’s capabilities and help manufacturers and engineers optimize their designs.

Power density, measured in watts per kilogram (W/kg), is a critical metric for evaluating electric motor performance. It represents the motor’s ability to produce power relative to its weight and size. High-power density electric motors are essential for achieving high-performance and efficiency in EVs. For example, the Tesla Model S’s electric motor has a power density of over 4,000 W/kg, making it one of the most efficient and powerful electric motors in the industry.

Efficiency, measured as a percentage, is another key metric for evaluating electric motor performance. It represents the motor’s ability to convert electrical energy into mechanical energy, with minimal energy loss as heat. High-efficiency electric motors are essential for achieving optimal range and performance in EVs. The International Electrotechnical Commission (IEC) sets standards for electric motor efficiency, with the IEC 60034-30 standard providing a framework for evaluating and comparing electric motor efficiency.

Torque output, measured in newton-meters (Nm), is also a critical metric for evaluating electric motor performance. It represents the motor’s ability to produce rotational force, which is essential for achieving high-performance and efficiency in EVs. High-torque electric motors are essential for heavy-duty applications, such as buses and trucks, where high-power and high-torque are required.

Industry benchmarks and standards, such as those set by the IEC, provide a framework for evaluating and comparing electric motor performance. These standards ensure that electric motors meet minimum performance and efficiency requirements, which is essential for ensuring safety and performance consistency across the industry. By understanding these metrics and benchmarks, manufacturers and engineers can design and develop high-performance electric motors that meet the demands of the EV industry.

The Role of Electric Vehicle Manufacturers in Setting Performance Standards

Electric vehicle (EV) manufacturers play a crucial role in setting performance standards for their vehicles. Companies like Tesla and BMW are at the forefront of the EV industry, and their performance standards have a significant impact on the market. These manufacturers must balance performance, efficiency, and cost to create competitive products that meet the demands of consumers.

Tesla, for example, has set a high bar for EV performance with its Model S and Model 3 vehicles. The company’s electric motors are designed to provide exceptional acceleration, range, and efficiency, making them a benchmark for the industry. Tesla’s performance standards are also reflected in its Autopilot technology, which is a advanced driver-assistance system (ADAS) that enables semi-autonomous driving.

BMW, on the other hand, has taken a more nuanced approach to setting performance standards. The company’s i-series vehicles, such as the i3 and iX3, are designed to provide a balance of performance, efficiency, and sustainability. BMW’s electric motors are optimized for efficiency and range, making them a popular choice for consumers who prioritize environmental sustainability.

Other EV manufacturers, such as Nissan and Volkswagen, are also setting performance standards for their vehicles. These companies are investing heavily in electric motor technology and battery development, which is driving innovation and improvement in the industry. As the EV market continues to grow, it is likely that performance standards will become even more important, as manufacturers compete to provide the best possible products to consumers.

The role of EV manufacturers in setting performance standards is critical to the development of the industry. By pushing the boundaries of what is possible with electric motor technology, these companies are driving innovation and improvement. As the industry continues to evolve, it is likely that performance standards will play an increasingly important role in shaping the future of electric vehicles.

Comparing Electric Vehicle Performance: A Review of the Tesla Model 3 and Chevrolet Bolt

The Tesla Model 3 and Chevrolet Bolt are two of the most popular electric vehicles (EVs) on the market, and their performance is often compared by consumers and industry experts. In this section, we will review the performance of these two vehicles using metrics such as acceleration, range, and charging time, and discuss how they meet or exceed industry performance standards.

The Tesla Model 3 is known for its exceptional acceleration, with a 0-60 mph time of just 5.1 seconds. The Chevrolet Bolt, on the other hand, has a 0-60 mph time of 6.5 seconds. While the Bolt’s acceleration is not as quick as the Model 3’s, it is still impressive for a vehicle in its class.

In terms of range, the Tesla Model 3 has an estimated range of up to 325 miles on a single charge, while the Chevrolet Bolt has an estimated range of up to 259 miles. Both vehicles have a range that is well within the industry standard for EVs, and they are both capable of meeting the daily driving needs of most consumers.

Charging time is also an important consideration for EV owners, and both the Model 3 and Bolt have fast charging capabilities. The Model 3 can charge to 80% in just 45 minutes, while the Bolt can charge to 80% in just 45 minutes as well.

Overall, both the Tesla Model 3 and Chevrolet Bolt meet or exceed industry performance standards for EVs. They both have impressive acceleration, range, and charging times, making them well-suited for consumers who are looking for a high-performance EV. As the EV market continues to grow, it is likely that we will see even more impressive performance from these and other vehicles.

In terms of electric motor performance standards, both the Model 3 and Bolt have motors that meet or exceed industry standards. The Model 3’s motor has a power output of 258 horsepower, while the Bolt’s motor has a power output of 200 horsepower. Both motors are designed to provide exceptional efficiency and performance, and they are both well-suited for the demands of daily driving.

Electric Motor Performance Standards for Heavy-Duty Applications

Heavy-duty electric vehicle applications, such as buses and trucks, require unique performance standards for their electric motors. These vehicles need high-torque and high-power electric motors to handle the demands of heavy loads and long driving distances. In this section, we will discuss the performance standards required for heavy-duty electric vehicle applications and the importance of high-torque and high-power electric motors in these applications.

High-torque electric motors are essential for heavy-duty electric vehicle applications because they provide the necessary power to handle heavy loads and steep inclines. These motors typically have a high power-to-weight ratio, which allows them to produce a lot of torque relative to their size and weight. For example, the electric motor used in the Tesla Semi truck has a peak torque output of 1,000 Nm, which is significantly higher than the torque output of most passenger electric vehicles.

High-power electric motors are also necessary for heavy-duty electric vehicle applications because they provide the necessary power to handle long driving distances and high speeds. These motors typically have a high power density, which allows them to produce a lot of power relative to their size and weight. For example, the electric motor used in the BYD K9 electric bus has a peak power output of 300 kW, which is significantly higher than the power output of most passenger electric vehicles.

In addition to high-torque and high-power electric motors, heavy-duty electric vehicle applications also require advanced battery management systems and high-capacity batteries. These systems and batteries must be designed to handle the high power and energy demands of heavy-duty electric vehicle applications, while also providing a long lifespan and low maintenance costs.

Overall, the performance standards required for heavy-duty electric vehicle applications are significantly different from those required for passenger electric vehicles. High-torque and high-power electric motors, advanced battery management systems, and high-capacity batteries are all necessary to handle the demands of heavy-duty electric vehicle applications. As the demand for heavy-duty electric vehicles continues to grow, it is likely that we will see significant advancements in these areas.

Advancements in Electric Motor Technology: What to Expect in the Future

The electric motor technology used in electric vehicles (EVs) is constantly evolving, with new advancements being made regularly. In this section, we will explore some of the latest developments in electric motor technology and discuss how they are expected to improve EV performance and efficiency in the future.

One of the most significant advancements in electric motor technology is the use of new materials, such as rare earth magnets and advanced steel alloys. These materials have improved the efficiency and power density of electric motors, allowing for more efficient and powerful EVs. For example, the use of rare earth magnets has enabled the development of more efficient and compact electric motors, which are ideal for use in EVs.

Another area of advancement is in the design of electric motors. New designs, such as the axial flux motor and the transverse flux motor, are being developed to improve efficiency and power density. These designs use advanced magnetic field configurations to optimize efficiency and reduce energy losses. For example, the axial flux motor uses a unique magnetic field configuration to reduce energy losses and improve efficiency.

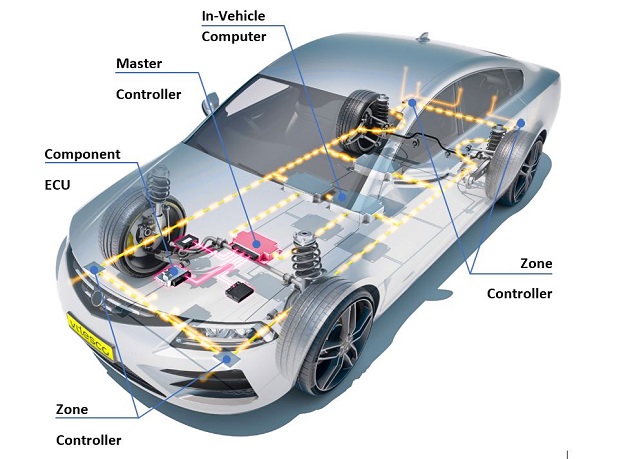

Advances in power electronics are also playing a crucial role in improving EV performance and efficiency. New power electronic devices, such as wide bandgap semiconductors, are being developed to improve the efficiency and reliability of EV powertrains. These devices enable the efficient and reliable control of high-power electric motors, which is essential for EVs.

In addition to these advancements, researchers are also exploring new electric motor technologies, such as the use of superconducting materials and advanced magnetic field configurations. These technologies have the potential to significantly improve EV performance and efficiency, and are expected to play a major role in the future of EV development.

Overall, the future of electric motor technology looks bright, with many exciting advancements on the horizon. As these technologies continue to evolve, we can expect to see significant improvements in EV performance and efficiency, which will help to drive the adoption of high-performance electric vehicles.

Regulatory Frameworks for Electric Vehicle Performance Standards

Regulatory frameworks play a crucial role in ensuring safety and performance consistency across the electric vehicle (EV) industry. Governments and industry organizations have established various standards and regulations to govern EV performance, including those related to electric motor performance. In this section, we will examine the regulatory frameworks that govern EV performance standards and discuss their importance in shaping the industry.

The International Electrotechnical Commission (IEC) is a key organization that sets standards for EV performance, including electric motor performance. The IEC has established a range of standards, including IEC 60034-30, which provides guidelines for the design and testing of electric motors for EVs. These standards help ensure that EVs meet minimum performance and safety requirements, which is essential for consumer protection and industry growth.

Government regulations also play a critical role in shaping EV performance standards. For example, the US National Highway Traffic Safety Administration (NHTSA) has established regulations for EV safety, including those related to electric motor performance. The NHTSA requires EV manufacturers to meet minimum safety standards, including those related to electric motor performance, to ensure that EVs are safe for consumers.

Industry organizations, such as the Society of Automotive Engineers (SAE), also play a key role in establishing EV performance standards. The SAE has established a range of standards, including those related to electric motor performance, to help ensure that EVs meet minimum performance and safety requirements. These standards are widely adopted across the industry and help ensure that EVs are safe and perform well.

Overall, regulatory frameworks are essential for ensuring safety and performance consistency across the EV industry. By establishing minimum performance and safety standards, governments and industry organizations can help ensure that EVs are safe and perform well, which is essential for consumer protection and industry growth.

Conclusion: The Future of Electric Vehicle Performance Standards

In conclusion, electric vehicle performance standards are a critical aspect of the EV industry, and understanding these standards is essential for manufacturers, regulators, and consumers. The key metrics used to evaluate electric motor performance, including power density, efficiency, and torque output, provide a framework for comparing and improving EV performance. The role of electric vehicle manufacturers in setting performance standards, as well as the regulatory frameworks that govern these standards, are also crucial in ensuring safety and performance consistency across the industry.

As the EV industry continues to evolve, we can expect to see significant advancements in electric motor technology, including the use of new materials and designs. These advancements will likely lead to improved electric vehicle performance and efficiency, making EVs an increasingly attractive option for consumers. However, to fully realize the potential of EVs, ongoing innovation and collaboration between manufacturers, regulators, and industry experts is necessary.

The future of electric vehicle performance standards is exciting, with many opportunities for growth and improvement. As the industry continues to mature, we can expect to see more stringent performance standards, as well as increased adoption of high-performance electric vehicles. By understanding the current state of electric vehicle performance standards and the trends shaping the industry, we can better prepare for the future of transportation.

Ultimately, the widespread adoption of high-performance electric vehicles will depend on the ability of manufacturers to balance performance, efficiency, and cost. By prioritizing innovation and collaboration, the EV industry can create vehicles that meet the needs of consumers, while also reducing emissions and improving air quality. As we look to the future, it is clear that electric vehicle performance standards will play a critical role in shaping the industry and driving the adoption of high-performance electric vehicles.