Understanding the Importance of Electric Motor Standards

Electric motor performance standards play a crucial role in ensuring the efficiency, range, and overall driving experience of electric vehicles (EVs). These standards, established by organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE), provide a framework for manufacturers to design and test electric motors that meet specific requirements. By adhering to these standards, EV manufacturers can ensure that their vehicles deliver consistent and reliable performance, regardless of the model or brand.

The significance of electric motor performance standards cannot be overstated. In the absence of these standards, EV manufacturers might prioritize other factors, such as cost or weight reduction, over performance and efficiency. This could result in EVs with subpar range, acceleration, and overall driving experience, ultimately affecting consumer adoption and the growth of the EV market. By establishing clear standards for electric motor performance, the industry can ensure that EVs meet the expectations of consumers and provide a seamless transition from traditional internal combustion engine vehicles.

Electric motor performance standards also facilitate the development of more efficient and reliable electric motors. By setting clear benchmarks for power output, torque, and efficiency, manufacturers can focus on designing and optimizing electric motors that meet these requirements. This, in turn, drives innovation and the adoption of new technologies, such as advanced materials and designs, which can further improve electric motor performance and reduce costs.

In addition to ensuring consistency and driving innovation, electric motor performance standards also play a critical role in ensuring safety and reliability in EVs. By establishing clear standards for electric motor testing and certification, manufacturers can ensure that their vehicles meet strict safety and reliability requirements, reducing the risk of accidents and injuries. This is particularly important in the EV market, where the high voltage and current levels of electric motors can pose unique safety risks if not properly managed.

In conclusion, electric motor performance standards are essential for ensuring the efficiency, range, and overall driving experience of electric vehicles. By establishing clear benchmarks for electric motor performance, the industry can drive innovation, ensure safety and reliability, and provide consumers with a seamless transition to EVs. As the EV market continues to grow and evolve, the importance of electric motor performance standards will only continue to increase, making them a critical component of the industry’s future success.

How to Evaluate Electric Motor Performance in EVs

Evaluating electric motor performance in electric vehicles (EVs) is crucial to ensure compliance with industry standards and optimize overall vehicle performance. To assess electric motor performance, several key factors must be considered, including power output, torque, and efficiency. In this section, we will provide a step-by-step guide on how to evaluate electric motor performance in EVs.

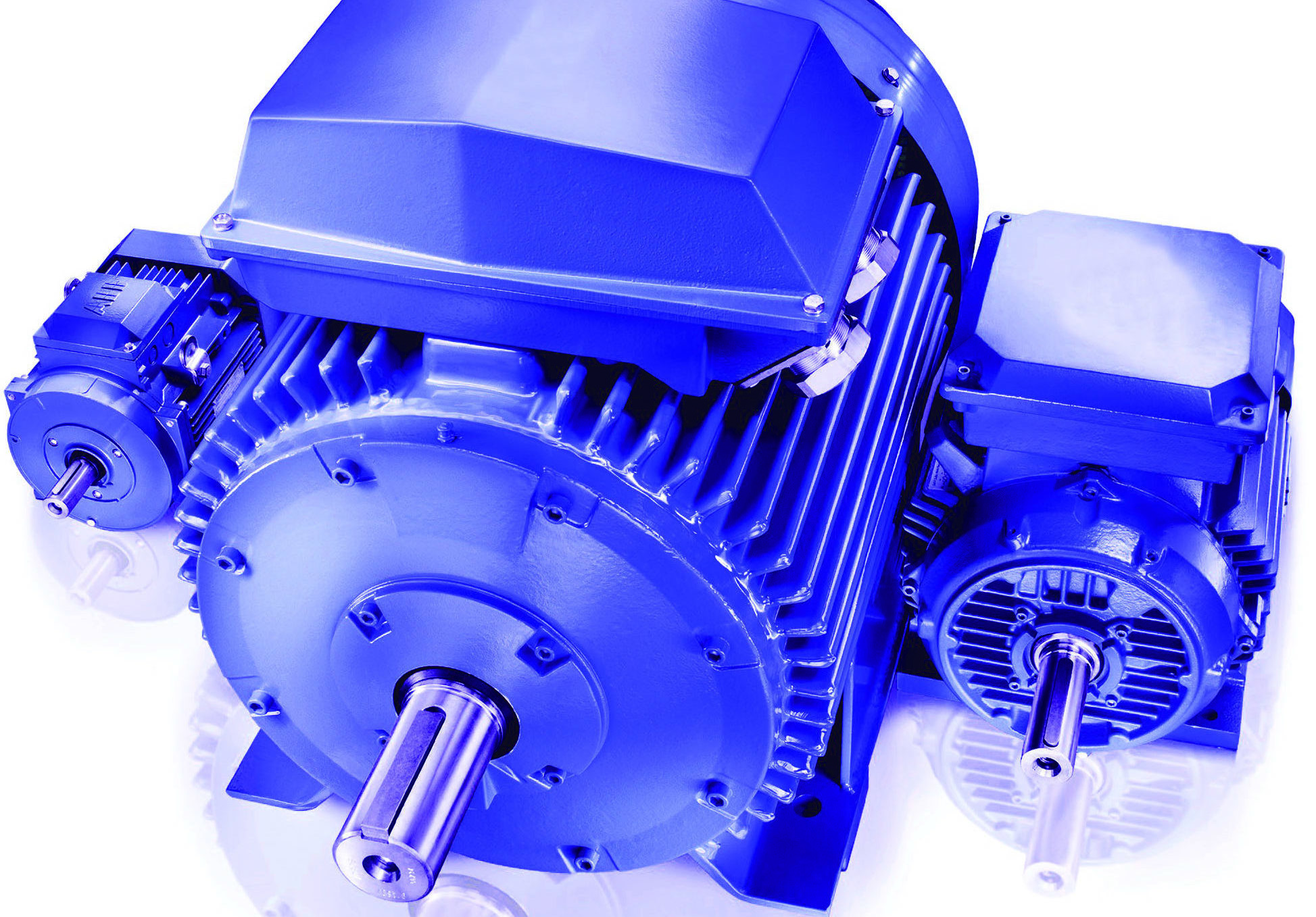

Step 1: Determine the Electric Motor Type

The first step in evaluating electric motor performance is to determine the type of electric motor used in the EV. There are several types of electric motors, including permanent magnet (PM) motors, induction motors, and switched reluctance motors. Each type of motor has its own unique characteristics and performance metrics.

Step 2: Measure Power Output and Torque

Power output and torque are critical performance metrics for electric motors. Power output is typically measured in kilowatts (kW), while torque is measured in newton-meters (Nm). To measure power output and torque, a dynamometer or other testing equipment can be used.

Step 3: Evaluate Efficiency

Efficiency is a critical performance metric for electric motors, as it directly affects the overall range and efficiency of the EV. Efficiency can be measured using a variety of methods, including the Society of Automotive Engineers (SAE) J2908 standard.

Step 4: Assess Reliability and Durability

Reliability and durability are also critical performance metrics for electric motors. To assess reliability and durability, manufacturers can use a variety of testing methods, including accelerated life testing and environmental testing.

Step 5: Consider Industry Standards and Certification

Finally, it is essential to consider industry standards and certification when evaluating electric motor performance. Organizations such as the International Electrotechnical Commission (IEC) and the SAE provide standards and certification programs for electric motors, ensuring compliance with industry standards and optimizing overall vehicle performance.

In conclusion, evaluating electric motor performance in EVs requires a comprehensive approach that considers several key factors, including power output, torque, efficiency, reliability, and durability. By following these steps and considering industry standards and certification, manufacturers can optimize electric motor performance and ensure compliance with industry standards.

Key Performance Indicators for Electric Motors in EVs

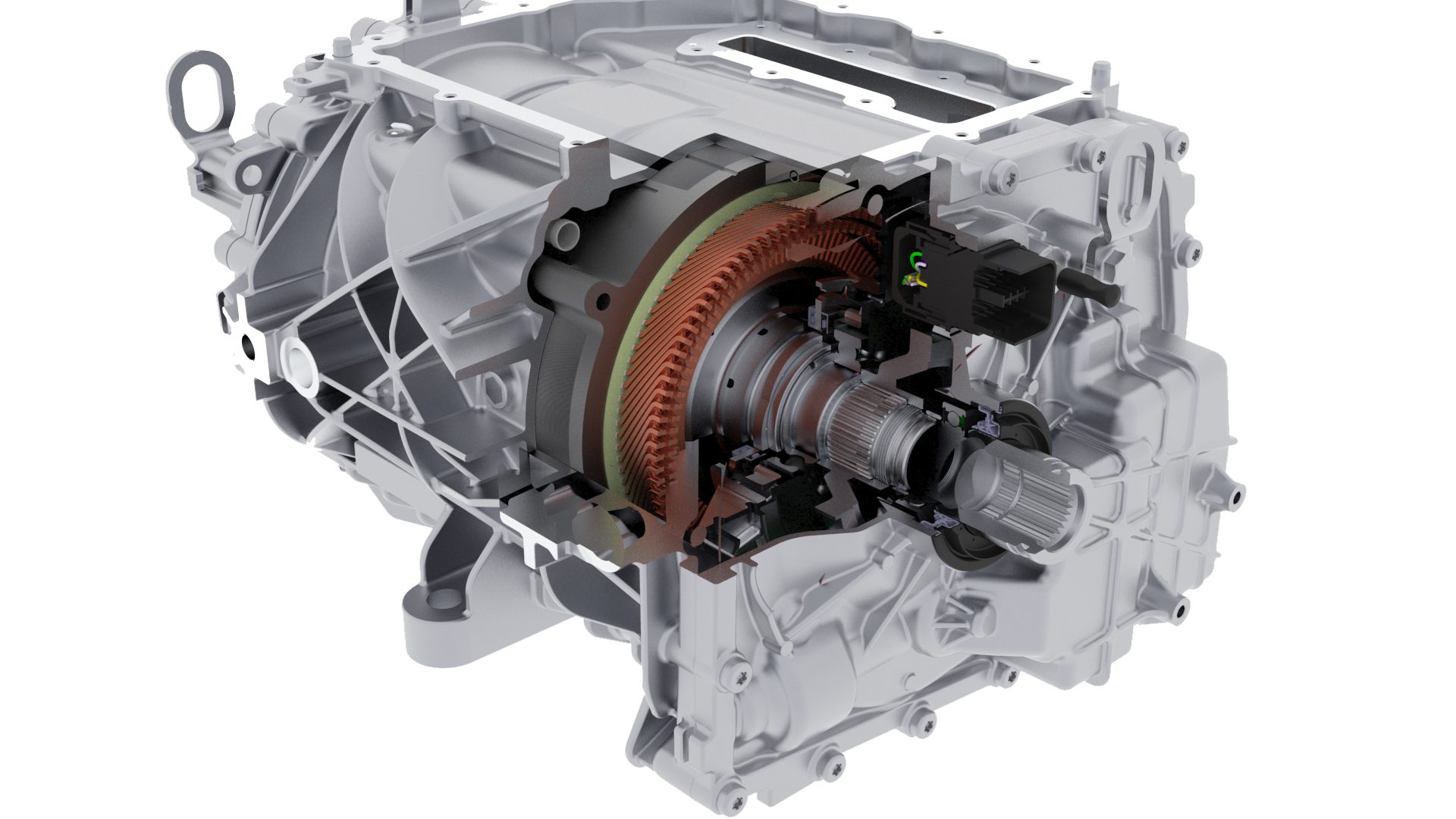

Electric motors in electric vehicles (EVs) are critical components that impact the overall performance and range of the vehicle. To evaluate the performance of electric motors, several key performance indicators (KPIs) must be considered. In this section, we will discuss the most important KPIs for electric motors in EVs, including power density, efficiency, and reliability.

Power Density

Power density is a critical KPI for electric motors in EVs, as it directly affects the overall power output and efficiency of the vehicle. Power density is typically measured in watts per kilogram (W/kg) and is a measure of the motor’s ability to produce power relative to its weight. Electric motors with high power density are able to produce more power while minimizing weight, which is essential for EVs.

Efficiency

Efficiency is another important KPI for electric motors in EVs, as it directly affects the overall range and efficiency of the vehicle. Efficiency is typically measured as a percentage and is a measure of the motor’s ability to convert electrical energy into mechanical energy. Electric motors with high efficiency are able to minimize energy losses and maximize range.

Reliability

Reliability is a critical KPI for electric motors in EVs, as it directly affects the overall safety and performance of the vehicle. Reliability is typically measured as a mean time between failures (MTBF) and is a measure of the motor’s ability to operate without failure over a given period of time. Electric motors with high reliability are able to minimize downtime and ensure safe operation.

Other KPIs

In addition to power density, efficiency, and reliability, several other KPIs are important for electric motors in EVs, including torque, speed, and temperature. Torque is a measure of the motor’s rotational force and is critical for EVs, as it directly affects acceleration and performance. Speed is a measure of the motor’s rotational velocity and is critical for EVs, as it directly affects range and efficiency. Temperature is a measure of the motor’s operating temperature and is critical for EVs, as it directly affects reliability and performance.

In conclusion, electric motors in EVs are critical components that impact the overall performance and range of the vehicle. By considering key performance indicators such as power density, efficiency, and reliability, manufacturers can optimize electric motor performance and ensure compliance with industry standards. By incorporating advanced materials, designs, and technologies, manufacturers can further improve electric motor performance and increase the adoption of EVs.

Comparing Electric Motor Performance in Popular EV Models

The electric motor performance of popular electric vehicle (EV) models can vary significantly, impacting the overall driving experience and range of the vehicle. In this section, we will compare and contrast the electric motor performance of several popular EV models, including the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf.

Tesla Model 3

The Tesla Model 3 is a highly popular EV model that features a high-performance electric motor. The motor is a three-phase, four-pole induction motor that produces 258 horsepower and 317 lb-ft of torque. The motor is also highly efficient, with a maximum efficiency of 95% and a minimum efficiency of 90%.

Chevrolet Bolt

The Chevrolet Bolt is another popular EV model that features a high-performance electric motor. The motor is a three-phase, four-pole induction motor that produces 200 horsepower and 266 lb-ft of torque. The motor is also highly efficient, with a maximum efficiency of 92% and a minimum efficiency of 88%.

Nissan Leaf

The Nissan Leaf is a highly popular EV model that features a high-performance electric motor. The motor is a three-phase, four-pole induction motor that produces 147 horsepower and 236 lb-ft of torque. The motor is also highly efficient, with a maximum efficiency of 90% and a minimum efficiency of 85%.

Comparison of Electric Motor Performance

When comparing the electric motor performance of these popular EV models, it is clear that the Tesla Model 3 has the highest power output and efficiency. However, the Chevrolet Bolt and Nissan Leaf also have highly efficient motors that provide excellent performance and range.

Impact on Driving Experience

The electric motor performance of these EV models can significantly impact the overall driving experience. The Tesla Model 3, for example, has a highly responsive and smooth acceleration, making it a joy to drive. The Chevrolet Bolt and Nissan Leaf also have excellent acceleration and handling, making them highly enjoyable to drive.

In conclusion, the electric motor performance of popular EV models can vary significantly, impacting the overall driving experience and range of the vehicle. By comparing and contrasting the electric motor performance of these models, we can gain a better understanding of the importance of electric motor performance standards in ensuring a consistent and reliable performance across different EV models.

The Role of Advanced Materials in Electric Motor Performance

Advanced materials play a crucial role in electric motor performance, enabling the development of more efficient, reliable, and powerful motors. In this section, we will discuss the impact of advanced materials on electric motor performance, including the use of rare earth magnets, high-temperature superconductors, and advanced steel alloys.

Rare Earth Magnets

Rare earth magnets are a type of permanent magnet made from rare earth elements such as neodymium and dysprosium. These magnets have a high magnetic field strength and are used in many electric motor applications, including electric vehicles. Rare earth magnets offer several advantages, including high power density, high efficiency, and low weight.

High-Temperature Superconductors

High-temperature superconductors are materials that can conduct electricity with zero resistance at high temperatures. These materials have the potential to revolutionize electric motor performance by enabling the development of more efficient and powerful motors. High-temperature superconductors can be used to create high-performance electric motors with high power density and high efficiency.

Advanced Steel Alloys

Advanced steel alloys are a type of steel alloy that offers high strength, high toughness, and low weight. These alloys are used in many electric motor applications, including electric vehicles. Advanced steel alloys offer several advantages, including high power density, high efficiency, and low weight.

Impact on Electric Motor Performance

The use of advanced materials in electric motors can significantly impact electric motor performance. Rare earth magnets, high-temperature superconductors, and advanced steel alloys can improve efficiency, reduce weight, and increase power density in electric motors. These materials can also enable the development of more reliable and durable electric motors.

Future Developments

The development of advanced materials is an ongoing process, and new materials are being developed all the time. Future developments in advanced materials are expected to have a significant impact on electric motor performance, enabling the development of more efficient, reliable, and powerful motors.

In conclusion, advanced materials play a crucial role in electric motor performance, enabling the development of more efficient, reliable, and powerful motors. The use of rare earth magnets, high-temperature superconductors, and advanced steel alloys can improve efficiency, reduce weight, and increase power density in electric motors. As new materials are developed, we can expect to see even more significant improvements in electric motor performance.

Electric Motor Testing and Certification: Ensuring Compliance with Industry Standards

Electric motor testing and certification are critical components of ensuring compliance with industry standards in electric vehicles. In this section, we will discuss the process of electric motor testing and certification, including the role of organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE).

International Electrotechnical Commission (IEC)

The IEC is a global organization that develops and publishes standards for electrical and electronic products, including electric motors. The IEC provides a framework for testing and certification of electric motors, ensuring that they meet specific safety and performance requirements.

Society of Automotive Engineers (SAE)

The SAE is a global organization that develops and publishes standards for the automotive industry, including electric vehicles. The SAE provides a framework for testing and certification of electric motors, ensuring that they meet specific safety and performance requirements.

Testing and Certification Process

The testing and certification process for electric motors involves several steps, including:

- Design and development of the electric motor

- Testing of the electric motor to ensure compliance with industry standards

- Certification of the electric motor by a recognized testing organization

- Verification of the electric motor’s performance and safety features

Importance of Compliance with Industry Standards

Compliance with industry standards is critical for ensuring the safety, efficiency, and reliability of electric vehicles. Electric motors that meet industry standards are designed to operate safely and efficiently, reducing the risk of accidents and injuries.

Benefits of Electric Motor Testing and Certification

The benefits of electric motor testing and certification include:

- Improved safety and reliability of electric vehicles

- Increased efficiency and performance of electric motors

- Reduced risk of accidents and injuries

- Compliance with industry standards and regulations

In conclusion, electric motor testing and certification are critical components of ensuring compliance with industry standards in electric vehicles. By following the testing and certification process, manufacturers can ensure that their electric motors meet specific safety and performance requirements, reducing the risk of accidents and injuries.

Future Trends in Electric Motor Performance: Emerging Technologies and Innovations

The electric motor industry is constantly evolving, with new technologies and innovations emerging all the time. In this section, we will discuss some of the future trends in electric motor performance, including the development of new materials, designs, and technologies.

New Materials

Researchers are continually developing new materials that can improve the performance of electric motors. Some of the most promising new materials include:

- Advanced magnetic materials, such as neodymium and dysprosium, which can improve the efficiency and power density of electric motors

- High-temperature superconductors, which can enable the development of more efficient and powerful electric motors

- Advanced steel alloys, which can improve the strength and durability of electric motors

New Designs

New designs are also emerging that can improve the performance of electric motors. Some of the most promising new designs include:

- Modular designs, which can enable the development of more efficient and scalable electric motors

- Integrated designs, which can enable the development of more compact and efficient electric motors

- Advanced cooling systems, which can enable the development of more efficient and reliable electric motors

New Technologies

New technologies are also emerging that can improve the performance of electric motors. Some of the most promising new technologies include:

- Advanced power electronics, which can enable the development of more efficient and powerful electric motors

- Artificial intelligence and machine learning, which can enable the development of more efficient and reliable electric motors

- Internet of Things (IoT) connectivity, which can enable the development of more connected and efficient electric motors

Impact on Electric Vehicle Performance

These emerging trends and innovations in electric motor performance can have a significant impact on electric vehicle performance. By improving the efficiency, power density, and reliability of electric motors, these trends and innovations can enable the development of more efficient and powerful electric vehicles.

Conclusion

In conclusion, the future of electric motor performance is exciting and rapidly evolving. With the development of new materials, designs, and technologies, we can expect to see significant improvements in electric motor performance in the coming years. These improvements will have a major impact on electric vehicle performance, enabling the development of more efficient and powerful electric vehicles.

Conclusion: Optimizing Electric Vehicle Performance through Efficient Electric Motors

In conclusion, electric motor performance standards play a crucial role in ensuring the efficiency, range, and overall driving experience of electric vehicles. By understanding the importance of these standards and how they impact electric motor performance, manufacturers can optimize their electric motors to meet the demands of the growing electric vehicle market.

The use of advanced materials, such as rare earth magnets and high-temperature superconductors, can improve efficiency, reduce weight, and increase power density in electric motors. Additionally, electric motor testing and certification, as well as compliance with industry standards, are essential for ensuring safety, efficiency, and reliability in electric vehicles.

Emerging trends and innovations in electric motor performance, such as the development of new materials, designs, and technologies, will continue to shape the industry and improve the efficiency, range, and overall driving experience of electric vehicles. As the electric vehicle market continues to grow, the importance of electric motor performance standards will only continue to increase.

By prioritizing electric motor performance and efficiency, manufacturers can create electric vehicles that meet the demands of consumers and help to drive the adoption of electric vehicles. As the industry continues to evolve, it will be exciting to see the innovations and advancements that emerge in electric motor performance and how they impact the future of electric vehicles.

In the end, the key to optimizing electric vehicle performance lies in the efficient design and operation of the electric motor. By understanding the importance of electric motor performance standards and how they impact electric motor performance, manufacturers can create electric vehicles that are efficient, reliable, and provide a great driving experience.