Understanding the Importance of Electric Motor Performance

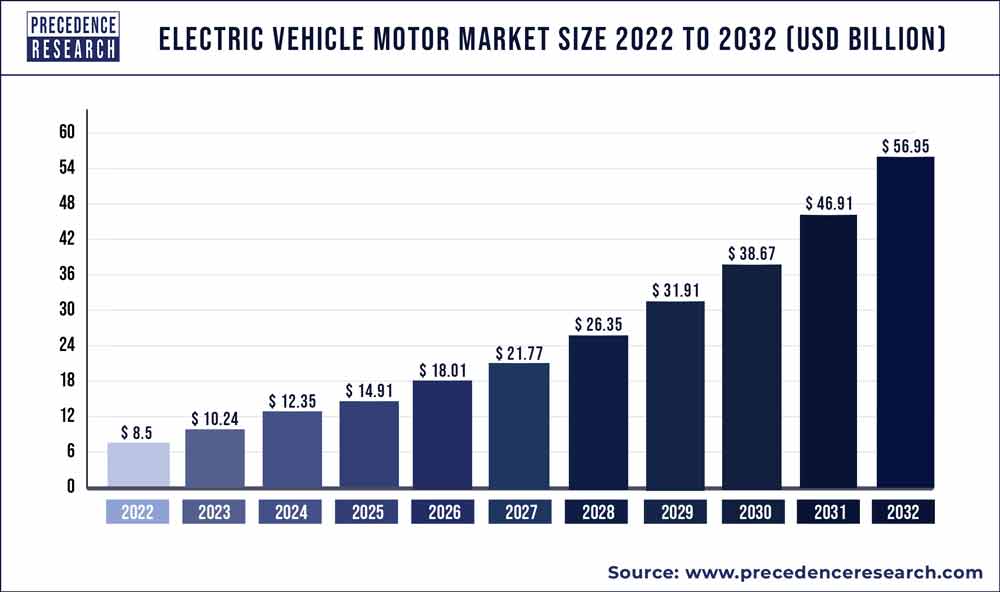

Electric motor performance plays a crucial role in the overall efficiency, range, and environmental sustainability of electric vehicles. As the demand for eco-friendly transportation continues to grow, manufacturers are under increasing pressure to optimize their designs and meet stringent performance standards. Electric motor performance standards, in particular, have become a key focus area for the industry, as they directly impact the vehicle’s ability to deliver exceptional driving experiences while minimizing environmental impact.

The significance of electric motor performance can be attributed to its direct influence on the vehicle’s power output, torque, and efficiency. A well-designed electric motor can provide improved acceleration, smoother operation, and reduced energy consumption, ultimately leading to enhanced overall performance. Moreover, electric motor performance standards help manufacturers ensure that their vehicles meet regulatory requirements, such as those set by the International Electrotechnical Commission (IEC) and the US Environmental Protection Agency (EPA).

By adhering to electric vehicle and electric motor performance standards, manufacturers can optimize their designs to achieve better efficiency, reduced emissions, and improved driving experiences. This, in turn, can lead to increased customer satisfaction, reduced maintenance costs, and a competitive edge in the market. As the electric vehicle industry continues to evolve, the importance of electric motor performance standards will only continue to grow, driving innovation and excellence in the sector.

Furthermore, electric motor performance standards also play a critical role in ensuring the environmental sustainability of electric vehicles. By optimizing electric motor performance, manufacturers can reduce energy consumption, lower emissions, and minimize the overall environmental footprint of their vehicles. This is particularly important, as the transportation sector is one of the largest contributors to greenhouse gas emissions, and electric vehicles are seen as a key solution to mitigating climate change.

In conclusion, electric motor performance is a critical component of electric vehicle design, and adherence to performance standards is essential for manufacturers to optimize their designs, meet regulatory requirements, and deliver exceptional driving experiences. As the industry continues to evolve, the importance of electric vehicle and electric motor performance standards will only continue to grow, driving innovation and excellence in the sector.

How to Evaluate Electric Motor Performance: Key Metrics and Benchmarks

Evaluating electric motor performance is crucial for manufacturers to optimize their designs and meet electric vehicle and electric motor performance standards. To assess electric motor performance, several key metrics and benchmarks are used, including power density, efficiency, and torque. These metrics provide a comprehensive understanding of an electric motor’s capabilities and help manufacturers identify areas for improvement.

Power density, measured in watts per kilogram (W/kg), is a critical metric for electric motor performance. It represents the motor’s ability to produce power relative to its weight and size. A higher power density indicates a more efficient motor, which is essential for electric vehicles that require high power output while minimizing weight and size.

Efficiency, measured as a percentage, is another key metric for electric motor performance. It represents the motor’s ability to convert electrical energy into mechanical energy, with higher efficiency indicating less energy loss as heat. Electric motor efficiency is critical for electric vehicles, as it directly impacts their range, performance, and overall efficiency.

Torque, measured in newton-meters (Nm), is a measure of an electric motor’s rotational force. It represents the motor’s ability to produce rotational motion and is critical for electric vehicles, which require high torque output to achieve smooth acceleration and responsive performance.

Benchmarks like the International Electrotechnical Commission (IEC) standards provide a framework for evaluating electric motor performance. The IEC standards outline specific requirements for electric motor performance, including power density, efficiency, and torque. By meeting these standards, manufacturers can ensure that their electric motors meet the necessary performance requirements for electric vehicles.

In addition to these metrics and benchmarks, manufacturers also use various testing protocols to evaluate electric motor performance. These protocols include dynamometer testing, which measures an electric motor’s power output and efficiency under controlled conditions, and vehicle testing, which evaluates an electric motor’s performance in a real-world driving scenario.

By understanding these key metrics and benchmarks, manufacturers can optimize their electric motor designs to meet electric vehicle and electric motor performance standards. This, in turn, can lead to improved performance, efficiency, and range for electric vehicles, ultimately enhancing the overall driving experience for consumers.

Electric Vehicle Performance Standards: A Review of Existing Regulations

The electric vehicle industry is subject to a range of performance standards and regulations, which vary by region and country. These standards aim to ensure that electric vehicles meet certain safety, environmental, and performance requirements, and are a critical factor in the development of electric vehicle and electric motor performance standards.

In the United States, the Environmental Protection Agency (EPA) sets standards for electric vehicle emissions and fuel economy. The EPA’s ratings provide a benchmark for electric vehicle performance, and manufacturers must ensure that their vehicles meet these standards in order to be sold in the US market.

In the European Union, the Euro 6 standards provide a framework for electric vehicle emissions and performance. These standards are more stringent than those in the US, and manufacturers must ensure that their vehicles meet these standards in order to be sold in the EU market.

Other countries, such as China and Japan, also have their own set of electric vehicle performance standards and regulations. These standards are often more stringent than those in the US and EU, and manufacturers must ensure that their vehicles meet these standards in order to be sold in these markets.

In addition to government regulations, industry organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) also play a critical role in setting electric vehicle performance standards. These organizations provide a framework for electric vehicle design and testing, and manufacturers must ensure that their vehicles meet these standards in order to be certified.

Examples of electric vehicle performance standards include the IEC 62660 standard for lithium-ion batteries, and the SAE J1772 standard for electric vehicle charging systems. These standards provide a benchmark for electric vehicle performance, and manufacturers must ensure that their vehicles meet these standards in order to be certified.

Overall, the existing regulations and standards for electric vehicle performance provide a framework for manufacturers to develop and test their vehicles. By meeting these standards, manufacturers can ensure that their vehicles are safe, efficient, and meet the performance expectations of consumers.

However, the regulatory landscape for electric vehicles is constantly evolving, and manufacturers must stay up-to-date with the latest standards and regulations in order to remain competitive. This requires a deep understanding of the technical requirements for electric vehicle performance, as well as the regulatory framework that governs the industry.

Real-World Examples: How Top Electric Vehicles Stack Up Against Performance Standards

The performance of electric vehicles is a critical factor in their adoption and success. To evaluate the performance of electric vehicles, we can look at how they stack up against existing performance standards. In this section, we will analyze the performance of popular electric vehicles like the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf against existing standards.

The Tesla Model 3 is a highly successful electric vehicle that has set a new standard for performance and efficiency. According to the US Environmental Protection Agency (EPA), the Tesla Model 3 has a range of up to 325 miles on a single charge, and its electric motor produces 258 horsepower. These numbers make it one of the top-performing electric vehicles on the market, and it easily meets the EPA’s performance standards for electric vehicles.

The Chevrolet Bolt is another highly successful electric vehicle that has gained widespread recognition for its performance and efficiency. According to the EPA, the Chevrolet Bolt has a range of up to 259 miles on a single charge, and its electric motor produces 200 horsepower. While its performance numbers are not quite as high as the Tesla Model 3, the Chevrolet Bolt still meets the EPA’s performance standards for electric vehicles.

The Nissan Leaf is a highly popular electric vehicle that has been on the market for several years. According to the EPA, the Nissan Leaf has a range of up to 147 miles on a single charge, and its electric motor produces 147 horsepower. While its performance numbers are not as high as some of the other electric vehicles on the market, the Nissan Leaf still meets the EPA’s performance standards for electric vehicles.

These examples demonstrate how top electric vehicles stack up against existing performance standards. By meeting or exceeding these standards, manufacturers can ensure that their vehicles are safe, efficient, and meet the performance expectations of consumers. However, it’s worth noting that the performance of electric vehicles can vary depending on a range of factors, including the type of electric motor used, the battery management system, and the overall design of the vehicle.

In addition to meeting performance standards, electric vehicles must also meet safety standards. The National Highway Traffic Safety Administration (NHTSA) sets safety standards for electric vehicles, including requirements for crash testing and safety features like airbags and anti-lock braking systems. By meeting these safety standards, manufacturers can ensure that their vehicles are safe for consumers and meet the regulatory requirements for electric vehicles.

Optimizing Electric Motor Design for Improved Performance

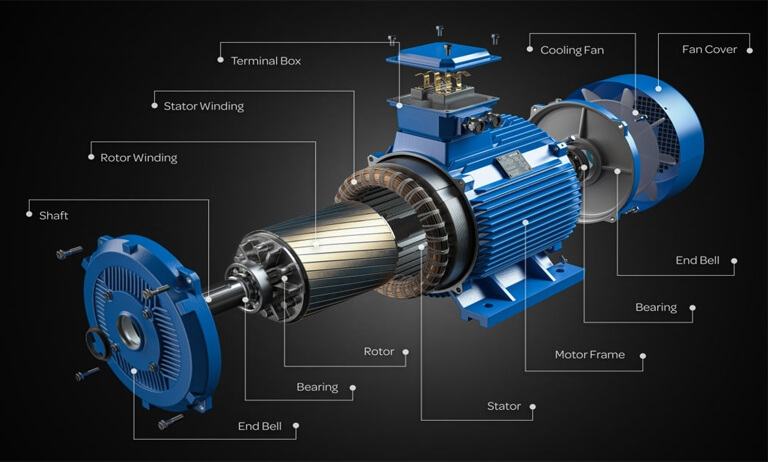

Electric motor design is a critical factor in determining the performance of an electric vehicle. To optimize electric motor design for improved performance, manufacturers must consider several key factors, including materials, cooling systems, and control strategies.

Materials play a crucial role in electric motor design, as they can significantly impact the motor’s efficiency, power density, and reliability. For example, the use of high-temperature superconducting materials can improve the motor’s efficiency and reduce its weight. Similarly, the use of advanced magnetic materials can improve the motor’s power density and reduce its size.

Cooling systems are also critical in electric motor design, as they can significantly impact the motor’s performance and reliability. For example, the use of advanced cooling systems such as liquid cooling or air cooling can improve the motor’s efficiency and reduce its temperature. This can help to improve the motor’s performance and extend its lifespan.

Control strategies are also important in electric motor design, as they can significantly impact the motor’s performance and efficiency. For example, the use of advanced control algorithms such as field-oriented control or direct torque control can improve the motor’s efficiency and reduce its energy consumption. This can help to improve the motor’s performance and reduce its environmental impact.

By optimizing electric motor design for improved performance, manufacturers can help to improve the overall efficiency and performance of electric vehicles. This can help to reduce energy consumption, lower emissions, and improve the driving experience for consumers. Additionally, optimized electric motor design can help to reduce the cost and weight of electric vehicles, making them more competitive with traditional gasoline-powered vehicles.

Manufacturers can use a variety of tools and techniques to optimize electric motor design for improved performance. For example, they can use computer-aided design (CAD) software to simulate and optimize the motor’s design. They can also use finite element analysis (FEA) to analyze the motor’s thermal and structural performance. Additionally, they can use testing and validation techniques to ensure that the motor meets the required performance standards.

Overall, optimizing electric motor design for improved performance is a critical factor in determining the success of electric vehicles. By considering key factors such as materials, cooling systems, and control strategies, manufacturers can help to improve the overall efficiency and performance of electric vehicles. This can help to reduce energy consumption, lower emissions, and improve the driving experience for consumers.

The Role of Advanced Technologies in Enhancing Electric Vehicle Performance

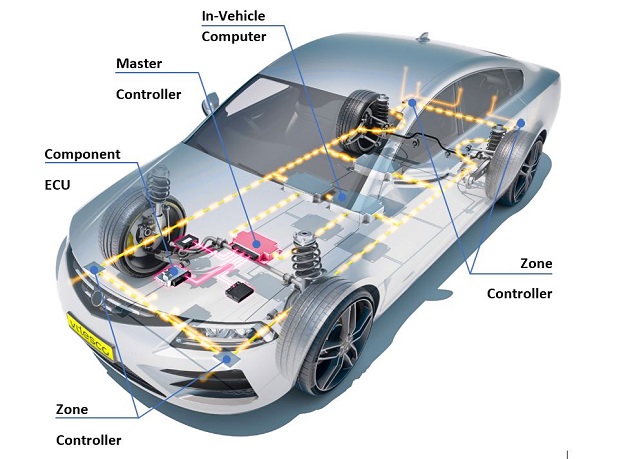

Advanced technologies play a crucial role in enhancing electric vehicle performance and meeting electric vehicle and electric motor performance standards. One of the key technologies that has improved electric vehicle performance is regenerative braking. Regenerative braking captures some of the kinetic energy that is lost during braking and converts it into electrical energy, which is then stored in the vehicle’s battery. This technology has improved the efficiency of electric vehicles and has helped to increase their range.

Another advanced technology that has improved electric vehicle performance is advanced battery management systems. These systems optimize the performance of the vehicle’s battery by controlling the charging and discharging of the battery, as well as monitoring the battery’s state of charge and state of health. This technology has improved the efficiency and range of electric vehicles, and has also helped to extend the lifespan of the battery.

Electric motor control algorithms are also an important advanced technology that has improved electric vehicle performance. These algorithms optimize the performance of the vehicle’s electric motor by controlling the flow of electrical energy to the motor, as well as monitoring the motor’s speed and torque. This technology has improved the efficiency and performance of electric vehicles, and has also helped to reduce the energy consumption of the vehicle.

Other advanced technologies that are being developed to enhance electric vehicle performance include vehicle-to-grid (V2G) technology, which allows electric vehicles to supply energy back to the grid, and advanced materials, such as lightweight composites and advanced battery chemistries. These technologies have the potential to further improve the efficiency and performance of electric vehicles, and to help meet electric vehicle and electric motor performance standards.

The adoption of advanced technologies has also helped to address some of the challenges faced by manufacturers in meeting electric vehicle performance standards. For example, the use of regenerative braking and advanced battery management systems has helped to improve the efficiency and range of electric vehicles, which has helped to address the challenge of limited range. Similarly, the use of electric motor control algorithms has helped to improve the performance and efficiency of electric vehicles, which has helped to address the challenge of limited performance.

Overall, the adoption of advanced technologies has played a crucial role in enhancing electric vehicle performance and meeting electric vehicle and electric motor performance standards. As the technology continues to evolve, we can expect to see further improvements in the efficiency and performance of electric vehicles, which will help to drive the adoption of electric vehicles and reduce our reliance on fossil fuels.

Challenges and Opportunities in Meeting Electric Vehicle Performance Standards

As the electric vehicle (EV) industry continues to evolve, manufacturers face numerous challenges in meeting electric motor performance standards. One of the primary obstacles is the delicate balance between cost, weight, and complexity. To achieve optimal performance, EVs require advanced technologies and materials, which can drive up costs and add weight to the vehicle. Moreover, the increasing complexity of EV systems can make it difficult for manufacturers to ensure reliability and efficiency.

Another significant challenge is the need to meet stringent regulatory requirements. Governments and industry organizations are implementing stricter standards for EV performance, emissions, and safety. For instance, the European Union’s Euro 6 standards and the US Environmental Protection Agency (EPA) ratings require EVs to meet specific targets for efficiency, range, and emissions. Manufacturers must invest significant resources in research and development to ensure their vehicles comply with these regulations.

Despite these challenges, there are opportunities for innovation and improvement. Advances in materials science and technology are enabling the development of more efficient and powerful electric motors. For example, the use of rare-earth magnets and advanced coil designs can improve motor efficiency and reduce weight. Additionally, the integration of advanced battery management systems and electric motor control algorithms can optimize energy consumption and enhance overall vehicle performance.

Manufacturers can also leverage emerging trends and technologies to improve EV performance. For instance, the adoption of vehicle-to-grid (V2G) technology can enable EVs to act as energy storage devices, providing additional revenue streams for manufacturers and consumers. Furthermore, the development of autonomous vehicles can lead to new opportunities for EV performance optimization, as autonomous systems can optimize energy consumption and improve overall vehicle efficiency.

To overcome the challenges and capitalize on the opportunities, manufacturers must adopt a holistic approach to EV design and development. This involves integrating advanced technologies, optimizing system design, and ensuring compliance with regulatory requirements. By doing so, manufacturers can create EVs that meet or exceed electric motor performance standards, while also providing a compelling value proposition for consumers.

Ultimately, the key to success lies in striking a balance between performance, efficiency, and cost. Manufacturers that can achieve this balance will be well-positioned to thrive in the rapidly evolving EV market. As the industry continues to evolve, it is likely that we will see significant advancements in electric motor performance standards, enabling the widespread adoption of EVs and reducing our reliance on fossil fuels.

Future Directions: Emerging Trends and Developments in Electric Vehicle Performance Standards

The electric vehicle (EV) industry is on the cusp of a revolution, driven by emerging trends and developments that will shape the future of electric motor performance standards. One of the most significant trends is the rise of autonomous vehicles, which will require EVs to be equipped with advanced sensors, software, and communication systems. This will lead to new opportunities for optimizing electric motor performance, as autonomous systems can optimize energy consumption and improve overall vehicle efficiency.

Another trend that is gaining traction is vehicle-to-grid (V2G) technology, which enables EVs to act as energy storage devices and supply electricity back to the grid. This technology has the potential to transform the way we think about energy consumption and generation, and will require EV manufacturers to develop new electric motor performance standards that can accommodate bidirectional energy flow.

Advanced materials are also set to play a crucial role in shaping the future of electric motor performance standards. New materials like graphene, nanomaterials, and advanced ceramics are being developed that can improve the efficiency, power density, and reliability of electric motors. These materials will enable EV manufacturers to develop more efficient and powerful electric motors, which will be essential for meeting future performance standards.

In addition to these trends, there are also several emerging technologies that will impact electric motor performance standards. For example, the development of advanced battery management systems (BMS) will enable EV manufacturers to optimize energy consumption and improve overall vehicle efficiency. Similarly, the use of electric motor control algorithms and machine learning techniques will enable EV manufacturers to optimize electric motor performance in real-time.

As the EV industry continues to evolve, it is likely that we will see significant advancements in electric motor performance standards. These advancements will be driven by emerging trends and developments, and will require EV manufacturers to develop new technologies and strategies for optimizing electric motor performance. By staying ahead of the curve and embracing these emerging trends, EV manufacturers can ensure that their vehicles meet the performance standards of the future.

The future of electric vehicle performance standards will also be shaped by regulatory developments. Governments and industry organizations will continue to play a crucial role in setting performance standards for EVs, and will need to adapt to emerging trends and developments. For example, the European Union’s Euro 7 standards and the US Environmental Protection Agency (EPA) ratings will need to be updated to reflect the latest advancements in electric motor technology.

Overall, the future of electric vehicle performance standards is exciting and rapidly evolving. By embracing emerging trends and developments, EV manufacturers can ensure that their vehicles meet the performance standards of the future and provide a compelling value proposition for consumers.