Unlocking the Secrets of Efficient Electric Motor Design

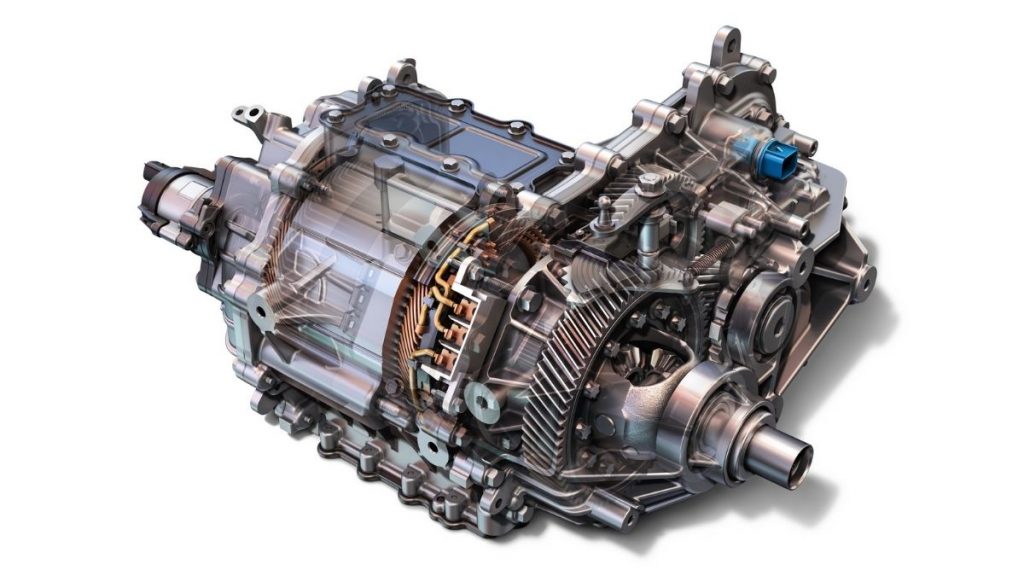

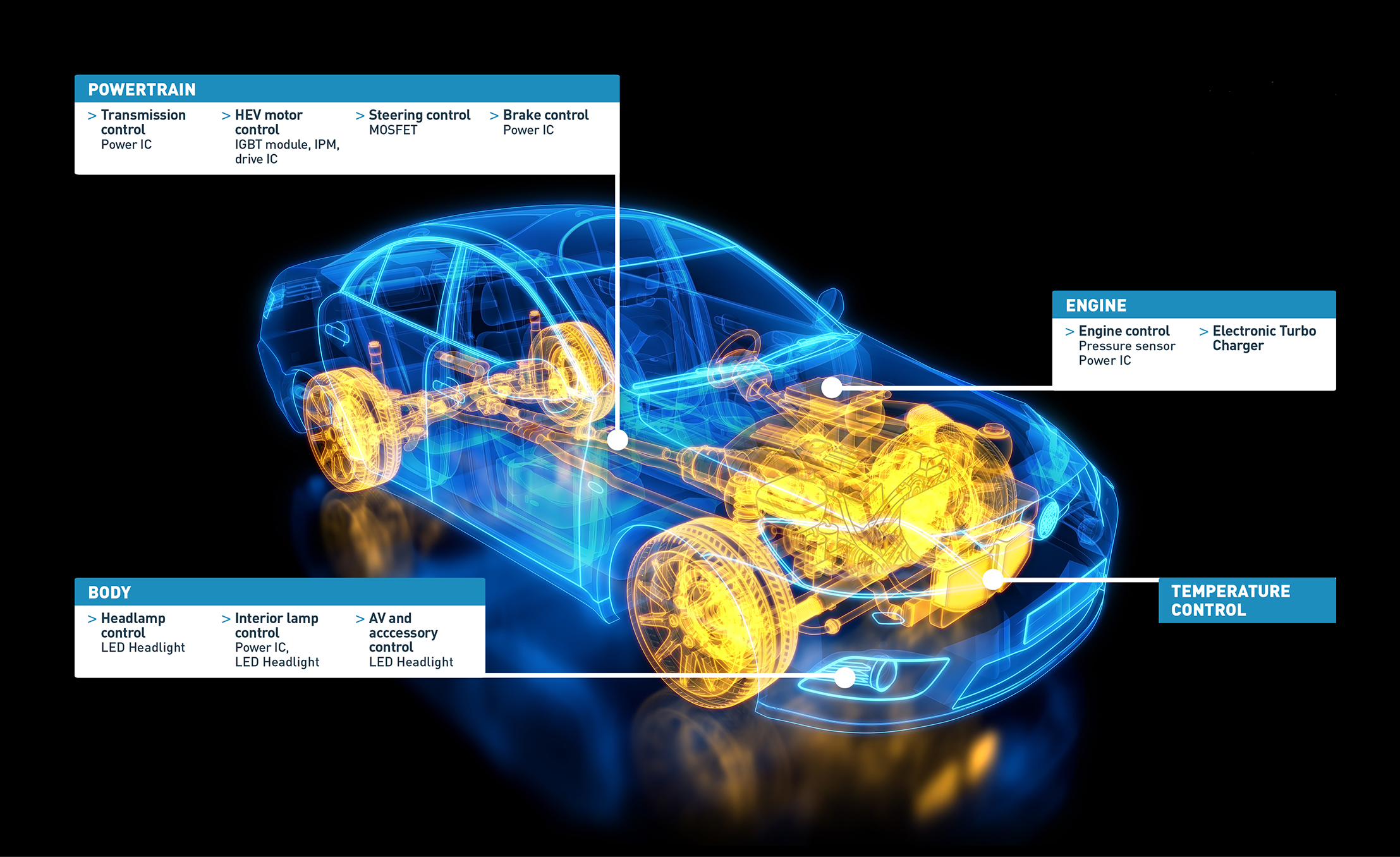

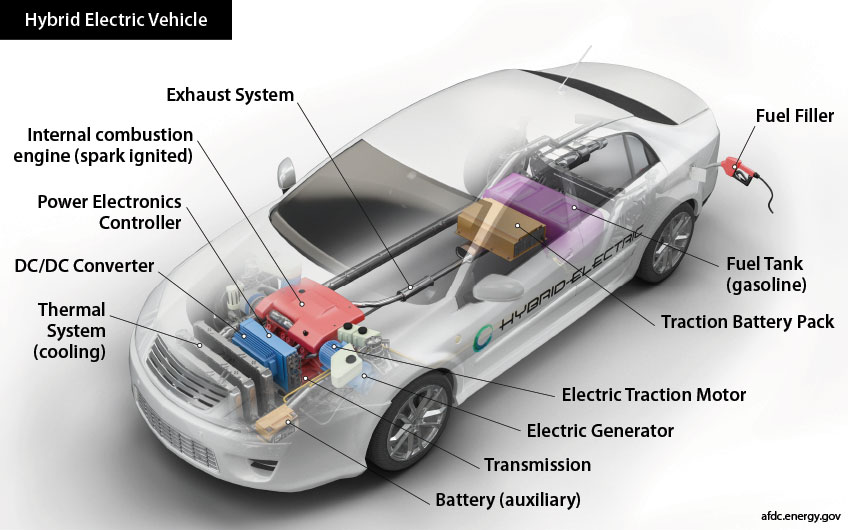

The electric motor is a crucial component of electric vehicles, playing a vital role in determining their performance, efficiency, and reliability. As the demand for electric vehicles continues to grow, the importance of efficient electric motor design has become increasingly evident. In recent years, advancements in electric motor design have been driving the adoption of electric vehicles, enabling them to achieve higher speeds, longer ranges, and improved overall performance.

One of the key factors contributing to the efficiency of electric motors is their design architecture. The use of advanced materials, such as rare-earth magnets and high-temperature superconductors, has enabled the development of more efficient and compact electric motors. Additionally, the implementation of innovative design techniques, such as 3D printing and topology optimization, has allowed for the creation of complex geometries and structures that can improve motor efficiency and reduce weight.

The impact of electric motor design on electric vehicle performance cannot be overstated. A well-designed electric motor can improve the overall efficiency of the vehicle, reducing energy consumption and increasing its range. Furthermore, a high-performance electric motor can enable electric vehicles to achieve faster acceleration and higher top speeds, making them more competitive with their gasoline-powered counterparts.

As the electric vehicle industry continues to evolve, the importance of efficient electric motor design will only continue to grow. As such, it is essential for manufacturers to prioritize the development of advanced electric motor technologies, incorporating innovative design techniques and materials to create more efficient and high-performance motors. By doing so, they can help drive the widespread adoption of electric vehicles, reducing greenhouse gas emissions and promoting a more sustainable transportation sector.

In the context of electric vehicle and electric motor quality management trends, the design of electric motors plays a critical role. By prioritizing the development of efficient and high-performance electric motors, manufacturers can help ensure the reliability and safety of their vehicles, while also reducing their environmental impact. As the industry continues to evolve, it will be essential to stay up-to-date with the latest advancements in electric motor design, incorporating innovative technologies and techniques to create more efficient and sustainable electric vehicles.

How to Ensure Electric Motor Quality in Electric Vehicles

Ensuring electric motor quality is crucial for the performance, reliability, and safety of electric vehicles. Several key factors can affect electric motor quality, including materials, manufacturing processes, and testing protocols. In this section, we will discuss the importance of each of these factors and provide tips on how to ensure electric motor quality in electric vehicles.

Materials play a critical role in determining electric motor quality. The use of high-quality materials, such as rare-earth magnets and high-temperature superconductors, can improve motor efficiency and reliability. However, the sourcing and procurement of these materials can be challenging, and manufacturers must ensure that their suppliers meet strict quality standards.

Manufacturing processes are also critical to ensuring electric motor quality. The use of advanced manufacturing techniques, such as 3D printing and robotics, can improve motor precision and reduce defects. Additionally, manufacturers must implement strict quality control measures, such as inspection and testing protocols, to ensure that motors meet quality standards.

Testing protocols are essential to ensuring electric motor quality. Manufacturers must implement comprehensive testing protocols, including dynamometer testing, thermal imaging, and vibration analysis, to ensure that motors meet performance and reliability standards. Additionally, the use of advanced testing equipment, such as simulation tools and data analytics software, can help manufacturers identify and address potential quality issues.

In the context of electric vehicle and electric motor quality management trends, ensuring electric motor quality is critical to the widespread adoption of electric vehicles. By prioritizing the use of high-quality materials, advanced manufacturing processes, and comprehensive testing protocols, manufacturers can help ensure the reliability and safety of their vehicles, while also reducing their environmental impact.

Some tips for ensuring electric motor quality in electric vehicles include:

- Implementing strict quality control measures, such as inspection and testing protocols, to ensure that motors meet quality standards.

- Using advanced testing equipment, such as simulation tools and data analytics software, to identify and address potential quality issues.

- Prioritizing the use of high-quality materials, such as rare-earth magnets and high-temperature superconductors, to improve motor efficiency and reliability.

- Investing in advanced manufacturing techniques, such as 3D printing and robotics, to improve motor precision and reduce defects.

By following these tips and prioritizing electric motor quality, manufacturers can help ensure the performance, reliability, and safety of their electric vehicles, while also driving the widespread adoption of electric vehicles.

The Role of Advanced Materials in Electric Motor Quality Management

Advanced materials play a crucial role in electric motor quality management, as they can significantly impact the performance, efficiency, and reliability of electric motors. In recent years, there has been a growing trend towards the use of advanced materials in electric motor design, driven by the need for improved performance, reduced weight, and increased efficiency.

One of the most significant advancements in electric motor materials has been the development of rare-earth magnets. These magnets offer high magnetic strength, high temperature stability, and resistance to demagnetization, making them ideal for use in electric motors. However, the use of rare-earth magnets also presents challenges, such as high cost, limited availability, and potential supply chain risks.

Another advanced material that is gaining traction in electric motor design is high-temperature superconductors. These materials offer zero electrical resistance, high current density, and high magnetic field tolerance, making them ideal for use in high-performance electric motors. However, the use of high-temperature superconductors also presents challenges, such as high cost, limited availability, and complex manufacturing processes.

Advanced composites are also being used in electric motor design to improve performance, reduce weight, and increase efficiency. These materials offer high strength-to-weight ratios, high stiffness, and high thermal stability, making them ideal for use in electric motor components such as rotor blades and stator cores. However, the use of advanced composites also presents challenges, such as high cost, limited availability, and complex manufacturing processes.

In the context of electric vehicle and electric motor quality management trends, the use of advanced materials is critical to improving the performance, efficiency, and reliability of electric motors. By leveraging the benefits of advanced materials, manufacturers can create electric motors that are more efficient, more reliable, and more sustainable.

Some of the benefits of using advanced materials in electric motor design include:

- Improved performance: Advanced materials can improve the efficiency, power density, and reliability of electric motors.

- Reduced weight: Advanced materials can reduce the weight of electric motors, making them more suitable for use in electric vehicles.

- Increased efficiency: Advanced materials can improve the efficiency of electric motors, reducing energy consumption and increasing range.

- Improved sustainability: Advanced materials can improve the sustainability of electric motors, reducing the use of rare earth metals and other critical materials.

However, the use of advanced materials also presents challenges, such as high cost, limited availability, and complex manufacturing processes. To overcome these challenges, manufacturers must invest in research and development, supply chain management, and manufacturing process optimization.

Electric Motor Testing and Validation: Best Practices and Emerging Trends

Electric motor testing and validation are critical components of electric motor quality management. Testing and validation ensure that electric motors meet performance, efficiency, and reliability standards, and are essential for ensuring the overall quality of electric vehicles.

Best practices for electric motor testing include the use of dynamometers, thermal imaging, and vibration analysis. Dynamometers are used to measure the torque and power output of electric motors, while thermal imaging is used to detect temperature anomalies and potential hotspots. Vibration analysis is used to detect potential imbalances and misalignments in the motor.

In addition to these best practices, emerging trends in electric motor testing include the use of artificial intelligence (AI) and machine learning (ML). AI and ML can be used to analyze large datasets and detect patterns and anomalies that may not be apparent through traditional testing methods. This can help to improve the accuracy and efficiency of electric motor testing, and reduce the risk of defects and failures.

Another emerging trend in electric motor testing is the use of simulation tools. Simulation tools can be used to model and simulate the behavior of electric motors under various operating conditions, allowing manufacturers to test and validate their designs without the need for physical prototypes. This can help to reduce the time and cost associated with testing and validation, and improve the overall efficiency of the design process.

In the context of electric vehicle and electric motor quality management trends, testing and validation are critical components of ensuring the overall quality of electric vehicles. By leveraging best practices and emerging trends in electric motor testing, manufacturers can improve the performance, efficiency, and reliability of their electric motors, and reduce the risk of defects and failures.

Some of the benefits of using AI and ML in electric motor testing include:

- Improved accuracy: AI and ML can be used to analyze large datasets and detect patterns and anomalies that may not be apparent through traditional testing methods.

- Increased efficiency: AI and ML can be used to automate the testing process, reducing the time and cost associated with testing and validation.

- Reduced risk: AI and ML can be used to detect potential defects and failures, reducing the risk of costly repairs and recalls.

However, the use of AI and ML in electric motor testing also presents challenges, such as the need for large datasets and the potential for bias in the algorithms used. To overcome these challenges, manufacturers must invest in data collection and analysis, and ensure that their AI and ML algorithms are transparent and explainable.

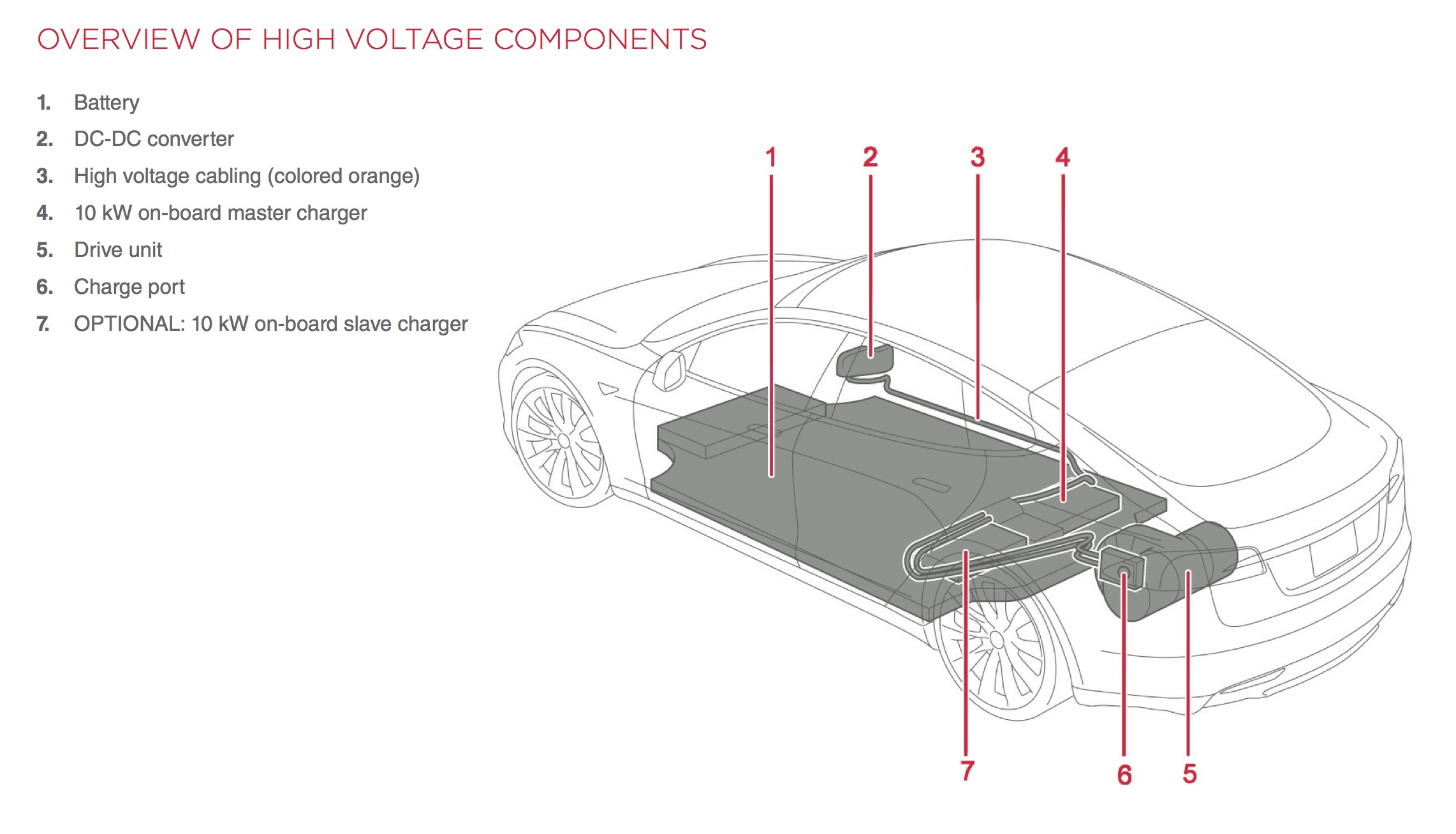

Case Study: Electric Motor Quality Management in the Tesla Model S

Tesla is a pioneer in the electric vehicle industry, and its Model S is a prime example of how electric motor quality management can impact the performance, reliability, and safety of electric vehicles. In this case study, we will explore the design and testing protocols used by Tesla to ensure electric motor quality in the Model S, and highlight the benefits of their approach.

Tesla’s electric motor design is centered around its proprietary induction motor technology, which provides high efficiency, high power density, and low maintenance. The motor is designed to operate at high speeds, with a maximum speed of 18,000 rpm, and is capable of producing up to 762 horsepower.

To ensure the quality of its electric motors, Tesla employs a rigorous testing and validation protocol. This includes a combination of simulation testing, dynamometer testing, and on-vehicle testing. Simulation testing is used to validate the motor’s performance under various operating conditions, while dynamometer testing is used to measure the motor’s torque and power output. On-vehicle testing is used to validate the motor’s performance in real-world driving conditions.

Tesla also uses advanced analytics and machine learning algorithms to monitor the performance of its electric motors in real-time. This allows the company to detect potential issues before they become major problems, and to optimize the performance of its motors for maximum efficiency and reliability.

The benefits of Tesla’s approach to electric motor quality management are numerous. By using advanced materials, design techniques, and testing protocols, Tesla is able to produce electric motors that are highly efficient, reliable, and safe. This has helped to establish Tesla as a leader in the electric vehicle industry, and has enabled the company to achieve significant reductions in emissions and operating costs.

In the context of electric vehicle and electric motor quality management trends, Tesla’s approach to electric motor design and testing is a prime example of how innovation and investment in quality management can drive the adoption of electric vehicles. By prioritizing electric motor quality, Tesla is able to produce vehicles that are not only environmentally friendly but also highly performant and reliable.

Some of the key takeaways from Tesla’s approach to electric motor quality management include:

- The importance of using advanced materials and design techniques to improve electric motor efficiency and reliability.

- The need for rigorous testing and validation protocols to ensure electric motor quality.

- The benefits of using advanced analytics and machine learning algorithms to monitor and optimize electric motor performance in real-time.

By following these best practices, electric vehicle manufacturers can improve the performance, reliability, and safety of their vehicles, and help to drive the widespread adoption of electric vehicles.

The Impact of Electric Motor Quality on Electric Vehicle Reliability and Safety

Electric motor quality has a significant impact on the reliability and safety of electric vehicles. A high-quality electric motor can ensure that the vehicle operates efficiently and reliably, while a low-quality motor can lead to reduced performance, increased maintenance costs, and even safety risks.

One of the most significant risks associated with low-quality electric motors is the potential for overheating. Electric motors can generate a significant amount of heat during operation, and if the motor is not designed or manufactured to handle this heat, it can lead to reduced performance, increased energy consumption, and even safety risks.

Another risk associated with low-quality electric motors is the potential for electrical failures. Electric motors rely on complex electrical systems to operate, and if these systems are not designed or manufactured to meet high standards, they can lead to electrical failures, reduced performance, and even safety risks.

In addition to these risks, low-quality electric motors can also lead to reduced vehicle performance, increased maintenance costs, and even safety risks. For example, a low-quality electric motor may not be able to provide the necessary torque or power to propel the vehicle, leading to reduced acceleration and performance. Similarly, a low-quality motor may require more frequent maintenance or repairs, leading to increased costs and downtime.

In the context of electric vehicle and electric motor quality management trends, ensuring electric motor quality is critical to ensuring the reliability and safety of electric vehicles. By prioritizing electric motor quality, manufacturers can help ensure that their vehicles operate efficiently and reliably, while also reducing the risk of safety risks and maintenance costs.

Some of the key takeaways from this discussion include:

- The importance of ensuring electric motor quality to ensure the reliability and safety of electric vehicles.

- The potential risks associated with low-quality electric motors, including overheating, electrical failures, and reduced vehicle performance.

- The need for manufacturers to prioritize electric motor quality in their design and manufacturing processes.

By prioritizing electric motor quality, manufacturers can help ensure that their vehicles operate efficiently and reliably, while also reducing the risk of safety risks and maintenance costs. This is critical to the widespread adoption of electric vehicles, as it will help to build consumer confidence and trust in the technology.

Emerging Trends in Electric Motor Quality Management: A Look Ahead

The electric vehicle industry is rapidly evolving, and electric motor quality management is no exception. Emerging trends in electric motor quality management are expected to shape the future of the industry, and it’s essential to stay ahead of the curve. In this section, we’ll explore some of the emerging trends in electric motor quality management, including the use of advanced analytics, machine learning, and the Internet of Things (IoT).

Advanced analytics is one of the emerging trends in electric motor quality management. By using advanced analytics tools, manufacturers can analyze large datasets and identify patterns and trends that can help improve electric motor quality. For example, advanced analytics can be used to analyze sensor data from electric motors to predict potential failures and schedule maintenance accordingly.

Machine learning is another emerging trend in electric motor quality management. Machine learning algorithms can be used to analyze data from electric motors and identify patterns and trends that can help improve quality. For example, machine learning can be used to analyze data from electric motors to predict potential failures and optimize maintenance schedules.

The Internet of Things (IoT) is also an emerging trend in electric motor quality management. IoT sensors can be used to collect data from electric motors and transmit it to the cloud for analysis. This can help manufacturers to monitor electric motor performance in real-time and identify potential issues before they become major problems.

These emerging trends in electric motor quality management have the potential to revolutionize the industry. By using advanced analytics, machine learning, and IoT sensors, manufacturers can improve electric motor quality, reduce maintenance costs, and increase efficiency.

In the context of electric vehicle and electric motor quality management trends, these emerging trends are expected to play a significant role in shaping the future of the industry. By staying ahead of the curve and adopting these emerging trends, manufacturers can improve electric motor quality, reduce maintenance costs, and increase efficiency.

Some of the potential benefits of these emerging trends include:

- Improved electric motor quality: Advanced analytics, machine learning, and IoT sensors can help manufacturers to identify potential issues before they become major problems, improving electric motor quality.

- Reduced maintenance costs: By using advanced analytics and machine learning to predict potential failures, manufacturers can schedule maintenance accordingly, reducing maintenance costs.

- Increased efficiency: IoT sensors can help manufacturers to monitor electric motor performance in real-time, optimizing maintenance schedules and increasing efficiency.

However, these emerging trends also present challenges, such as the need for significant investment in new technologies and the potential for data overload. To overcome these challenges, manufacturers must invest in training and development, and ensure that their data management systems are capable of handling large datasets.

Conclusion: The Future of Electric Vehicle Performance Depends on Electric Motor Quality Management

In conclusion, electric motor quality management is a critical component of electric vehicle performance, reliability, and safety. The importance of electric motor design, materials, testing, and validation cannot be overstated, as they all play a crucial role in ensuring the overall quality of electric vehicles.

As the electric vehicle industry continues to evolve, it is essential to stay ahead of the curve and adopt emerging trends in electric motor quality management. The use of advanced analytics, machine learning, and IoT sensors can help manufacturers to improve electric motor quality, reduce maintenance costs, and increase efficiency.

However, these emerging trends also present challenges, such as the need for significant investment in new technologies and the potential for data overload. To overcome these challenges, manufacturers must invest in training and development, and ensure that their data management systems are capable of handling large datasets.

In the context of electric vehicle and electric motor quality management trends, it is clear that the future of electric vehicle performance depends on electric motor quality management. By prioritizing electric motor quality, manufacturers can improve performance, reliability, and safety, and help to drive the widespread adoption of electric vehicles.

Some of the key takeaways from this article include:

- The importance of electric motor design, materials, testing, and validation in ensuring electric vehicle quality.

- The potential benefits and challenges of emerging trends in electric motor quality management, such as the use of advanced analytics, machine learning, and IoT sensors.

- The need for manufacturers to invest in training and development, and ensure that their data management systems are capable of handling large datasets.

By following these best practices and staying ahead of the curve, manufacturers can improve electric motor quality, reduce maintenance costs, and increase efficiency, ultimately driving the widespread adoption of electric vehicles.