Understanding the Anatomy of an Electric Motor

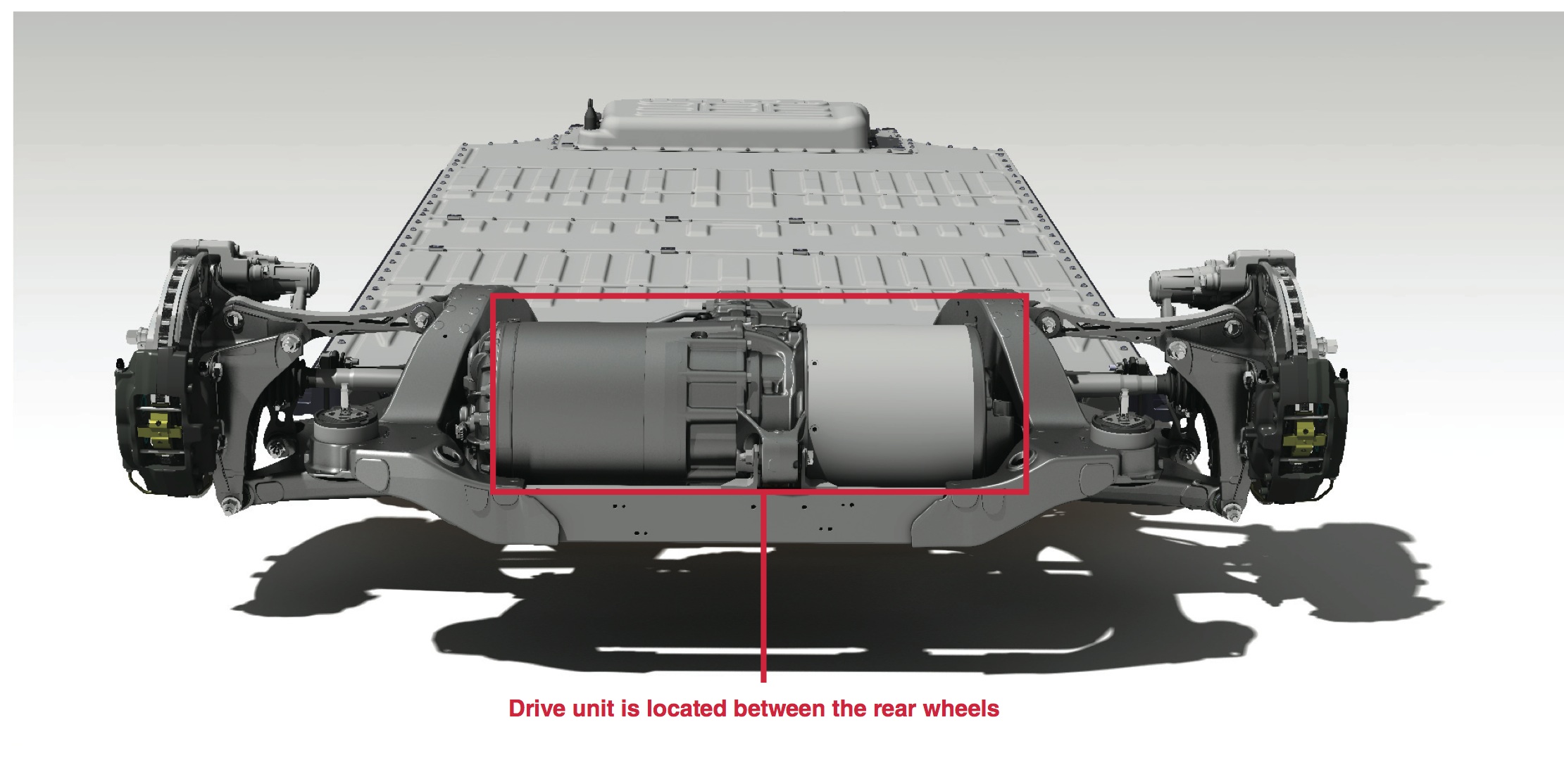

An electric motor is a crucial component of an electric vehicle, responsible for converting electrical energy into mechanical energy to propel the vehicle forward. At its core, an electric motor consists of three primary components: the stator, rotor, and bearings. The stator, typically a stationary part, houses the motor’s windings and provides a magnetic field. The rotor, on the other hand, is a moving part that rotates within the stator, driven by the magnetic field. The bearings, usually located at the ends of the rotor, enable smooth rotation and reduce friction.

When these components work together in harmony, they provide efficient and reliable performance. The stator’s magnetic field induces an electromotive force (EMF) in the rotor, causing it to rotate. As the rotor spins, it generates torque, which is then transmitted to the wheels of the electric vehicle. The bearings play a critical role in maintaining the rotor’s stability and minimizing energy losses due to friction.

Regular maintenance of these components is essential to ensure the longevity and reliability of the electric motor. Neglecting maintenance can lead to reduced performance, decreased efficiency, and even motor failure. As electric vehicles become increasingly popular, understanding the anatomy of an electric motor is vital for owners and enthusiasts alike. By grasping the fundamental principles of electric motor operation, individuals can better appreciate the importance of proper maintenance and take steps to maximize the lifespan of their vehicle’s motor.

In the context of electric vehicle and electric motor reliability and maintenance, it is essential to recognize the interdependence of these components. A well-maintained stator, rotor, and bearings can significantly enhance the overall performance and reliability of the electric motor. Conversely, neglecting maintenance can lead to a decline in motor efficiency, ultimately affecting the vehicle’s overall reliability and lifespan.

Common Causes of Electric Motor Failure

Electric motor failure can be a significant concern for electric vehicle owners, resulting in reduced performance, decreased efficiency, and even costly repairs. Understanding the common causes of electric motor failure is crucial in preventing these issues and ensuring the reliability and maintenance of the motor. Overheating, overcharging, and physical damage are among the most common causes of electric motor failure.

Overheating can occur due to excessive load, high ambient temperatures, or inadequate cooling systems. When an electric motor overheats, the insulation and windings can deteriorate, leading to a reduction in motor efficiency and potentially causing a complete failure. For instance, driving an electric vehicle in extreme temperatures or towing a heavy load can cause the motor to overheat, highlighting the importance of monitoring temperature levels and adjusting driving habits accordingly.

Overcharging is another common cause of electric motor failure. When an electric vehicle’s battery is overcharged, it can cause the motor to work harder, leading to increased wear and tear on the components. This can result in reduced motor lifespan and decreased performance. To prevent overcharging, it is essential to follow the manufacturer’s recommended charging guidelines and avoid overcharging the battery.

Physical damage can also cause electric motor failure. This can occur due to accidents, poor maintenance, or manufacturing defects. For example, a collision can cause physical damage to the motor, leading to a failure. Regular maintenance, such as inspecting the motor and its components, can help identify potential issues before they become major problems.

In the context of electric vehicle and electric motor reliability and maintenance, it is essential to recognize the importance of addressing these common causes of failure. By understanding the root causes of motor failure, owners can take proactive steps to prevent these issues, ensuring the longevity and reliability of their electric vehicle’s motor. Regular maintenance, proper charging habits, and safe driving practices can all contribute to maximizing the lifespan of an electric vehicle’s motor.

How to Perform Routine Maintenance on Your Electric Vehicle’s Motor

Routine maintenance is essential to ensure the reliability and longevity of an electric vehicle’s motor. Regular checks and maintenance tasks can help prevent motor failure, reduce downtime, and optimize performance. Here are some step-by-step instructions on how to perform routine maintenance tasks on your electric vehicle’s motor:

Checking and Replacing Bearings: The bearings in an electric motor play a crucial role in reducing friction and ensuring smooth operation. Over time, bearings can wear out, causing vibrations and noise. To check the bearings, use a multimeter to measure the bearing’s resistance and compare it to the manufacturer’s specifications. If the bearings are worn out, replace them with new ones.

Inspecting Electrical Connections: Electrical connections are critical to the proper functioning of an electric motor. Inspect the connections regularly to ensure they are clean, tight, and free from corrosion. Use a wire brush to clean the connections and apply a small amount of electrical contact cleaner to prevent corrosion.

Updating Software: Electric vehicles rely on sophisticated software to control the motor and other systems. Regular software updates can help improve performance, fix bugs, and enhance reliability. Check with the manufacturer for software updates and follow their instructions to update the software.

Additional Maintenance Tasks: In addition to the above tasks, it is essential to perform other maintenance tasks, such as checking the motor’s temperature, inspecting the cooling system, and monitoring the battery’s state of charge. These tasks can help identify potential issues before they become major problems.

Regular maintenance is crucial to ensuring the reliability and longevity of an electric vehicle’s motor. By following these step-by-step instructions, owners can help prevent motor failure, reduce downtime, and optimize performance. In the context of electric vehicle and electric motor reliability and maintenance, regular maintenance is essential to maximizing the lifespan of the motor.

Comparing the Reliability of Popular Electric Vehicles

When it comes to electric vehicle and electric motor reliability and maintenance, different models have varying levels of performance and requirements. In this section, we’ll compare the reliability and maintenance requirements of popular electric vehicles, including the Tesla Model 3, Chevrolet Bolt, and Nissan Leaf.

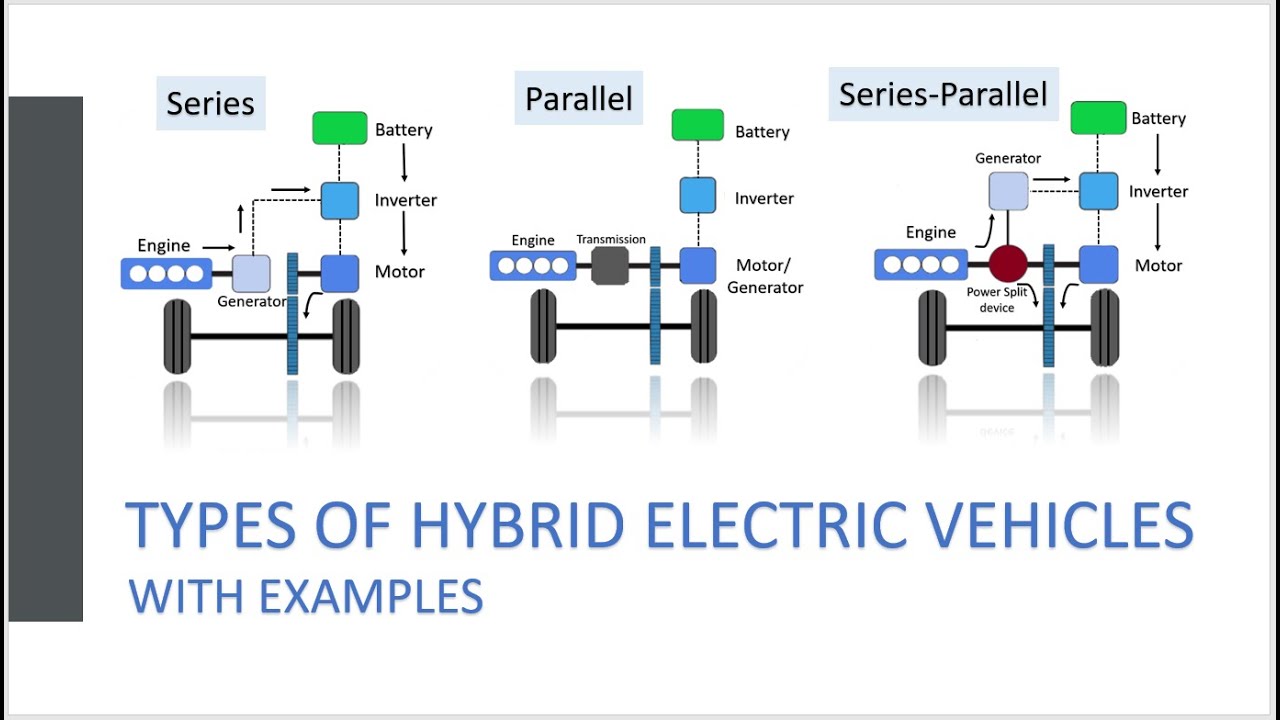

Tesla Model 3: The Tesla Model 3 is known for its impressive range and performance. However, its motor design and maintenance schedule are unique compared to other electric vehicles. The Model 3’s motor uses a permanent magnet design, which provides excellent efficiency and reliability. However, the motor’s high-performance capabilities require regular maintenance, including software updates and tire rotations.

Chevrolet Bolt: The Chevrolet Bolt is another popular electric vehicle that boasts an impressive range and performance. Its motor design is similar to the Tesla Model 3, using a permanent magnet design. However, the Bolt’s maintenance schedule is less frequent, with recommended maintenance every 7,500 miles. The Bolt’s motor is also designed to be more robust, with a higher torque output and faster acceleration.

Nissan Leaf: The Nissan Leaf is one of the most popular electric vehicles on the market, with a reputation for reliability and low maintenance costs. Its motor design uses a induction motor, which provides excellent efficiency and reliability. The Leaf’s maintenance schedule is also relatively infrequent, with recommended maintenance every 15,000 miles.

Comparison of Maintenance Requirements: When comparing the maintenance requirements of these popular electric vehicles, it’s clear that each model has its unique needs. The Tesla Model 3 requires more frequent maintenance due to its high-performance capabilities, while the Chevrolet Bolt and Nissan Leaf have less frequent maintenance schedules. However, all three models require regular software updates and tire rotations to ensure optimal performance and reliability.

In conclusion, when it comes to electric vehicle and electric motor reliability and maintenance, different models have varying levels of performance and requirements. By understanding the unique needs of each model, owners can ensure optimal performance and reliability, maximizing the lifespan of their electric vehicle’s motor.

Troubleshooting Common Electric Motor Issues

Electric motor issues can be a significant concern for electric vehicle owners, as they can impact performance, efficiency, and overall reliability. Fortunately, many common problems can be diagnosed and repaired with the right tools and knowledge. In this section, we’ll explore some common electric motor issues, their symptoms, and troubleshooting steps to help you get back on the road.

Unusual Noises

Unusual noises, such as grinding, whining, or humming, can indicate a problem with the electric motor. To troubleshoot, check the motor mounts, bearings, and gearbox for any signs of wear or damage. Verify that all electrical connections are secure and not loose. If the noise persists, it may be necessary to replace the motor or a faulty component.

Vibrations

Vibrations can be caused by an imbalance in the motor or a problem with the drivetrain. Check the motor’s balance and ensure that all bolts and screws are tightened properly. Inspect the drivetrain for any signs of wear or damage, and replace any faulty components as needed.

Reduced Performance

Reduced performance, such as decreased acceleration or torque, can be caused by a variety of factors, including a faulty motor controller, worn-out bearings, or a malfunctioning gearbox. Check the motor controller for any error codes or signs of damage. Inspect the bearings and gearbox for wear or damage, and replace any faulty components as needed.

Overheating

Overheating can be caused by a variety of factors, including high ambient temperatures, excessive load, or a malfunctioning cooling system. Check the cooling system for any blockages or leaks, and ensure that the motor is properly ventilated. Reduce the load on the motor, if possible, and consider upgrading to a more efficient cooling system.

Troubleshooting Tools and Techniques

To troubleshoot electric motor issues, it’s essential to have the right tools and techniques. Some common tools include a multimeter, oscilloscope, and thermal imaging camera. Techniques such as visual inspection, electrical testing, and thermal analysis can help identify the root cause of the problem.

By following these troubleshooting steps and using the right tools and techniques, electric vehicle owners can quickly diagnose and repair common electric motor issues, ensuring optimal performance, efficiency, and reliability. Regular maintenance and inspections can also help prevent issues from arising in the first place, maximizing the lifespan of the electric motor and overall electric vehicle reliability and maintenance.

The Role of Battery Health in Electric Motor Reliability

Battery health plays a crucial role in electric motor reliability and maintenance. A well-maintained battery is essential for optimal motor performance, efficiency, and lifespan. In this section, we’ll explore the relationship between battery health and electric motor reliability, and discuss how factors like charging habits, temperature, and age can impact battery performance and motor lifespan.

Charging Habits

Charging habits can significantly impact battery health and electric motor reliability. Avoiding extreme temperatures, keeping the battery level between 20% and 80% if possible, and avoiding deep discharges can help prolong battery life. It’s also essential to follow the manufacturer’s recommended charging schedule and avoid overcharging, which can cause damage to the battery and motor.

Temperature

Temperature is another critical factor that affects battery health and electric motor reliability. Extreme temperatures, either hot or cold, can impact battery performance and lifespan. Keeping the battery and motor in a temperature-controlled environment, avoiding exposure to direct sunlight, and using a thermal management system can help maintain optimal temperatures.

Age

Age is a natural factor that affects battery health and electric motor reliability. As batteries age, their capacity and performance may degrade, impacting motor efficiency and lifespan. Regular maintenance, such as updating software and replacing worn-out components, can help mitigate the effects of aging and ensure optimal motor performance.

Battery Health Monitoring

Monitoring battery health is essential for maintaining electric motor reliability. Many modern electric vehicles come equipped with built-in battery health monitoring systems, which provide real-time data on battery state of charge, voltage, and temperature. Using this data, owners can adjust their charging habits, driving style, and maintenance schedule to optimize battery health and motor performance.

Best Practices for Battery Health and Electric Motor Reliability

To maintain optimal battery health and electric motor reliability, follow these best practices:

- Avoid extreme temperatures and keep the battery level between 20% and 80% if possible.

- Follow the manufacturer’s recommended charging schedule and avoid overcharging.

- Regularly update software and replace worn-out components.

- Monitor battery health using built-in monitoring systems or third-party tools.

- Adjust charging habits, driving style, and maintenance schedule based on battery health data.

By understanding the relationship between battery health and electric motor reliability, and following these best practices, electric vehicle owners can maximize the lifespan of their motor and ensure optimal performance, efficiency, and reliability.

Advanced Maintenance Techniques for Electric Vehicle Owners

For experienced electric vehicle owners, advanced maintenance techniques can help optimize motor performance, improve efficiency, and extend the lifespan of the vehicle. In this section, we’ll explore some advanced maintenance techniques, including how to use specialized tools and software to monitor and optimize motor performance.

Using Specialized Tools

Specialized tools, such as oscilloscopes and thermal imaging cameras, can help diagnose and repair complex motor issues. These tools can provide detailed information on motor performance, allowing owners to identify and address potential problems before they become major issues.

Monitoring Motor Performance with Software

Advanced software, such as motor control software and data logging tools, can help owners monitor and optimize motor performance in real-time. These tools can provide detailed information on motor temperature, voltage, and current, allowing owners to adjust their driving style and maintenance schedule to optimize motor performance.

Advanced Diagnostic Techniques

Advanced diagnostic techniques, such as vibration analysis and acoustic emissions testing, can help identify potential motor issues before they become major problems. These techniques can provide detailed information on motor performance, allowing owners to identify and address potential problems before they become major issues.

Customizing Motor Performance

For experienced owners, customizing motor performance can help optimize efficiency and performance. This can include adjusting motor parameters, such as torque and speed, to optimize performance for specific driving conditions.

Best Practices for Advanced Maintenance

To get the most out of advanced maintenance techniques, follow these best practices:

- Use specialized tools and software to monitor and optimize motor performance.

- Regularly update software and firmware to ensure optimal motor performance.

- Use advanced diagnostic techniques to identify potential motor issues before they become major problems.

- Customize motor performance to optimize efficiency and performance for specific driving conditions.

- Keep detailed records of maintenance and repairs to track motor performance and identify potential issues.

By using advanced maintenance techniques, experienced electric vehicle owners can optimize motor performance, improve efficiency, and extend the lifespan of their vehicle. Regular maintenance and repairs can help prevent major issues, ensuring optimal electric vehicle and electric motor reliability and maintenance.

Conclusion: Best Practices for Electric Vehicle Motor Reliability and Maintenance

In conclusion, maximizing the lifespan of an electric vehicle’s motor requires a combination of regular maintenance, proper troubleshooting, and smart charging habits. By understanding the anatomy of an electric motor, common causes of motor failure, and advanced maintenance techniques, electric vehicle owners can take proactive steps to ensure optimal motor performance and reliability.

Key Takeaways

To summarize, the key takeaways from this article are:

- Regular maintenance is crucial for preventing motor failure and ensuring optimal performance.

- Proper troubleshooting techniques can help diagnose and repair common motor issues.

- Smart charging habits, such as avoiding extreme temperatures and keeping the battery level between 20% and 80%, can help prolong battery life and motor lifespan.

- Advanced maintenance techniques, such as using specialized tools and software, can help optimize motor performance and extend the lifespan of the vehicle.

Best Practices for Electric Vehicle Motor Reliability and Maintenance

To ensure optimal electric vehicle and electric motor reliability and maintenance, follow these best practices:

- Regularly check and replace bearings, inspect electrical connections, and update software.

- Monitor battery health and adjust charging habits accordingly.

- Use specialized tools and software to monitor and optimize motor performance.

- Keep detailed records of maintenance and repairs to track motor performance and identify potential issues.

By following these best practices and staying informed about the latest advancements in electric vehicle technology, owners can maximize the lifespan of their motor and ensure optimal performance, efficiency, and reliability. Remember, regular maintenance and proper troubleshooting are key to extending the lifespan of an electric vehicle’s motor and ensuring a safe and enjoyable driving experience.