Understanding the Importance of Electric Motor Safety in EVs

The growing demand for electric vehicles (EVs) has led to a surge in the development of innovative technologies aimed at improving their performance, efficiency, and safety. As the world shifts towards a more sustainable and environmentally friendly mode of transportation, the need for prioritizing safety in EV design has become increasingly important. Electric motor safety, in particular, plays a crucial role in preventing accidents and ensuring the well-being of drivers and passengers. Electric vehicle and electric motor safety engineering have become essential considerations in the design and manufacture of EVs.

Electric motors are a critical component of EVs, providing the power and propulsion needed for movement. However, they also pose a significant risk if not designed and manufactured with safety in mind. Electrical shock, fires, and explosions are just a few of the potential hazards associated with electric motors. Furthermore, the high voltage and current levels present in EVs can be particularly hazardous if not properly managed.

Despite these risks, many EV manufacturers have made significant strides in prioritizing electric motor safety in their designs. For instance, some EVs are equipped with advanced safety features such as multiple airbags, electronic stability control, and advanced battery management systems. These features help to mitigate the risks associated with electric motors and provide a safer driving experience for EV owners.

However, there is still much work to be done in the field of electric motor safety engineering. As EV technology continues to evolve, it is essential that safety considerations remain at the forefront of design and development. By prioritizing electric motor safety, EV manufacturers can help to ensure the safety of drivers and passengers, while also promoting the widespread adoption of sustainable and environmentally friendly transportation solutions.

In the context of electric vehicle and electric motor safety engineering, it is clear that safety considerations must be integrated into every stage of the design and development process. From the selection of materials to the implementation of safety features, every aspect of EV design must be carefully considered to ensure the safety of drivers and passengers. By doing so, EV manufacturers can help to create a safer and more sustainable transportation future.

Key Components of Electric Motor Safety Engineering

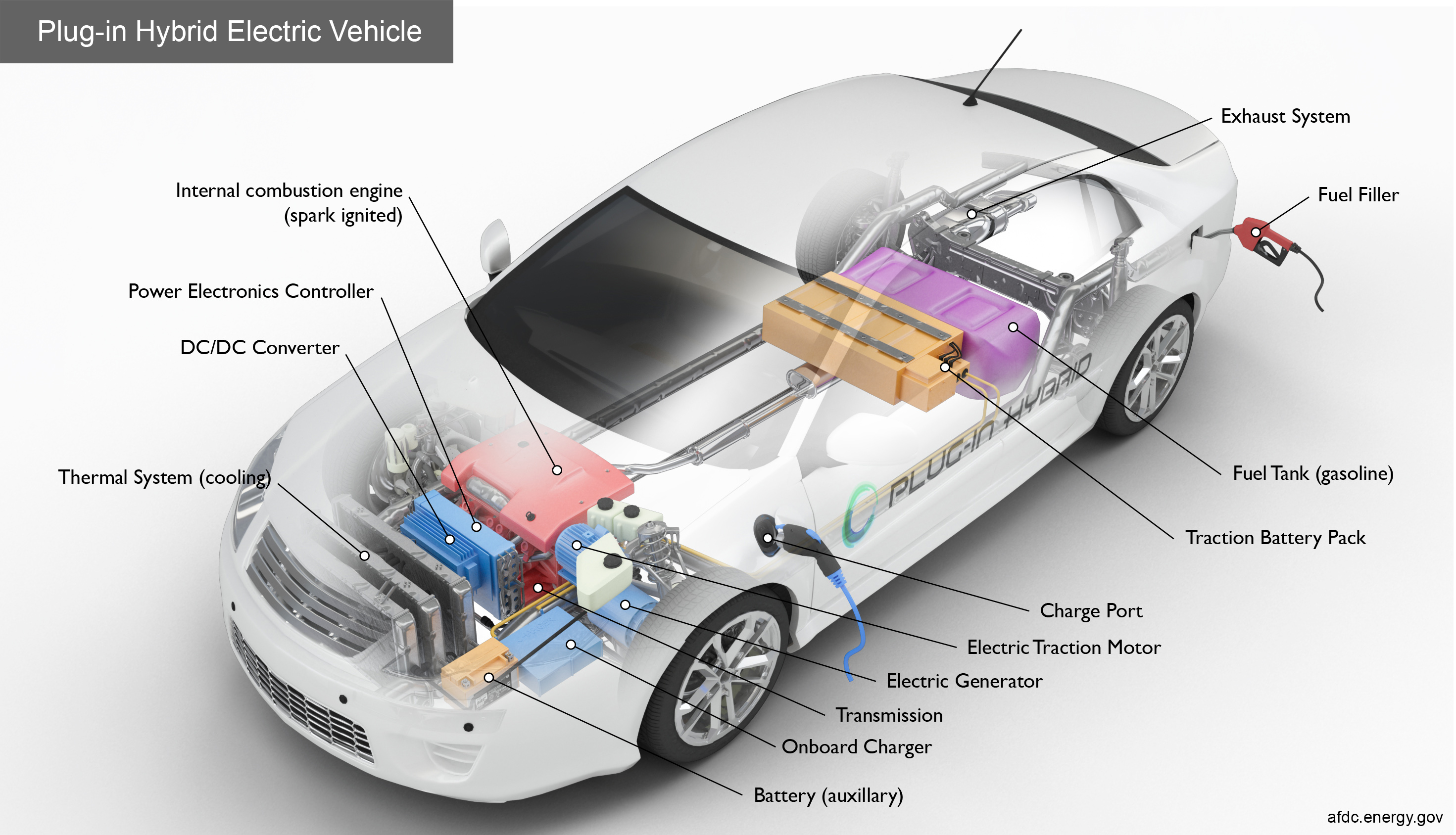

In the context of electric vehicle and electric motor safety engineering, several key components play a crucial role in preventing electrical shock, fires, and other hazards. Insulation, grounding, and thermal management are three essential components that work together to ensure the safe operation of electric motors in EVs.

Insulation is a critical component of electric motor safety engineering, as it helps to prevent electrical shock and short circuits. Electric motors in EVs are designed with insulation materials that can withstand high temperatures and electrical stresses. These materials, such as ceramic or glass fiber, provide a barrier between the electrical windings and the motor’s metal casing, preventing electrical shock and ensuring safe operation.

Grounding is another essential component of electric motor safety engineering. Grounding provides a safe path for electrical currents to flow to the ground, preventing electrical shock and ensuring the safe operation of the motor. In EVs, grounding is typically achieved through the use of grounding straps or wires that connect the motor to the vehicle’s chassis.

Thermal management is also a critical component of electric motor safety engineering. Electric motors in EVs generate heat during operation, which can lead to reduced efficiency, increased wear and tear, and even fires. Thermal management systems, such as cooling fans or heat sinks, help to dissipate heat and maintain a safe operating temperature.

These three components – insulation, grounding, and thermal management – work together to ensure the safe operation of electric motors in EVs. By incorporating these components into the design of electric motors, manufacturers can help to prevent electrical shock, fires, and other hazards, and ensure the safety of drivers and passengers.

In addition to these components, electric motor safety engineering also involves the use of protective features such as overcurrent protection and thermal monitoring. These features help to detect and prevent potential safety hazards, such as electrical overloads and overheating, and ensure the safe operation of the motor.

By incorporating these key components and protective features into the design of electric motors, manufacturers can help to ensure the safety of EVs on the road. Electric vehicle and electric motor safety engineering play a critical role in preventing accidents and ensuring the well-being of drivers and passengers.

How to Design Electric Motors for Enhanced Safety

Designing electric motors with safety in mind is crucial for ensuring the safe operation of electric vehicles (EVs). Electric vehicle and electric motor safety engineering require a comprehensive approach that incorporates multiple design considerations. Here is a step-by-step guide on how to design electric motors for enhanced safety:

Step 1: Select the Right Materials

Choosing the right materials for the electric motor is critical for ensuring safety. Materials with high thermal conductivity, such as copper or aluminum, can help to dissipate heat and reduce the risk of overheating. Additionally, materials with high electrical insulation properties, such as ceramic or glass fiber, can help to prevent electrical shock.

Step 2: Design for Thermal Management

Thermal management is essential for preventing overheating and ensuring the safe operation of the electric motor. Designing the motor with a thermal management system, such as a cooling fan or heat sink, can help to dissipate heat and maintain a safe operating temperature.

Step 3: Implement Protective Features

Implementing protective features, such as overcurrent protection and thermal monitoring, can help to prevent electrical shock and overheating. Overcurrent protection can detect and prevent electrical overloads, while thermal monitoring can detect and prevent overheating.

Step 4: Consider Electromagnetic Compatibility (EMC)

EMC is critical for ensuring the safe operation of the electric motor in the presence of other electrical systems. Designing the motor with EMC in mind can help to prevent electromagnetic interference (EMI) and ensure safe operation.

Step 5: Test and Validate the Design

Testing and validating the design is essential for ensuring the safe operation of the electric motor. Using simulation tools, laboratory testing, and on-road testing can help to identify and address potential safety hazards.

By following these steps, designers and engineers can create electric motors that are safe, efficient, and reliable. Electric vehicle and electric motor safety engineering require a comprehensive approach that incorporates multiple design considerations. By prioritizing safety in the design process, manufacturers can help to ensure the safe operation of EVs on the road.

Electric Vehicle Safety Standards and Regulations

The design and manufacture of electric vehicles (EVs) are governed by various safety standards and regulations, including those related to electric motor safety. These standards and regulations play a crucial role in ensuring the safety of EVs on the road. Electric vehicle and electric motor safety engineering must comply with these standards and regulations to ensure the safe operation of EVs.

One of the key safety standards for EVs is the Society of Automotive Engineers (SAE) J2954 standard, which covers the safety requirements for electric vehicles. This standard includes requirements for electric motor safety, including insulation, grounding, and thermal management. Additionally, the International Electrotechnical Commission (IEC) 61558 standard provides guidelines for the safety of electric motors, including those used in EVs.

In the United States, the National Highway Traffic Safety Administration (NHTSA) regulates the safety of EVs, including electric motor safety. The NHTSA has established standards for the safety of electric vehicles, including requirements for electric motor safety. Similarly, in the European Union, the European New Car Assessment Programme (Euro NCAP) evaluates the safety of EVs, including electric motor safety.

Compliance with these safety standards and regulations is essential for ensuring the safety of EVs on the road. Electric vehicle and electric motor safety engineering must prioritize compliance with these standards and regulations to ensure the safe operation of EVs. By complying with these standards and regulations, manufacturers can help to prevent accidents and ensure the well-being of drivers and passengers.

In addition to these safety standards and regulations, manufacturers must also conduct rigorous testing and validation to ensure the safety of their EVs. This includes testing for electric motor safety, as well as other safety features such as battery management systems and electronic stability control. By conducting thorough testing and validation, manufacturers can help to identify and address potential safety hazards, ensuring the safe operation of their EVs.

Real-World Examples of Electric Motor Safety in EVs

Several electric vehicles (EVs) have prioritized electric motor safety in their design, demonstrating the importance of electric vehicle and electric motor safety engineering. The Tesla Model S, for example, features a robust electric motor safety system that includes multiple airbags, electronic stability control, and advanced battery management systems. These safety features help to prevent accidents and ensure the well-being of drivers and passengers.

The Chevrolet Bolt is another example of an EV that has prioritized electric motor safety. The Bolt features a comprehensive safety system that includes a high-strength steel body structure, multiple airbags, and advanced electronic stability control. Additionally, the Bolt’s electric motor is designed with safety in mind, featuring a robust insulation system and advanced thermal management.

Other EVs, such as the Nissan Leaf and the BMW i3, have also prioritized electric motor safety in their design. These vehicles feature advanced safety systems, including multiple airbags, electronic stability control, and advanced battery management systems. Additionally, their electric motors are designed with safety in mind, featuring robust insulation systems and advanced thermal management.

These real-world examples demonstrate the importance of electric vehicle and electric motor safety engineering in ensuring the safety of EVs on the road. By prioritizing electric motor safety, manufacturers can help to prevent accidents and ensure the well-being of drivers and passengers. As the demand for EVs continues to grow, it is essential that manufacturers continue to prioritize electric motor safety in their design.

In addition to these examples, there are also several industry initiatives that aim to promote electric motor safety in EVs. For example, the Society of Automotive Engineers (SAE) has established a set of standards for electric motor safety in EVs, which provides guidelines for manufacturers to follow. Additionally, the International Electrotechnical Commission (IEC) has established a set of standards for electric motor safety in EVs, which provides guidelines for manufacturers to follow.

Common Electric Motor Safety Hazards and How to Mitigate Them

Electric motor safety is a critical aspect of electric vehicle and electric motor safety engineering. However, there are several common safety hazards associated with electric motors that can be mitigated through proper design, testing, and maintenance. Some of the most common electric motor safety hazards include electrical shock, fires, and explosions.

Electrical shock is a common safety hazard associated with electric motors. It can occur when an individual comes into contact with a live electrical component, such as a wire or terminal. To mitigate this hazard, electric motor designers can implement safety features such as insulation, grounding, and protective covers. Additionally, regular maintenance and testing can help to identify and address potential electrical shock hazards.

Fires are another common safety hazard associated with electric motors. They can occur due to a variety of factors, including overheating, electrical arcing, and fuel leaks. To mitigate this hazard, electric motor designers can implement safety features such as thermal management systems, fire-resistant materials, and fire suppression systems. Additionally, regular maintenance and testing can help to identify and address potential fire hazards.

Explosions are a rare but potentially catastrophic safety hazard associated with electric motors. They can occur due to a variety of factors, including electrical arcing, fuel leaks, and mechanical failure. To mitigate this hazard, electric motor designers can implement safety features such as explosion-proof enclosures, fire-resistant materials, and emergency shutdown systems. Additionally, regular maintenance and testing can help to identify and address potential explosion hazards.

In addition to these safety hazards, there are several other common electric motor safety hazards that can be mitigated through proper design, testing, and maintenance. These include vibration, noise, and electromagnetic interference (EMI). By understanding and addressing these safety hazards, electric motor designers can help to ensure the safe operation of electric vehicles and prevent accidents.

Regular maintenance and testing are critical components of electric motor safety. By regularly inspecting and testing electric motors, individuals can help to identify and address potential safety hazards before they become major issues. Additionally, regular maintenance can help to extend the lifespan of electric motors and prevent costly repairs.

The Role of Testing and Validation in Electric Motor Safety

Testing and validation play a crucial role in ensuring electric motor safety in electric vehicles (EVs). Electric vehicle and electric motor safety engineering require a comprehensive approach to testing and validation to ensure that electric motors are designed and manufactured to meet safety standards and regulations.

Simulation tools are an essential part of the testing and validation process for electric motor safety. These tools allow engineers to simulate various scenarios and test the performance of electric motors under different conditions. This helps to identify potential safety hazards and address them before the electric motor is manufactured.

Laboratory testing is another critical component of the testing and validation process for electric motor safety. This involves testing electric motors in a controlled laboratory environment to ensure that they meet safety standards and regulations. Laboratory testing can help to identify potential safety hazards and address them before the electric motor is manufactured.

On-road testing is also an essential part of the testing and validation process for electric motor safety. This involves testing electric vehicles on public roads to ensure that they meet safety standards and regulations. On-road testing can help to identify potential safety hazards and address them before the electric vehicle is manufactured.

The use of testing and validation methods such as simulation tools, laboratory testing, and on-road testing helps to ensure that electric motors are designed and manufactured to meet safety standards and regulations. This is critical for ensuring the safety of EVs on the road and preventing accidents.

In addition to these testing and validation methods, manufacturers can also use other methods such as accelerated life testing and environmental testing to ensure the safety of electric motors. Accelerated life testing involves testing electric motors under extreme conditions to simulate the effects of aging and wear and tear. Environmental testing involves testing electric motors under different environmental conditions such as temperature, humidity, and vibration.

By using a combination of testing and validation methods, manufacturers can ensure that electric motors are designed and manufactured to meet safety standards and regulations. This is critical for ensuring the safety of EVs on the road and preventing accidents.

Future Directions in Electric Motor Safety Engineering

As the demand for electric vehicles (EVs) continues to grow, electric vehicle and electric motor safety engineering will play an increasingly important role in ensuring the safety of EVs on the road. In the future, we can expect to see the development of new materials, advanced simulation tools, and innovative safety features that will further improve the safety of electric vehicles.

One area of future development is the use of advanced materials in electric motor design. New materials such as high-temperature superconductors and advanced magnetic materials will enable the creation of more efficient and safer electric motors. Additionally, the use of advanced materials in electric motor design will enable the creation of more compact and lightweight electric motors, which will improve the overall efficiency and safety of EVs.

Another area of future development is the use of advanced simulation tools in electric motor design. Advanced simulation tools such as finite element analysis and computational fluid dynamics will enable engineers to simulate the behavior of electric motors under various operating conditions, which will help to identify and address potential safety hazards. Additionally, advanced simulation tools will enable engineers to optimize electric motor design for improved safety and efficiency.

Innovative safety features are also being developed to further improve the safety of electric vehicles. For example, some EVs are being equipped with advanced safety features such as automatic emergency braking and lane departure warning systems. These features will help to prevent accidents and improve the overall safety of EVs on the road.

In addition to these developments, there is also a growing trend towards the use of autonomous vehicles, which will require advanced electric motor safety engineering to ensure safe and efficient operation. Autonomous vehicles will require advanced electric motors that can operate safely and efficiently in a variety of operating conditions, and advanced simulation tools will be needed to simulate the behavior of these motors under various operating conditions.

Overall, the future of electric vehicle and electric motor safety engineering looks promising, with the development of new materials, advanced simulation tools, and innovative safety features that will further improve the safety of electric vehicles on the road.